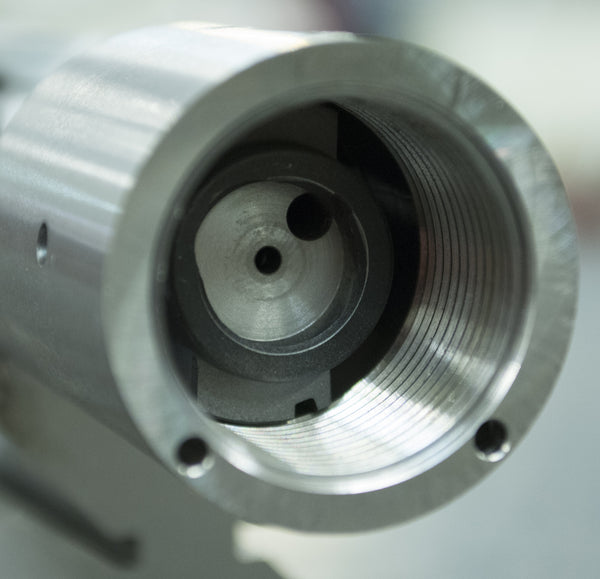

Ordered some new tooling to try out for the bolt head portion of our blueprinting services. The pics are at 2.5x, 5x, and 8x magnification.

One setup, one op. We control the nose, the bolt face, the top side of the lugs, and the bottom side of the lugs. Tolerance stack is basically zero as its one setup and probe inspected before and after. We are basically working at the resolution capacity of the machine due to it being such lightweight work. Simply to mean tool deflection really isn't an issue.

The new tooling knocks it out of the park. It doesn't really make anything any better other than splitting just a few more hairs to ensure we do as well a job as we possibly can.

2.5x:

5x:

8x:

One setup, one op. We control the nose, the bolt face, the top side of the lugs, and the bottom side of the lugs. Tolerance stack is basically zero as its one setup and probe inspected before and after. We are basically working at the resolution capacity of the machine due to it being such lightweight work. Simply to mean tool deflection really isn't an issue.

The new tooling knocks it out of the park. It doesn't really make anything any better other than splitting just a few more hairs to ensure we do as well a job as we possibly can.

2.5x:

5x:

8x: