Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

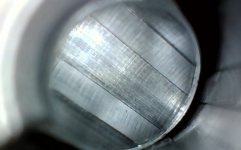

Tooling marks in bore

- Thread starter accurate obsession

- Start date

Good god that’s ugly. Whose barrel? And I take it you haven’t shot it yet?I'm no expert, but I've looked down a few barrels and I have never seen tool marks like these. They are consistent, going from the leade to the muzzle. Is this a different process, zero lapping, idk.

Unknown date of manufacture .22 lr TC Contender barrel.View attachment 8106583View attachment 8106584

Good god that’s ugly. Whose barrel? And I take it you haven’t shot it yet?

Says by the Pic, unknown date, Thompson Center Contender barrel.

No, haven't shot it yet, person I got it from was in the "never clean your rimfire barrel" camp and I stripped it to bare metal before going to the range.

I don't think I could stop myself from going to town on that with JB paste hoping to smooth that out a bit. I doubt it's gonna matter much.

That has been JB'ed, several times. Finding all that was my reward after removing all the carbon.I don't think I could stop myself from going to town on that with JB paste hoping to smooth that out a bit. I doubt it's gonna matter much.

I'm thinking several hundred strokes on that clean bore will help smooth it a bit. maybe not.That has been JB'ed, several times. Finding all that was my reward after removing all the carbon.

I saw the post by justin amature but I just don't know.Never saw a hammed forged barrel that looked like that.

I'm assuming it was made in the 80's, I didn't think hammer forging processes were used by TC during that time period. But just speculating.

Each impact of the hammers moves the steel along the mandrel incrementally.

The pattern is in the lands and in the grooves.

If the bore is not lapped afterwards, the pattern remains.

Button or cut rifling leaves a linear pattern.

That visible a pattern indicates a problem with the process.

Wasn't caught during final inspection or was ignored.

Hard to find good help, eh?

Note: I was just informed that too fast a speed in cutting the rifling can cause chatter marks also.

The pattern is in the lands and in the grooves.

If the bore is not lapped afterwards, the pattern remains.

Button or cut rifling leaves a linear pattern.

That visible a pattern indicates a problem with the process.

Wasn't caught during final inspection or was ignored.

Hard to find good help, eh?

Note: I was just informed that too fast a speed in cutting the rifling can cause chatter marks also.

Last edited:

Yes, that would explain how the marks are in the lands and grooves.Each impact of the hammers moves the steel along the mandrel incrementally.

The pattern is in the lands and in the grooves.

If the bore is not lapped afterwards, the pattern remains.

That visible a pattern indicates a problem with the process.

Wasn't caught during final inspection or was ignored.

Hard to find good help, eh?

Shouldn't take more than a 1000 rounds to re-season the barrel

Note: I was just informed that too fast a speed in cutting the rifling can cause chatter marks also.

That was my initial suspicion because I didn't think hammer forging was available to small companies like TC during that time period. But they are very consistent from end to end, if it was feed chatter seems like it should vary some.

Hammer forged barrels have very smooth finishes.

Gun drilled with a bad combo of cutter wear, feed rates, chip clearing. Then button rifled without and honing or lapping before or after drilling. Pushed the ridges the drill left behind into the lands and groves. May shoot, may not. I wouldn’t try to polish too much out. You’re likely to oversize the bore before you get all of that smoothed out.

Damn Vodak, I didn't think it would be that convoluted.

That means you'd really have to work at doing it wrong.

Not just one step in the process, but repeated errors.

That's some serious tolerance stacking.

Then not catch the problems during inspection.

I was thinking just a rough mandrel or tool chatter.

That means you'd really have to work at doing it wrong.

Not just one step in the process, but repeated errors.

That's some serious tolerance stacking.

Then not catch the problems during inspection.

I was thinking just a rough mandrel or tool chatter.

I toured the old Thompson Center factory several times and they used button rifling.I saw the post by justin amature but I just don't know.

I'm assuming it was made in the 80's, I didn't think hammer forging processes were used by TC during that time period. But just speculating.

Each impact of the hammers moves the steel along the mandrel incrementally.

The pattern is in the lands and in the grooves.

If the bore is not lapped afterwards, the pattern remains.

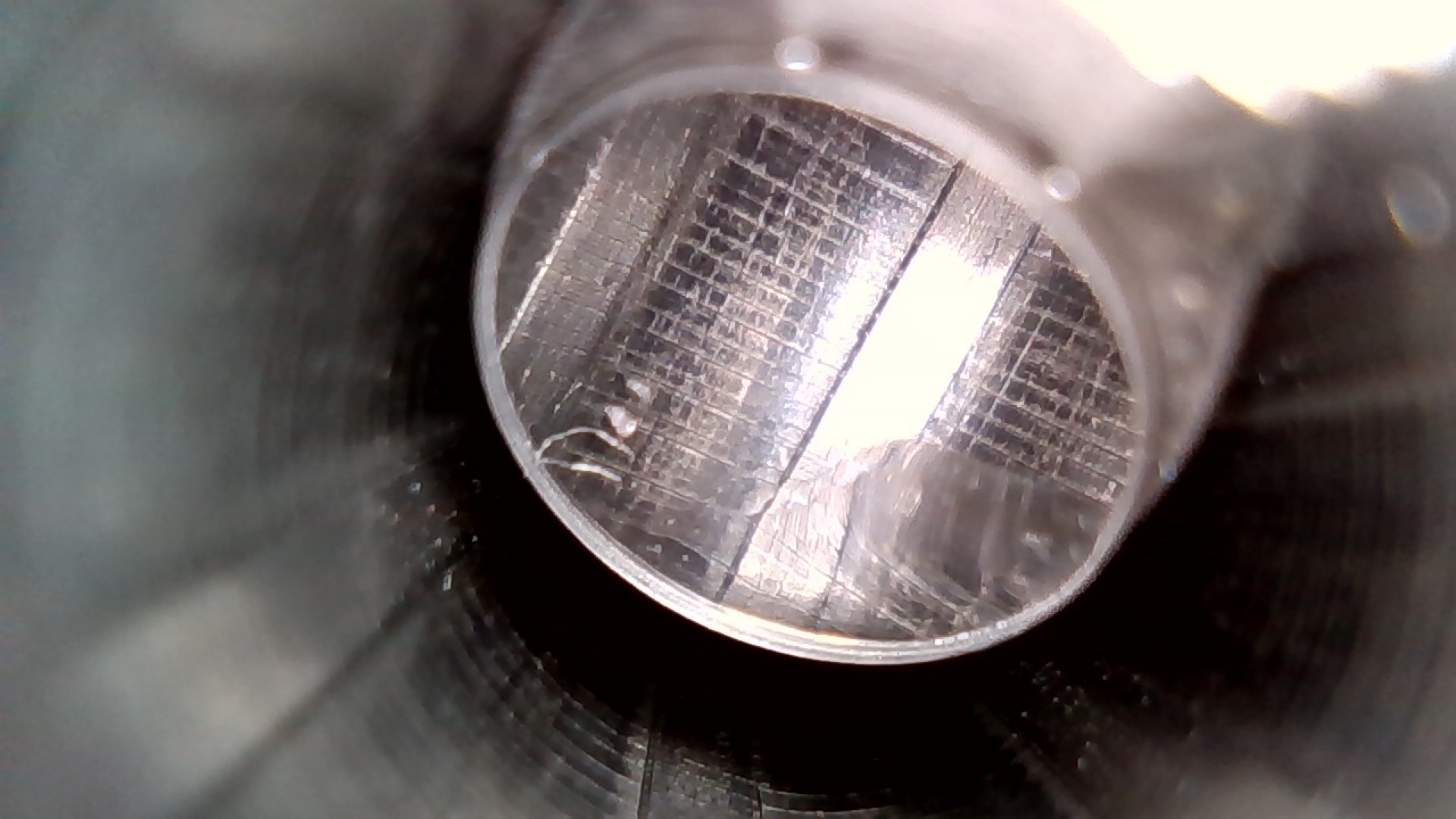

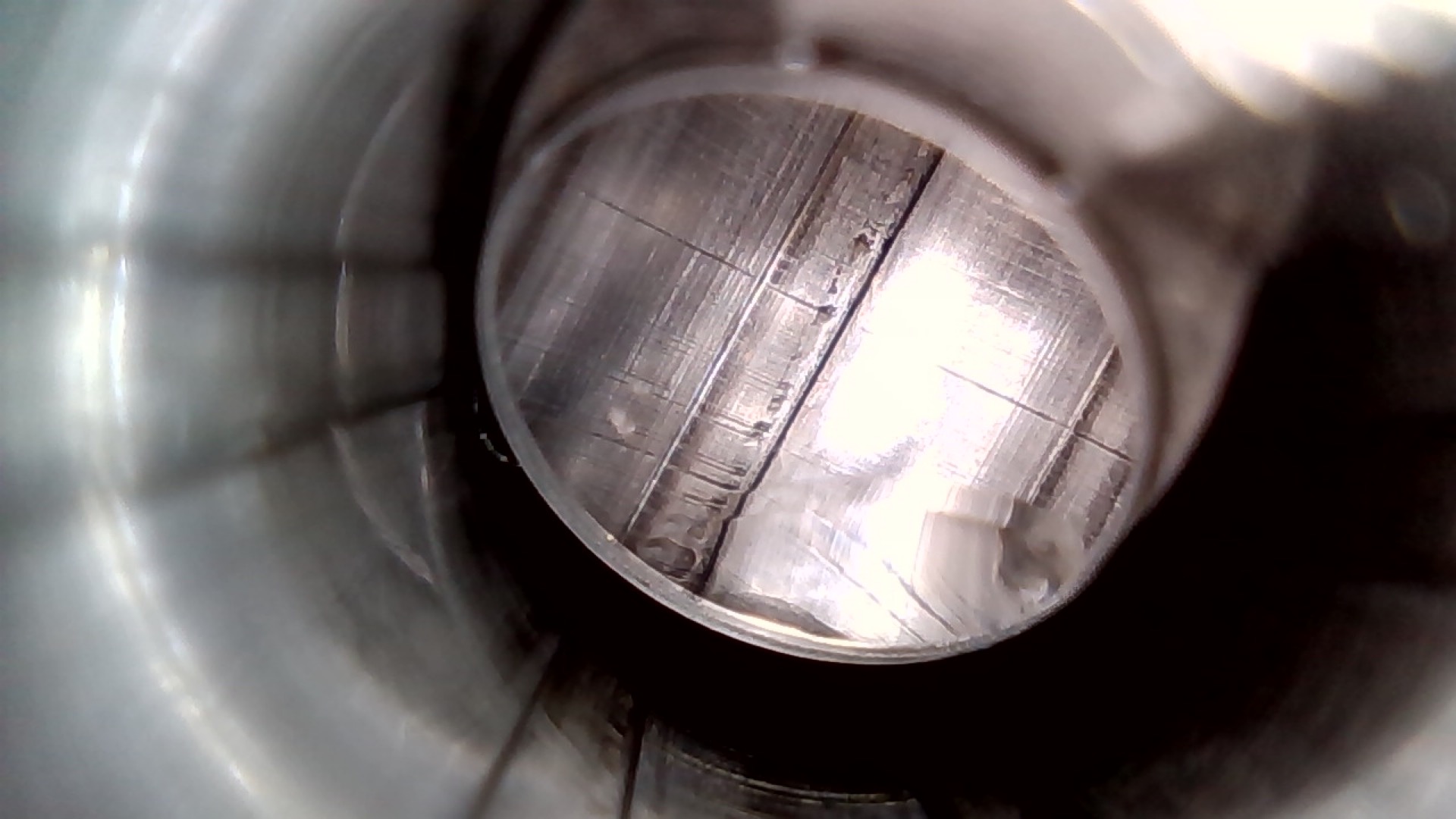

I have a 7 mm Mag Ruger 77 that I bought in 1981. It looks just like that inside. It shot well in the past after I glass bedded the stock, but I haven’t shot it much in the last 20 years. I actually gave it a good cleaning yesterday and I plan to shoot it today. We shall see. I expect it to be a little erratic until I get the barrel carboned and coppered up again. I should have taken some pictures when I ran my borescope down it yesterday, it looks like that the whole length of the barrel. I’m guessing it was hammer forged.

This is every Savage barrel. Do not try to smooth it out. They are typically great shooters.

Gun drilled with a bad combo of cutter wear, feed rates, chip clearing. Then button rifled without and honing or lapping before or after drilling. Pushed the ridges the drill left behind into the lands and groves. May shoot, may not. I wouldn’t try to polish too much out. You’re likely to oversize the bore before you get all of that smoothed out.

I have to agree. I had an old Mauser that would shoot well, but the bore looked rough. I cleaned and polished the bore until I thought it looked acceptable. Accuracy went south and I could never get the rifle to group well after that. I should have left the barrel alone.

Some of the best looking rifling I’ve seen too!Hammer forged barrels have very smooth finishes.

Nope you will need round balls for new smooth bore rifle.If you fully polish out those tool marks you will need to shoot 6mm bullets.

Like the above savage barrel all of mine looked similar. I have been using the tubbs final finish on mine since he started selling it. 2 things it does. removes most of the tooling marks not all and puts a perfect taper lap in the bore for at least 100fps gain in speed. They clean up quicker than stock however it's still a major process to get them perfectly clean. They do shoot looking like that however a criterion or shillen etc replacement will break in, clean and shoot without all the time. With a hunting rifle a must with a new competitor shoot them like that till you are fundamentally sound and can outshoot the platform then change out the barrel.

That looks like most, if not all of my Savage factory barrels. And I'm talking about the heavy barreled and target versions. I was a little taken aback when I first got a bore scope and saw that. Then I looked at my log book for the 6br model and saw that it hadn't shot a single group that wasn't smaller than 3/4" and had shot a bunch that were 3/8" or less and grudgingly decided it must not be the end of the world.

I would agree that you don't want to use abrasives to get those tooling marks out. It wouldn't shoot at all after that. or you'd need to use a paper patch, which would seriously slow down the process. Although it could be entertaining for others.

I would agree that you don't want to use abrasives to get those tooling marks out. It wouldn't shoot at all after that. or you'd need to use a paper patch, which would seriously slow down the process. Although it could be entertaining for others.

Don’t worry about it. I’ve never had a TC barrel they didn’t shoot.

Best fix is to take that cool new bore scope and throw it in the very back of your junk drawer and forget you own one.

And go shooting!

Sirhr

Best fix is to take that cool new bore scope and throw it in the very back of your junk drawer and forget you own one.

And go shooting!

Sirhr

Allow me to ask a really stupid question.........I'm no expert, but I've looked down a few barrels and I have never seen tool marks like these. They are consistent, going from the leade to the muzzle. Is this a different process, zero lapping, idk.

Unknown date of manufacture .22 lr TC Contender barrel.View attachment 8106583View attachment 8106584

Have you shot it yet ? How does it shoot ?

Thank you for treading on thin ice so that I didn't have to.........Don’t worry about it. I’ve never had a TC barrel they didn’t shoot.

Best fix is to take that cool new bore scope and throw it in the very back of your junk drawer and forget you own one.

And go shooting!

Sirhr

Allow me to ask a really stupid question.........

Have you shot it yet ? How does it shoot ?

I took stack of different ammos, mostly Lapua/SK flavors. It shows promise, certainly not shooting one hole groups, I just got to find which one of my orphan lots of ammo it wants most.

Because that's what this pistol is gonna do, give me a reason to use all the odd lots of ammo the rifles just don't seem to like. I got this Contender as part of a package deal and really didn't have any interest in it at the time but I got bored on a rainy weekend and figured I'd set it up to use in a little local silhouette match.

I had never fired a single shot through it, when I looked at the huge carbon ring in front of the chamber my OCD kicked in and that's where the post comes in.

Thank you for being up front about it.Actually, finally was able to get to the range on Wednesday. I slugged the barrel before the range trip and it isn't perfect but has a good choke at the muzzle.

I took stack of different ammos, mostly Lapua/SK flavors. It shows promise, certainly not shooting one hole groups, I just got to find which one of my orphan lots of ammo it wants most.

Because that's what this pistol is gonna do, give me a reason to use all the odd lots of ammo the rifles just don't seem to like. I got this Contender as part of a package deal and really didn't have any interest in it at the time but I got bored on a rainy weekend and figured I'd set it up to use in a little local silhouette match.

I had never fired a single shot through it, when I looked at the huge carbon ring in front of the chamber my OCD kicked in and that's where the post comes in.

The whole point of my question is that if it shoots well, it really doesn't matter what the chamber/bore/muzzle looks like. There have been far too many people that have bought borescopes, scoped (in many cases, unfired weapons), found tool marks and "concluded" that it's a shitty barrel. This, before even shooting said weapon.

I have a borescope and per @sirhrmechanic's post above, my borescope sits in the back of the bottom drawer of my toolbox. Does that mean I think borescopes are bad/useless ? No, not at all. But, it doesn't come out of the toolbox very often. I use it as a troubleshooting tool, typically after most (if not all) other traditional/assumed remedies have been attempted.

If a person were to have problems with accuracy/groupings, regardless of which type of ammo used, a borescope is very helpful in providing a piece of the puzzle as to why. But, there are far too many barrels out there that look shitty under inspection with a borescope that actually shoot lights out. Where I get my panties bunched up is when someone hasn't even fired the weapon, scopes it and based on the scoping, automatically concludes that it won't shoot/group.

Am I happy that I have a borescope ? Sure.

Do I base all of my decisions about a barrels accuracy/repeatability/consistency based on what I see with the borescope ? No, not at all. Yes, it would be nice to see nothing but perfection/no tool marks in a barrel with a borescope, but I've had too many barrels that shoot that aren't "perfect" inside.

I hear you, and in many ways, agree.Thank you for being up front about it.

The whole point of my question is that if it shoots well, it really doesn't matter what the chamber/bore/muzzle looks like. There have been far too many people that have bought borescopes, scoped (in many cases, unfired weapons), found tool marks and "concluded" that it's a shitty barrel. This, before even shooting said weapon.

I have a borescope and per @sirhrmechanic's post above, my borescope sits in the back of the bottom drawer of my toolbox. Does that mean I think borescopes are bad/useless ? No, not at all. But, it doesn't come out of the toolbox very often. I use it as a troubleshooting tool, typically after most (if not all) other traditional/assumed remedies have been attempted.

If a person were to have problems with accuracy/groupings, regardless of which type of ammo used, a borescope is very helpful in providing a piece of the puzzle as to why. But, there are far too many barrels out there that look shitty under inspection with a borescope that actually shoot lights out. Where I get my panties bunched up is when someone hasn't even fired the weapon, scopes it and based on the scoping, automatically concludes that it won't shoot/group.

Am I happy that I have a borescope ? Sure.

Do I base all of my decisions about a barrels accuracy/repeatability/consistency based on what I see with the borescope ? No, not at all. Yes, it would be nice to see nothing but perfection/no tool marks in a barrel with a borescope, but I've had too many barrels that shoot that aren't "perfect" inside.

The OCD comment was sort of tongue-in-cheek. I'm not slavishly scrubbing all my barrels to bare metal.

A few years back when I began to get interested in higher-end rimfires I listened to the old guard at the range.

I don’t ever clean my bore, they said. Maybe at the end of the season, you'll ruin that barrel, just a patch or two occasionally, they assured.

Yea right! I had a awesome shooting rifle begin to print groups worthy of a turkey shoot, thus the borescope purchase.

I see that I've developed a nasty carbon ring in front of the chamber and it was a total PITA to clear. The borescope now allows me to know when and how much cleaning is needed.

I agree that I should have shot the TC first, but the CR in the throat looked familiar.

You guys must not know anything about machining. The photos show the feed rate that the barrel was drilled at. The barrel was not reamed or lapped after drilling. Then the barrels were button rifled. Hammer forged can also show this but it not be as bad. It is a cost cutting thing they do for mass produced barrels.

I know a little about machining, but I have never taken a borescope to work to look at the wall of a gun drilled hole and we don't make barrels.You guys must not know anything about machining. The photos show the feed rate that the barrel was drilled at. The barrel was not reamed or lapped after drilling. Then the barrels were button rifled. Hammer forged can also show this but it not be as bad. It is a cost cutting thing they do for mass produced barrels.

That was one part of my original post was questioning the process, maybe there was "zero lapping". So it makes sense considering the pics of other mass-produced barrels that were posted.

You guys must not know anything about machining.

It's true, I'm not a machinist.

I read anything and everything I can find dealing with firearms.

Examples of poorly finished barrels aren't difficult to find.

Not an isolated example posted by @accurate obsession.

I found images of sloppy work using multiple methods of cutting the rifling.

They're production barrels made as inexpensively as possible, as fast as possible.

Problems are going to slip through to the consumer, who is the last inspector for quality control.

That's why manufacturers have a warranty.

It's true, I'm not a machinist.

I read anything and everything I can find dealing with firearms.

Examples of poorly finished barrels aren't difficult to find.

Not an isolated example posted by @accurate obsession.

I found images of sloppy work using multiple methods of cutting the rifling.

They're production barrels made as inexpensively as possible, as fast as possible.

Problems are going to slip through to the consumer, who is the last inspector for quality control.

That's why manufacturers have a warranty.

1000%Don’t worry about it. I’ve never had a TC barrel they didn’t shoot.

Best fix is to take that cool new bore scope and throw it in the very back of your junk drawer and forget you own one.

And go shooting!

Sirhr

the target tells you what kind of barrel you have

it could look like a bad welding job inside, as long as it shoots tight i dont care

You want to see a smooth rf barrel? This is a Ruger American rimfire compact I picked up a couple weeks ago. This was unfired by me right out of the box. I have not shot it yet. Scope will be here tomorrow.

I have an older T/C Contender in 44 Mag and you can see the same thing looking down the bore with just your eye. They are tooling marks that where in the bore before they pulled/pushed a button through it. It's a factory barrel so as long as it's safe and somewhat shoots, it's good enough.

Like mine It will foul more and take a little work to scrub clean, but it actually shoots pretty well if I do my part.

If you're really concerned about it, it's possible to slug the bore to see what the bore diminutions are and what you have to work with. It's possible to lap the bore but you have to be super careful and know what you're doing. It's easy to wash out your leade and you don't want to lap any loose spot in the bore. In this case the lemon isn't probably worth the squeeze. MGM make great shooting match grade contender barrel.

Like mine It will foul more and take a little work to scrub clean, but it actually shoots pretty well if I do my part.

If you're really concerned about it, it's possible to slug the bore to see what the bore diminutions are and what you have to work with. It's possible to lap the bore but you have to be super careful and know what you're doing. It's easy to wash out your leade and you don't want to lap any loose spot in the bore. In this case the lemon isn't probably worth the squeeze. MGM make great shooting match grade contender barrel.

I have no plans to try and lap this out, it just looked different from other barrels and I was curious. Apparently this is common to certain mass produced barrels.I have an older T/C Contender in 44 Mag and you can see the same thing looking down the bore with just your eye. They are tooling marks that where in the bore before they pulled/pushed a button through it. It's a factory barrel so as long as it's safe and somewhat shoots, it's good enough.

Like mine It will foul more and take a little work to scrub clean, but it actually shoots pretty well if I do my part.

If you're really concerned about it, it's possible to slug the bore to see what the bore diminutions are and what you have to work with. It's possible to lap the bore but you have to be super careful and know what you're doing. It's easy to wash out your leade and you don't want to lap any loose spot in the bore. In this case the lemon isn't probably worth the squeeze. MGM make great shooting match grade contender barrel.

After all the cleaning I did slug the barrel. About 1.5" past the throat it basically free slides to the last 1/2" where there is a good choke at the muzzle.

Only have a couple hundred rounds thru it so far, while not impressive, I'm hoping to get good enough performance to use in a rimfire silhouette match.

I am not a tech obsessed guy, in fact I try to keep things as simple as possible, and when it comes to use of a bore scope/ examining bore condition the reality is:

if it shoots good, it doesn’t matter how bad it looks

if it shoots bad, it doesn’t matter how good it looks

if it shoots good, it doesn’t matter how bad it looks

if it shoots bad, it doesn’t matter how good it looks

tomme boy: You are almost correct. The marks in the images the OP posted are REAMER marks. Barrels are not button rifled after drilling without reaming to a final dimension. Virtually all barrels have these marks (button or cut rifled) until or unless these marks are lapped out. Low end barrelmakers do not lap these out. High end barrelmakers lap after reaming and before rifling and/or after rifling. Lapping is done by machines (i.e. Sunnen) and/or by hand.

Last edited:

I have a few of the older contender match 22LR barrels and I can honestly say that every one of them shoot very well. I`ve never bore scoped one but as long as they shoot good I don`t care what they look like inside. A lot of people think they need to polish, lap, etc. but what they might not realize is they are taking away life from the barrel and could very well be taking away the best life of the barrel without even realizing it. You can always clean a new to you gun but I would shoot before I polished or lapped. Let the gun tell you what it needs... Is it a match barrel? Chamber a round and pull it back out and you should see distinct rifling marks where it pushed it in the lands.

What, then, is a "match barrel"?"Chamber a round and pull it back out and you should see distinct rifling marks where it pushed it in the lands."

This will tend to indicate a match chamber, not necessarily a match barrel.

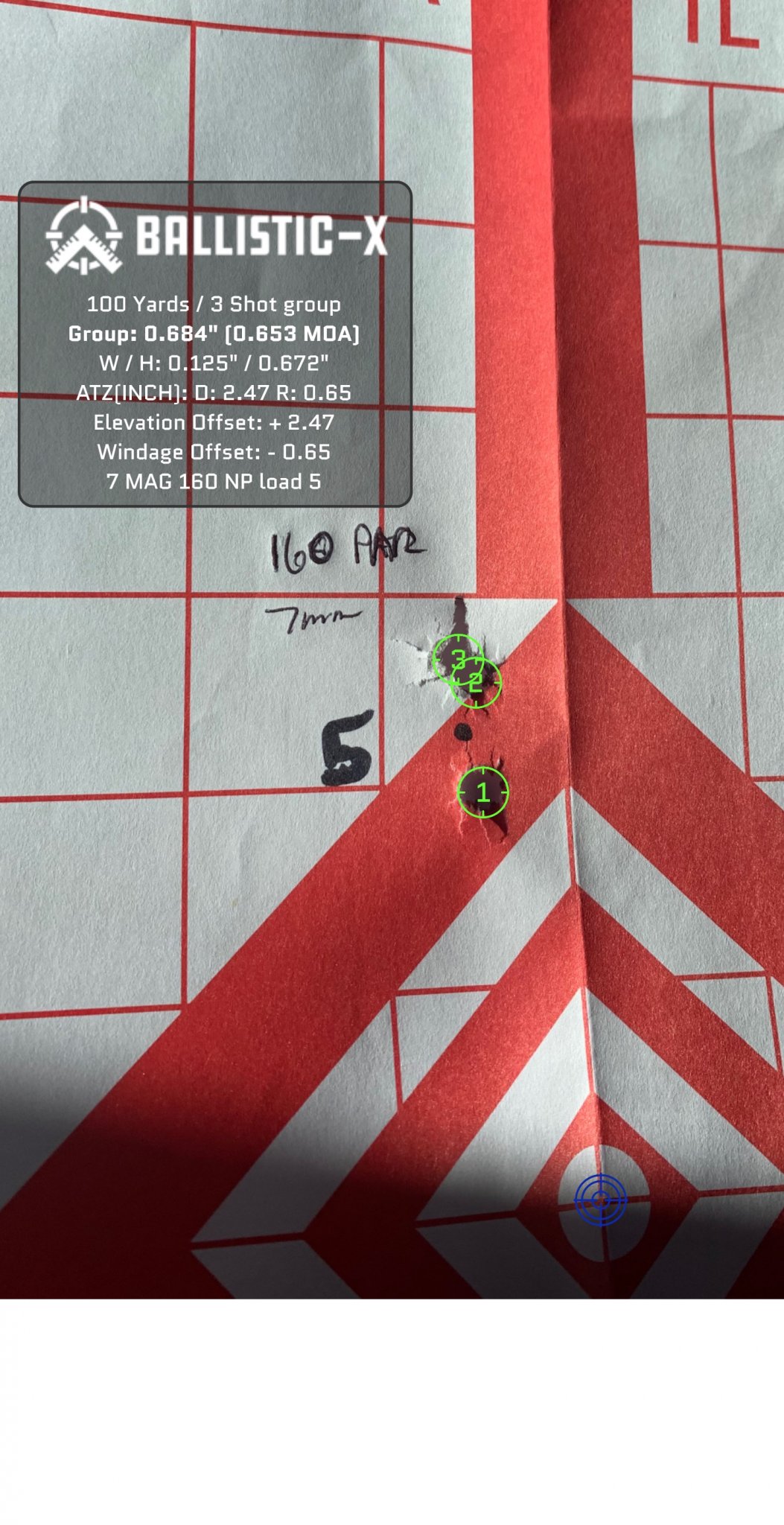

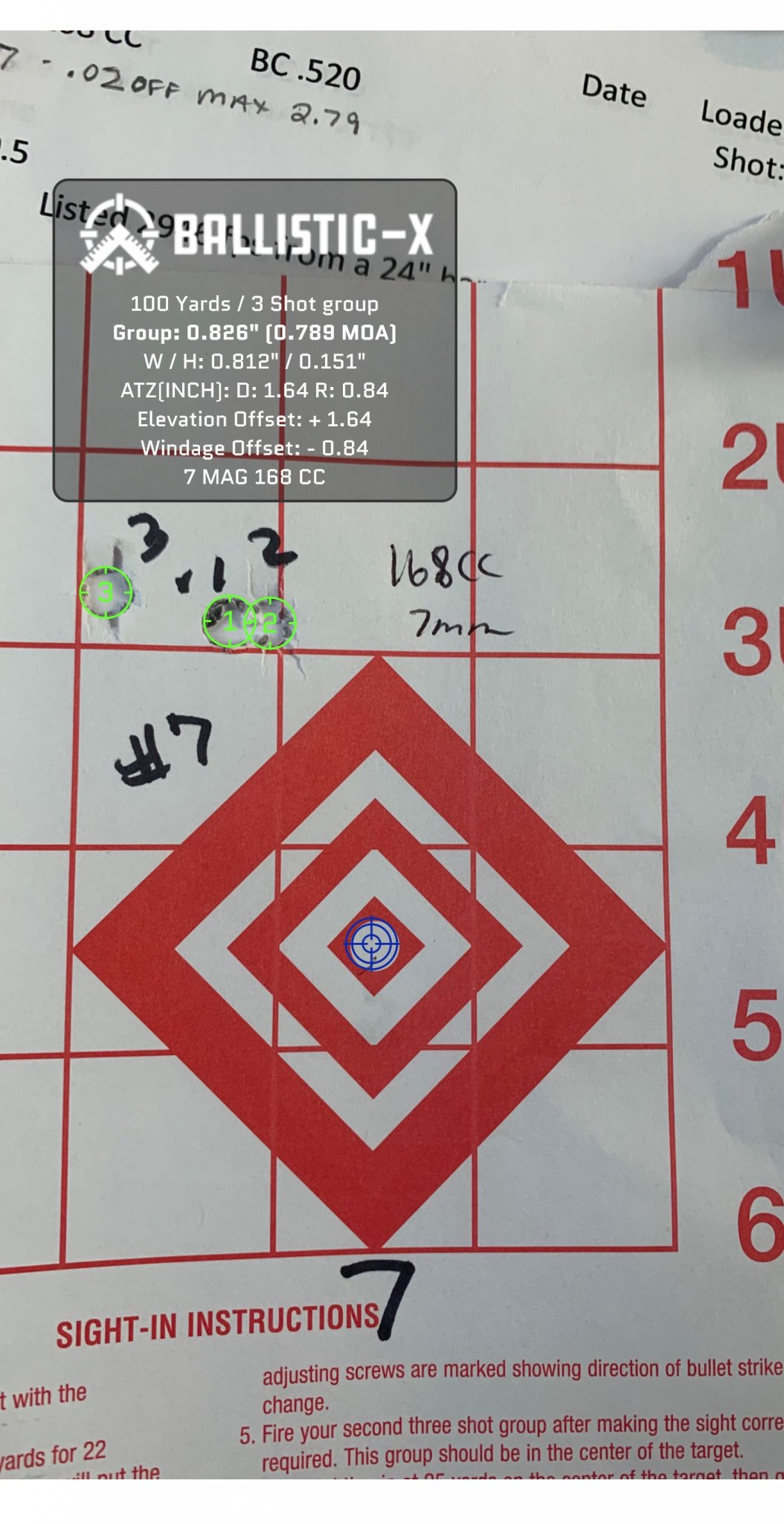

These pictures are from the barrel of my 42 year old Ruger 77 7mm Mag. Yikes is all I can say. However, it’s still turning in the groups below using 160 Nosler Partitions and 168 CC’s. I love my borescope, but I care more about how the barrel shoots. A drop of oil got on my borescope lens in the bottom right, otherwise the pictures are good.

What, then, is a "match barrel"?

Good Question - as there is some disagreement . . .

Generally a true "match" barrel is a 416R Stainless Steel barrel, either cut or button rifled (never hammer forged), that has the bore dimension held to very tight tolerances the entire length of the barrel. This is typically +/- .0001" end to end. Virtually all "match" barrels have been lapped at some point during their production to significantly reduce or completely eliminate reamer marks. Typical "match" grade barrelmakers include Kreiger, Shilen, Bartlein, Rock Creek, Brux, Muller etc. (apologies to those not named). However, some barrelmakers (and shooters) prefer a very slight reduction (usually from .0001" to .0003") in the bore diameter very close to the muzzle, which is usually accomplished by hand lapping by a skilled and experienced lapper. This is called taper or choke lapping,and is also called MI by at least one manufacturer (< My error, corrected by Turbo2). Krieger will not taper lap a barrel upon request - and they make astoundingly good barrels. Many top rimfire BR shooters prefer barrels with some slight choke or taper. Some gunsmiths/gunbuilders will lap barrel blanks prior to chambering (this is an acquired skill). You will rarely see reamer marks in the bore of top quality "match" barrels.

Does that mean these barrel will always be awesome shooters - NO. Does it mean you can't have a fantastic shooting chrome-moly hammer forged barrel - NO. But the odds of getting a great shooting barrel are FAR better with a "match" barrel as described above.

Good Question - as there is some disagreement . . .

Generally a true "match" barrel is a 416R Stainless Steel barrel, either cut or button rifled (never hammer forged), that has the bore dimension held to very tight tolerances the entire length of the barrel. This is typically +/- .0001" end to end. Virtually all "match" barrels have been lapped at some point during their production to significantly reduce or completely eliminate reamer marks. Typical "match" grade barrelmakers include Kreiger, Shilen, Bartlein, Rock Creek, Brux, Muller etc. (apologies to those not named). However, some barrelmakers (and shooters) prefer a very slight reduction (usually from .0001" to .0003") in the bore diameter very close to the muzzle, which is usually accomplished by hand lapping by a skilled and experienced lapper. This is called taper or choke lapping,

Does that mean these barrel will always be awesome shooters - NO. Does it mean you can't have a fantastic shooting chrome-moly hammer forged barrel - NO. But the odds of getting a great shooting barrel are FAR better with a "match" barrel as described above.

Last edited:

Is the reduction or elimination of reamer marks in the barrel the only purpose of lapping?Virtually all "match" barrels have been lapped at some point during their production to significantly reduce or completely eliminate reamer marks.

If lapping is a criteria of a "match barrel" it would seem to exclude barrels on rifles made by Anschutz, probably Walther and FWB also.