The issue at hand is that I cannot bump the shoulder because my die is bottomed out. Redding Competition Dies with Shell holder kit.

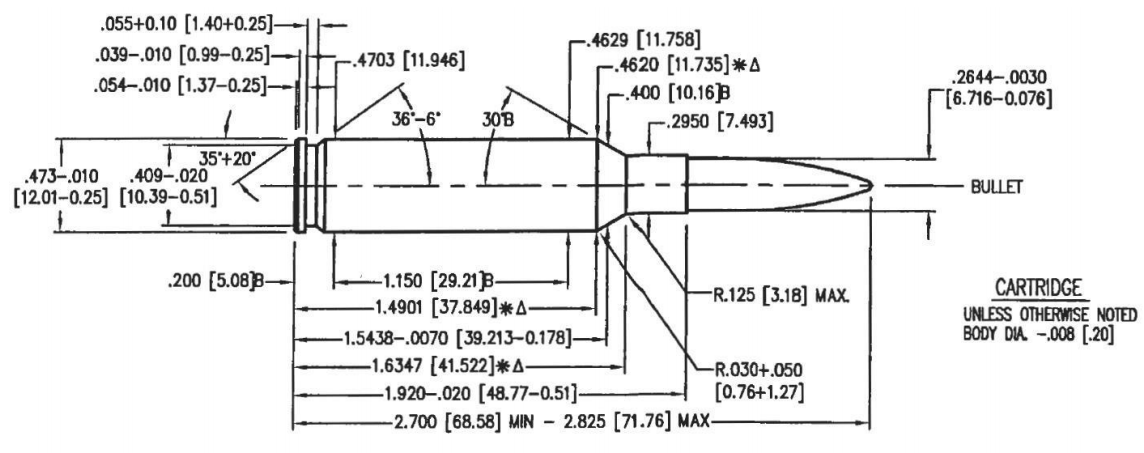

I am using a .400 dia Hornady bushing on my caliper. This will allow me to take a measurement from the base of the case to the shoulder tangent (where dia is 0.400”)

The saami specs shows the base to shoulder 1.5438” I measure my 3x fired Lapua brass and I have 1.5365” – so I am still 0.0073” from the shoulder after brass is fired formed. (I have sorted my fired brass I have base to shoulder tangent from 1.5355"-1.5365" with 90% at 1.5360") IS this even possible? Fire forming should espand that case to occupy the entire chamber(?)

My case length is 1.911 so I know that I have not grown my brass with only 3 fires.

The information shows that brass has not expanded to fit my chamber. OR my chamber does not meet specs and is under sized. Therefore full length sizing is not possible because the die bottoms out before contact to the shoulder has occurred.

Once the shoulder has made contact I will bump 0.002”

Does my theory seem correct – that I just haven’t fired my brass enough to occupy the headspace or Seekins undersizes their chambers.

I could have a shell holder milled ground down to prevent bottoming out and this would expose the truth of the situation.

THOUGHTS???

I am using a .400 dia Hornady bushing on my caliper. This will allow me to take a measurement from the base of the case to the shoulder tangent (where dia is 0.400”)

The saami specs shows the base to shoulder 1.5438” I measure my 3x fired Lapua brass and I have 1.5365” – so I am still 0.0073” from the shoulder after brass is fired formed. (I have sorted my fired brass I have base to shoulder tangent from 1.5355"-1.5365" with 90% at 1.5360") IS this even possible? Fire forming should espand that case to occupy the entire chamber(?)

My case length is 1.911 so I know that I have not grown my brass with only 3 fires.

The information shows that brass has not expanded to fit my chamber. OR my chamber does not meet specs and is under sized. Therefore full length sizing is not possible because the die bottoms out before contact to the shoulder has occurred.

Once the shoulder has made contact I will bump 0.002”

Does my theory seem correct – that I just haven’t fired my brass enough to occupy the headspace or Seekins undersizes their chambers.

I could have a shell holder milled ground down to prevent bottoming out and this would expose the truth of the situation.

THOUGHTS???