Re: Scope base screw holes out of alignment?

I used to bore sight, but it made it hard to work at night.

Now I use a Leupold Magnetic Illuminated Boresighter

http://www.amazon.com/Leupold-Magnetic-Illuminated-Boresighter-Md/dp/B0014VRPPW

I like to install Weaver mounts so that there is no bind and the scope will be on the paper if the reticule is in the center of the tube.

I buy a lot of guns for cheap, especially Mausers, and the most common problem is that the sights don't work, never could work, the rifle is being dumped.

If the holes are drilled off center, I try to avoid drilling more holes or welding up the old holes. I prefer to work with the holes that are there.

If I "waller over" the holes in the mount, because the holes that were drilled and tapped were off center, I have to waller over the countersink too. I cannot waller over a countersink for a tapered flat head screw, but I can for a Fillister head, by using an end mill. If the mount starts out as a tapered counter sink for a flat head screw, I convert it, when I waller over, to a flat bottomed countersink for a fillister head screw.

In dual mounts, I sometimes move over the concave radius on the bottom of the mount with a boring head or end mill or fly cutter or what ever, but I prefer to shim with narrow masking tape and epoxy bed the mount's underside to the receiver to keep the bore sighter centered. I rough up the bottom of the mount and put release agent on the receiver. I mask off the receiver around the mount.

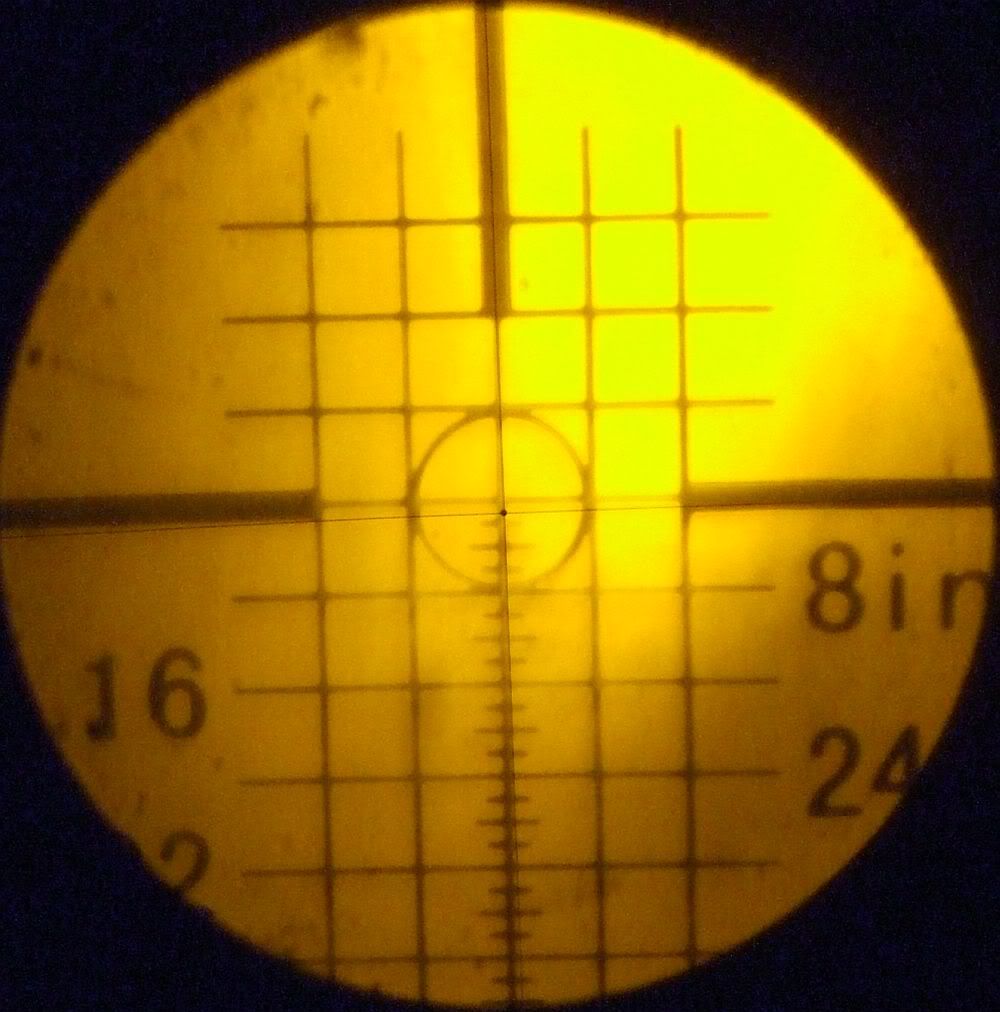

If the bore sighter looks like this when the epoxy is hard and the screws are tightened, then I clean the threaded holes and screws and apply loctite 242 and give the mount screws their final torquing.

Then scopes should be able to move from rifle to rifle and be on the paper and no ring lapping.

If things really go wrong, I will mill out a Weaver rail from scratch that is custom to the rifle, but that is lots more work than modifying a factory mount to fit.