I reload mostly in my shop out back, however it gets humid in summer and I'd prefer to keep some of my reloading stuff in the house and be able to use one of my two presses (or either), in the house or the shop. So I figured I needed to up the interchangeability and organization of everything, specifically in the house. We're converting one of our spare rooms to an office and a reloading room soo I got a few quick change plates from Inline Fabrication, the 7.5" mount, the flush fit mount, wall rails and Dillon 550 tool head holders for the wall rails (also fits acro bins).

First and foremost, I had a few questions for Dan at Inline and he was very helpful. When I got my package, I was missing the dillon toolhead light I ordered. Although I'm pretty sure it fell out of the gaping hole in the box (thank USPS), Dan still sent me another one free of charge. And for anyone wondering, the quality and fit of the products is GREAT and well worth the money for sure.

Everything was packages well and wrapped well. He threw in a sticker too....cause who doesn't love stickers right.

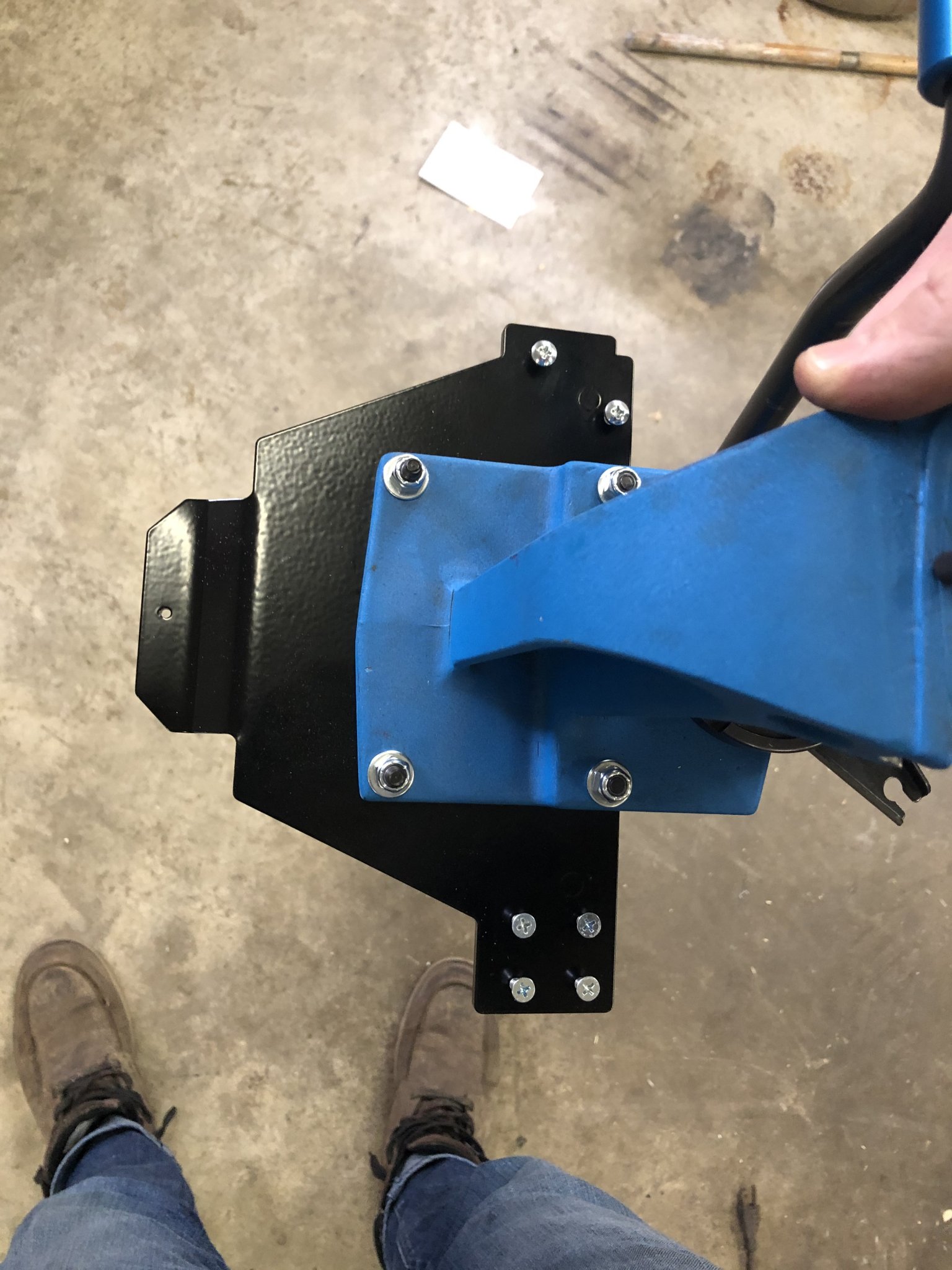

I got the quick change plates for the two presses I have and use: Dillon 550 and Lyman T-mag II turret press. The Dillon plate comes with the spot to mount the spent cartridge schute, as well as the bullet tray on the left side.

All my work benches in my shop are all the same height of 37.5" for uniformity... and this was always a little low to reload on without a mount. I've reloaded close to 10k rounds on these benches and boy am I glad to have a higher mount now. The 7.5" raised Inline Fab. mount is perfect in my opinion for going on top of a 37.5" high work bench.

The reloading bench in my house I specifically made for reloading, so it is 43" tall. I got the flush mount Inline Fab mount for this bench, which does have to be routed into the bench. I'm not amazing with a router, but I do have an old Makita 1/2" router and speciality 2" carbide flattening bit for live edge wood slabs that I used. Made relative short work of it, then cleaned it up with chisels. I also chiseled out a spot for the quick change tab on the plates like the instructions recommend.

I also purchased the 32" wall rail which is a great design and allows you to put various different things on the rail including standard acro bins of any size. I was unfortunately in between any studs and wanted it centered so I just used the fat plastic drywall screw anchors. I rarely use studs anymore honestly, unless its obviously there or its something seriously heavy. I got the Dillon toolhead holders as well, which for the money are far better than the Dillon stands, and they're cheaper.

Aaaaand heres the finished room. The 7.5" mount will go out in the shop, and then I can switch presses back and forth easily as needed, or depending on where I feel like reloading at the time.

Worth noting that ALL HARDWARE is included with the exception of the bolts for the mounts...obviously because everyones benches are different thicknesses. I ordered some black, allen head, counter sunk 1/4-20 bolts from McMaster Carr and they were perfect. They match the mounts and I've always preferred to bolt through the bench as opposed to lagging or screwing. Legit set up and can't thank Dan enough.

First and foremost, I had a few questions for Dan at Inline and he was very helpful. When I got my package, I was missing the dillon toolhead light I ordered. Although I'm pretty sure it fell out of the gaping hole in the box (thank USPS), Dan still sent me another one free of charge. And for anyone wondering, the quality and fit of the products is GREAT and well worth the money for sure.

Everything was packages well and wrapped well. He threw in a sticker too....cause who doesn't love stickers right.

I got the quick change plates for the two presses I have and use: Dillon 550 and Lyman T-mag II turret press. The Dillon plate comes with the spot to mount the spent cartridge schute, as well as the bullet tray on the left side.

All my work benches in my shop are all the same height of 37.5" for uniformity... and this was always a little low to reload on without a mount. I've reloaded close to 10k rounds on these benches and boy am I glad to have a higher mount now. The 7.5" raised Inline Fab. mount is perfect in my opinion for going on top of a 37.5" high work bench.

The reloading bench in my house I specifically made for reloading, so it is 43" tall. I got the flush mount Inline Fab mount for this bench, which does have to be routed into the bench. I'm not amazing with a router, but I do have an old Makita 1/2" router and speciality 2" carbide flattening bit for live edge wood slabs that I used. Made relative short work of it, then cleaned it up with chisels. I also chiseled out a spot for the quick change tab on the plates like the instructions recommend.

I also purchased the 32" wall rail which is a great design and allows you to put various different things on the rail including standard acro bins of any size. I was unfortunately in between any studs and wanted it centered so I just used the fat plastic drywall screw anchors. I rarely use studs anymore honestly, unless its obviously there or its something seriously heavy. I got the Dillon toolhead holders as well, which for the money are far better than the Dillon stands, and they're cheaper.

Aaaaand heres the finished room. The 7.5" mount will go out in the shop, and then I can switch presses back and forth easily as needed, or depending on where I feel like reloading at the time.

Worth noting that ALL HARDWARE is included with the exception of the bolts for the mounts...obviously because everyones benches are different thicknesses. I ordered some black, allen head, counter sunk 1/4-20 bolts from McMaster Carr and they were perfect. They match the mounts and I've always preferred to bolt through the bench as opposed to lagging or screwing. Legit set up and can't thank Dan enough.