A couple of years ago, I approached one of my friends about the possibility of making a single-shot mag block for my AI. The majority of the time, I find myself loading one round at a time and hardly ever loading from the magazine. Most of my shooting is at the range doing load development, shooting F Class matches or varmint hunting. He’s a machinist with a pretty tight schedule so I wasn’t really expecting anything quick. I was hoping that the end product would be functional, aesthetically pleasing and feel good in the hand.

One of the initial prototypes held the loaded round on the left side and would hit the corresponding feed ramp on its way into the chamber. We thought that would be the best approach considering the staggered mag and dual feed ramps. . . It was great in theory but in match conditions, I noted that the round would ricochet and jam just outside of the chamber. Over time and many revisions later, he made one that fit and functioned fine. This took approximately 25 different design modifications and over 200 hours of programming and test fitting for function.

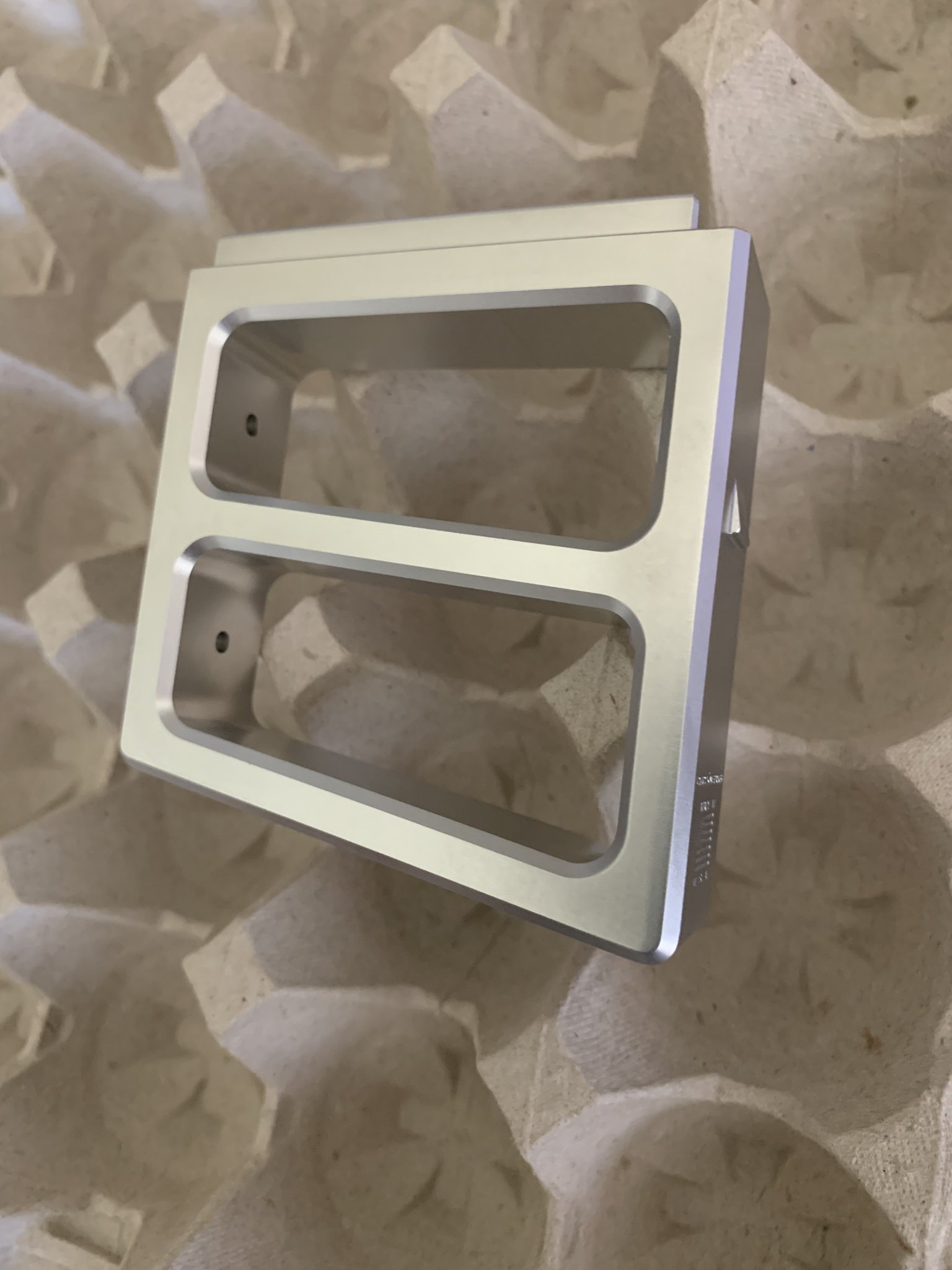

He wanted these to be able to function flawlessly in AI short-action rifles with a .470 bolt face diameter. That includes 6mmBR, .243, .308, 6.5 Creedmoor, etc. The overall dimensions mirror the OEM AW magazines but have no sharp edges. Here’s the final prototype in a machined finish:

Here is the final product with Type III hard anodize:

I’m extremely satisfied with the end product. It’s been performing fine in my F Class matches and at the range. These have been thoroughly tested in Accuracy International AW, AT, and AX short-actions. Let me know what you guys think.

One of the initial prototypes held the loaded round on the left side and would hit the corresponding feed ramp on its way into the chamber. We thought that would be the best approach considering the staggered mag and dual feed ramps. . . It was great in theory but in match conditions, I noted that the round would ricochet and jam just outside of the chamber. Over time and many revisions later, he made one that fit and functioned fine. This took approximately 25 different design modifications and over 200 hours of programming and test fitting for function.

He wanted these to be able to function flawlessly in AI short-action rifles with a .470 bolt face diameter. That includes 6mmBR, .243, .308, 6.5 Creedmoor, etc. The overall dimensions mirror the OEM AW magazines but have no sharp edges. Here’s the final prototype in a machined finish:

Here is the final product with Type III hard anodize:

I’m extremely satisfied with the end product. It’s been performing fine in my F Class matches and at the range. These have been thoroughly tested in Accuracy International AW, AT, and AX short-actions. Let me know what you guys think.

Last edited: