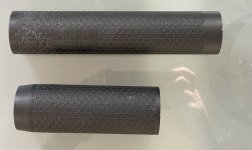

I'm purchasing a suppressor to run on my newest "AR." Let's call it a JR because I made it, not Armalite. I want a 3D printed 718 inconel but would consider a 17-4 stainless if it checks all the other boxes.

I'm running a 13.7" Roscoe purebred .223 wylde mid length barrel with a 10" MCMR, Vltor MUR, Superlative piston kit, ADAC-15 lower, Wilson ETU 2 stage. I plan to get the faxon 11.5 mid length barrel and switch it back and forth periodically for different situations. What I care about most is flash suppression, then noise reduction, then maneuverability, and lastly weight. I don't really give an ish about backpressure(piston operated). But it must be 3D printed.

I'm seriously eyeing the SCI-SIX. But I wonder if since it's designed with low backpressure in mind if I'm sacrificing flash and noise reduction. Perhaps someone knows of a suppressor that was engineered without backpressure as a consideration? Or am I just tripping over semantics and will low backpressure not have much of an impact on flash suppression.

Thanks,

John.

I'm running a 13.7" Roscoe purebred .223 wylde mid length barrel with a 10" MCMR, Vltor MUR, Superlative piston kit, ADAC-15 lower, Wilson ETU 2 stage. I plan to get the faxon 11.5 mid length barrel and switch it back and forth periodically for different situations. What I care about most is flash suppression, then noise reduction, then maneuverability, and lastly weight. I don't really give an ish about backpressure(piston operated). But it must be 3D printed.

I'm seriously eyeing the SCI-SIX. But I wonder if since it's designed with low backpressure in mind if I'm sacrificing flash and noise reduction. Perhaps someone knows of a suppressor that was engineered without backpressure as a consideration? Or am I just tripping over semantics and will low backpressure not have much of an impact on flash suppression.

Thanks,

John.