Stainless is fairly smooth... if you want it to last, blast it with Aluminum Oxide (clean media, oil free), not glass beads to get the surface rough... they use a product like Alumnahyde or alumnahyde 2.

Rattle can dissolves with gun cleaning solvents... you want a product that cures and becomes resistant to solvents. If you don't have access to a clean blasting cabinet, I would still rough it up with

aluminum oxide sandpaper. Degrease with MEK or at least 90+% alcohol before you start.

wear nitrile gloves while sanding. Degrease one more time- plug the holes- cover places you don't want covered and coat.

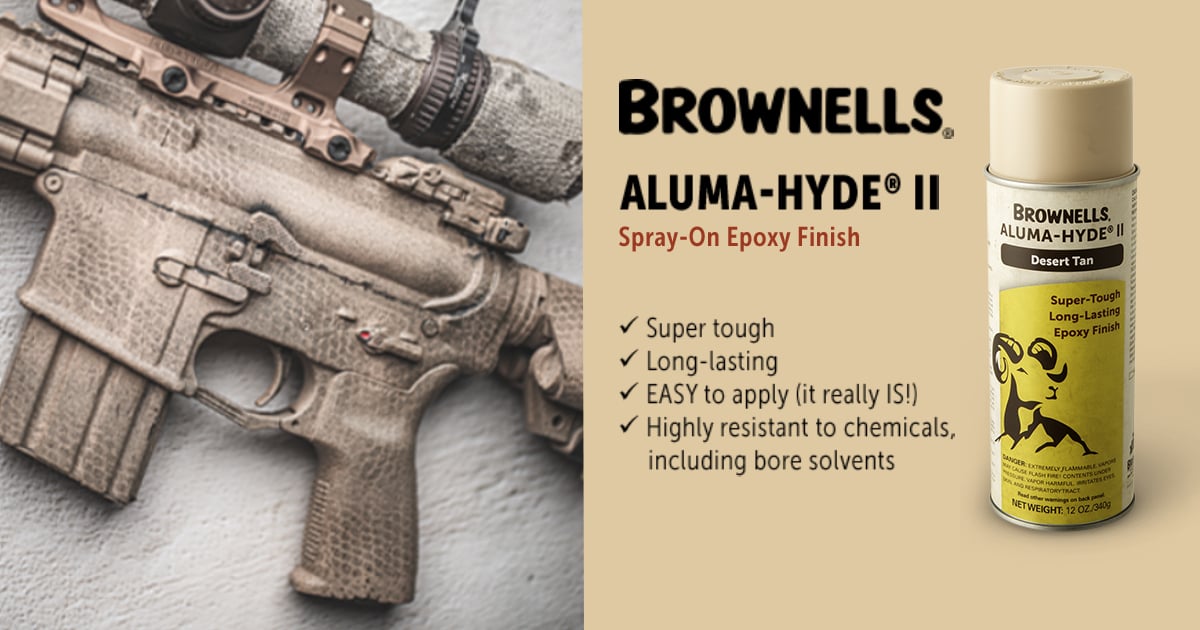

Developed by Brownells, Aluma-Hyde II is a unique finish offering increased resistance to cleaners, solvents, and other chemicals. Aluma-Hyde is the perfect choice for gun enthusiasts who want to protect and keep their firearms looking great for years to come.

www.brownells.com

If you don't want to order the alumnahyde, consider stopping by the local municipal airport. Many have a place that sells airplane products, including Propeller Paint. Propeller paint is an epoxy spray can and the product is vastly superior to any rattle can- similar to durakote.

Aircraft Spruce is a worldwide distributor of certified and homebuilt aircraft supplies.

www.aircraftspruce.com

Rust- to be a rust free stainless, it needs to be a marine grade stainless steel. I don't think that steel makes for a good barrel.

most factory stainless barrels are good... wipe them down after handling and you should not have issues

Tempo’s Propeller Epoxy Coating is formulated with the extra adhesion and abrasion resistance needed to protect propellers from corrosion and wear. Compared to standard enamel and lacquers paints, our epoxy formula stays on the blade more flying hours. With regular use, this formula can extend blade life.