I was anxious to try some new Horn 153 gr A-tip so I broke down and bought a box of 100. I Measured them in sequence and all measured the same diameter and length with-in 1/2 of a thousand and base to ogive was .832 for all. I loaded them with H4350 at different weights for load development. I measured each loaded round to the ogive loading every 5 at different distances from the lands even though my bolt 6.5 RPR likes 0.010 to 0.015 as a sweet spot for now until I get my ordered new Bartlein gain twist barrel form SPR, hopefully in a few weeks. I noticed the first five (5) came out with depths varying by .001 to .003 measured from base to Ogive. I thought I had the variables all taken into consideration, but apparently not. Below is my method for reloading.

Here is my method for this batch of New Hornady 6.5 Creedmoor.:

New 6.5 Hornady Brass (all same lot)

Full case sized all to.288

Headspace compared cases at 5.554 all same size

Brass all same length overall

Primers all under flush.

all brass chamfered and reamed.

All 153 gr A-Tip bullets had the same base to Ogive exactly.

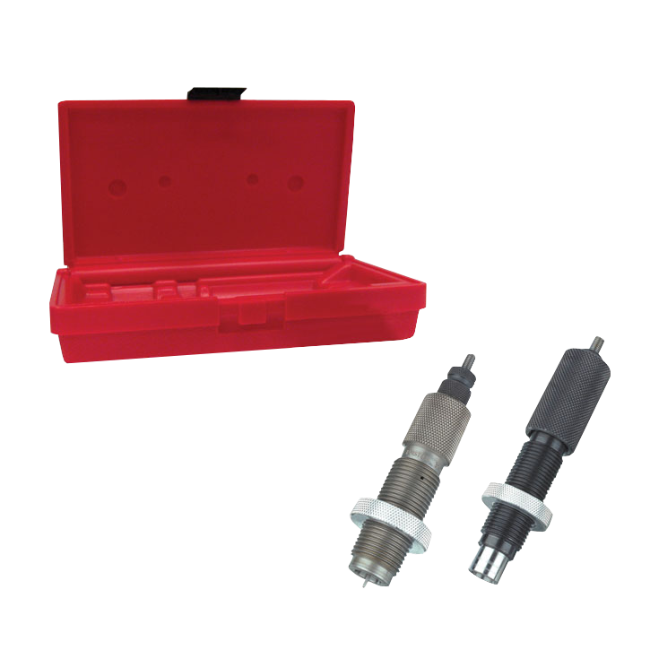

Used a Horn Match 544655 die with micro seater.

Hornady Iron Press with auto primer loader.

What else could I have done to get them within .001..... I used the same pressure seating them. I thought about putting a washer under the die thinking that might keep the pressure the same but wasn't any help. Any ideas?

Here is my method for this batch of New Hornady 6.5 Creedmoor.:

New 6.5 Hornady Brass (all same lot)

Full case sized all to.288

Headspace compared cases at 5.554 all same size

Brass all same length overall

Primers all under flush.

all brass chamfered and reamed.

All 153 gr A-Tip bullets had the same base to Ogive exactly.

Used a Horn Match 544655 die with micro seater.

Hornady Iron Press with auto primer loader.

What else could I have done to get them within .001..... I used the same pressure seating them. I thought about putting a washer under the die thinking that might keep the pressure the same but wasn't any help. Any ideas?