So after saving brass for 10 years I finally dived into the deep end with reloading this past year. It’s been 12 months of slowly gathering parts, I just tonight started my load development for Hornady .308 178 gr ELD’s.

Brass is once fired Federal from factory gold medal match.

Primers are Federal 210M large rifle primers

Bullets are Hornady 178 gr ELD’s

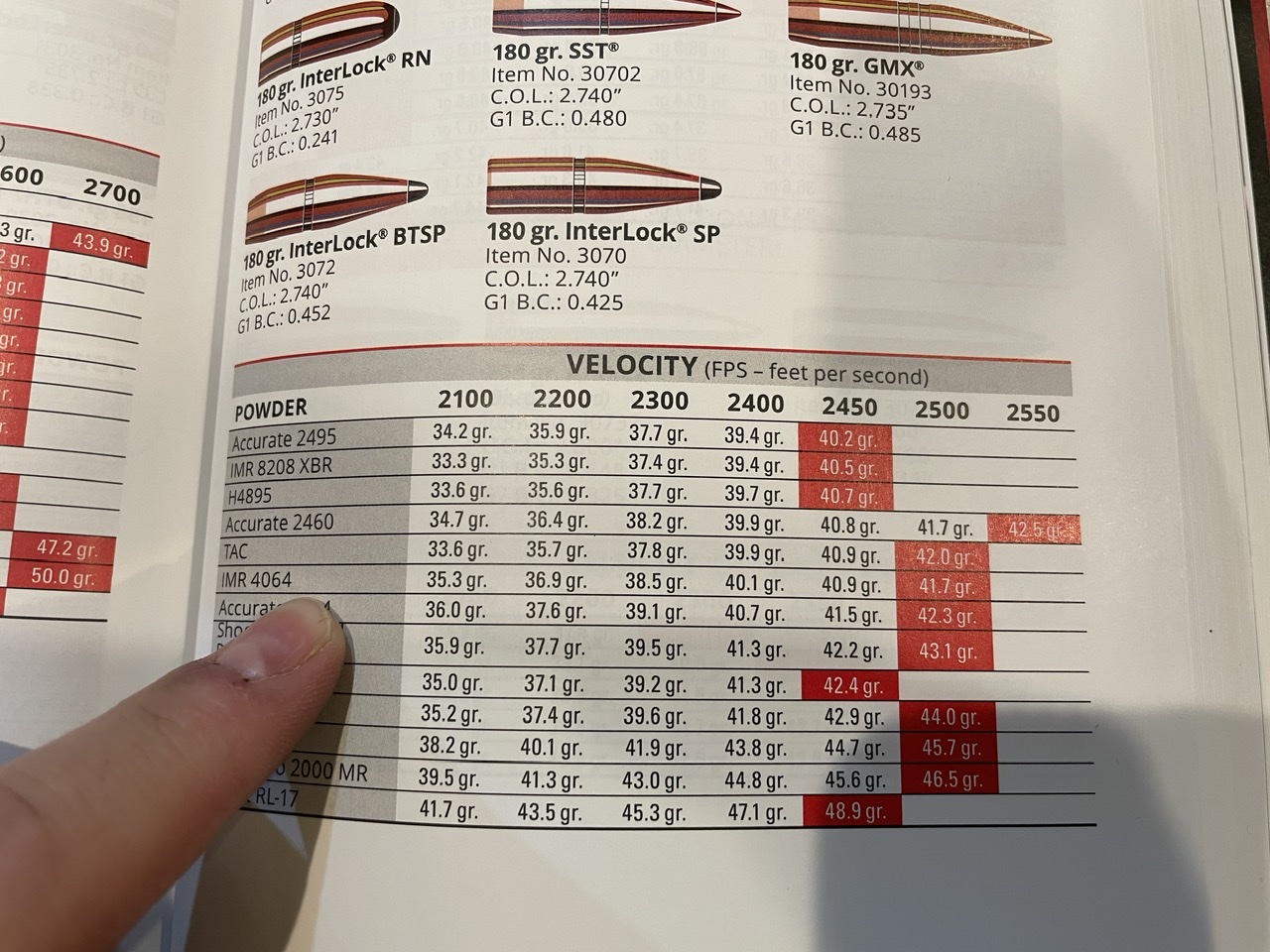

Powder is IMR 4064.

Using Hornady’s reloading manual it shows the range as 35.3 to 41.7 gr

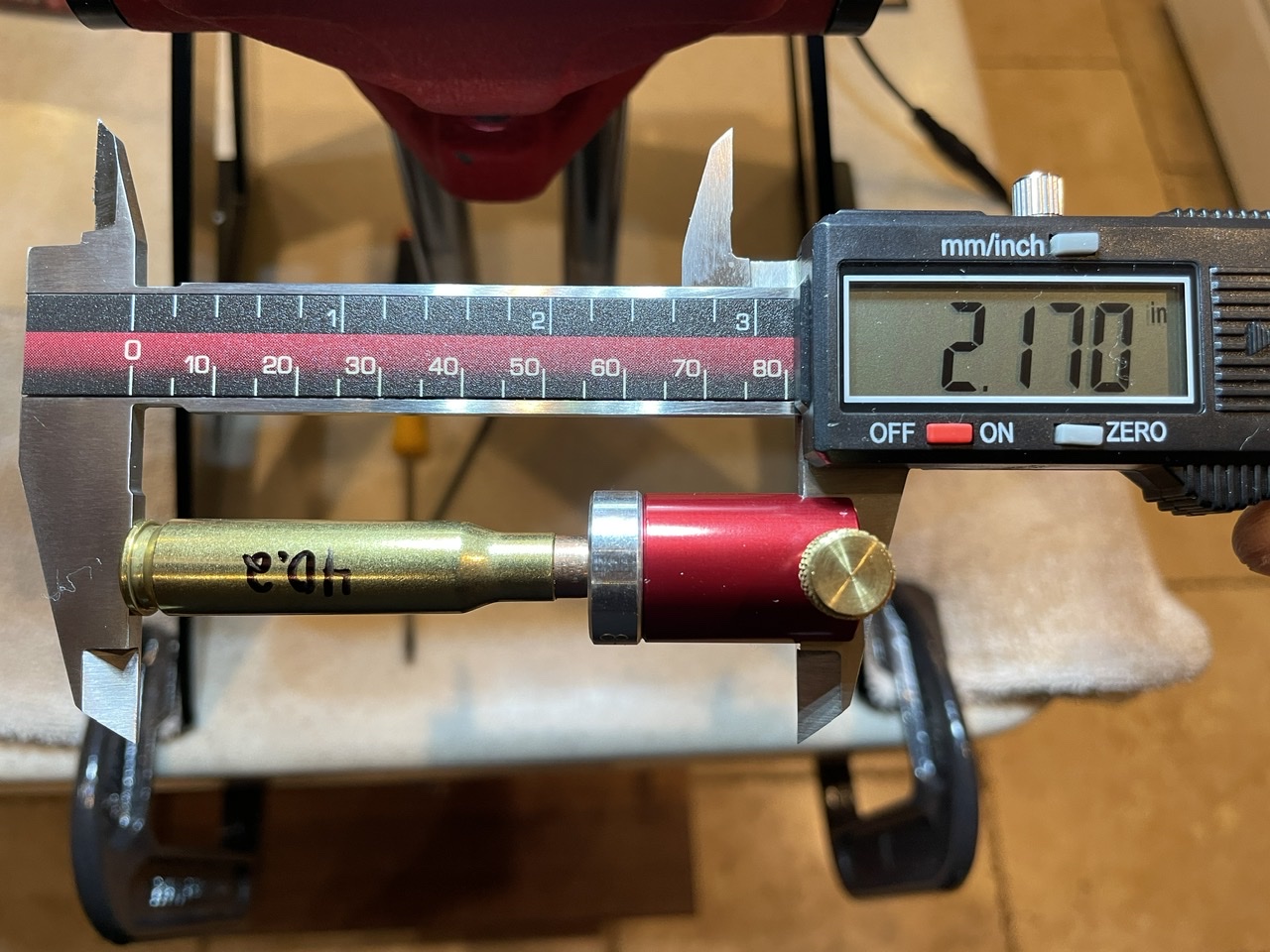

I started at the minimum and did one round each at .03 increments. From 35.3 gr to 40.2 my OAL was consistent at 2.170.

As soon as I jumped to 40.5 I could feel and slightly hear the load compress. I measured it and it bumped my OAL to 2.174

I loaded one more round at 40.8 gr and could feel and hear the load compress again. Checked the OAL and it had now bumped my OAL to 2.180. So at this point I stopped although Hornady lists max at 41.7.

Questions:

Is .308 compressed ok?

Obviously I’ll start at the minimum when I fire them, but would you even bother attempting to shoot the 40.5 and 40.8 loads that I know are compressed and bumped my OAL?

Would my brass type, Federal, account for the load compressing almost a full grain before max?

Brass is once fired Federal from factory gold medal match.

Primers are Federal 210M large rifle primers

Bullets are Hornady 178 gr ELD’s

Powder is IMR 4064.

Using Hornady’s reloading manual it shows the range as 35.3 to 41.7 gr

I started at the minimum and did one round each at .03 increments. From 35.3 gr to 40.2 my OAL was consistent at 2.170.

As soon as I jumped to 40.5 I could feel and slightly hear the load compress. I measured it and it bumped my OAL to 2.174

I loaded one more round at 40.8 gr and could feel and hear the load compress again. Checked the OAL and it had now bumped my OAL to 2.180. So at this point I stopped although Hornady lists max at 41.7.

Questions:

Is .308 compressed ok?

Obviously I’ll start at the minimum when I fire them, but would you even bother attempting to shoot the 40.5 and 40.8 loads that I know are compressed and bumped my OAL?

Would my brass type, Federal, account for the load compressing almost a full grain before max?