So I have a blued Tikka action which was previously spray painted. I'm not saying I'm the one who spray painted it, nor am I saying that I am not the one who spray painted it. In my infinite wisdom I removed the spray pain with mineral spirits and a soft buffing bit for a dremel. Worked like a treat, except that some of the bluing is wearing off and I can see streaks. Over the next x months / years, I'm going to be building a new precision rifle for PRS off of this action, but would like to avoid rust (and ugliness, for that matter).

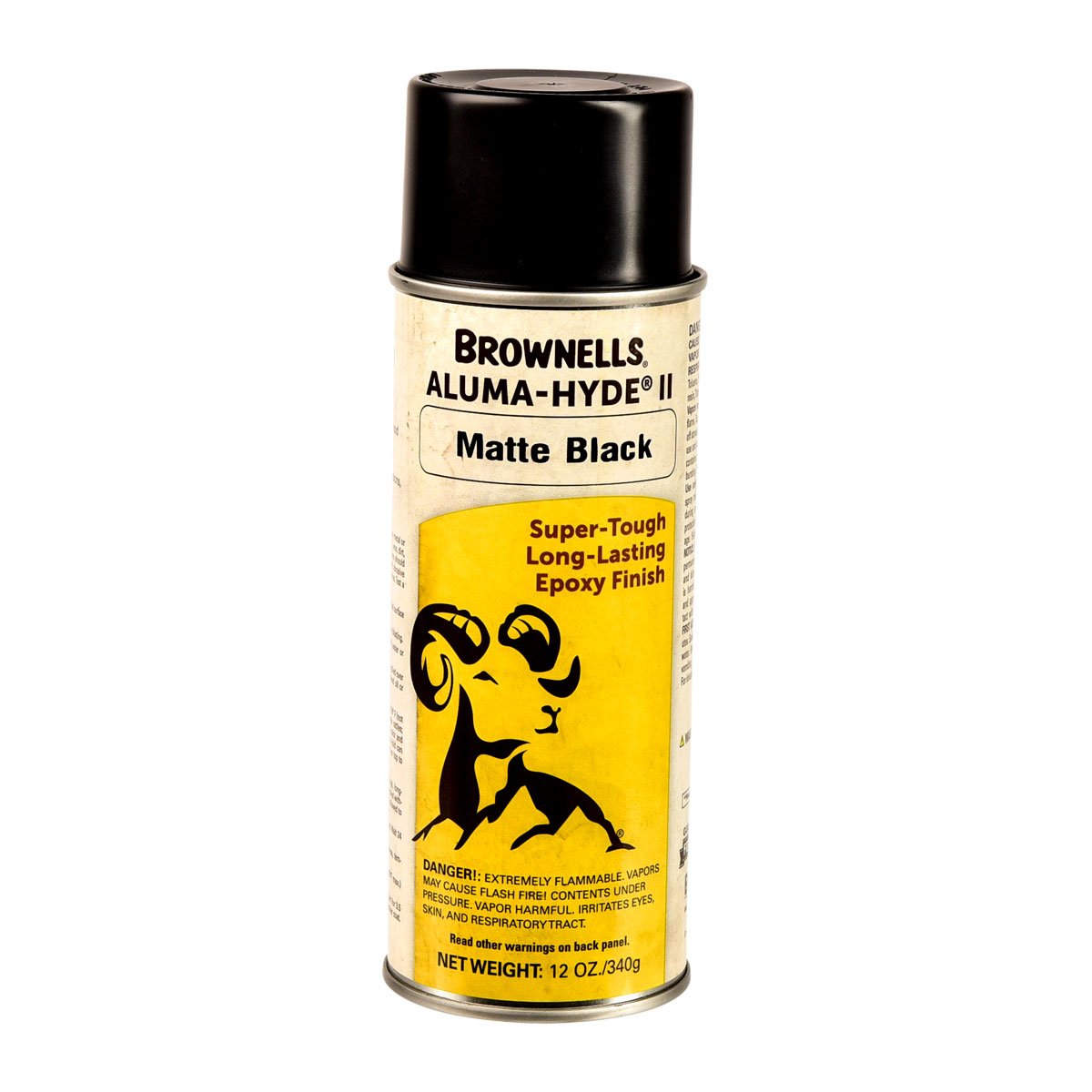

What would be the recommended way forward? There is (as of now) no rust of corrosion, the action is great. I'm hesitant to have it cerakoted due to concerns about QC and having a truly flat surface at the top for a rail. I could also just get one of those bluing kits, I suppose - haven't done that before, but I'm guessing it would take it back up to factory standards?

Thoughts are appreciated!

P.S. I've heard Tikka say that all of their actions are SS and I've also heard otherwise. Would this have an effect on the bluing process? If there are a couple of materials possible in my action, how can I tell which I have?

What would be the recommended way forward? There is (as of now) no rust of corrosion, the action is great. I'm hesitant to have it cerakoted due to concerns about QC and having a truly flat surface at the top for a rail. I could also just get one of those bluing kits, I suppose - haven't done that before, but I'm guessing it would take it back up to factory standards?

Thoughts are appreciated!

P.S. I've heard Tikka say that all of their actions are SS and I've also heard otherwise. Would this have an effect on the bluing process? If there are a couple of materials possible in my action, how can I tell which I have?