So I'm a new listener to the podcast and I heard mention of some modifications to cheaper ball heads to minimize the mechanical play in the ballhead-clamp-rifle interface. The modifications Frank talks about require permanent modification to the stem of the ball head and I would rather not exercise Athlon's lifetime warranty by grinding off the nubs on my stem with hand tools.

So I looked at the mechanical wobble in my Midas CF36 tripod and noticed the main cause of the wobble was the mating surface between the clamp and the ball head stem (7mils left and right for a total of 14mils in play). Then I figured might as well burn up some of my JB Weld supply and bed the Arca clamp to the ball stem and see what kind of results I got with that.

Naturally first step in any coating procedure is surface prep. I used a diamond head bit for my dremel to rough up the channel on the clamp then wiped down both the stem and the clamp with 99% isopropyl alcohol twice.

Next I coated the clamp screw, threads, and stem in Imperial sizing die wax to act as a release agent.

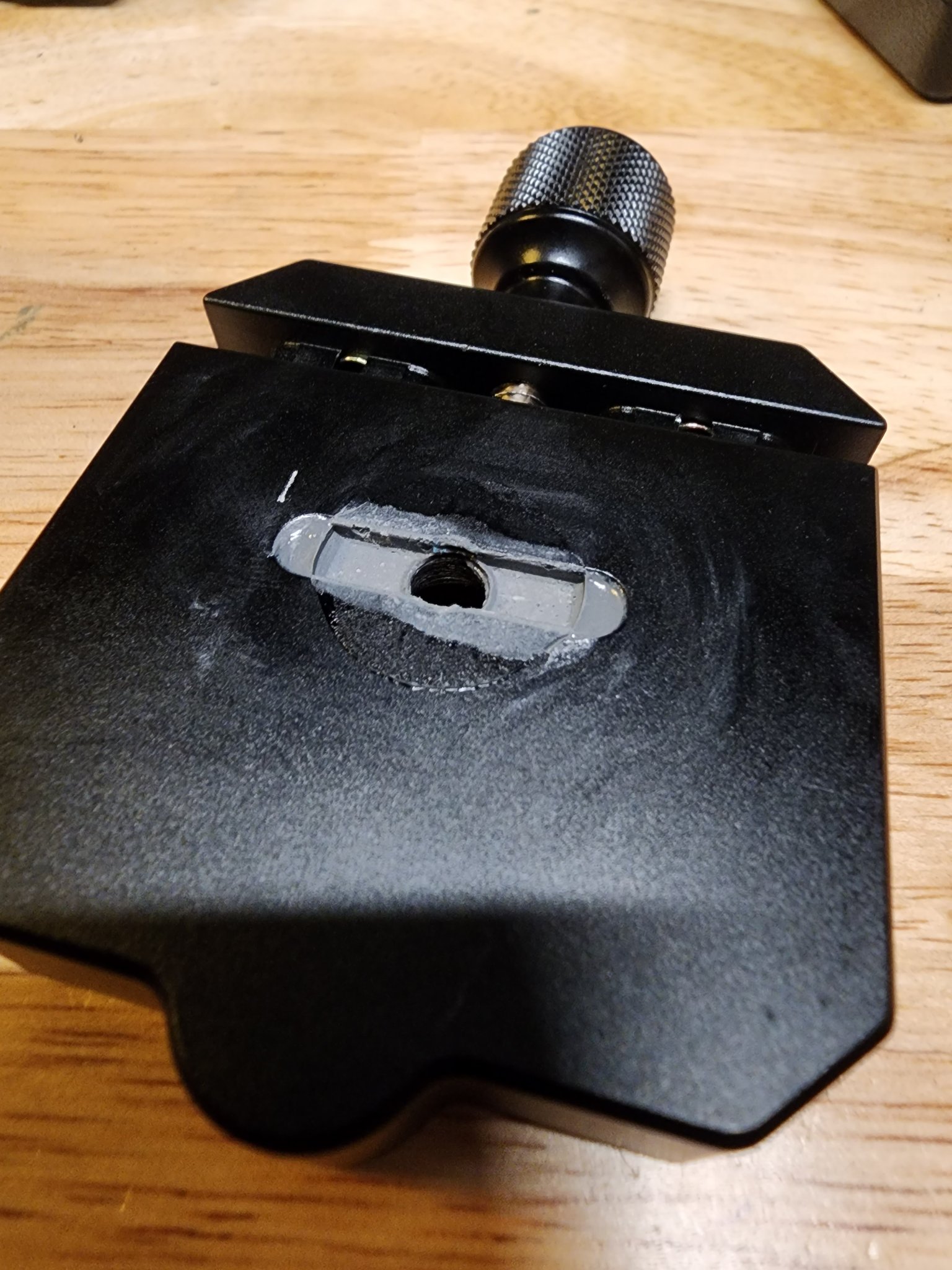

Then mixed up JB Weld and filled the channel on the clamp before mounting it up to the stem, allowing the excess to squish out where it wanted to before wiping that up with q-tips. Also be sure to get any runoff out of the stem itself with a toothpick or something.

Then allowed it to cure and ta-da! Mechanical wobble is down to 3mils either side with the first two leg segments fully extended. And 2 mils either side fully collapsed.

So I looked at the mechanical wobble in my Midas CF36 tripod and noticed the main cause of the wobble was the mating surface between the clamp and the ball head stem (7mils left and right for a total of 14mils in play). Then I figured might as well burn up some of my JB Weld supply and bed the Arca clamp to the ball stem and see what kind of results I got with that.

Naturally first step in any coating procedure is surface prep. I used a diamond head bit for my dremel to rough up the channel on the clamp then wiped down both the stem and the clamp with 99% isopropyl alcohol twice.

Next I coated the clamp screw, threads, and stem in Imperial sizing die wax to act as a release agent.

Then mixed up JB Weld and filled the channel on the clamp before mounting it up to the stem, allowing the excess to squish out where it wanted to before wiping that up with q-tips. Also be sure to get any runoff out of the stem itself with a toothpick or something.

Then allowed it to cure and ta-da! Mechanical wobble is down to 3mils either side with the first two leg segments fully extended. And 2 mils either side fully collapsed.