I installed a Badger bolt knob on my 700P, from what I have read it's a good idea to get the handle tig welded to the bolt body afterwards. So I already have my rifle at the smith getting a brake installed and had asked him to weld it for me. He said he wouldn't do it, he has never see one break and tig welding the bolt will take the temper out of it. What are your guys thoughts here? I can see the handle being stressed more with the longer knob on it. Will it be ok?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

Having trouble using the site?

Contact support

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing Tig welded bolt handle on 700

- Thread starter 700P

- Start date

Re: Tig welded bolt handle on 700

I could see maybe a quick tack but I really don't see the need and personally would do it.

Some Loctite or even a small swage would be better.

I could see maybe a quick tack but I really don't see the need and personally would do it.

Some Loctite or even a small swage would be better.

Re: Tig welded bolt handle on 700

I'd agree with locktite. I know that there are some welded handles but if its a threaded job, simply use the right thread locker. Red is great because you'll need a torch to get that handle off if the surface is properly prepped.

Green locktite is another good one with better gap filling qualities. Again, you'll need a torch to break this stuff off.

I'd agree with locktite. I know that there are some welded handles but if its a threaded job, simply use the right thread locker. Red is great because you'll need a torch to get that handle off if the surface is properly prepped.

Green locktite is another good one with better gap filling qualities. Again, you'll need a torch to break this stuff off.

Re: Tig welded bolt handle on 700

I think he means the handle to the body....

If you can weld an aluminum knob to a CRMO handle, you know something I don't.......

I weld for a living, and I don't pour heat into something unless I have to.....

If you're worried about it, I would do this first..

http://www.snipershide.com/forum/ubbthreads.php?ubb=showflat&Number=785937&page=1

(although I would only use one screw closest to "cam" point on the handle)

In reality, I'd just leave it alone and drive on....

I think he means the handle to the body....

If you can weld an aluminum knob to a CRMO handle, you know something I don't.......

I weld for a living, and I don't pour heat into something unless I have to.....

If you're worried about it, I would do this first..

http://www.snipershide.com/forum/ubbthreads.php?ubb=showflat&Number=785937&page=1

(although I would only use one screw closest to "cam" point on the handle)

In reality, I'd just leave it alone and drive on....

Re: Tig welded bolt handle on 700

I have a badger knob ordered. What is the best way to take the factory knob off? I hear, 1. Cut the knob off, drill into the lever and tap in a threaded shank.

2. Mill the knob into a smooth shank then run a dye over it

3. Take a grinder to it and dye the shank

I don't really want to grind on my bolt though and I do have access to a mill

I have a badger knob ordered. What is the best way to take the factory knob off? I hear, 1. Cut the knob off, drill into the lever and tap in a threaded shank.

2. Mill the knob into a smooth shank then run a dye over it

3. Take a grinder to it and dye the shank

I don't really want to grind on my bolt though and I do have access to a mill

Re: Tig welded bolt handle on 700

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: DirectAssault</div><div class="ubbcode-body">I have a badger knob ordered. What is the best way to take the factory knob off? I hear, 1. Cut the knob off, drill into the lever and tap in a threaded shank.

2. Mill the knob into a smooth shank then run a dye over it

3. Take a grinder to it and dye the shank

I don't really want to grind on my bolt though and I do have access to a mill </div></div>

What's the best brand of truck? Ford, Chevy or Dodge?

All will get you down the road.

Here is how I do them:

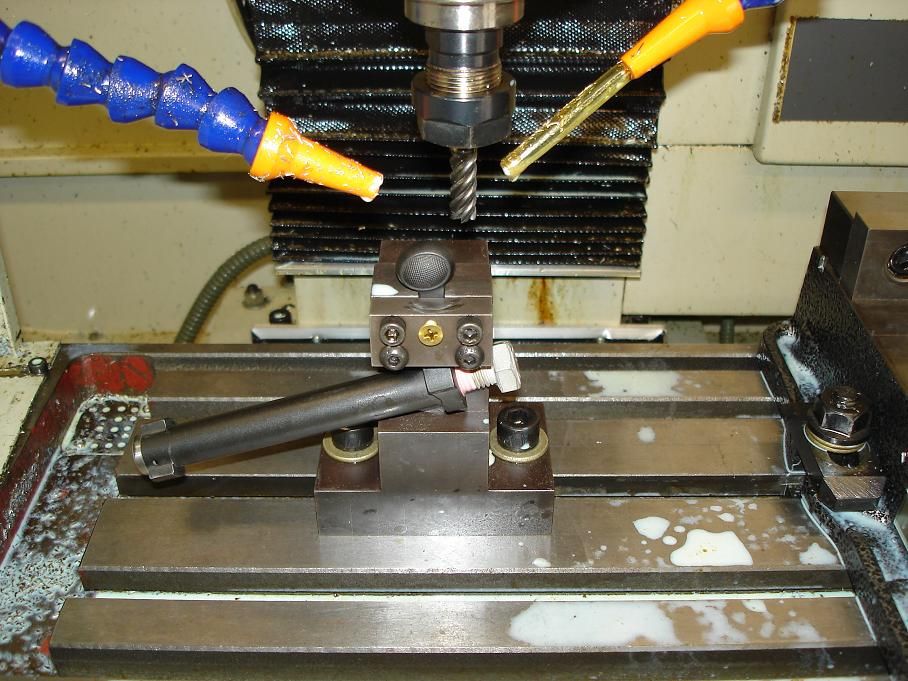

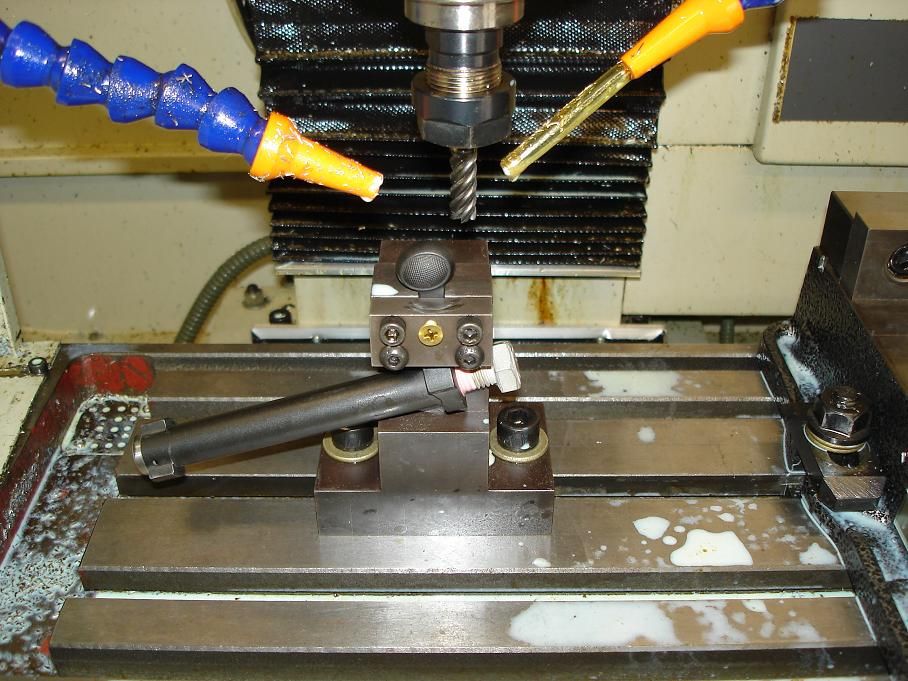

I start out by cutting off the existing knob:

The bolt goes into the vise in a fixture that sets the angle and then it's milled perpendicular:

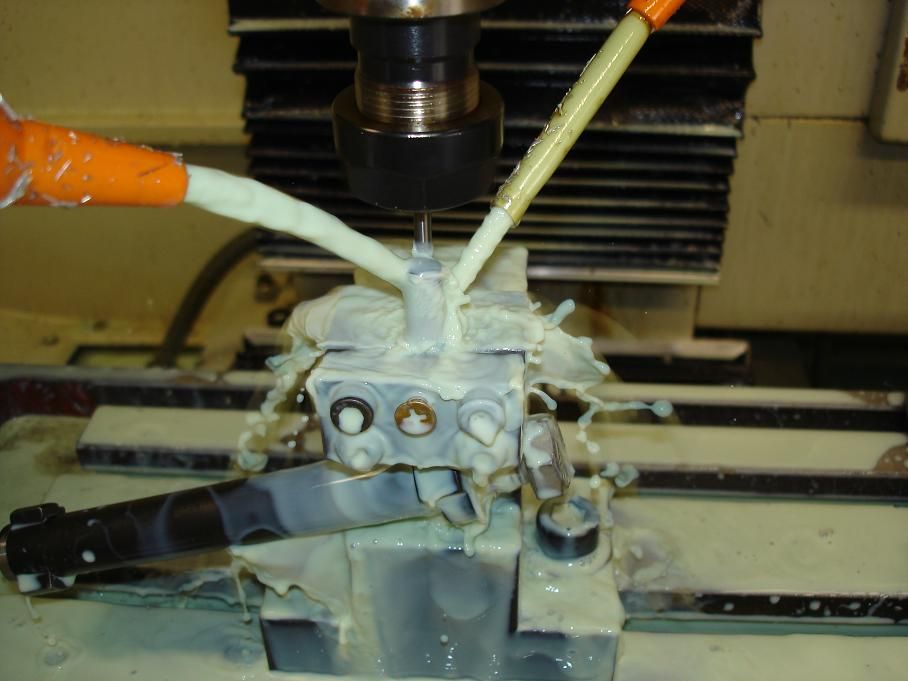

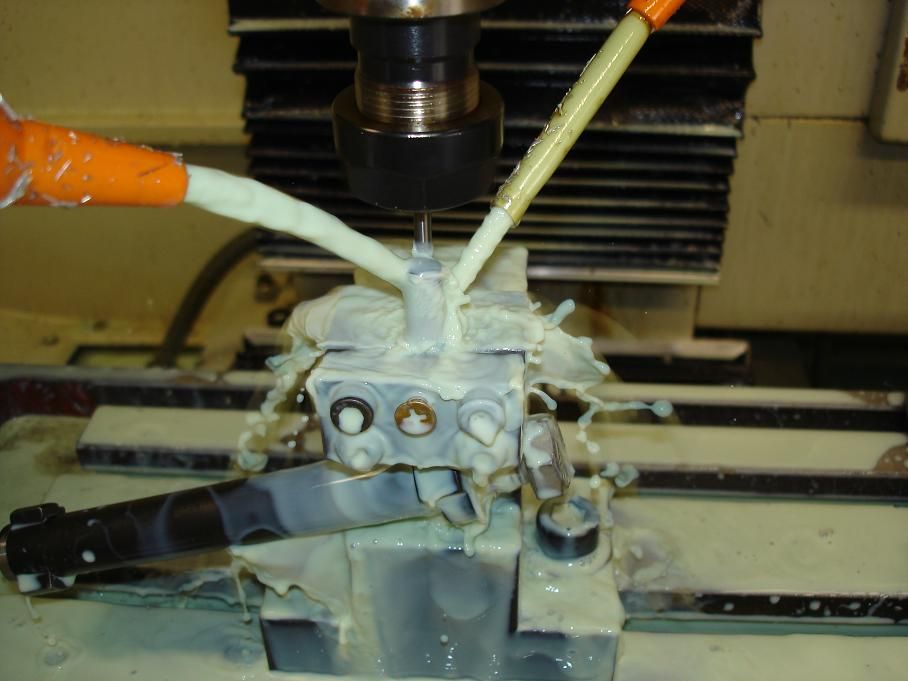

A hole is driled down into the shank:

A setscrew is turned down into a pin that will lightly press into the hole:

The setscrew is pressed into the bolt handle shank:

The setscrew is tig welded to the bolt handle shank:

The bolt knob threads on to the setscrew:

Finished results:

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: DirectAssault</div><div class="ubbcode-body">I have a badger knob ordered. What is the best way to take the factory knob off? I hear, 1. Cut the knob off, drill into the lever and tap in a threaded shank.

2. Mill the knob into a smooth shank then run a dye over it

3. Take a grinder to it and dye the shank

I don't really want to grind on my bolt though and I do have access to a mill </div></div>

What's the best brand of truck? Ford, Chevy or Dodge?

All will get you down the road.

Here is how I do them:

I start out by cutting off the existing knob:

The bolt goes into the vise in a fixture that sets the angle and then it's milled perpendicular:

A hole is driled down into the shank:

A setscrew is turned down into a pin that will lightly press into the hole:

The setscrew is pressed into the bolt handle shank:

The setscrew is tig welded to the bolt handle shank:

The bolt knob threads on to the setscrew:

Finished results:

Re: Tig welded bolt handle on 700

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: chpprguy</div><div class="ubbcode-body">I think he means the handle to the body </div></div>

You are correct there. The knob is already has loctite on it.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: chpprguy</div><div class="ubbcode-body">I think he means the handle to the body </div></div>

You are correct there. The knob is already has loctite on it.

Re: Tig welded bolt handle on 700

If it was attached properly then the chances of your breaking it off are slim unless you are abusing the shit out of it.

I have seen a couple fail with light use but unpon inspection you caould see where the solder was only contacting maybe 10% of the handel.

Id leave it alone and if it breaks have it tiged on.` That being said anytime i rebuild a Rem 700 i use a PTG bolt and i have that handel tig welded on

If it was attached properly then the chances of your breaking it off are slim unless you are abusing the shit out of it.

I have seen a couple fail with light use but unpon inspection you caould see where the solder was only contacting maybe 10% of the handel.

Id leave it alone and if it breaks have it tiged on.` That being said anytime i rebuild a Rem 700 i use a PTG bolt and i have that handel tig welded on

Re: Tig welded bolt handle on 700

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: DirectAssault</div><div class="ubbcode-body">I have a badger knob ordered. What is the best way to take the factory knob off? I hear, 1. Cut the knob off, drill into the lever and tap in a threaded shank.

2. Mill the knob into a smooth shank then run a dye over it

3. Take a grinder to it and dye the shank

I don't really want to grind on my bolt though and I do have access to a mill </div></div>

i machine and thread mill the factory handle/knob on a cnc mill. since i am machining the handle, my fixture holds the handle only and doesn't touch the bolt body. this way i am not putting any stress on the soldered joint between the handle and body.

edit: to the op, i'd probably leave the handle alone. if you end up having a problem, then decide on how to attach it. tig welded handles can fail when abused too.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: DirectAssault</div><div class="ubbcode-body">I have a badger knob ordered. What is the best way to take the factory knob off? I hear, 1. Cut the knob off, drill into the lever and tap in a threaded shank.

2. Mill the knob into a smooth shank then run a dye over it

3. Take a grinder to it and dye the shank

I don't really want to grind on my bolt though and I do have access to a mill </div></div>

i machine and thread mill the factory handle/knob on a cnc mill. since i am machining the handle, my fixture holds the handle only and doesn't touch the bolt body. this way i am not putting any stress on the soldered joint between the handle and body.

edit: to the op, i'd probably leave the handle alone. if you end up having a problem, then decide on how to attach it. tig welded handles can fail when abused too.

Re: Tig welded bolt handle on 700

Show off. Wish I had the machine, and know how to use it. That's really nice and fast. I also wouldn't worry about breaking the handle off. If it does break, then get it fixed. Not broken yet, don't fix it.

Show off. Wish I had the machine, and know how to use it. That's really nice and fast. I also wouldn't worry about breaking the handle off. If it does break, then get it fixed. Not broken yet, don't fix it.

Similar threads

- Replies

- 2

- Views

- 1K

- Replies

- 6

- Views

- 291

- Replies

- 19

- Views

- 1K

- Replies

- 1

- Views

- 410

- Replies

- 12

- Views

- 631