Shooters and Reloaders, I wanted to start a thread to address questions, comments and updates regarding our new reloading products. We have always been a Precision Rifle specific shop, everything we do revolves around our core business. So, as shooters and reloaders ourselves, we have always had products or features that we wanted to see to facilitate our Precision Rifle shooting, reloading and building passion! Here is a quick breakdown of our current products, these are all original in design and execution from Short Action Customs.

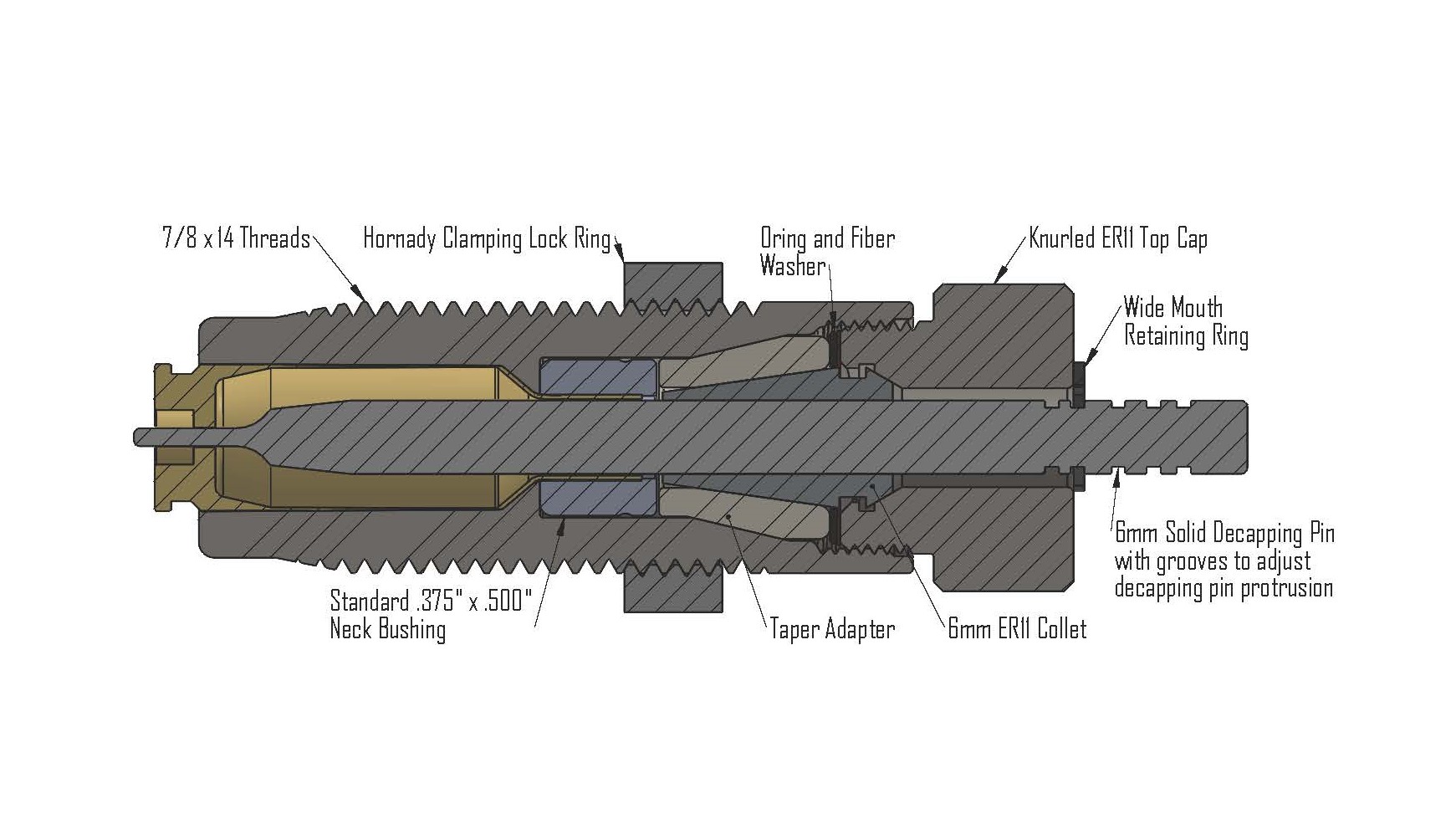

Precision Resizing Dies: FOUND HERE Made from 17-4 Stainless with a brand new heat treat process with a lower friction coefficient which is superior to conventional Melonite and Salt Bath Nitride. Key features include caliber specific decapping pins, unique ER collet design which holds the decapping pin extremely concentric, optimized resizing geometry to size the base of the cartridge more and the cartridge shoulder a less than most dies. When you combine the superior surface finish of 17-4 stainless with this heat treat process, you have an extremely smooth resizing die that is stronger than most conventional resizing dies.

Neck Sizing Bushings: FOUND HERE, The only thing standard is the .500" x .375" outside dimensions making it compatible with any die that can use Redding neck bushings or other of a similar size. The inside geometry is brand new and gently "funnels" the neck of the brass into the die, reducing neck concentricity runout. Furthermore, our new Neck Sizing Bushings leave the neck/shoulder junction of the brass around fireformed diameters minimizing the affects of donuts inside the necks. Furthermore, this helps loaded ammunition maintain concentricity with the chamber.

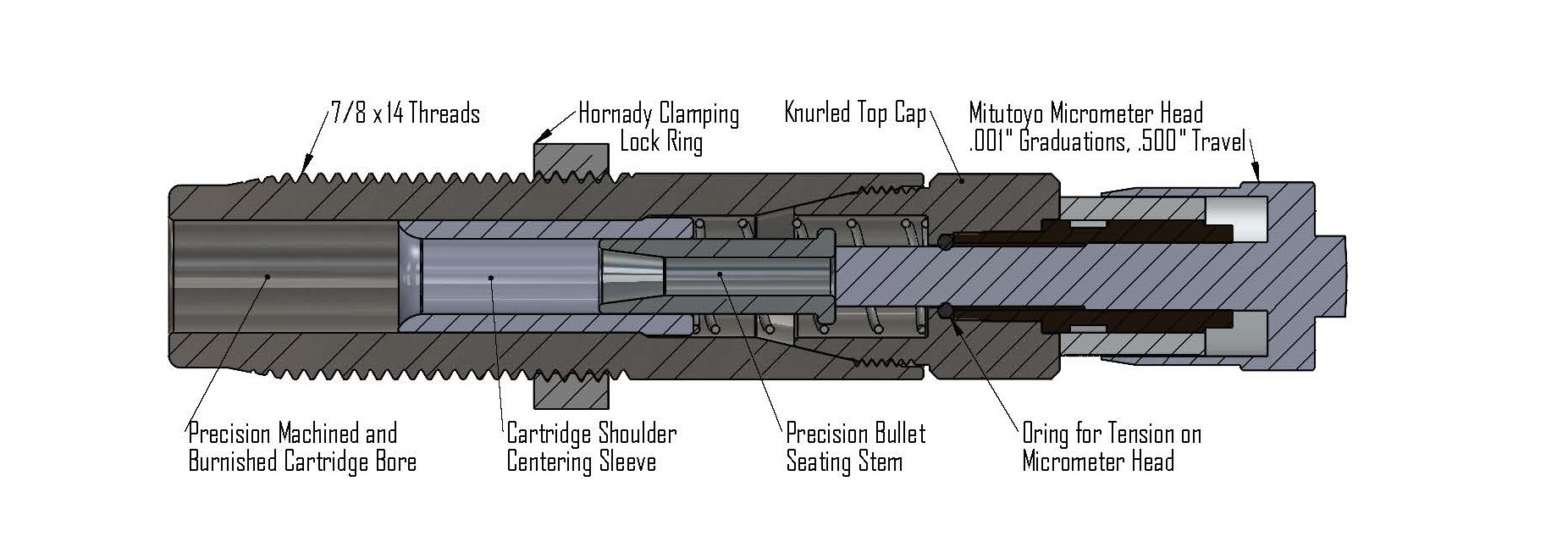

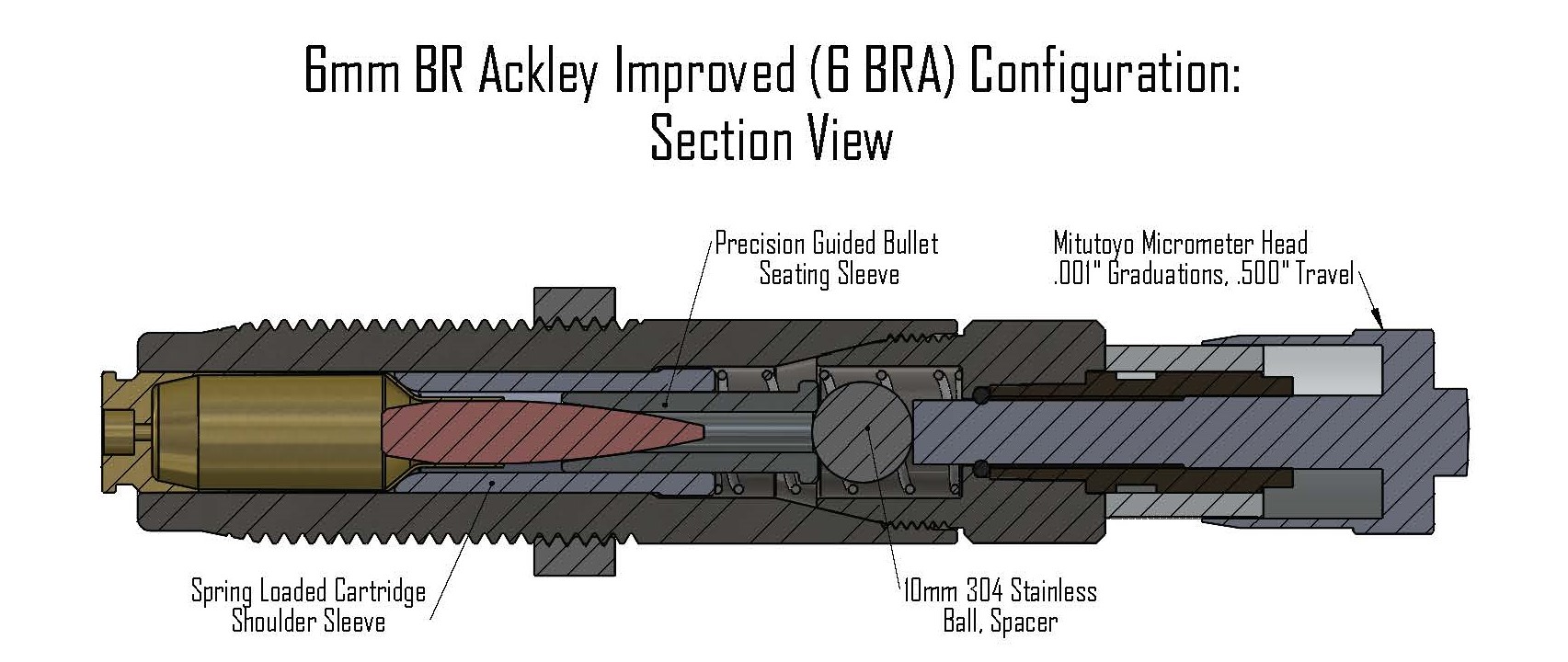

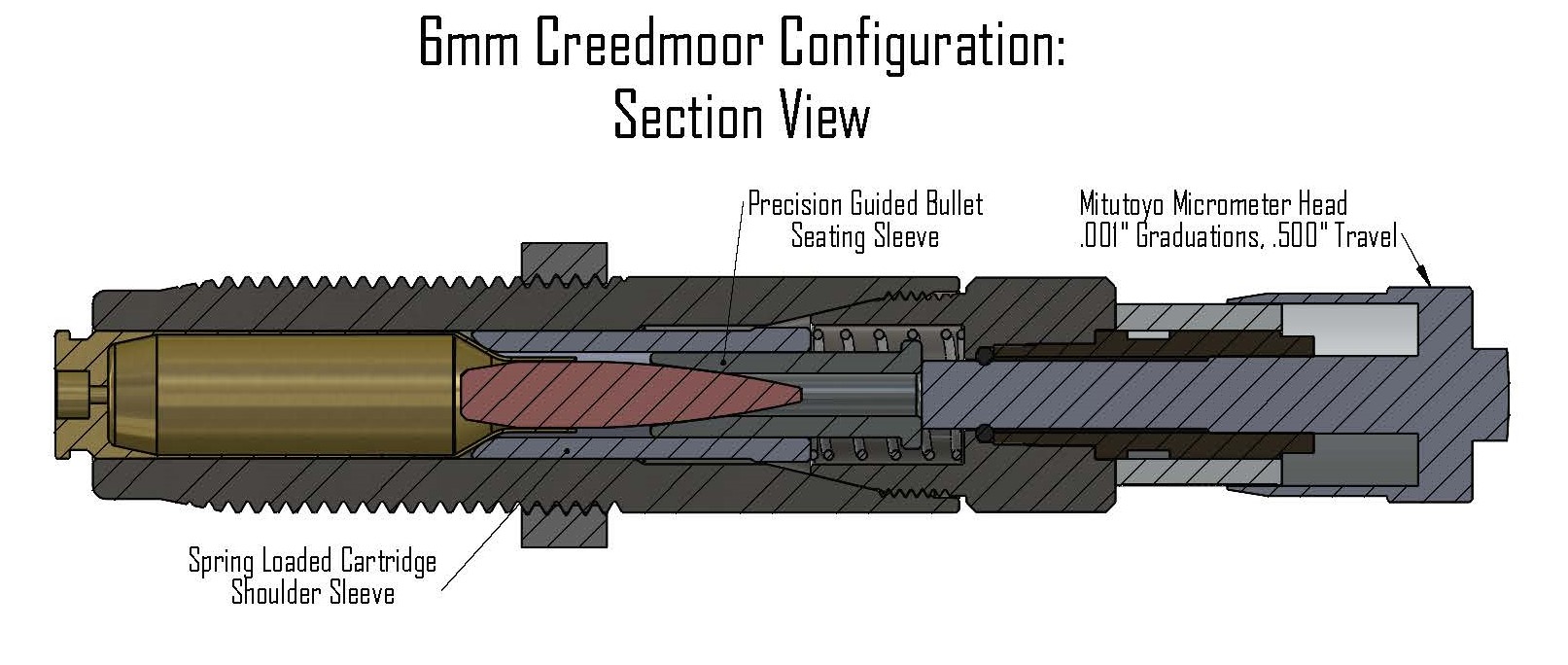

"The" Seating Die: FOUND HERE, We started designing "The" Seating Die with the goal of being able to offer one die that could seat bullets in a very straight, concentric fashion on a variety of cartridges. Furthermore, we wanted to solve the seating stem geometry problem that most dies have of damaging or marking bullets. The heart of "The" Seating Die is the through bore which is incredibly straight and has an extremely consistent bore diameter. This allows the Cartridge base to be held concentric in the die, then the Cartridge Shoulder Sleeve centers and supports the cartridge shoulder while the bullet seating stem is guided down during the seating process. All aligned from the die body's center bore. With a Mitutoyo Micrometer head with .001" graduations and a Short Action Customs proprietary tool-less tension system to secure the micrometer head, "The" Seating Die seats bullets in a straighter, more concentric fashion than most dies while simultaneously having the ability to work with a large variety of cartridges. For short cartridges, use the supplied 10mm spacer ball.

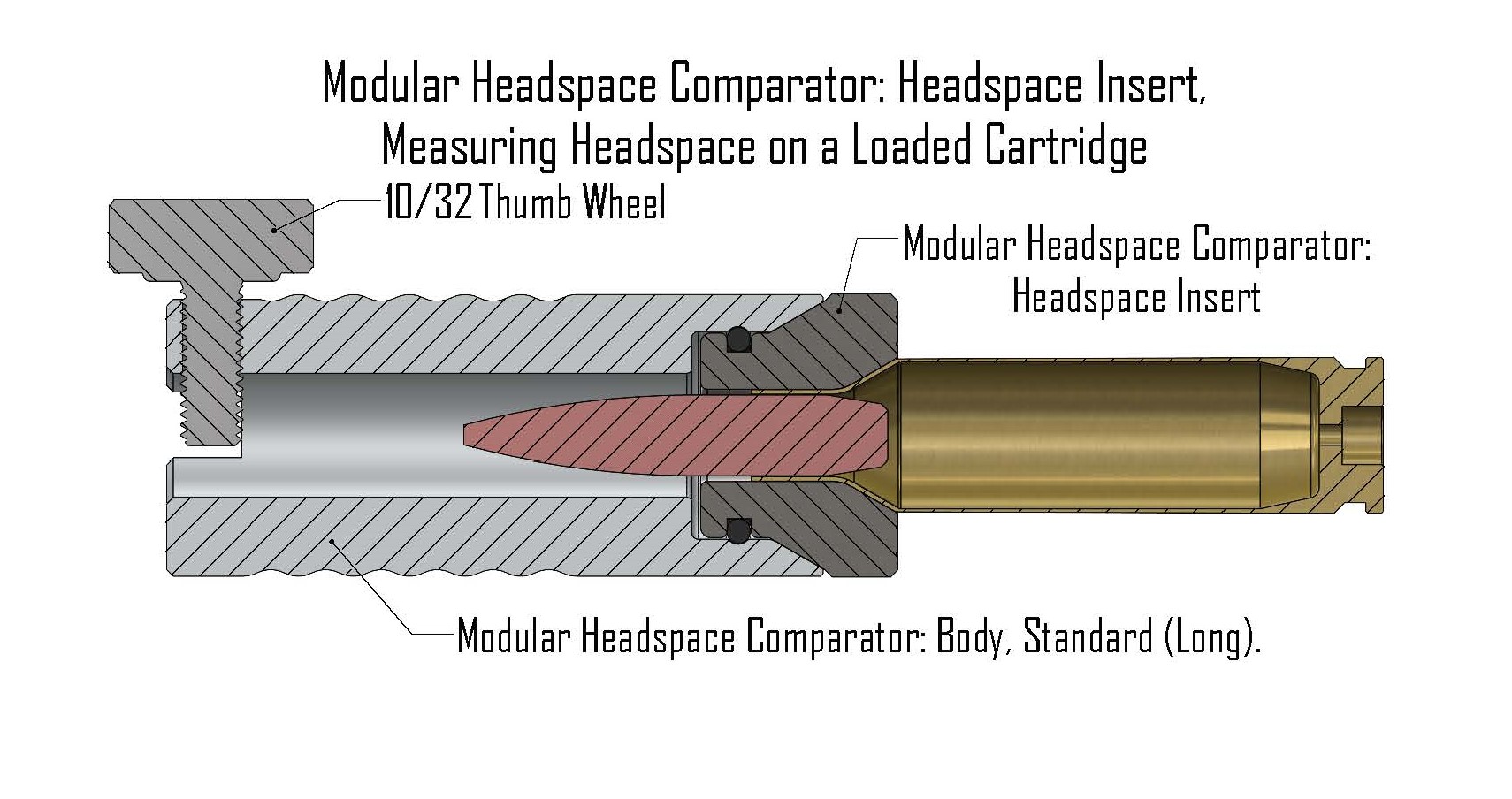

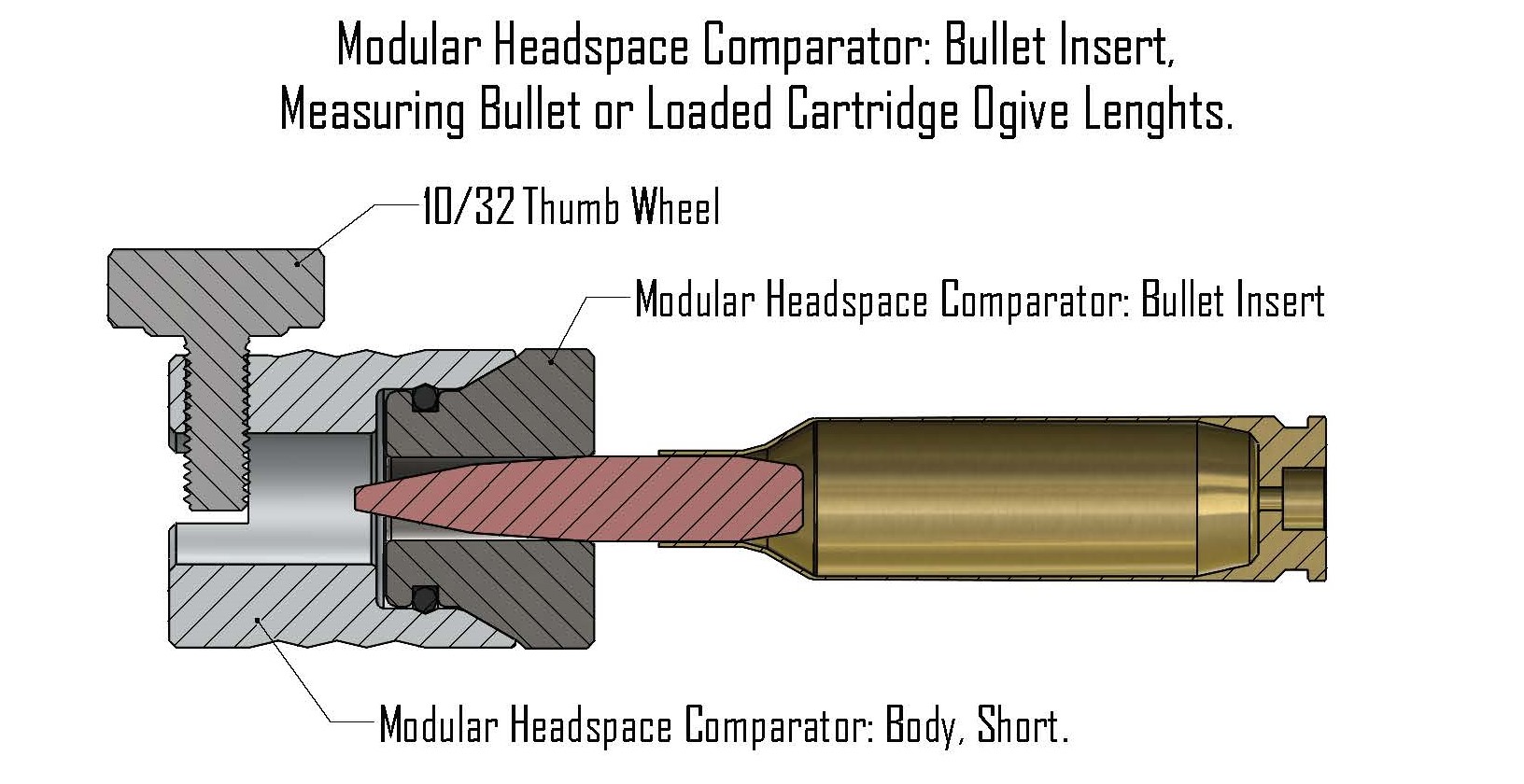

Modular Headspace Comparators: FOUND HERE, The highest quality and most functional headspace and bullet ogive tools on the market. The Modular Headspace Comparator is comprised of THREE main parts. The BODY, BULLET INSERTS and HEADSPACE INSERTS. The Body clamps onto your dial calipers and it comes in two different lengths. We have a Short Body which is light and handy, works great for measuring bullets, loaded ammunition base to ogive and non-loaded brass for headspace. The Standard (Long) body is longer which is required to measure loaded ammunition for headspace, otherwise, can do everything that the Short Body can do, but in a slightly longer package.

Made from 17-4 Stainless, Bullet Inserts start at .0005" larger than bullet diameter and taper down at 3° until reaching the groove diameter for that cartridge. For example the 6.5mm Bullet Insert starts at .2645", tapers down at 3° to .256". This mirrors the actual bore extremely well. We chose 3° compared to 1.5° because of bullets sticking in the 1.5° taper. FOUND HERE

Made from 17-4 Stainless, Headspace Inserts are specific to a bullet diameter and shoulder angle. For example, the 6mm x 30° is designed to work with cartridges such as the 6BR, 6XC, 6x47 Lapua, 6mm Creedmoor and any other 6mm or smaller cartridge with a 30° shoulder angle. We try to match the chamber geometry as closely as possible. The benefit of this system is it interfaces with the cartridge brass over the length of the shoulder, just like your chamber does, not at one small contact point/diameter like current headspace comparators. FOUND HERE

Modified Cartridge COAL Brass: FOUND HERE, Modified Cartridge Case Over All Length (COAL) Brass have been modified to be used with the Hornady or Stoney Point COAL tool to measure your chambered COAL with a given bullet. Each piece of brass has the neck uniformed and reamed .001" over bullet diameter. The base of the cartridge is precision machined on our CNC for a clean and correct fit.

Each piece of brass is either brand new, or has been fired, cleaned and properly sized to match the Go Gauge for that cartridge to ensure an accurate fit in your chamber. These pieces of brass are perfectly executed to offer the most performance out of your COAL tools.

- Precision Resizing Dies

- Neck Sizing Bushings

- "The" Seating Die

- Modular Headspace Comparator: Standard (Long) and Short Bodies, Bullet and Headspace inserts.

- Modified COAL brass for Hornady/Stoney Point style COAL measuring tools

Precision Resizing Dies: FOUND HERE Made from 17-4 Stainless with a brand new heat treat process with a lower friction coefficient which is superior to conventional Melonite and Salt Bath Nitride. Key features include caliber specific decapping pins, unique ER collet design which holds the decapping pin extremely concentric, optimized resizing geometry to size the base of the cartridge more and the cartridge shoulder a less than most dies. When you combine the superior surface finish of 17-4 stainless with this heat treat process, you have an extremely smooth resizing die that is stronger than most conventional resizing dies.

Neck Sizing Bushings: FOUND HERE, The only thing standard is the .500" x .375" outside dimensions making it compatible with any die that can use Redding neck bushings or other of a similar size. The inside geometry is brand new and gently "funnels" the neck of the brass into the die, reducing neck concentricity runout. Furthermore, our new Neck Sizing Bushings leave the neck/shoulder junction of the brass around fireformed diameters minimizing the affects of donuts inside the necks. Furthermore, this helps loaded ammunition maintain concentricity with the chamber.

"The" Seating Die: FOUND HERE, We started designing "The" Seating Die with the goal of being able to offer one die that could seat bullets in a very straight, concentric fashion on a variety of cartridges. Furthermore, we wanted to solve the seating stem geometry problem that most dies have of damaging or marking bullets. The heart of "The" Seating Die is the through bore which is incredibly straight and has an extremely consistent bore diameter. This allows the Cartridge base to be held concentric in the die, then the Cartridge Shoulder Sleeve centers and supports the cartridge shoulder while the bullet seating stem is guided down during the seating process. All aligned from the die body's center bore. With a Mitutoyo Micrometer head with .001" graduations and a Short Action Customs proprietary tool-less tension system to secure the micrometer head, "The" Seating Die seats bullets in a straighter, more concentric fashion than most dies while simultaneously having the ability to work with a large variety of cartridges. For short cartridges, use the supplied 10mm spacer ball.

Modular Headspace Comparators: FOUND HERE, The highest quality and most functional headspace and bullet ogive tools on the market. The Modular Headspace Comparator is comprised of THREE main parts. The BODY, BULLET INSERTS and HEADSPACE INSERTS. The Body clamps onto your dial calipers and it comes in two different lengths. We have a Short Body which is light and handy, works great for measuring bullets, loaded ammunition base to ogive and non-loaded brass for headspace. The Standard (Long) body is longer which is required to measure loaded ammunition for headspace, otherwise, can do everything that the Short Body can do, but in a slightly longer package.

Made from 17-4 Stainless, Bullet Inserts start at .0005" larger than bullet diameter and taper down at 3° until reaching the groove diameter for that cartridge. For example the 6.5mm Bullet Insert starts at .2645", tapers down at 3° to .256". This mirrors the actual bore extremely well. We chose 3° compared to 1.5° because of bullets sticking in the 1.5° taper. FOUND HERE

Made from 17-4 Stainless, Headspace Inserts are specific to a bullet diameter and shoulder angle. For example, the 6mm x 30° is designed to work with cartridges such as the 6BR, 6XC, 6x47 Lapua, 6mm Creedmoor and any other 6mm or smaller cartridge with a 30° shoulder angle. We try to match the chamber geometry as closely as possible. The benefit of this system is it interfaces with the cartridge brass over the length of the shoulder, just like your chamber does, not at one small contact point/diameter like current headspace comparators. FOUND HERE

Modified Cartridge COAL Brass: FOUND HERE, Modified Cartridge Case Over All Length (COAL) Brass have been modified to be used with the Hornady or Stoney Point COAL tool to measure your chambered COAL with a given bullet. Each piece of brass has the neck uniformed and reamed .001" over bullet diameter. The base of the cartridge is precision machined on our CNC for a clean and correct fit.

Each piece of brass is either brand new, or has been fired, cleaned and properly sized to match the Go Gauge for that cartridge to ensure an accurate fit in your chamber. These pieces of brass are perfectly executed to offer the most performance out of your COAL tools.

Last edited: