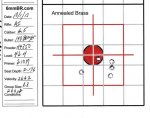

Shot with my 6.5 Creedmoor (26" barrel, prone with bipod and rear bag, scope is the Vortex Razor HD 5-20) today at 200 yds. on three targets with five rounds on each. Allowed two min. between shots to cool barrel. Two targets were shot using annealed brass and the third was with non-annealed brass. All brass had been reloaded 3 to 4 time before. The annealing was done with the Bench Source annealer.The Bullets were all Berger 140 Target VLD in Harnady brass, Powder was H4350 of 42.4 gr. with the Fed. 210M primer. Ogive seating depth of 2.176 which is .030 off the lands. Squares on the target are 1 inch.

Do I need to do a OCW for just the annealed brass or is this a seating depth problem in order to tighten up the annealed brass group size? Not sure what direction to start working the problem. Looking like I may need to have a load work up for annealed brass and one for non-annealed brass.

Open to any and all recommendations.......thanks Richard

Do I need to do a OCW for just the annealed brass or is this a seating depth problem in order to tighten up the annealed brass group size? Not sure what direction to start working the problem. Looking like I may need to have a load work up for annealed brass and one for non-annealed brass.

Open to any and all recommendations.......thanks Richard