That looks very close to a Sniper Gray. My BA on order is Sniper Grey. Should be any time now. Was waiting on an 20" Ace Barrel to come in.Found this picture on the VGW Facebook page. Anyone know what color cerakote the barrel is?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DeLane Development Group Rimfire Ventures

- Thread starter RAVAGE88

- Start date

Tracked down the owner and he said it was matte clear over stainless.Found this picture on the VGW Facebook page. Anyone know what color cerakote the barrel is?

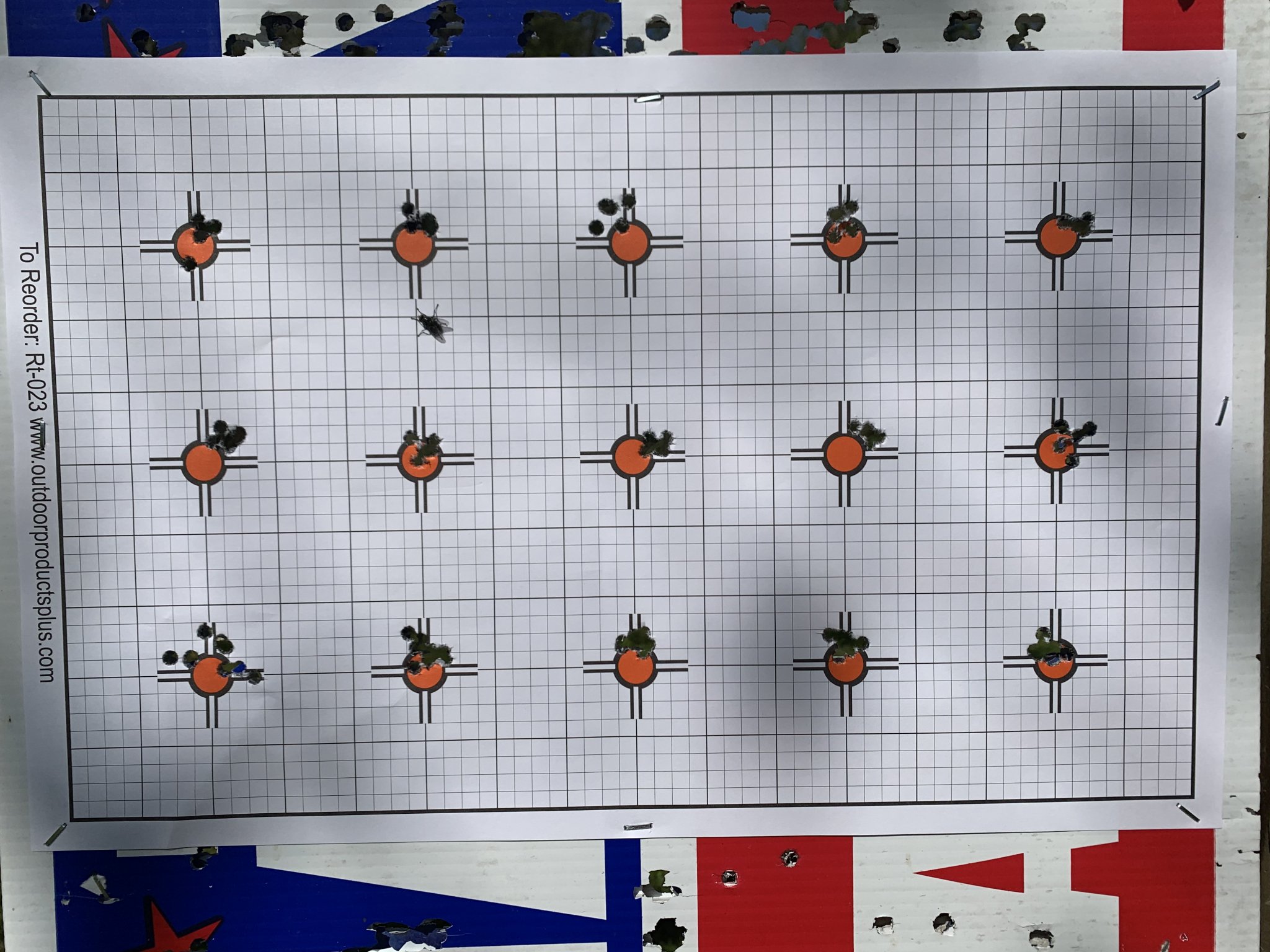

This Vudoo keeps impressing me. It now has 355 rounds down the tube. Today I shot 100 rounds of SK Standard + at 50 yards. Top 2 rows are 5 shot groups. Bottom row is 10 shot groups. Other than 1 group this is Damn Good in my book. Why I didn’t buy a V22 Barreled Action when I bought the Bergara is beyond me. I can’t wait for the full Vudoo Build to ship out. Should be a couple of weeks away.

It was... Those are actually all misses, haha!

Damn good shooting, man.

Damn good shooting, man.

You selling yours right now or waiting for 360 to come in?My poor vudoo has been neglected for the last few weeks. Sitting against the wall, clean. Unfired. Waiting to be sold for a three 60 vudoo lol

I have a 22" kukri unthreaded on order from Vudoo. Will be using my 90 degree 18" kukri at nationals. Can't wait for the 360.

Voodoo in the wild

It was great to finally be able to make it up to my spot for some much needed practice.

It was great to finally be able to make it up to my spot for some much needed practice.

It still needs some fine tuning adjustments to the zero. it will work for Saturdays NRL22 match in the rain in West KY!!!It was... Those are actually all misses, haha!

Damn good shooting, man.

It is a Burris RT25 5-25/56 SCR2 Mil reticle in ARC 30mm Low rings. I have 2 of them and an XTR3 ordered with the same reticle.Nice shooting materig looks good too. What scope is that?

He landed as I finished the last string. It was his lucky day.Too bad that fly wasn't on the target when it was up!

Was hoping to use my left hand 22" in Nebraska, but it hasn't come in yet and i don't think I'll have enough time to train on it...so back to right hand 20"MTU....I have a 22" kukri unthreaded on order from Vudoo. Will be using my 90 degree 18" kukri at nationals. Can't wait for the 360.

@J-Ham here is an updated 5x10 or 10x5 at 50. POI was adjusted Down .2 and R .1. Same SK Standard Plus.

I picked up my full Vudoo V22 build this past Thursday from my FFL. The rifle looks absolutely amazing and the quality is impeccable, however, I'm having some major bolt cycling issues with it:

The bolt doesn't feel very smooth in the action. Almost as though the paint inside the action is too thick. I have a Volquartsen Scorpion pistol that is very smooth, and I expected the same kind of smoothness. I tried some light oil, then a lot of oil, then tried removing most of the oil, tried a bit of grease, but still the same issue with the sticky feeling. Will this get smoother over time?

Within the hour I took it to my local range to sight in the scope. I had to do a double-take when it put 10 bullets through a hole at 25 yards, and had no trouble hitting a bullseye at 200 yards. However, after about 100 rounds I started having feeding issues where the bullets would smash up inside and not enter the bore, bending the bullet in the casing, denting the bullet. I had to pull the magazine to get the bent bullet out. I put a few hundred rounds of Midas+ through it, and got the scope zeroed, but after awhile I'd have to eject the magazine each time and waste a bullet.

I took it to the range again on Friday, and put another 400 rounds through it (mainly Midas+, SK Rifle, and tried some Wolf Match Extra and X-Act). I noticed right away that the Wolf and X-Act were sized differently. The primer rim was too wide in these rounds to fit the stock Vudoo mags. However, the X-Act seemed to be more accurate downrange. I ended up sticking with Midas+ and SK Rifle Match. When I got back home, I looked in the action and noticed metal shavings everywhere in there. An examination of the bullet casings showed that the casings themselves are being scraped somehow. This could have been the reason for the bolt action not being smooth. It's basically shaving metal off the bullets and casing! I cleaned it out, put a bit of oil on the bolt, and it seemed to cycle much more smoothly once I did that.

Saturday I took it to my first ever PRS match. Throughout the match my rifle would constantly jam, I'd have to eject a bullet, or eject the entire magazine and fiddle with putting another one in. This cost me time, and I wasn't able to finish several of the stages because of this (aside from the fact that a poor functioning rifle messes with your head).

I heard there are issues with Vudoo magazines and the MPA BA Comp chassis, but I'm not noticing the mags tilting at all. I watched this video and it looks like an adjustable mag release might solve the issue, but I question whether or not this is really the issue:

The magazines seem like they are in the magwell very snug and tight with only a bit of side to side play, no forward backward play. And if there were consistent issues with the BA Comp chassis, why wouldn't Vudoo ship them with the extended mag release as standard? What I am noticing is the bolt seems sticky when cycling it right before the bullet jams. It's not perfectly smooth. I can feel the bolt dragging on something. Any ideas what I could be doing wrong? I read that you can put some velcro on the mags to keep the mags from rotating, which I will try today and test it out again at the range. Any other things I can try to make this work? As is, I don't feel I can compete with this rifle (just way too many jams). Numerous people were also running Vudoos and they observed the same issues with my rifle. They tried it out, checking out the bolt, and offered some tips on the feeding issues, but advised sending the action back if these issues continue. I'm also wondering if I'm cycling the bolt incorrectly...not grabbing it at the correct position, not using enough force, or perhaps too much force.

Any advice would be much appreciated! I really love this rifle and would like to solve this!

The bolt doesn't feel very smooth in the action. Almost as though the paint inside the action is too thick. I have a Volquartsen Scorpion pistol that is very smooth, and I expected the same kind of smoothness. I tried some light oil, then a lot of oil, then tried removing most of the oil, tried a bit of grease, but still the same issue with the sticky feeling. Will this get smoother over time?

Within the hour I took it to my local range to sight in the scope. I had to do a double-take when it put 10 bullets through a hole at 25 yards, and had no trouble hitting a bullseye at 200 yards. However, after about 100 rounds I started having feeding issues where the bullets would smash up inside and not enter the bore, bending the bullet in the casing, denting the bullet. I had to pull the magazine to get the bent bullet out. I put a few hundred rounds of Midas+ through it, and got the scope zeroed, but after awhile I'd have to eject the magazine each time and waste a bullet.

I took it to the range again on Friday, and put another 400 rounds through it (mainly Midas+, SK Rifle, and tried some Wolf Match Extra and X-Act). I noticed right away that the Wolf and X-Act were sized differently. The primer rim was too wide in these rounds to fit the stock Vudoo mags. However, the X-Act seemed to be more accurate downrange. I ended up sticking with Midas+ and SK Rifle Match. When I got back home, I looked in the action and noticed metal shavings everywhere in there. An examination of the bullet casings showed that the casings themselves are being scraped somehow. This could have been the reason for the bolt action not being smooth. It's basically shaving metal off the bullets and casing! I cleaned it out, put a bit of oil on the bolt, and it seemed to cycle much more smoothly once I did that.

Saturday I took it to my first ever PRS match. Throughout the match my rifle would constantly jam, I'd have to eject a bullet, or eject the entire magazine and fiddle with putting another one in. This cost me time, and I wasn't able to finish several of the stages because of this (aside from the fact that a poor functioning rifle messes with your head).

I heard there are issues with Vudoo magazines and the MPA BA Comp chassis, but I'm not noticing the mags tilting at all. I watched this video and it looks like an adjustable mag release might solve the issue, but I question whether or not this is really the issue:

The magazines seem like they are in the magwell very snug and tight with only a bit of side to side play, no forward backward play. And if there were consistent issues with the BA Comp chassis, why wouldn't Vudoo ship them with the extended mag release as standard? What I am noticing is the bolt seems sticky when cycling it right before the bullet jams. It's not perfectly smooth. I can feel the bolt dragging on something. Any ideas what I could be doing wrong? I read that you can put some velcro on the mags to keep the mags from rotating, which I will try today and test it out again at the range. Any other things I can try to make this work? As is, I don't feel I can compete with this rifle (just way too many jams). Numerous people were also running Vudoos and they observed the same issues with my rifle. They tried it out, checking out the bolt, and offered some tips on the feeding issues, but advised sending the action back if these issues continue. I'm also wondering if I'm cycling the bolt incorrectly...not grabbing it at the correct position, not using enough force, or perhaps too much force.

Any advice would be much appreciated! I really love this rifle and would like to solve this!

Attachments

Last edited:

I got into trouble with mine yesterday by running the bolt wrong, at least in my rifle. If I put my thumb on the end of the bolt and don't go at warp speed it will feed fine. If I torque the bolt by grabbing it on the end at times it will not feed. If yours is a newer BA Comp it should have the adjustable mag well catch. I run mine in a Hybrid but have 2 BA Comp chassis on other rifles. In all 3 the catch needs to be adjusted for what mag I am using, that is plastic or metal. If I run it in between it gets iffy with either. If I run plastic mags or metal mags makes a difference. MPA sells plastic blocks that go into the magwell, my rifles runs better in MPA chassis with one or the other of the blocks. I would suggest ordering one of those kits and see if it locks things up tighter for you. Some experimentation may help resolve these issues.

I agree with the above regarding the mag catch - I don't think you can even buy a new MPA without the adjustable catch. If playing with the mag height doesn't solve the bolt and feeding issue (if the bolt cycles smoothly without a magazine, that may be a clue re your height adjustment), I'd contact Vudoo/MB. They will take care of you.

Last edited:

Just checked and you are correct. My mag catch is adjustable. I just adjusted it to less than a hair's breadth and I'm getting no play in the mag. I'll add some velcro to the mag as well and take it to the range today and test the bolt cycling. I'm sure Vudoo will take care of me. Not concerned that they won't.I agree with the above regarding the mag catch - I don't think you can even buy a new MPA without the adjustable catch. If playing with the mag height doesn't solve the bolt and feeding issue, I'd contact Vudoo/MB (If the bolt cycles smoothly without a magazine, that may be a clue re your height adjustment). They will take care of you.

I’m not sure if you’ve seen my email response from last night at 11:53p ET, but I mentioned that it’d be easier to talk through what you’re seeing on the phone (was going to cover the mag release). I was checking into a hotel as I replied, so couldn’t offer up any detail at the time. I’m flying today and available via telephone tomorrow.Just checked and you are correct. My mag catch is adjustable. I just adjusted it to less than a hair's breadth and I'm getting no play in the mag. I'll add some velcro to the mag as well and take it to the range today and test the bolt cycling. I'm sure Vudoo will take care of me. Not concerned that they won't.

MB

MB is always on the ball and always helping people at any given time. The Vudoo help is part of what made me buy this rifle. Everyone is will to help at any given time.

Holy shit! @RAVAGE88 returns calls and sends emails while on the road checking into a hotel. On a SATURDAY night. This is why I 'push' Vudoo when people ask. It also gives me hope in this hopeless world. Thank you good sir.

I just tried a few things (before I discuss this with Mike tomorrow) to see if I could figure out what was happening. I adjusted the mag release catch, so now there is absolutely no play whatsoever. There used to be an audible CLICK when the mag was inserted. Now it's a dull latching sound. The magazine is in there firmly, with no movement forward to back. I tried velcro, but it's just too thick. It's possible I had a bit too much oil in there so I cleaned it all out, and added just a bit of oil at the wear spots that have appeared on my bolt, and tried cycling it a few dozen times. The bolt action seems a lot smoother now. I also tried changing how I hold the bolt when I cycle. I switched a Wallace Machine Works V2 knob (https://wallacemachineworks.com/shop/ols/products/vudoo-bolt-knob-v3), which seems to help with the cycling I use my thumb in the groove of the knob when pushing it forward, but put my finger closer to the bolt when returning. This seems to reduce much of the friction I was experiencing at the wear spots. But it did get me wondering if side to side movement could also be contributing to feeding issues. Could that have any effect on the bullet entering the chamber incorrectly?

MB will solve your issue so this post is pretty much meaningless except I'm bored on a Sunday morning drinking coffee.

If the mag latch isn't set right and the rear of the mag is drooping, the rim isn't caught into the bolt and instead you're not pushing the bolt with it hitting the edge of the rim or pushing right into the case of the brass which will then cause it to pin and bend / jam the bullet as you are seeing.

If the mag latch is right, I've seen shooters do this a lot in matches due to short stroking the bolt. Same concept, but basically they didn't pull the bolt far enough back during cycling and pushing forward doesn't fully catch the rim and seat it into the bolt face and again a similar jam because you now rammed the bullet and jammed it into the breach face.

The last thing, in one of MB's videos talks about tightening the action screws with the mag seated to make sure the action is centered properly into the chassis. I've personally never had to do that, but I've seen that solve a few people's issues that were really struggling getting it right.

If you don't cycle the bolt in a straight back/forth motion there is also binding on the bolt that can happen. It'll smooth out over time as you're basically polishing out the grooves on the channel that is meant to only go forward and backward. That just takes practice in terms of getting that cycling to go smoother. I clean/grease my bolt about every 600 rounds. People who are used to running 60 degree short throw/stroke CZ 457's or Tikka T1X's usually will have issues when they switch to a Vudoo until they get their bolt manipulation fundamentals solid.

I'd choose a tighter tolerance, less play bolt, for the increased accuracy then to have something that has lighter tolerance but allow more torsional play (possibly smoother feeding like my Tikka)

If the mag latch isn't set right and the rear of the mag is drooping, the rim isn't caught into the bolt and instead you're not pushing the bolt with it hitting the edge of the rim or pushing right into the case of the brass which will then cause it to pin and bend / jam the bullet as you are seeing.

If the mag latch is right, I've seen shooters do this a lot in matches due to short stroking the bolt. Same concept, but basically they didn't pull the bolt far enough back during cycling and pushing forward doesn't fully catch the rim and seat it into the bolt face and again a similar jam because you now rammed the bullet and jammed it into the breach face.

The last thing, in one of MB's videos talks about tightening the action screws with the mag seated to make sure the action is centered properly into the chassis. I've personally never had to do that, but I've seen that solve a few people's issues that were really struggling getting it right.

If you don't cycle the bolt in a straight back/forth motion there is also binding on the bolt that can happen. It'll smooth out over time as you're basically polishing out the grooves on the channel that is meant to only go forward and backward. That just takes practice in terms of getting that cycling to go smoother. I clean/grease my bolt about every 600 rounds. People who are used to running 60 degree short throw/stroke CZ 457's or Tikka T1X's usually will have issues when they switch to a Vudoo until they get their bolt manipulation fundamentals solid.

I'd choose a tighter tolerance, less play bolt, for the increased accuracy then to have something that has lighter tolerance but allow more torsional play (possibly smoother feeding like my Tikka)

I am having feeding issues - not like the ones described above - it’s just the ‘nose tilted up’ problem. I watched the video on this issue and did some additional reading but am wondering if there’s any way to solve this more consistently. I make sure that each round is tilted up - don’t pull the button down too far - tap the magazine - etc. I still end up having to pull the magazine out every time. I’m using the JP APAC chassis and so far Midas + and Eley Match which seems to slightly worse than the Lapua for feeding.

Round tilted up means the rim isn't getting seated / control fed into the bolt face so it's getting pushed by barely catching the rim / and then eventually pushing directly into the side of the brass and when it hits the edge it'll just flip up.I am having feeding issues - not like the ones described above - it’s just the ‘nose tilted up’ problem. I watched the video on this issue and did some additional reading but am wondering if there’s any way to solve this more consistently. I make sure that each round is tilted up - don’t pull the button down too far - tap the magazine - etc. I still end up having to pull the magazine out every time. I’m using the JP APAC chassis and so far Midas + and Eley Match which seems to slightly worse than the Lapua for feeding.

That could have to do with the magazine tilted in any sort of direction which prevented the rim to fully seat into the bolt face. Without shooting ammo, let's say you loaded a magazine, and just cycled and extracted them and you can get it to happen. Then try pushing against the mag in different directions and test until which way will make it feed reliably, if it's L / R direction then it means your chassis/action isn't sitting perfectly flat and might be at a slight angle, if it's fore/aft direction then that means your mag latch needs to be adjusted.

Is this feeding issue normally just in certain chassis? Or is it across the board depending on DBM used, etc? My Vudoo Three 60 will mainly live in a McMillan A5 with Badger M5 DBM.

Also Mike @RAVAGE88 is there any plans to make a single shot adaptor for the Three 60 action? Im going to drop mine into a spare McMillan LV/HV stock I have when/if I wanna shoot some smallbore BR/F-Class with it.

Also Mike @RAVAGE88 is there any plans to make a single shot adaptor for the Three 60 action? Im going to drop mine into a spare McMillan LV/HV stock I have when/if I wanna shoot some smallbore BR/F-Class with it.

I could get down with a single shot adapter for the 3 lug too!Is this feeding issue normally just in certain chassis? Or is it across the board depending on DBM used, etc? My Vudoo Three 60 will mainly live in a McMillan A5 with Badger M5 DBM.

Also Mike @RAVAGE88 is there any plans to make a single shot adaptor for the Three 60 action? Im going to drop mine into a spare McMillan LV/HV stock I have when/if I wanna shoot some smallbore BR/F-Class with it.

Yeah the stock used to have a Sleeved Rem700 in it. Im going to machine up an adaptor plate to suit the Three 60 when it rocks up. Also means I dont have to bog it all up and re-inlet the stock either. I dont mind machining up a single shot adaptor for it really but if Mike has one in the works already with correct angles and alike, saves me alot of maths and machining time.I could get down with a single shot adapter for the 3 lug too!

Should be a fun lil project at any rate.

Is this feeding issue normally just in certain chassis? Or is it across the board depending on DBM used, etc? My Vudoo Three 60 will mainly live in a McMillan A5 with Badger M5 DBM.

Also Mike @RAVAGE88 is there any plans to make a single shot adaptor for the Three 60 action? Im going to drop mine into a spare McMillan LV/HV stock I have when/if I wanna shoot some smallbore BR/F-Class with it.

So far I've had a MDT ACC, Manners PRS-TCS, and XLR Envy. If you load the magazines correctly and pay attention when lining up the chassis with the action when installing it, I haven't had to do anything.

For MPA BA, I've had to deal with adjustable mag latch.

For ARC Xylo, I had to get a longer mag latch

But I haven't had to deal with much and this is across 3 Actions, gen1, 1.2, and gen 2.

My Vudoo V22 has the KRG stock and after reading SYS700's post, I did recall that feeding the cartidge from the mag was sometimes unreliable. This stock has no Vudoo bottom metal. I checked the mag fit ant it was kinda sloppy, so I followed Mike's recommendation and put some Velcro on the front surface of the mag. Now the slop is gone. Off to the range tomorrow to check it out.

I watched the video on mag feeding and am very particular about how each bullet is placed in the mag so that’s not the issue for me. Hopefully the fixes I made to the mag release will fix the issues I’m experiencing.Well - as it turns out if I am more careful with each round as I place it in the mag I don’t get any mis feeds

View attachment 7612130

I picked up my full Vudoo V22 build this past Thursday from my FFL. The rifle looks absolutely amazing and the quality is impeccable, however, I'm having some major bolt cycling issues with it:

The bolt doesn't feel very smooth in the action. Almost as though the paint inside the action is too thick. I have a Volquartsen Scorpion pistol that is very smooth, and I expected the same kind of smoothness. I tried some light oil, then a lot of oil, then tried removing most of the oil, tried a bit of grease, but still the same issue with the sticky feeling. Will this get smoother over time?

Within the hour I took it to my local range to sight in the scope. I had to do a double-take when it put 10 bullets through a hole at 25 yards, and had no trouble hitting a bullseye at 200 yards. However, after about 100 rounds I started having feeding issues where the bullets would smash up inside and not enter the bore, bending the bullet in the casing, denting the bullet. I had to pull the magazine to get the bent bullet out. I put a few hundred rounds of Midas+ through it, and got the scope zeroed, but after awhile I'd have to eject the magazine each time and waste a bullet.

I took it to the range again on Friday, and put another 400 rounds through it (mainly Midas+, SK Rifle, and tried some Wolf Match Extra and X-Act). I noticed right away that the Wolf and X-Act were sized differently. The primer rim was too wide in these rounds to fit the stock Vudoo mags. However, the X-Act seemed to be more accurate downrange. I ended up sticking with Midas+ and SK Rifle Match. When I got back home, I looked in the action and noticed metal shavings everywhere in there. An examination of the bullet casings showed that the casings themselves are being scraped somehow. This could have been the reason for the bolt action not being smooth. It's basically shaving metal off the bullets and casing! I cleaned it out, put a bit of oil on the bolt, and it seemed to cycle much more smoothly once I did that.

Saturday I took it to my first ever PRS match. Throughout the match my rifle would constantly jam, I'd have to eject a bullet, or eject the entire magazine and fiddle with putting another one in. This cost me time, and I wasn't able to finish several of the stages because of this (aside from the fact that a poor functioning rifle messes with your head).

I heard there are issues with Vudoo magazines and the MPA BA Comp chassis, but I'm not noticing the mags tilting at all. I watched this video and it looks like an adjustable mag release might solve the issue, but I question whether or not this is really the issue:

The magazines seem like they are in the magwell very snug and tight with only a bit of side to side play, no forward backward play. And if there were consistent issues with the BA Comp chassis, why wouldn't Vudoo ship them with the extended mag release as standard? What I am noticing is the bolt seems sticky when cycling it right before the bullet jams. It's not perfectly smooth. I can feel the bolt dragging on something. Any ideas what I could be doing wrong? I read that you can put some velcro on the mags to keep the mags from rotating, which I will try today and test it out again at the range. Any other things I can try to make this work? As is, I don't feel I can compete with this rifle (just way too many jams). Numerous people were also running Vudoos and they observed the same issues with my rifle. They tried it out, checking out the bolt, and offered some tips on the feeding issues, but advised sending the action back if these issues continue. I'm also wondering if I'm cycling the bolt incorrectly...not grabbing it at the correct position, not using enough force, or perhaps too much force.

Any advice would be much appreciated! I really love this rifle and would like to solve this!

Might also be an optical illusion but from the picture it looks like magazine is drooping in the back (towards the shooter). Definitely doesn't look horizontally lined up with the chassis.

The bottom of the Vudoo magazine is not parallel with the top. See photo:Might also be an optical illusion but from the picture it looks like magazine is drooping in the back (towards the shooter). Definitely doesn't look horizontally lined up with the chassis.

Attachments

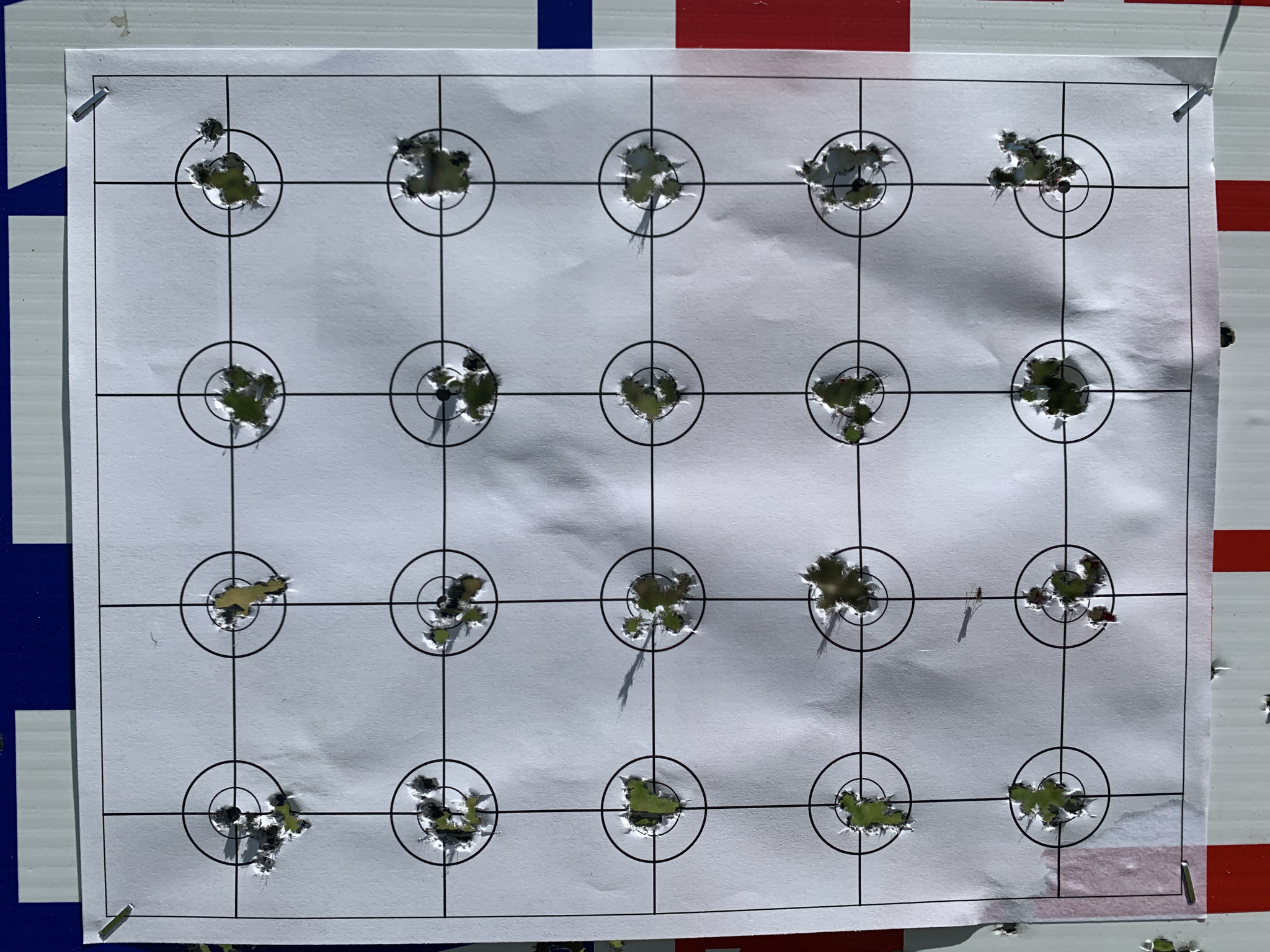

With the new Vudoo I have been trying to true data as I had something off for Saturdays match and could not hit a single plate at 100. I shot about 500 rounds on Sunday and I am getting somewhere finally. I re built the profile in the Kestrel and started over then did the Cal DSF at 201 yards. that was the distance at my head laying behind the rifle. I'm not 100% sure on where that distance should be bu either way I used it. the call was 7.8mil at 201. Actual was 7mil flat. I had 2 rounds on the 10 that hit the 1100FPS mark and went high. the other 8 were golden. Now I just need to stretch it out to 400 and verify that data.

Below is the 201 yard group and the 200 rounds at 50.

Shooting SK Rifle match 72* average was 1083, MAX 1104, MIN 1072, ES 32, SD 6.9. This was over 50 rounds. I shot 200 rounds with 4 - 50 shot strings across the MagnetoSpeed.

Below is the 201 yard group and the 200 rounds at 50.

Shooting SK Rifle match 72* average was 1083, MAX 1104, MIN 1072, ES 32, SD 6.9. This was over 50 rounds. I shot 200 rounds with 4 - 50 shot strings across the MagnetoSpeed.

The bottom of the Vudoo magazine is not parallel with the top. See photo:

Oops, I've been using my alu mags for too long. They're level.

With the new Vudoo I have been trying to true data as I had something off for Saturdays match and could not hit a single plate at 100. I shot about 500 rounds on Sunday and I am getting somewhere finally. I re built the profile in the Kestrel and started over then did the Cal DSF at 201 yards. that was the distance at my head laying behind the rifle. I'm not 100% sure on where that distance should be bu either way I used it. the call was 7.8mil at 201. Actual was 7mil flat. I had 2 rounds on the 10 that hit the 1100FPS mark and went high. the other 8 were golden. Now I just need to stretch it out to 400 and verify that data.

Below is the 201 yard group and the 200 rounds at 50.

Shooting SK Rifle match 72* average was 1083, MAX 1104, MIN 1072, ES 32, SD 6.9. This was over 50 rounds. I shot 200 rounds with 4 - 50 shot strings across the MagnetoSpeed.

View attachment 7612415View attachment 7612416

If you have a Kestrel Elite, the Center-X AB profile works for the SK Rifle Match, Standard +, etc ammo. Never need to DSF it. Just reset a new profile and use the Center-X Custom Curve profile. Make sure your atmospherics are current, and put in your velocity. I've done this across multiple rifles at different locations out to 400 yards and never needed to use DSF.

Also most important... make sure your 50yd zero is 100% solid, not .1 or .2 off. If your 2nd picture is your 50 yard groups I guess your zero is pretty decent, though the groups are a bit large.

Also check your bore height to make sure you're measuring it correctly. That can also throw a .1/.2 off at distance which will cause you to incorrectly true things.

I read you post for 2020 in the rimfire section about this as built another profile using that and my data. It lined up at 6.98 for 200 yards.If you have a Kestrel Elite, the Center-X AB profile works for the SK Rifle Match, Standard +, etc ammo. Never need to DSF it. Just reset a new profile and use the Center-X Custom Curve profile. Make sure your atmospherics are current, and put in your velocity. I've done this across multiple rifles at different locations out to 400 yards and never needed to use DSF.

Also most important... make sure your 50yd zero is 100% solid, not .1 or .2 off. If your 2nd picture is your 50 yard groups I guess your zero is pretty decent, though the groups are a bit large.

Also check your bore height to make sure you're measuring it correctly. That can also throw a .1/.2 off at distance which will cause you to incorrectly true things.

I am going to test it out farther this week to 400 and see if it needs adjusting but it looks spot on for now.

I have 3 Vudoo profiles. OG, V1 & V2

They are 10 shot groups at 50 instead of 5 shot. 5 shot groups were real tight. The circle is 1" outside ring and .5" inside ring.

Last edited:

Took my Vudoo to the range again today. A bit windy and cold but I was mainly testing out the action. After shooting around 300 rounds, I only experienced two jammed bullets.

Here's what I did to correct the feeding issues:

1) Removed most of the oil in the bolt. I had more than necessary, and I think it was resulting in issues due to tight tolerances.

2) Adjusted the magazine release catch so that it just lightly clicks and no forward/backward rotation

3) Switched out the stock Vudoo knob (I had both a medium and a large) for a Wallace Machine Works V2 knob. The shape of the new knob helps me grab the bolt at a consistent location and move it properly.

A couple of things I noticed: 1) although there is no more vertical play, there is still some side-to-side play with the magazine. If you have the magazine sitting at the extreme left and move it to the right, it can result in about a millimeter of bullet movement side to side. It's not much, but this could result in a misaligned bullet that catches slightly and then results in a jam. I'm going to add some velcro inside both sides of the mag well to prevent any side to side play. 2) I tried some Wolf Extra Match again and it fit the magazine perfectly, so ignore my previous comment about Wolf ammo not working well in these mags (although I didn't try every mag).

Here's what I did to correct the feeding issues:

1) Removed most of the oil in the bolt. I had more than necessary, and I think it was resulting in issues due to tight tolerances.

2) Adjusted the magazine release catch so that it just lightly clicks and no forward/backward rotation

3) Switched out the stock Vudoo knob (I had both a medium and a large) for a Wallace Machine Works V2 knob. The shape of the new knob helps me grab the bolt at a consistent location and move it properly.

A couple of things I noticed: 1) although there is no more vertical play, there is still some side-to-side play with the magazine. If you have the magazine sitting at the extreme left and move it to the right, it can result in about a millimeter of bullet movement side to side. It's not much, but this could result in a misaligned bullet that catches slightly and then results in a jam. I'm going to add some velcro inside both sides of the mag well to prevent any side to side play. 2) I tried some Wolf Extra Match again and it fit the magazine perfectly, so ignore my previous comment about Wolf ammo not working well in these mags (although I didn't try every mag).

Attachments

Last edited:

I'm due for a cleaning, but my round doesn't sit at that angle. From here when I push forward, it goes perfectly horizontal into a control-fed mechanism. I was actually trying to time the control-feed by pushing super slow and it popped up past the bolt face... that didn't work, but yeh the first picture is right before it pops up into control-feed. My round looks like it's going in at less steep angle than yours.

Finally have the saltwater camo manners stock I’ve been wanting!

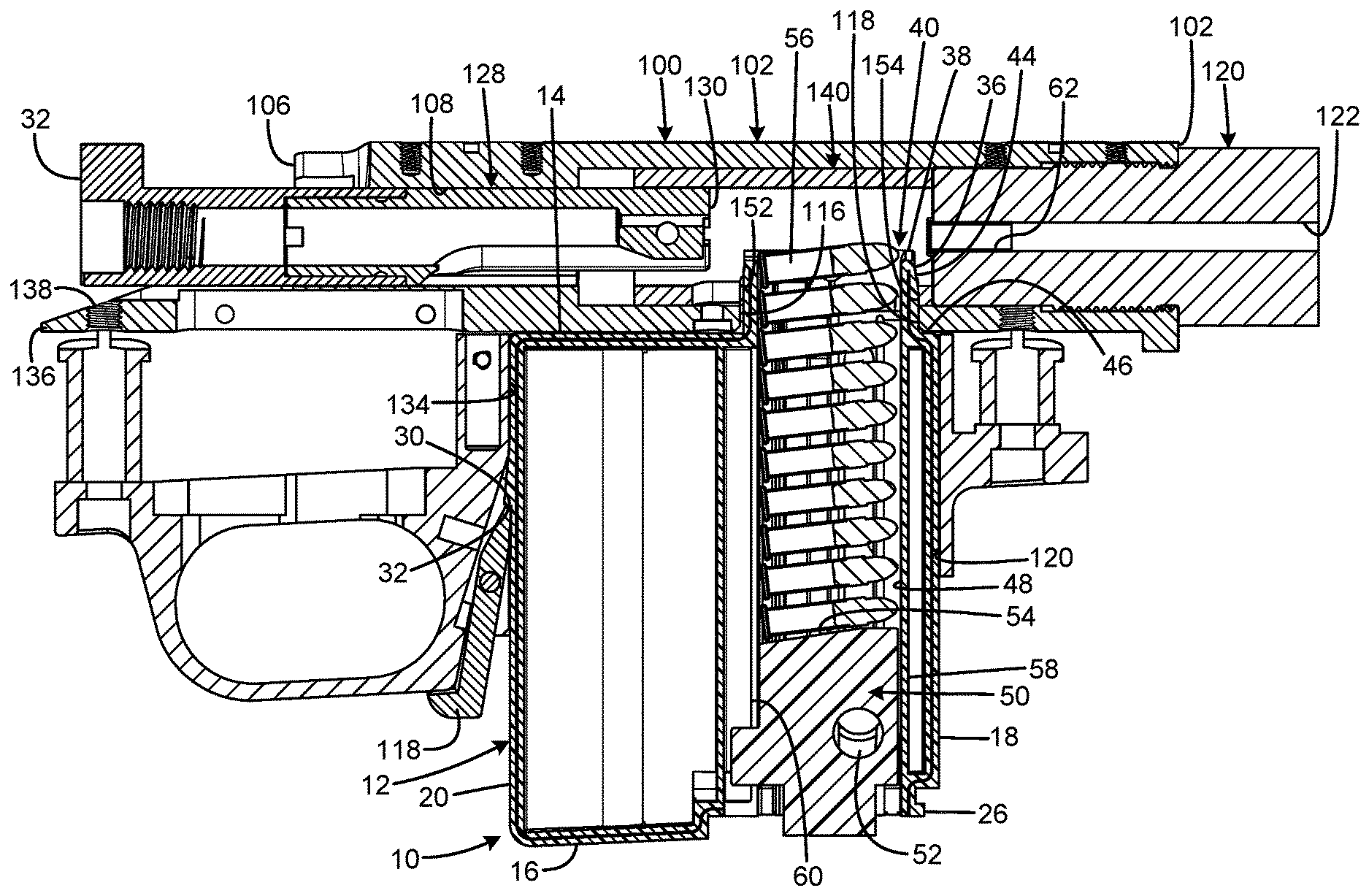

The patent for the original mags is interesting:Oops, I've been using my alu mags for too long. They're level.

"...the magazine tower having a front surface angled rearwardly with respect to the vertical plane of reference."

Ammunition Magazine Patent Application

U.S. Patent Application 20200064091 for Ammunition Magazine

uspto.report

uspto.report

Similar threads

- Replies

- 2

- Views

- 1K

- Replies

- 205

- Views

- 54K

- Replies

- 39

- Views

- 14K