I bought my LMT MWSE (308 AR-10 semi auto with chrome lined barrel) a few weeks ago, and have been simultaneously training with it (using factory ammo) and preparing everything I need to hand load.

I am an experienced handgun shooter, but new to precision rifle shooting. I have been reading everything I can in books and website forums, while getting down to the range as often as possible to get actual trigger time. I have also been assembling all the loading gear I need to make really good ammunition.

Today I realized that the rifle is so much better than I am that it is complicating both my training and my loading preparations.

On the training side, I have both "new shooter" and "fit" issues, so my average groups are currently 1 1/8" at 100 yards off a bipod and rear bag on a bench. I have been trying to remember to do all the "right things" that I have read here and elsewhere (load the bipod, natural POA, weak hand positioning, cheek weld, etc), but still have a major consistency problem and a fit problem.

The fit problem stems from scope height relative to rifle stock. The lower edge of my cheekbone, which measures at over 2" below the center of my eye and is broad from center of face, is hitting the (factory stock) SOPMOD stock firmly long before I can get my eye down far enough to be centered in the scope. I have to "tilt" my head enough that the correctly vertical reticle is visibly "cocked" as I aim. The Nightforce scope is mounted in Nightforce lightweight rings in the highest height they offer - about 1 1/2 inches. The problem is obvious: 1 1/2 inches of ring height is insufficient to get the center of the scope high enough to work with my facial bone structure. So, I plan to get a riser, and will likely look for a very high quality QD riser, so that I can also remove the scope for rifle cleaning and to try open sights.

I am currently shooting 3-shot group, so that I can rest frequently between groups, as I am not used to this level of concentration and focus.

But today, after I applied some of the lessons I have learned over the past few days, the rifle really impressed me - and presented some issues. Now, don't get too excited, as my average groups today were still only slightly better - 1 and 1/16 inch. BUT, the BEST groups, where I did get my act together briefly (despite the optics issue), were REALLY good. Here are photos of the best 2:

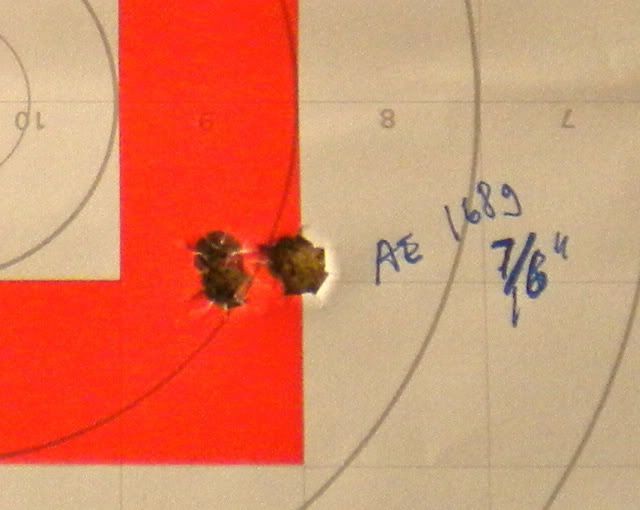

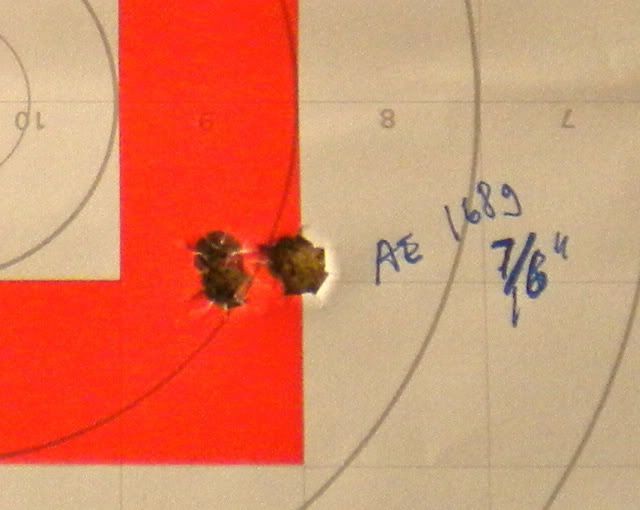

This one was fired with factory American Eagle 168 grain:

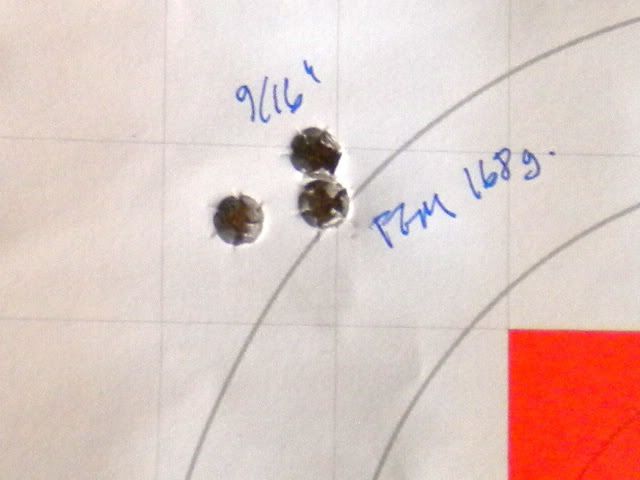

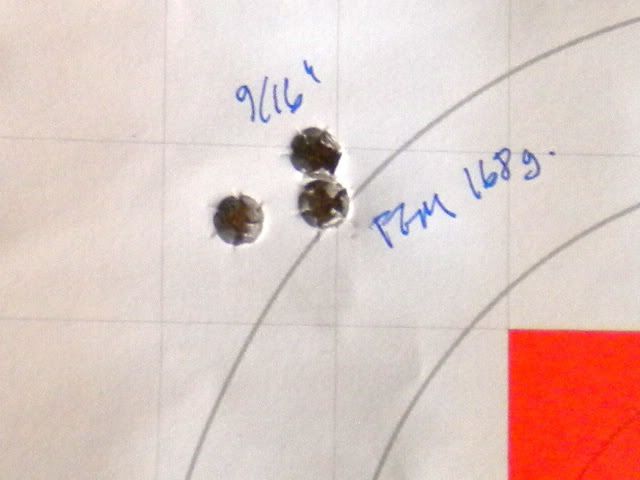

This one was fired with Federal Gold medal 168 grain:

Note that I was firing 3 shot groups, but from the look of the rightmost shot on the American Eagle, I may have erred and fired 4 there. (I fire at 10 different "red corner" targets on each target sheet and must have fired an extra shot at this POA).

Note that the AE group is only 7/16" across (actually, close to 3/8", but I called the measure conservatively). This was the best AE group.

The best Federal Gold Medal group was not quite as good (actually measured 9/16"), but within the coarse limits of this type of inexperienced rifle shooting, let's realistically call them even at about 1/2 inch. This in itself is interesting, as the FGM is supposedly much better ammunition than the inexpensive AE.

The aim point was in both cases the "red corner" immediately below the group. The rifle is currently shooting a bit high and perhaps a bit left at 100 yards, and I see no need to adjust it yet until I get CONSISTENT in both technique and ammunition used (the 175g and 168g, and the 2 brands, shoot to sighted different points for the same POA).

Also, at previous range sessions, I have fired exclusively 175g Federal Gold Medal. Today was the first try with 168g ammunition. It was very clear today that the rifle prefers 168g, as my best 175g groups, both today and prior to today, were not even close to the best 168g groups (over 1 inch for the 175 g Federal Gold Medal). This is despite the 1 in 10 twist rate.

Here's the pleasant "problems" I see with this rifle:

1. It's accurate enough that my groups will continue to be inconsistent until I get REALLY good, as its intrinsic accuracy, even with the chrome lined barrel is good enough that gross shooter errors REALLY show in the groups.

2. It's going to be tough to find a hand load good enough to beat the half inch 3-shot groups the rifle showed me today it can shoot with factory ammo - including CHEAP factory ammo (the American Eagle cost me far less than the Federal GM).

3. Doing a meaningful ladder test at my current (lack of) skill level is going to be humorous at best. I amply can't yet shoot the rifle consistently enough to make a ladder test trustworthy.

4. Is the more costly LMT stainless barrel even BETTER than the chrome lined one I have? If so, I'm pretty impressed with what these rifles can apparently do.

I figure my best strategies at this point are:

1. Get a riser to solve the optical problem. The trick is knowing how HIGh a riser to get. How do I figure that out?

2. Go ahead and hand load - to cut the cost of shooting - factory ammo is expensive compared to even the best of hand loads

3. Start hand loading at some very safe point between start load and maximum, and don't worry about the ladder test until I am a much more consistent shooter with this rifle. THEN, do the ladder test, and a "best jump-to-lands distance" test, to further optimize the load. I know I will have a "jump" to the lands, as using the Stoney Point gage showed me that I have a .045" or so jump at COAL = 2.805", so trying to jam into the lands is sheer foolishness, as cartridges long enough to do that won't ft in the 308 Magpul P-Mags, and I INSIST on feeding from the mags. No exceptions (I do not intend to compete in Highpower

).

).

I'd appreciate some experienced feedback and advice . . .

Jim G

I am an experienced handgun shooter, but new to precision rifle shooting. I have been reading everything I can in books and website forums, while getting down to the range as often as possible to get actual trigger time. I have also been assembling all the loading gear I need to make really good ammunition.

Today I realized that the rifle is so much better than I am that it is complicating both my training and my loading preparations.

On the training side, I have both "new shooter" and "fit" issues, so my average groups are currently 1 1/8" at 100 yards off a bipod and rear bag on a bench. I have been trying to remember to do all the "right things" that I have read here and elsewhere (load the bipod, natural POA, weak hand positioning, cheek weld, etc), but still have a major consistency problem and a fit problem.

The fit problem stems from scope height relative to rifle stock. The lower edge of my cheekbone, which measures at over 2" below the center of my eye and is broad from center of face, is hitting the (factory stock) SOPMOD stock firmly long before I can get my eye down far enough to be centered in the scope. I have to "tilt" my head enough that the correctly vertical reticle is visibly "cocked" as I aim. The Nightforce scope is mounted in Nightforce lightweight rings in the highest height they offer - about 1 1/2 inches. The problem is obvious: 1 1/2 inches of ring height is insufficient to get the center of the scope high enough to work with my facial bone structure. So, I plan to get a riser, and will likely look for a very high quality QD riser, so that I can also remove the scope for rifle cleaning and to try open sights.

I am currently shooting 3-shot group, so that I can rest frequently between groups, as I am not used to this level of concentration and focus.

But today, after I applied some of the lessons I have learned over the past few days, the rifle really impressed me - and presented some issues. Now, don't get too excited, as my average groups today were still only slightly better - 1 and 1/16 inch. BUT, the BEST groups, where I did get my act together briefly (despite the optics issue), were REALLY good. Here are photos of the best 2:

This one was fired with factory American Eagle 168 grain:

This one was fired with Federal Gold medal 168 grain:

Note that I was firing 3 shot groups, but from the look of the rightmost shot on the American Eagle, I may have erred and fired 4 there. (I fire at 10 different "red corner" targets on each target sheet and must have fired an extra shot at this POA).

Note that the AE group is only 7/16" across (actually, close to 3/8", but I called the measure conservatively). This was the best AE group.

The best Federal Gold Medal group was not quite as good (actually measured 9/16"), but within the coarse limits of this type of inexperienced rifle shooting, let's realistically call them even at about 1/2 inch. This in itself is interesting, as the FGM is supposedly much better ammunition than the inexpensive AE.

The aim point was in both cases the "red corner" immediately below the group. The rifle is currently shooting a bit high and perhaps a bit left at 100 yards, and I see no need to adjust it yet until I get CONSISTENT in both technique and ammunition used (the 175g and 168g, and the 2 brands, shoot to sighted different points for the same POA).

Also, at previous range sessions, I have fired exclusively 175g Federal Gold Medal. Today was the first try with 168g ammunition. It was very clear today that the rifle prefers 168g, as my best 175g groups, both today and prior to today, were not even close to the best 168g groups (over 1 inch for the 175 g Federal Gold Medal). This is despite the 1 in 10 twist rate.

Here's the pleasant "problems" I see with this rifle:

1. It's accurate enough that my groups will continue to be inconsistent until I get REALLY good, as its intrinsic accuracy, even with the chrome lined barrel is good enough that gross shooter errors REALLY show in the groups.

2. It's going to be tough to find a hand load good enough to beat the half inch 3-shot groups the rifle showed me today it can shoot with factory ammo - including CHEAP factory ammo (the American Eagle cost me far less than the Federal GM).

3. Doing a meaningful ladder test at my current (lack of) skill level is going to be humorous at best. I amply can't yet shoot the rifle consistently enough to make a ladder test trustworthy.

4. Is the more costly LMT stainless barrel even BETTER than the chrome lined one I have? If so, I'm pretty impressed with what these rifles can apparently do.

I figure my best strategies at this point are:

1. Get a riser to solve the optical problem. The trick is knowing how HIGh a riser to get. How do I figure that out?

2. Go ahead and hand load - to cut the cost of shooting - factory ammo is expensive compared to even the best of hand loads

3. Start hand loading at some very safe point between start load and maximum, and don't worry about the ladder test until I am a much more consistent shooter with this rifle. THEN, do the ladder test, and a "best jump-to-lands distance" test, to further optimize the load. I know I will have a "jump" to the lands, as using the Stoney Point gage showed me that I have a .045" or so jump at COAL = 2.805", so trying to jam into the lands is sheer foolishness, as cartridges long enough to do that won't ft in the 308 Magpul P-Mags, and I INSIST on feeding from the mags. No exceptions (I do not intend to compete in Highpower

I'd appreciate some experienced feedback and advice . . .

Jim G