So last winter, had a chance to buy this out of England. Sight unseen. But from a 'reputable' dealer. And price was sort of off the charts low. That said, it had a small repaired crack in the stock and sleeved barrels, which both dramatically affect value. I also had no idea of mechanical condition, etc.

After 8 months of paperwork and import fun... Arrived. And while the 'disclosed' items were right on... it was a hodgepodge of 'other' items. Issues with single trigger. Barrels didn't break cleanly. Automatic ejectors not working. And the crack that was 'repaired' was re-cracked. And more extensive internally than first believed. Oh and the buttplate was extended and pinned/glued. And I assumed was owned by either an NBA player or Lurch. Because it was a good 1/2" too long.

But... it is a Thomas Boss & Co. made in 1902. Their new 'Racehorse' style as it was the sleekest, slimmest gun on the English market. And the fit, finish, engraving, etc. is amazing. So, off to the workshops at Schloss Nitrocellulose for the treatment... First time I've really torn down a London Best gun... but there ya go. Might as well dive in.

First issue, it was bone dry. Not sure why it was not lubricated and properly 'tuned' when the barrels were sleeved. But everything inside was dry. Lots of burrs. Things were hanging up. This gun led a hard life, apparently. But lots of careful work and I have the locks and trigger working right. Then got the ejectors working (messed up during the re-sleeving process, probably.)

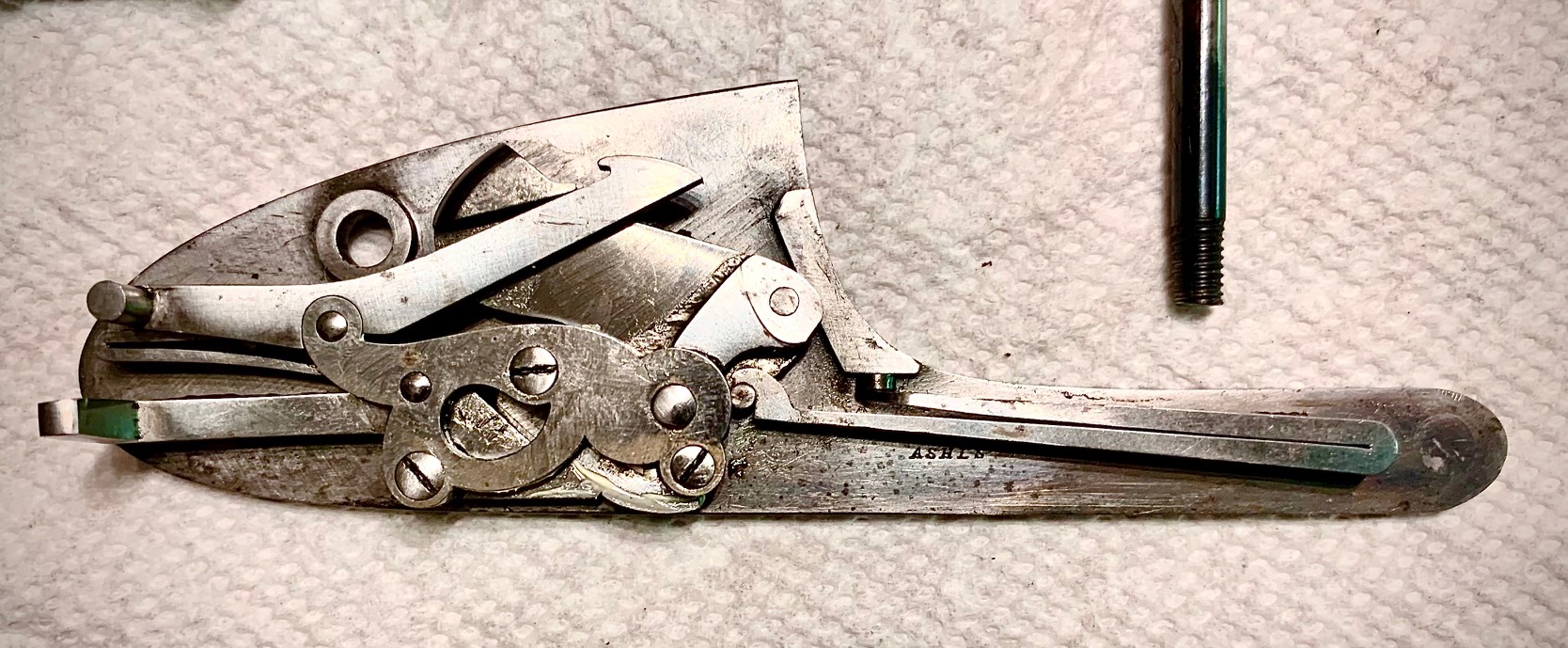

Just thought you guys would like to see some pictures of the inside of a pretty cool old gun. One of the interesting things about Boss is that since they were founded c. 1820, they have produced just over 10,000 guns. So many details have been saved and recorded that we know just about everyone involved in making it. Joseph Brazier of "The Ashes" (his workshop name) made the locks. It was engraved by John James Sumner III the third engraver in a family of four master engravers dating back to 1809.

Anyway, just some cool pictures. Everything is hand filed, hand-fitted and hand-engraved.

Brazier supplied 'soft' actions for engraving and finishing.

Cleaned up and lubricated. And de-burred.

"The Ashes" was the name of Brazier's workshop in Wolverhampton. Company is still in business and makes barrels still.

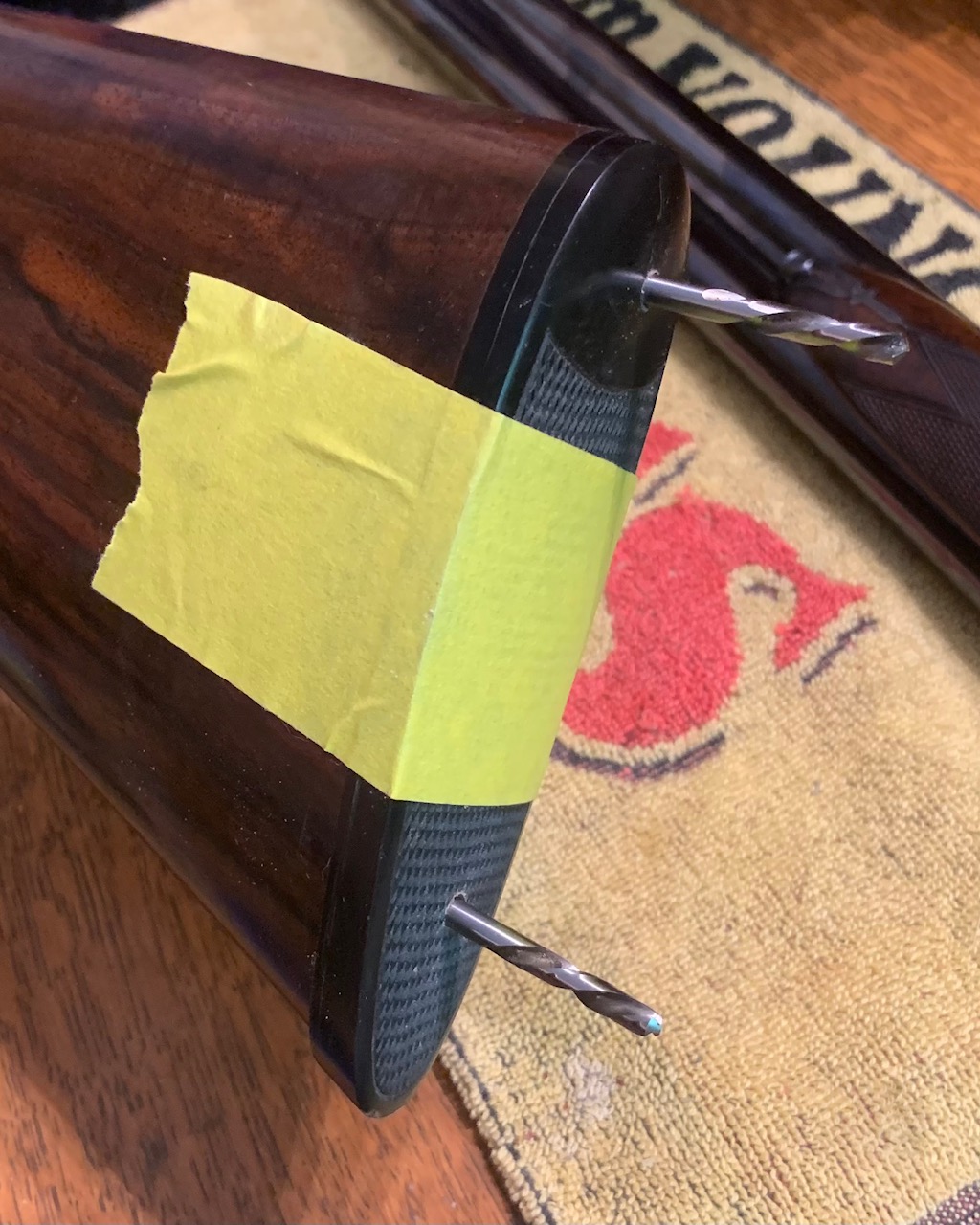

And had to remove the old horn buttplate, which was over an inch thick. I sawed through the thick part with a bandsaw and then used a belt sander to thin the nice checkered horn plate to a more... presentable and better-fitting thickness. Then had to heat the 'thin' part of the plate that was glued and pinned to the stock. Yes, glued. So took a blowtorch to the horn (without getting flame on the oil finish!) and the glue let go enough to pry the remains of the plate off.

I have a couple of special screws ordered for the rear plate (just like the last one) and will final fit the checkered horn plate probably next weekend.

I also de-greased, spread and properly glued the stock crack(s) and hopefully they will hold. I think they will once I have the sideplates re-fitted. Re-Stocking this would be spendy... I don't want to go there!

Anyway, more pix to follow, but rather pleased with this gamble as I think the sweat equity is going to be well worth it. Not to mention, it's just a perfect field gun.

Cheers,

Sirhr

PS.... this gun, new cost just over 70 Pounds sterling in 1902. By comparison, a skilled engineer at that time would have been making about 110 pounds... a year. It was nice to be king!

After 8 months of paperwork and import fun... Arrived. And while the 'disclosed' items were right on... it was a hodgepodge of 'other' items. Issues with single trigger. Barrels didn't break cleanly. Automatic ejectors not working. And the crack that was 'repaired' was re-cracked. And more extensive internally than first believed. Oh and the buttplate was extended and pinned/glued. And I assumed was owned by either an NBA player or Lurch. Because it was a good 1/2" too long.

But... it is a Thomas Boss & Co. made in 1902. Their new 'Racehorse' style as it was the sleekest, slimmest gun on the English market. And the fit, finish, engraving, etc. is amazing. So, off to the workshops at Schloss Nitrocellulose for the treatment... First time I've really torn down a London Best gun... but there ya go. Might as well dive in.

First issue, it was bone dry. Not sure why it was not lubricated and properly 'tuned' when the barrels were sleeved. But everything inside was dry. Lots of burrs. Things were hanging up. This gun led a hard life, apparently. But lots of careful work and I have the locks and trigger working right. Then got the ejectors working (messed up during the re-sleeving process, probably.)

Just thought you guys would like to see some pictures of the inside of a pretty cool old gun. One of the interesting things about Boss is that since they were founded c. 1820, they have produced just over 10,000 guns. So many details have been saved and recorded that we know just about everyone involved in making it. Joseph Brazier of "The Ashes" (his workshop name) made the locks. It was engraved by John James Sumner III the third engraver in a family of four master engravers dating back to 1809.

Anyway, just some cool pictures. Everything is hand filed, hand-fitted and hand-engraved.

Brazier supplied 'soft' actions for engraving and finishing.

Cleaned up and lubricated. And de-burred.

"The Ashes" was the name of Brazier's workshop in Wolverhampton. Company is still in business and makes barrels still.

And had to remove the old horn buttplate, which was over an inch thick. I sawed through the thick part with a bandsaw and then used a belt sander to thin the nice checkered horn plate to a more... presentable and better-fitting thickness. Then had to heat the 'thin' part of the plate that was glued and pinned to the stock. Yes, glued. So took a blowtorch to the horn (without getting flame on the oil finish!) and the glue let go enough to pry the remains of the plate off.

I have a couple of special screws ordered for the rear plate (just like the last one) and will final fit the checkered horn plate probably next weekend.

I also de-greased, spread and properly glued the stock crack(s) and hopefully they will hold. I think they will once I have the sideplates re-fitted. Re-Stocking this would be spendy... I don't want to go there!

Anyway, more pix to follow, but rather pleased with this gamble as I think the sweat equity is going to be well worth it. Not to mention, it's just a perfect field gun.

Cheers,

Sirhr

PS.... this gun, new cost just over 70 Pounds sterling in 1902. By comparison, a skilled engineer at that time would have been making about 110 pounds... a year. It was nice to be king!