I would’ve just DM’d Mike B. instead of making yourself disappointed for no reason. I understand your frustration but it’s pretty well known on this thread that Mike is always doing what he can to make sure people are satisfied with their vudoos. Shit happens. Small parts get missed. It’s less than ideal but they will do you right.That would explain why I can't get in touch with anyone to get the missing parts on the barreled action I picked up from Mile high. Rather disappointed to say the least...

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

Top Shot Throwback Contest - Only a Few Hours Left To Enter!

Tell us about your best shot or proudest moment on the range this past year! Winner gets new limited edition Hide merch. Remember, subscribers have a better chance of winning!

Join contest Subscribe

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DeLane Development Group Rimfire Ventures

- Thread starter RAVAGE88

- Start date

If it's trigger pins, make sure you look in the foam slots, sometimes the little ziplock bag that the trigger pins are in get pushed under the foam.

Not sure what other parts were in my box. It was the BA, Bolt, Trigger Pins.

Not sure what other parts were in my box. It was the BA, Bolt, Trigger Pins.

What parts are you missing? We can resolve this quickly....

MB

That would be great. Trigger pins and the set screw for the bolt.

Copy, PM your address and I’ll square it away quickly.That would be great. Trigger pins and the set screw for the bolt.

MB

ordered my raven today. pretty excited. now I need to figure out what glass im going to top it off with....

When I got my first vudoo with the Gen 1.2 receiver, I was a little disappointed with the bolt throw. It was not as smooth as I would’ve expected and would kinda bind up. But after a while it was as smooth as my impact and couldn’t complain. My Gen 2 is very smooth though right off the bat. Oil your bolt lightly and run the bolt a bunch. It’ll break in and it’ll be smooth.

Went shooting a bit more. It is much better now since I run the bolt while watching TV but still, from time to time, bolt get blocked by that protruding pin made to protect / align mag 'tower'. I wonder what to do with that issue.

Went shooting a bit more. It is much better now since I run the bolt while watching TV but still, from time to time, bolt get blocked by that protruding pin made to protect / align mag 'tower'. I wonder what to do with that issue.

What protruding pin? I don't understand what you mean by the align mag 'tower'

That would be great. Trigger pins and the set screw for the bolt.

Trigger pins and set screw went out in the early mail via USPS Priority; you'll have them NLT Saturday.

Please reach out if you have any questions or need anything,

MB

Went shooting a bit more. It is much better now since I run the bolt while watching TV but still, from time to time, bolt get blocked by that protruding pin made to protect / align mag 'tower'. I wonder what to do with that issue.

Run the bolt with the magazine inserted as it's designed as a system. The "pin" you're referring to is the ejector, it's not there to protect the magazine.

MB

Run the bolt with the magazine inserted as it's designed as a system. The "pin" you're referring to is the ejector, it's not there to protect the magazine.

MB

thanks for the info. Action is already much smoother. Still blocks here when bolt lever pushed at max height:

Attachments

thanks for the info. Action is already much smoother. Still blocks here when :

That bolt appears terribly devoid of any lubrication.

"bolt lever pushed at max height"----Are you purposely driving the bolt off-axis to the receiver?

MB

Last edited:

oh, it is well lubed, ejector window area a bit wiped but not the reason of locking

shoul i put grease?

shoul i put grease?

oh, it is well lubed, ejector window area a bit wiped but not the reason of locking

shoul i put grease?

Either a higher viscosity oil (I use Lucas Oil Gun Oil) or one of two grease lubes I'll use on the outside of the bolt; XF7 or Lucas Oil Gun Grease. Never put grease on the firing pin/spring because it creates drag.

MB

Either a higher viscosity oil (I use Lucas Oil Gun Oil) or one of two grease lubes I'll use on the outside of the bolt; XF7 or Lucas Oil Gun Grease. Never put grease on the firing pin/spring because it creates drag.

MB

I've been using this Pro Shot Pro Gold https://amzn.to/2Lv5hAX for my bolt / lugs. Do you have any concerns on this one? I had purchased this before VGW recommended the Lucas stuff.

Either a higher viscosity oil (I use Lucas Oil Gun Oil) or one of two grease lubes I'll use on the outside of the bolt; XF7 or Lucas Oil Gun Grease. Never put grease on the firing pin/spring because it creates drag.

MB

agree! As Canadian I know that grease will create drag , it gets even worse in the cold.

maybe firing pin touching the ejector while bolt fully extended?

still I’ll give another 500 rounds through it + a tv night and get back with results. Pretty confident it will be all right tho.

Cheers and thanks for your time.

Attachments

I've been using this Pro Shot Pro Gold https://amzn.to/2Lv5hAX for my bolt / lugs. Do you have any concerns on this one? I had purchased this before VGW recommended the Lucas stuff.

Based on the operating temperature, I don't see it being a problem, just don't put it on the interior workings of the bolt assembly. The interior should get a lighter viscosity oil.

MB

agree! As Canadian I know that grease will create drag , it gets even worse in the cold.

maybe firing pin touching the ejector while bolt fully extended?

still I’ll give another 500 rounds through it + a tv night and get back with results. Pretty confident it will be all right tho.

Cheers and thanks for your time.

Firing pin physically can not touch the ejector, it's richly clearanced. With the magazine not inserted, the bolt nose is allowed to rotate just enough such that it will lightly contact the ejector enough so that you'd feel it. The magazine serves a few purposes as part of a functional system.

MB

Trigger pins and set screw went out in the early mail via USPS Priority; you'll have them NLT Saturday.

Please reach out if you have any questions or need anything,

MB

Thank you very much!

The sweet "middle" spot is basically where you have to be, I just learned to cycle my bolt properly and never have had any issues. I don't have any other suggestions. With such tight tolerances everything is fitting like a glove in the action, which I assume increases the accuracy a bit, but yes it's not a loose wobbly smooth action like my Tikkas.

Hasn't bothered me ever in a match though. Only if I'm OCD trying to gently analyze my bolt do I notice.

Humm ... I got much more play in the Vudoo than the Tikka.

I dont care about a little play on an open bolt as long as the rifle is accurate and it doesnt bite in raceways or anything else.

But for now this V22 blocks 100% when boltface is 0.75'' from the front of the ejection port when pushing the bolt at maximum height. I just cant run the bolt as fast as on my Tikka. Sad thing because otherwise it is a perfect rifle.

This is in no way something I was expecting reading all those comments about how smooth this action is.

I should post a video regarding this, I ll do this weekend.

Humm ... I got much more play in the Vudoo than the Tikka.

I dont care about a little play on an open bolt as long as the rifle is accurate and it doesnt bite in raceways or anything else.

But for now this V22 blocks 100% when boltface is 0.75'' from the front of the ejection port when pushing the bolt at maximum height. I just cant run the bolt as fast as on my Tikka. Sad thing because otherwise it is a perfect rifle.

This is in no way something I was expecting reading all those comments about how smooth this action is.

I should post a video regarding this, I ll do this weekend.

"bolt lever pushed at max height"----Are you purposely driving the bolt off-axis to the receiver?

MB

This ^

Looks like these are going to finally be available... should be a great addition to your Vudoo!

cuttingedgebullets.com

cuttingedgebullets.com

New Solid Copper 22lr Bullets

Solid copper, monolithic lead-free 22lr bullets

Why would you purposely push the bolt off-axis to the receiver? By doing so over a short period, you actually create "play." Operate the bolt back and forth along it's axis the way it was actually designed to work.....when pushing the bolt at maximum height.

MB

Yeah, this is the vudoo thread. There’s another place to discuss ammo.

OH. Thanks Jon. This is very helpful. I appreciate your input fine sir!

Funny you say that Mike our lgs had some of this ( Lucas Oil Gun Oil) and I have been using it for almost 6 months and around 6k rounds with great success.Either a higher viscosity oil (I use Lucas Oil Gun Oil) or one of two grease lubes I'll use on the outside of the bolt; XF7 or Lucas Oil Gun Grease. Never put grease on the firing pin/spring because it creates drag.

MB

I was using wilson universal lube before but wanted to try something easier to obtain.

Last edited:

Why would you purposely push the bolt off-axis to the receiver? By doing so over a short period, you actually create "play." Operate the bolt back and forth along it's axis the way it was actually designed to work.

MB

[/QUOTE]

Not sure to understand, There is no good reason I would try to abuse and ruin a brand new quality rifle. But when I run the bolt, I just run it.

Read my first post here. Really want to love the rifle. It smells quality in materials and finish . it shoots great at 300m. I could also say that it looks amazing in my accuracy AT stock, balance and ergo similar to my AI so it is a perfect trainer.

Not searching for trouble here but solutions.

BUT:

I just run the bolt and it happens to stop hard from time to time always in the same spot. That is just a fact. There is more movement in the open bolt than my T1X. if it is by design , it is all right. Where I feel less comfortable is that bolt operation is not as smooth.

I do not believe that normal use could create a play over a short period of time either , I just shoot it tho. I do not see smoke or metal chips!!

If I have to grease it like my M14 to have smooth operation then I'll do. I ll gave this guy more rounds to chew and see how this goes .

Here is the video I sent to vudoo customer care, waiting for a reply:

So if your rifles did that back then and now it is smooth as butter , I got nothin to worry about.

MB

[/QUOTE]

Not sure to understand, There is no good reason I would try to abuse and ruin a brand new quality rifle. But when I run the bolt, I just run it.

Read my first post here. Really want to love the rifle. It smells quality in materials and finish . it shoots great at 300m. I could also say that it looks amazing in my accuracy AT stock, balance and ergo similar to my AI so it is a perfect trainer.

Not searching for trouble here but solutions.

BUT:

I just run the bolt and it happens to stop hard from time to time always in the same spot. That is just a fact. There is more movement in the open bolt than my T1X. if it is by design , it is all right. Where I feel less comfortable is that bolt operation is not as smooth.

I do not believe that normal use could create a play over a short period of time either , I just shoot it tho. I do not see smoke or metal chips!!

If I have to grease it like my M14 to have smooth operation then I'll do. I ll gave this guy more rounds to chew and see how this goes .

Here is the video I sent to vudoo customer care, waiting for a reply:

So if your rifles did that back then and now it is smooth as butter , I got nothin to worry about.

Why would you purposely push the bolt off-axis to the receiver? By doing so over a short period, you actually create "play." Operate the bolt back and forth along it's axis the way it was actually designed to work.

MB

Not sure to understand, There is no good reason I would try to abuse and ruin a brand new quality rifle. But when I run the bolt, I just run it.

Read my first post here. Really want to love the rifle. It smells quality in materials and finish . it shoots great at 300m. I could also say that it looks amazing in my accuracy AT stock, balance and ergo similar to my AI so it is a perfect trainer.

Not searching for trouble here but solutions.

BUT:

I just run the bolt and it happens to stop hard from time to time always in the same spot. That is just a fact. There is more movement in the open bolt than my T1X. if it is by design , it is all right. Where I feel less comfortable is that bolt operation is not as smooth.

I do not believe that normal use could create a play over a short period of time either , I just shoot it tho. I do not see smoke or metal chips!!

If I have to grease it like my M14 to have smooth operation then I'll do. I ll gave this guy more rounds to chew and see how this goes .

Here is the video I sent to vudoo customer care, waiting for a reply:

So if your rifles did that back then and now it is smooth as butter , I got nothin to worry about.

[/QUOTE]

PM Sent.

MB

No sir, the bolt nose is stopping on the ejector....already told him (via PM) how to fix it.Could he have an action screw thats too long?

MB

There's a shoulder about mid way back on the bolt nose that, for whatever reason, is hitting the ejector. A very simple fix.Thanks Mike....I dont have the issue but could you pm me what happened?

MB

Mike,There's a shoulder about mid way back on the bolt nose that, for whatever reason, is hitting the ejector. A very simple fix.

MB

I have experienced something similar from time to time. If the issue is what you describe above, can it be intermitent? If so, could you share the adjustment with me also?

Hasen't done it in a while, I thought it may have been a mag issue.

Not sure which action you have, but in the Gen 1, as long as the magazine was inserted, you'll never feel the ejector. A long time ago, we did receive ejectors that were a tad too tall, and a few swipes with a #2 file to remove .01" to .015" resolved any contact issues. For the masses: This is no longer the case, so please don't call the shop and tell them I said your ejector needs to be replaced or repaired.Mike,

I have experienced something similar from time to time. If the issue is what you describe above, can it be intermitent? If so, could you share the adjustment with me also?

Hasen't done it in a while, I thought it may have been a mag issue.

If you have a Gen 2, I'd be incredibly surprised if you're having this issue, but in the event you are, the fix is the same....a few swipes with a #2 file on the very top of the ejector, the file should not touch anywhere else on the ejector.

MB

Thanks Mike, Gen 1 for me. If the problem arises again, I will inspect closer and perform the above. Thanks for the reply.Not sure which action you have, but in the Gen 1, as long as the magazine was inserted, you'll never feel the ejector. A long time ago, we did receive ejectors that were a tad too tall, and a few swipes with a #2 file to remove .01" to .015" resolved any contact issues. For the masses: This is no longer the case, so please don't call the shop and tell them I said your ejector needs to be replaced or repaired.

If you have a Gen 2, I'd be incredibly surprised if you're having this issue, but in the event you are, the fix is the same....a few swipes with a #2 file on the very top of the ejector, the file should not touch anywhere else on the ejector.

MB

Thanks Mike, Gen 1 for me. If the problem arises again, I will inspect closer and perform the above. Thanks for the reply.

Copy, just swipe it a few times with a file and you'll be good to go. Also, reach out to me if you need anything, I'll be here.

MB

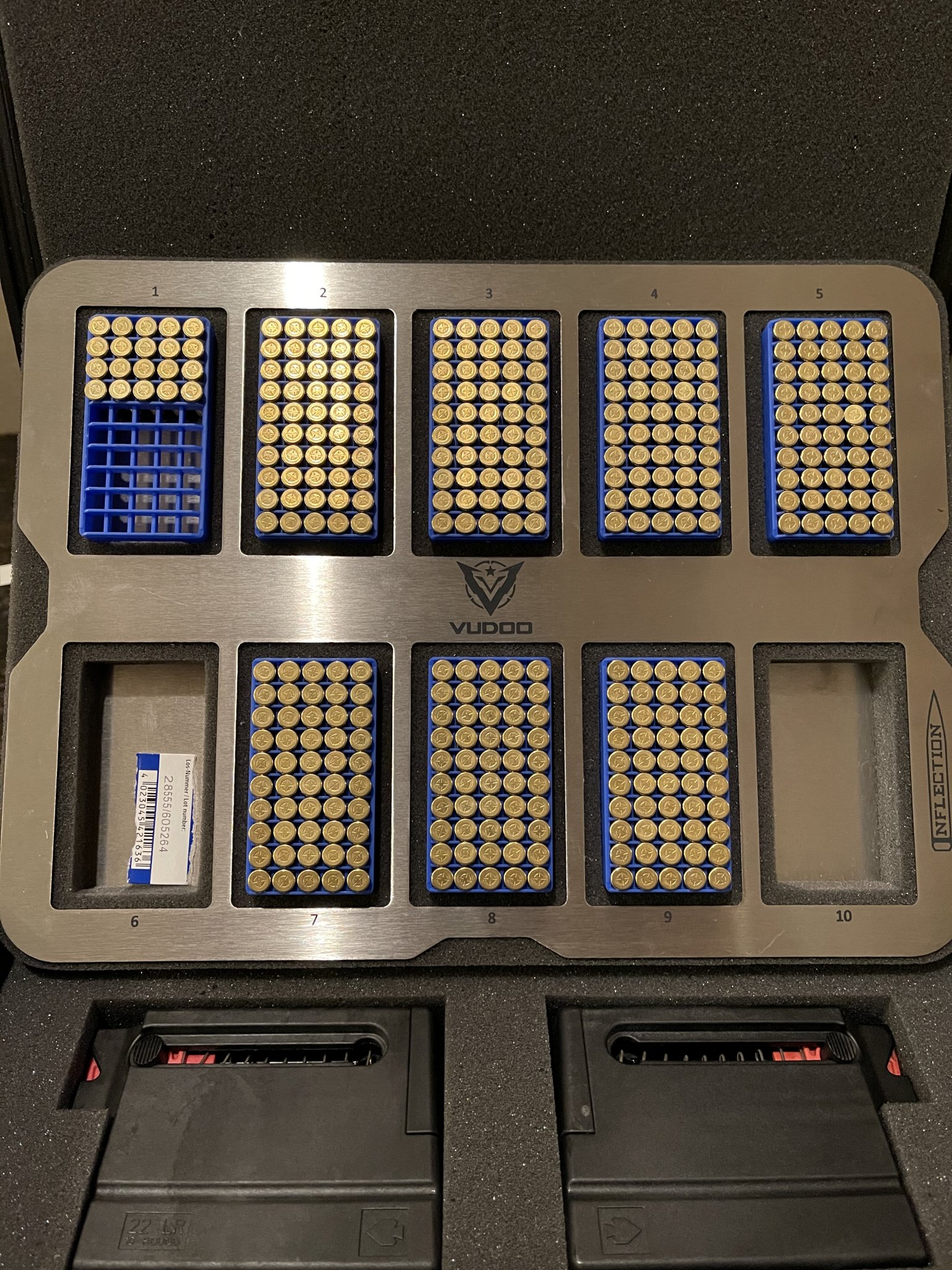

Just got my super boujee Inflection ammo storage hard case in after three weeks of the post office doing what the do best  . Had to spice it up of course lol Everything fits perfectly too, nothing is loose

. Had to spice it up of course lol Everything fits perfectly too, nothing is loose

More data. Did the Kraft 12 shot 4 position drill at 100yds with vudoo and sk+. I was extremely fortunate all 12 maintained good enough velocity.

Then I shot 88rnds off bipod/bag at 100yds. All but those bottom 6 stayed inside 1.3moa. So not awful for mid grade ammo.

Then I shot 88rnds off bipod/bag at 100yds. All but those bottom 6 stayed inside 1.3moa. So not awful for mid grade ammo.

Attachments

Not everyone has enough mags to load a brick intoNeeds more mags.

More data. Did the Kraft 12 shot 4 position drill at 100yds with vudoo and sk+. I was extremely fortunate all 12 maintained good enough velocity.

Then I shot 88rnds off bipod/bag at 100yds. All but those bottom 6 stayed inside 1.3moa. So not awful for mid grade ammo.

That's crazy. Your 12 shot group across 4 positions is what I can get in prone. Pretty crazy that you basically have only a .5moa, if that, wobble across all your positions... 22 rimfire target sizes are always at least 2-3 moa when not in prone, which means you must be cleaning up almost everything. Impressive.

That's crazy. Your 12 shot group across 4 positions is what I can get in prone. Pretty crazy that you basically have only a .5moa, if that, wobble across all your positions... 22 rimfire target sizes are always at least 2-3 moa when not in prone, which means you must be cleaning up almost everything. Impressive.

That group was a bit lucky obviously.

In the matches we have here, there’s a couple of use who hover around the top. Normal day is 1-3 dropped shots in about 70-80 depending on CoF. Last week I dropped 6 (3 on a mover @155yds) and winner dropped 5 out of 82 possible.

In a competition setting, Rimfire is easier to get stable as you don’t have to engage the rifle as much to manage recoil to see shots like you do in centerfire. Obviously in a perfect world, you drive them the exact same. But in a match, you’ll use every advantage.

Last edited:

Also, with the weight of the rifles we shoot now + sand bangs like fortune cookies and gamechangers, on a stable prop like a steel barricade, IMO the goal is about .1 of visible wobble.

If the weather holds up, I’ll try to get some through optic footage.

If the weather holds up, I’ll try to get some through optic footage.

For those of you that have typically communicated with me via FB, I’ll be deleting my personal account within the next few days. For the time being, the VGW pages will remain.

Please continue to reach out to me here or shoot an email to [email protected]. For those of you that have my cell number, shoot a text or find me on Signal.

Thanks,

MB

Please continue to reach out to me here or shoot an email to [email protected]. For those of you that have my cell number, shoot a text or find me on Signal.

Thanks,

MB

Last edited:

I would delete this quickly and post this in the PXI have a V22 boreguide from Boretech for sale. If you are interested, $30 plus shipping. PM if interested.

Thanks,

RFS99

Similar threads

- Replies

- 2

- Views

- 986

- Replies

- 205

- Views

- 46K

- Replies

- 39

- Views

- 13K