As some here may know, I’m a firm believer in POF rifles (the flagship lineup...not their newer “budget” stuff), and I currently run a Revolution .308 that is the most accurate & reliable rifle I have ever owned. I have, however, heard of issues guys are having with the newer stuff, particularly stuff built after Frank’s untimely passing.

I ran into one of those issues at the range yesterday with a newer Revolution (Piston .308 16.5) that a buddy just purchased. I have picked this thing apart, luckily having my flawless Revolution (same specs) to compare & swap parts with. This thing is driving me crazy, so I’m hoping some of the experts here can help me out.

Side Note: the obvious answer is to just ship it back to POF, but I’m not the kind to just give up on an issue without exhausting every possible option. Also, the owner is a little paranoid, and is very reluctant to ship a black rifle, considering the current climate.

Sorry for the long intro, but now on to the issue. The gun is incredibly accurate (~ 1/2 MOA consistently with 178 ELD-X), but is having feeding issues, particularly with the first round out of the mag, and is wreaking havoc on the brass and bullet of any round that is chambered successfully. My first thought was a mag issue, but we were able to replicate the issue with 10,20,and 25 round Pmags, as well as my D&H SR-25 pattern 20 round mags (neon green follower), which I have tuned up to run smooth (corrected & polished feed lips), and the issue is present whether the mag is fully loaded, or only partially.

As I began troubleshooting, it became very obvious that the round is catching (hard) in between the lug recesses as it travels up the feed ramp. It seems as though the round is getting bound up between the feed ramp and the lip of the magazine...so as the feed ramp is trying to tilt the round up towards the chamber, the lip of the magazine is preventing it from doing so without a fight.

This is how the round is presented with the BCG back

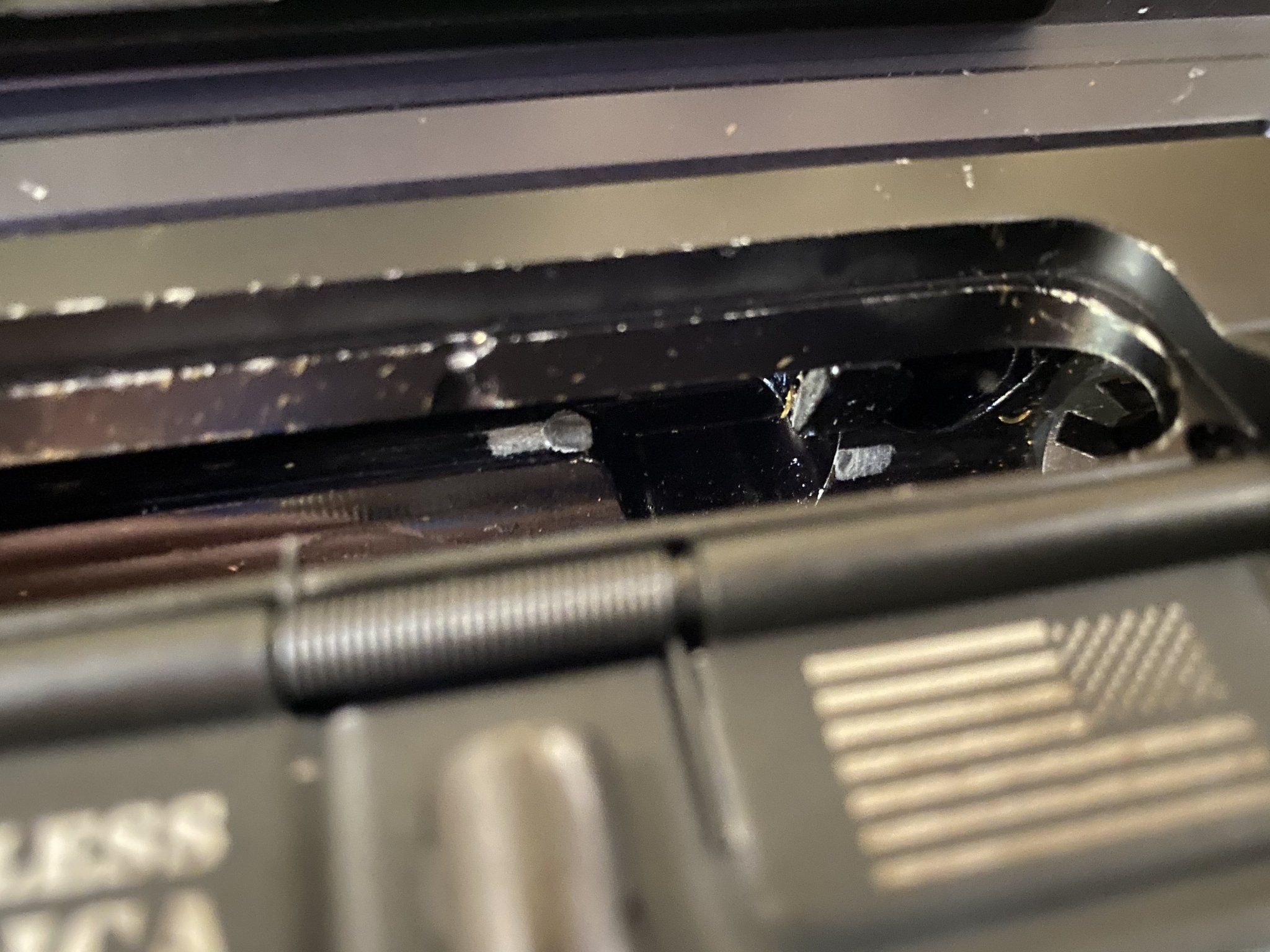

And this is how the FTF goes

The magazine is properly seated, and the lips barely clear the BCG.

The feed ramps are fighting the magazine lips so bad that it actually bent the front of the lip of the D&H mag

This issue happens with both sides of the mag, both feed ramps. I ran a q-tip along both feed ramps to check for any burrs, but they seem smooth.

Something else I noticed (possibly unrelated) is that the cam pin is beating up the cam pin slot a lot more than I think it should, especially considering the rifle has POF’s roller cam pin, which is designed to mitigate that very thing.

I’m sure I am forgetting things, but I can provide any additional info or pics as needed. Thanks in advance for your help.

I ran into one of those issues at the range yesterday with a newer Revolution (Piston .308 16.5) that a buddy just purchased. I have picked this thing apart, luckily having my flawless Revolution (same specs) to compare & swap parts with. This thing is driving me crazy, so I’m hoping some of the experts here can help me out.

Side Note: the obvious answer is to just ship it back to POF, but I’m not the kind to just give up on an issue without exhausting every possible option. Also, the owner is a little paranoid, and is very reluctant to ship a black rifle, considering the current climate.

Sorry for the long intro, but now on to the issue. The gun is incredibly accurate (~ 1/2 MOA consistently with 178 ELD-X), but is having feeding issues, particularly with the first round out of the mag, and is wreaking havoc on the brass and bullet of any round that is chambered successfully. My first thought was a mag issue, but we were able to replicate the issue with 10,20,and 25 round Pmags, as well as my D&H SR-25 pattern 20 round mags (neon green follower), which I have tuned up to run smooth (corrected & polished feed lips), and the issue is present whether the mag is fully loaded, or only partially.

As I began troubleshooting, it became very obvious that the round is catching (hard) in between the lug recesses as it travels up the feed ramp. It seems as though the round is getting bound up between the feed ramp and the lip of the magazine...so as the feed ramp is trying to tilt the round up towards the chamber, the lip of the magazine is preventing it from doing so without a fight.

This is how the round is presented with the BCG back

And this is how the FTF goes

The magazine is properly seated, and the lips barely clear the BCG.

The feed ramps are fighting the magazine lips so bad that it actually bent the front of the lip of the D&H mag

This issue happens with both sides of the mag, both feed ramps. I ran a q-tip along both feed ramps to check for any burrs, but they seem smooth.

Something else I noticed (possibly unrelated) is that the cam pin is beating up the cam pin slot a lot more than I think it should, especially considering the rifle has POF’s roller cam pin, which is designed to mitigate that very thing.

I’m sure I am forgetting things, but I can provide any additional info or pics as needed. Thanks in advance for your help.