I have a Seekins Havak Hit with the quick change barrels and bolt heads. I wanted a 6.5 PRC Seekins barrel but they are OOS, but I do have a 6.5 CM barrel for it. Can a 6.5 CM barrel be rechambered to 6.5 PRC without being set back? If all I had to do is have my gunsmith run a PRC reamer in it that would be awesome.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

The Shot You’ll Never Forget Giveaway - Enter To Win A Barrel From Rifle Barrel Blanks!

Tell us about the best or most memorable shot you’ve ever taken. Contest ends June 13th and remember: subscribe for a better chance of winning!

Join contest Subscribe

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rechamber 6.5 CM barrel to 6.5 PRC?

- Thread starter ArmchairOperator

- Start date

I don't know the answer, but I thought that to set back the barrel was only for throat erosion, so on a new barrel that should not be an issue.

Do you have the bolt for the PRC?

Do you have the bolt for the PRC?

Seekins HIT has interchangeable bolt heads, and I have the PRC bolt head. I have a MOS-TEK shorty 6.5 PRC in order but I was wanting a factory 6.5 PRC 24” M24 barrel which is out of stock. I have a Creedmoor barrel and a 308 as well.I don't know the answer, but I thought that to set back the barrel was only for throat erosion, so on a new barrel that should not be an issue.

Do you have the bolt for the PRC?

Only reason I was thinking to set back was if the CM chamber is larger anywhere than the PRC then you’d have to set it back. If the CM chamber will clean up to PRC then it should work, but I was hoping someone who knows if this works would confirm this for me since I’m just guessing. I can always call my gunsmith.

Indicate the bore, not the chamber, take a light boring cut to true up old CM chamber and run your finish 6.5 PRC reamer in.

Presto you have a 6.5 PRC along with your new magnum bolt face, of course...easy.

Presto you have a 6.5 PRC along with your new magnum bolt face, of course...easy.

I'm a bit new to this game, so I'm still learning, but what are hybrid cases? How close to PRC velocity can you get from the CM round with hybrid cases?Just run hybrid cases in your 6.5 CM when ya want extra velocity, like a 6.5 PRC, with good accuracy. Factory 6.5 CM rifle running 140s over 3100 fps, 150 SMK 3000 fps. Hybrid cases and RL 26, in 6.5 CM, or rechamber to 6.5 PRC.

Do you mean the barrel being removed is also unfired? Or just the new PRC barrel?Some gunsmiths will prefer the barrel be unfired for this but is possible either way

It will usually be faster than a 6.5 PRC with the same barrel length, and bullets in the 140 to 153 weight class. My 24" CM will match the 26" PRC in the Hornady manual, with hybrid cases...using RL 26 same as the PRC but a little less than the Hornady manual recommendation, for the top loads. But the PRC is the easy button for those who don't handload, or want to mess with the case forming, or neck turning.I'm a bit new to this game, so I'm still learning, but what are hybrid cases? How close to PRC velocity can you get from the CM round with hybrid cases?

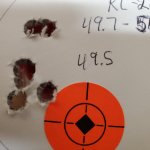

Here's the load data 24" Ruger factory rifle in 6.5 CM with 150 gr SMK, notice the split in the group as the powder charge increased. I went for the 2990 fps for the 150 gr and excellent accuracy in the 6.5 CM just another possibility for improving the vocity in a cartridge you already own.

Works for the 308 Win too.

Attachments

Some gunsmiths like the barrel never fired for a rechamber job to be easier on the tooling is one reason.Do you mean the barrel being removed is also unfired? Or just the new PRC barrel?

@45-90 are you working with the fury cases for that or is there a specific creed case now?

@yo-yo hybrid cases are bi metal with steel heads which allow much greater pressures. The sig 277 fury is an example. You can see the head of the cart in the pic is steel.

Ah, wow. Interesting. Thanks! Hmm...yeah, might be interested in trying that, before committing to a swap to PRC. I talked to James a NSS and he said the swap could be accomplished with a barrel and a bolt face and a different front bolt baffle. The bigger issue is the large shank barrels are not on a shelf and 10-20 weeks away.It will usually be faster than a 6.5 PRC with the same barrel length, and bullets in the 140 to 153 weight class. My 24" CM will match the 26" PRC in the Hornady manual, with hybrid cases...using RL 26 same as the PRC but a little less than the Hornady manual recommendation, for the top loads.

Here's the load data 24" Ruger factory rifle in 6.5 CM with 150 gr SMK, notice the split in the group as the powder charge increased. I went for the 2990 fps for the 150 gr and excellent accuracy in the 6.5 CM just another possibility for improving the vocity in a cartridge you already own.

Works for the 308 Win too.

But, I like the idea of the hybrid cases! I'll look into that!

Ah got ya. Makes sense.Some gunsmiths like the barrel never fired for a rechamber job to be easier on the tooling is one reason.

@yo-yo hybrid cases are bi metal with steel heads which allow much greater pressures. The sig 277 fury is an example. You can see the head of the cart in the pic is steel.

Those cases are really interesting. I will look into that. I have a friend that reloads a lot, but he hasn't done the hybrid case approach yet. Looks interesting and fun! Thanks for the additional detail!

I am not new at this but this one is new to me.@yo-yo hybrid cases are bi metal with steel heads which allow much greater pressures. The sig 277 fury is an example. You can see the head of the cart in the pic is steel.

So the bimetal case takes you from 62,000 max psi in the 6.5 Creedmoor to what max psi?

Who makes these cases?

Thanks

Can hit ~ 80k if the rest of the system can.

I'm assuming it's a 277 sig fury case being used for this. Fury primed pull cases are sometimes available. I'll let 45-90 speak to more because I haven't tried this nor compared the dimensional differences beyond imagining using a BR bushing neck die to neck down.

I'm assuming it's a 277 sig fury case being used for this. Fury primed pull cases are sometimes available. I'll let 45-90 speak to more because I haven't tried this nor compared the dimensional differences beyond imagining using a BR bushing neck die to neck down.

Being a machinist and not a gunsmith, many of whom would not qualify as "machinist"..never had 5 yr apprenticeship, college, or an extensive machining background....are giving out general gunsmithing advice, much of it to "obtain" work, or "not do" metal work they are unfamiliar with.

A comfort zone.

I don't do that...

I rechamber any thing that fits my imagination.

Why limit yourself, to the limitations others make for you, that's out of their comfort zone.

Wear tooling?.. so I don't want to chamber your AR 10 308 win to 338 RCM?

I use my own tooling ...it is an excuse, not reality.

Rechambering and existing barrel, to a larger cartridge of the same bullet diameter is common place in my shop.

But I'm not gonna do your gunsmithing work.

Who would consider a 510 whisper in an AR 10...it can be done, but the mag constraints limit the cartridge severely to sub sonic mostly with heavy 650 gr bullets.

So it went into a bolt gun ...and the 338 RCM AR 10 was created.

Notice the sharper than print radius on the newly made 338 RCM brass compared to the 308 Win case, this is machined when neck turning, as well as the 30° angle. to eliminate donuts, in the neck. An important pressure area when working with high pressures.

A comfort zone.

I don't do that...

I rechamber any thing that fits my imagination.

Why limit yourself, to the limitations others make for you, that's out of their comfort zone.

Wear tooling?.. so I don't want to chamber your AR 10 308 win to 338 RCM?

I use my own tooling ...it is an excuse, not reality.

Rechambering and existing barrel, to a larger cartridge of the same bullet diameter is common place in my shop.

But I'm not gonna do your gunsmithing work.

Who would consider a 510 whisper in an AR 10...it can be done, but the mag constraints limit the cartridge severely to sub sonic mostly with heavy 650 gr bullets.

So it went into a bolt gun ...and the 338 RCM AR 10 was created.

Notice the sharper than print radius on the newly made 338 RCM brass compared to the 308 Win case, this is machined when neck turning, as well as the 30° angle. to eliminate donuts, in the neck. An important pressure area when working with high pressures.

Attachments

I've been doing this for several years, when the cases first came out.Can hit ~ 80k if the rest of the system can.

I'm assuming it's a 277 sig fury case being used for this. Fury primed pull cases are sometimes available. I'll let 45-90 speak to more because I haven't tried this nor compared the dimensional differences beyond imagining using a BR bushing neck die to neck down.

There is a procedure for every caliber. I have described it extensively many times here.

For 6.5 CM over view ...it's 308 FL die bump back at 20° leave a bit to finish With the 6.5CM FL die 30°, brass moves easier at 20°.

Neck turn, anneal, resize.

I have described it all in detail probably 20 times...

I neck turn in a lathe with a ground carbide tool...this is 308.

Next is 8.6 Blkout steps to make hybrid cases for it, with a 6.5 twist...not the silly hype marketed, 3 twist, which restricts velocity and bullet selection...really improving the cartridge, any 338 bullet available, at greatly increased speeds, similar to 338 Federal for supers and very accurate subs. To make it a truly dual purpose cartridge.

Attachments

I've been telling the general public about this for several years when the hybrid case first came out, they said there were no dies for reloading it .

Others laughed at the idea.

So I bought a few hundred and found they size in regular factory dies, like the cheap Lee, or Wilson.

They have been available from American Reloading, no one bought hybrid cases but me it seemed.

I spread the word on performance for several yrs, and now it seems fairly popular...as American Reloading had close to 200,000 in stock and they were all gone in s couple of weeks.

The last batch was pull down that had stuck bull powder in the case, just blow it out with a skinny air nozzle and compressed air.

I use QL as a guideline for pressure, and do not run the full value the cases are capable of, back off just a bit and excellent accuracy is there, at relatively high speed, for the standard cartridges.

Others laughed at the idea.

So I bought a few hundred and found they size in regular factory dies, like the cheap Lee, or Wilson.

They have been available from American Reloading, no one bought hybrid cases but me it seemed.

I spread the word on performance for several yrs, and now it seems fairly popular...as American Reloading had close to 200,000 in stock and they were all gone in s couple of weeks.

The last batch was pull down that had stuck bull powder in the case, just blow it out with a skinny air nozzle and compressed air.

I use QL as a guideline for pressure, and do not run the full value the cases are capable of, back off just a bit and excellent accuracy is there, at relatively high speed, for the standard cartridges.

By the way, the image of the case shown in the posted picture looks like a steel butt on the care…not the head. Am I looking at this correctly?Some gunsmiths like the barrel never fired for a rechamber job to be easier on the tooling is one reason.

@45-90 are you working with the fury cases for that or is there a specific creed case now?

@yo-yo hybrid cases are bi metal with steel heads which allow much greater pressures. The sig 277 fury is an example. You can see the head of the cart in the pic is steel.

Hybrid "case heads" are stainless steel. Case body is standard cartridge brass.

They are lighter, and have slightly more case volume than non hybrid cases.

These are 308s but you get the idea of what they look like...some heavy duty test loads.

Copper bullet turning.

Some serious neck turning

And some serious 308s with 215 Bergers and why one might want hybrid cases, to improve the 6.5 CM.

If you are new to these concepts and are used to the same old song and dance.

It's educational, and sharing ideas, that can be utilized... or not, ...in your cartridge loading proceedures.

Don't just build rifles ...everything is explored,

Specialty die, no lube needed, takes 30-06 down to 8.6 Blackout in one pass, better than carbide dies ..."top secert" only one of its kind, actually have several made for various wildcats, ...but a light spray of Hornady lube desired, here and there, as cases get hot from sizing with no lube.

I probably won't share that million dollar idea. Maybe RCBS, will one day figure it out.

An example of not going along all the shooting hobby norms, when ideas come your way, implement them. Test them, to see if they are valid.

They are lighter, and have slightly more case volume than non hybrid cases.

These are 308s but you get the idea of what they look like...some heavy duty test loads.

Copper bullet turning.

Some serious neck turning

And some serious 308s with 215 Bergers and why one might want hybrid cases, to improve the 6.5 CM.

If you are new to these concepts and are used to the same old song and dance.

It's educational, and sharing ideas, that can be utilized... or not, ...in your cartridge loading proceedures.

Don't just build rifles ...everything is explored,

Specialty die, no lube needed, takes 30-06 down to 8.6 Blackout in one pass, better than carbide dies ..."top secert" only one of its kind, actually have several made for various wildcats, ...but a light spray of Hornady lube desired, here and there, as cases get hot from sizing with no lube.

I probably won't share that million dollar idea. Maybe RCBS, will one day figure it out.

An example of not going along all the shooting hobby norms, when ideas come your way, implement them. Test them, to see if they are valid.

Attachments

Damn I love this type of innovation.Hybrid "case heads" are stainless steel. Case body is standard cartridge brass.

They are lighter, and have slightly more case volume than non hybrid cases.

These are 308s but you get the idea of what they look like...some heavy duty test loads.

Copper bullet turning.

Some serious neck turning

And some serious 308s with 215 Bergers and why one might want hybrid cases, to improve the 6.5 CM.

If you are new to these concepts and are used to the same old song and dance.

It's educational, and sharing ideas, that can be utilized... or not, ...in your cartridge loading proceedures.

Don't just build rifles ...everything is explored,

Specialty die, no lube needed, takes 30-06 down to 8.6 Blackout in one pass, better than carbide dies ..."top secert" only one of its kind, actually have several made for various wildcats, ...but a light spray of Hornady lube desired, here and there, as cases get hot from sizing with no lube.

I probably won't share that million dollar idea. Maybe RCBS, will one day figure it out.

An example of not going along all the shooting hobby norms, when ideas come your way, implement them. Test them, to see if they are valid.

As will all great projects, let discuss the downsides of steel based “hybrid” cases?

- Multiple reloads? More or less than brass?

- Die wear?

- Bolt, extractor, chamber wear?

- Obviously will burn barrels faster with higher pressures/ velocities?

- Longer term storage with mixed dissimilar metals?

- Any other downsides?

- Base on the first question primer pocket hold up indefinitely?

Thanks again for your info on this.

Oh, wow. Thanks! I didn't understand the anatomy of the case! Crazy the head is at the back. Make sense now..."headspace".

Thanks for all this. I will digest this a bit.Being a machinist and not a gunsmith, many of whom would not qualify as "machinist"..never had 5 yr apprenticeship, college, or an extensive machining background....are giving out general gunsmithing advice, much of it to "obtain" work, or "not do" metal work they are unfamiliar with.

A comfort zone.

I don't do that...

Probably can’t answer all the questions, but a few. The FL dies never fully sizes the last .2" of the solid case head.Damn I love this type of innovation.

As will all great projects, let discuss the downsides of steel based “hybrid” cases?

Pros

- Multiple reloads? More or less than brass?

- Die wear?

- Bolt, extractor, chamber wear?

- Obviously will burn barrels faster with higher pressures/ velocities?

- Longer term storage with mixed dissimilar metals?

- Any other downsides?

Are you actually sizing the steel or just neck sizing?

- Base on the first question primer pocket hold up indefinitely?

Thanks again for your info on this.

The first pic is a fully resized 308 case...notice the die never touches the last .2" this portion of the case is solid hardened brass, with only the primer cut out then the flash hole through the center.

It never gets sized, on brass or stainless steel.

This solid portion does not expand under normal chamber pressure.

Next pic the brass portion expanded 4 1/2 ten thousandths of an inch. This expanded portion and the rest of tbe case is the part that the FL die resizes.

An actual 308 factory chamber, with the cartridge case inserted...note the solid head portion iof the case is not supported by steel. Repeated high pressure loads or one really high pressure load expands the solid head, so it will no longer hold primers.

So the stainless steel solid case head never gets resized, just like the solid brass case.

I'm personally doing alot of other projects, but I have cycled the Stainless steel case head through 5 high pressure cycles and primer pockets are still tight.

Don't have to worry about die wear.

I store them in 50BMG military cartridge storage containers.

I checked headspace for lug set back, ...no change, on 2 factory rifles I really pushed hard, for experimental purposes.

On normal pressure loads the primer pockets, may last until the brass case gives out.

The brass will start to seperate near the head or down the body after repeated firings, no matter how little one resizes the case each time. When you trim the brass comes from the case stretching slightly, anf brass flow towards the shoulder making the body thin.

Example, years back, after 40 to 50 firing resizing cycles on Lapua brass the case is so thin it seperates, even with neck sizing only with a shoulder bump die every third firing. So with that setup I scrapped the 308 Lapua brass after 40 cycles... max for this loading proceedure.

You have to trim cases after the first firing the 3 piece SS case tends to stretch, more than normal first time under pressure.

Do Not forget to lube this hybrid case or think it has has enough lube when it doesn't...they are strong but will seperate. The case head and the body left in the die.

To get the broken shell our take the die to the lathe, bore for 7/16 X 20 tap, tap in lathe to keep exactly centered. Use bolt & cup method to pull stuck case.

No noticeable wear on any rifles from Stainless case heads.

Barrel wear will most likely be greater...but that would be an exhaustive test to see if a 6.5 CM with higher pressure and slightly less powder would out last a 6.5 PRC burning 5 grains more RL 26 to get the same velocity. Probably about equal...maybe.

No excessive wear on rifle parts from various calibers noticed.

Remember the military runs this high pressure ammo in machineguns, and slect fire rifles for soldiers.

A semi auto civilian version is available to the public complete with suppressor and 13" barrel, for a hefty price.... 6.8X 51 able to penetrate Russian body armor.

Don't have all the answers, this is a hobby, and what I have learned...learning new things every day....it's up to you, and others, to add more to the experience.

Attachments

Heck, yeah guys utilizing those hybrid cases is going to change the way we look at the current calibers being able to push it to 80,000 psi is going to be giving these smaller lightweight cartridges and rifles, Some pretty impressive results.

When I heard about the bimetal case and the military adopting that it’s going be a really great next 10 years, as far as new speeds and development on our current rifles.

Will the AR 10 be able to handle that extra pressure? We’ve seen the limits of the small frame AR bolts when dealing with the six ARC pretty quickly… but AR 10 bolt would not have to be cut and enlarged..

When I heard about the bimetal case and the military adopting that it’s going be a really great next 10 years, as far as new speeds and development on our current rifles.

Will the AR 10 be able to handle that extra pressure? We’ve seen the limits of the small frame AR bolts when dealing with the six ARC pretty quickly… but AR 10 bolt would not have to be cut and enlarged..

You can buy a semi auto civilians version for a bunch of coin. It comes with 13" barrel and suppressor, same as the select fire military version.Heck, yeah guys utilizing those hybrid cases is going to change the way we look at the current calibers being able to push it to 80,000 psi is going to be giving these smaller lightweight cartridges and rifles, Some pretty impressive results.

When I heard about the bimetal case and the military adopting that it’s going be a really great next 10 years, as far as new speeds and development on our current rifles.

Will the AR 10 be able to handle that extra pressure? We’ve seen the limits of the small frame AR bolts when dealing with the six ARC pretty quickly… but AR 10 bolt would not have to be cut and enlarged..

These and machine guns have been altered to handle the 80,000 psi loads.

There are videos of civilian guys shooting the high pressure loads in run and gun drills, out of these civilian semi auto versions.

It's been around for quite awhile, but manufacturers are not jumping on board.

New powders are needed to get the full potential out of each caliber & bullet combination. Plus 80,000 psi seems a bit scary, but magnums are already running 65,000 psi.

Similar threads

- Replies

- 4

- Views

- 580

- Replies

- 1

- Views

- 599