That was smart to protect the trigger that way. Mine got damaged by ups on the return trip and I never got anything from the claim.1. I took the stock and scope off of the rifle and just sent them the barreled action, bolt and a magazine. I used plastic spacers (like 'pillars') to keep the trigger guard in place for shipping (to protect the actual TriggerTech Diamond trigger itself) and put it all in the original padded case that the complete gun came in from Vudoo, and used the original cardboard overbox.

2. I just purchased and printed my own shipping label off of UPS.com.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DeLane Development Group Rimfire Ventures

- Thread starter RAVAGE88

- Start date

That was smart to protect the trigger that way. Mine got damaged by ups on the return trip and I never got anything from the claim.

Thanks -- do you think it would be worthwhile to make them available with my other 3D-print items (https://www.snipershide.com/shootin...-mag-loader-tool-magazine-bench-tray.7100374/) ? I hadn't thought about other people maybe needing to use something like that.

That was smart to protect the trigger that way. Mine got damaged by ups on the return trip and I never got anything from the claim.

I ended up just putting packing peanuts around the trigger in the Vudoo box to keep it secure from vibration during shipping.

Thanks for the response!Purchase label from the shipper, which I do UPS and insure it for $2000.

I put my barreled action in the original Vudoo shipping boxes (the white one) and then the white one inside of a slightly larger cardboard one with some packing material.

Thanks for the response. I like using the trigger guard to protect the trigger.1. I took the stock and scope off of the rifle and just sent them the barreled action, bolt and a magazine. I used plastic spacers (like 'pillars') to keep the trigger guard in place for shipping (to protect the actual TriggerTech Diamond trigger itself) and put it all in the original padded case that the complete gun came in from Vudoo, and used the original cardboard overbox.

2. I just purchased and printed my own shipping label off of UPS.com.

Could be one of those things some may throw in the cart while they are at it if they are cheap enough.Thanks -- do you think it would be worthwhile to make them available with my other 3D-print items (https://www.snipershide.com/shootin...-mag-loader-tool-magazine-bench-tray.7100374/) ? I hadn't thought about other people maybe needing to use something like that.

I have several of your items and they work great. I would use the spacers.Thanks -- do you think it would be worthwhile to make them available with my other 3D-print items (https://www.snipershide.com/shootin...-mag-loader-tool-magazine-bench-tray.7100374/) ? I hadn't thought about other people maybe needing to use something like that.

I had to order the one time adjustable mag catch and then I was able to use the 15 round mag. Before the bolt would just glide over the top and not pick up a round unless I held the bottom of the mag.I am contemplating purchasing a KRG Bravo chassis for a Vudoo. Are there magazine seating issues, i.e. vertical play, rocking/rotational play, for the Vudoo 10 shot polymer mags or any of the Vudoo aluminum mags? If so, is there an effective remediation?

Thanks for any intel.

I have one on backorder and will post pics as soon as I get it.Anyone running the Vision KRG Hand Guard?

I dropped a Vudoo gen 2 BA into a Bravo and had zero issues. Yet to have a feed/extraction issue of any kind. I installed a Triggertech Diamond single stage and adjusted the pull and never had an issue with it either. I have only used the plastic 10 rd. magazines. Easy peasy!I am contemplating purchasing a KRG Bravo chassis for a Vudoo. Are there magazine seating issues, i.e. vertical play, rocking/rotational play, for the Vudoo 10 shot polymer mags or any of the Vudoo aluminum mags? If so, is there an effective remediation?

Thanks for any intel.

I know this is a lie, a blatant terrible lie at that!My best method is the best and highly recommended. I remove barrel, insert in vise. Pull out my 8" long x 2" thick penus. Roll my penus till it comes out tu be .223 Dia by 27" long. Lube penus with vagisil lubricant. Insert elongated penus into barrel, pump barrel with 50 strokes in and out. Pull out penus, clean carbon off penus. Penus takes two days to return to normal size. Go have a beer and potato chip. Done.

No one only eats 1 potato chip!

Lightweight rimfire-centerfire pair for positional shooting:

Both rifles:

Grayboe Phoenix Stock with two Tough Tactical Tools M-Lok ARCA rails

Bix’nAndy 2-Stage trigger with Gator shoe

Swarovski Z8i 1-8 x 24 scope with Innomount Picatinny to SR mount

Centerfire:

TL3 SA action with Proof Research Carbon Fiber 20”, 1:8 twist, Sendaro contour, 223 Rem barrel

Hawkins Precision M5 DBM bottom metal with Hawkins M5 DBM Long Latch

Accurate Magazine 5 round 223 Rem magazine

Rimfire:

Vudoo V22 Gen 3 with Bartlein Carbon Fiber 20”, 1:16 twist, Kukri contour, 22LR barrel

Vudoo DBM bottom metal

Vudoo Aluminum 5 round 22LR magazine

Centerfire weight: 9.5lb

Rimfire weight: 9.7lb

Both rifles:

Grayboe Phoenix Stock with two Tough Tactical Tools M-Lok ARCA rails

Bix’nAndy 2-Stage trigger with Gator shoe

Swarovski Z8i 1-8 x 24 scope with Innomount Picatinny to SR mount

Centerfire:

TL3 SA action with Proof Research Carbon Fiber 20”, 1:8 twist, Sendaro contour, 223 Rem barrel

Hawkins Precision M5 DBM bottom metal with Hawkins M5 DBM Long Latch

Accurate Magazine 5 round 223 Rem magazine

Rimfire:

Vudoo V22 Gen 3 with Bartlein Carbon Fiber 20”, 1:16 twist, Kukri contour, 22LR barrel

Vudoo DBM bottom metal

Vudoo Aluminum 5 round 22LR magazine

Centerfire weight: 9.5lb

Rimfire weight: 9.7lb

I don't think that dog has moved since you last posted a photo.

So latest issue with Vudoo. When mounted in the Manners Mini-chassis Gen 2, the mag does not sit high enough for the bolt to feed it. Is there a custom mag catch made for these? Don't have the same problem with hawkins BM, just in the Mini-chassis.

Hi,

That's odd, I've got mine in a TCS (with mini chassis of course) & have never had a problem... Which I realize helps you exactly zero.

Sincerely,

J-Ham

That's odd, I've got mine in a TCS (with mini chassis of course) & have never had a problem... Which I realize helps you exactly zero.

Sincerely,

J-Ham

So latest issue with Vudoo. When mounted in the Manners Mini-chassis Gen 2, the mag does not sit high enough for the bolt to feed it. Is there a custom mag catch made for these? Don't have the same problem with hawkins BM, just in the Mini-chassis.

Have had mine in nothing but Mini Chassis, both Gens, and never an issue. Did you try a different mag? There should be no issues with a Gen 2 Mini Chassis.

Contact manners and they’ll send you a longer mag latch. Had to do it with my .223 when using the polymer mags. Not every chassis is plug and play.So latest issue with Vudoo. When mounted in the Manners Mini-chassis Gen 2, the mag does not sit high enough for the bolt to feed it. Is there a custom mag catch made for these? Don't have the same problem with hawkins BM, just in the Mini-chassis.

Yea i have 2 of the poly mags and both sit too low to feed. I can push mag up from bottom.Have had mine in nothing but Mini Chassis, both Gens, and never an issue. Did you try a different mag? There should be no issues with a Gen 2 Mini Chassis.

No issues otherwise using accurate, AICS, ARC mags and also .223 Accurate mags with Impact action.

Yup yeah give Manners a call and see if they have another mag latch. Could also check with Vudoo about the mags to make sure no issues on those. Anyone around you have a Vudoo with mags you could try?

Yea they do but they all run foundations and not manners so they don't have the same issues. I actually have a LRH with the M5 Mini chassis with Hawkins BM and that works fine as well. I think its just the mini chassis gen 2 that beeds a new mag latch like you guys said.Yup yeah give Manners a call and see if they have another mag latch. Could also check with Vudoo about the mags to make sure no issues on those. Anyone around you have a Vudoo with mags you could try?

Just try a couple of their mags though to rule out the mags. As I said I have had mine in multiple mini chassis both Gen 1 and 2 and mags worked great. Know others also. Worth trying to make sure it’s not the mags and then you change the latch and it won’t work with other mags.

Awesome sauce!! Post pics!Mine shipped today. So stoked!!!

I wanted a heavy rig for support shooting so purchased a Foundation Centurion for a Vudoo with a 22" MTU barrel. The Centurion had a Vudoo action inlet and a Vudoo DBM bottom metal inlet. With Vudoo DBM bottom metal there should be no magazine fitment issues. There were none with five 5 round, one 10 round and one 15 round aluminum mag. However, there were with 10 round polymer mags. The action screws were torqued to 6.2Nm, the recommended value by Foundation. Only 8 of 25 of the 10 round polymer mags would lock but many of the others seemed very close. So I retorqued the action screws to 5.6Nm and 13 would lock. Finally I retorqued the action screws to 5.1Nm and all 25 locked. What is the dimensional difference due to the different torques? A few mils?

Is it technologically possible to have mil sized tolerances on polmer? Economically feasible for a product selling for $33?

The workaround was simple but expensive, four more 10 shot aluminum magazines. The added weight is no problem, perhaps a benefit for supported shooting. With a NF ATACR 7-35 x56F1, the total weight of the rig is 17.4lb. It is a brute.

Is it technologically possible to have mil sized tolerances on polmer? Economically feasible for a product selling for $33?

The workaround was simple but expensive, four more 10 shot aluminum magazines. The added weight is no problem, perhaps a benefit for supported shooting. With a NF ATACR 7-35 x56F1, the total weight of the rig is 17.4lb. It is a brute.

Have you added the front weights yet?I wanted a heavy rig for support shooting so purchased a Foundation Centurion for a Vudoo with a 22" MTU barrel. The Centurion had a Vudoo action inlet and a Vudoo DBM bottom metal inlet. With Vudoo DBM bottom metal there should be no magazine fitment issues. There were none with five 5 round, one 10 round and one 15 round aluminum mag. However, there were with 10 round polymer mags. The action screws were torqued to 6.2Nm, the recommended value by Foundation. Only 8 of 25 of the 10 round polymer mags would lock but many of the others seemed very close. So I retorqued the action screws to 5.6Nm and 13 would lock. Finally I retorqued the action screws to 5.1Nm and all 25 locked. What is the dimensional difference due to the different torques? A few mils?

Is it technologically possible to have mil sized tolerances on polmer? Economically feasible for a product selling for $33?

The workaround was simple but expensive, four more 10 shot aluminum magazines. The added weight is no problem, perhaps a benefit for supported shooting. With a NF ATACR 7-35 x56F1, the total weight of the rig is 17.4lb. It is a brute.

I'm running same setup / 22" mtu, nightforce ATACR with spuhr mount. With the front weight it's still rear heavy.

No issues with magazines but i am running Hawkins bottom with extended latch. I've added a 7" brass ARCA rail to the front for more balance.

I don't mind the extra weight or how heavy the rifle is.

My only chassis that was finicky with magazines was MPA. The foundation, XLR envy and cadex have zero issues regardless of magazine

@BadjujuuHave you added the front weights yet?

I'm running same setup / 22" mtu, nightforce ATACR with spuhr mount. With the front weight it's still rear heavy.

No issues with magazines but i am running Hawkins bottom with extended latch. I've added a 7" brass ARCA rail to the front for more balance.

I don't mind the extra weight or how heavy the rifle is.

My only chassis that was finicky with magazines was MPA. The foundation, XLR envy and cadex have zero issues regardless of magazine

No front weights, only the full length ARCA rail. I chose the light weight stock. Rifle is not noticeably rear heavy although balance not important since I do not do PRS/NRL22 shooting. The support will be a bench with a bipod and rear squeeze bag to do rapid shooting at 200yd at steel targets with diameters of 10", 5" and 3". Goal is 4 impacts on the 10" and 3 impacts on the other two within a minute. Something like KYL with a time constraint.

I agree with you about Hawkins M5 DBM bottom metal with extended latch. It can eliminate lock and feeding issues for both 22LR and 223 Rem mags in a variety of stocks.

Last edited:

@gillis2My set up as shown above ( with the dog in the background ) is Vudoo 360 in Foundation stock with Vudoo mag assembly. So far only tried the 5 round aluminum mag and no feeding issues.

Gilbert

Now have two samples of Foundation stock with Vudoo DBM inlet/bottom metal having no feeding issues with Vudoo aluminum mags.

Here's another sample of Foundation / Vudoo DBM with no feeding issues using 10rd polymer, 10rd aluminum, and 15rd aluminum mags. Action screws torqued to 50 in-lb.@gillis2

Now have two samples of Foundation stock with Vudoo DBM inlet/bottom metal having no feeding issues with Vudoo aluminum mags.

Nice, sounds interesting. I got the centurion from another member here so it's not the light weight option. Had I ordered from foundation directly I'd definitely go with that.@Badjujuu

No front weights, only the full length ARCA rail. I chose the light weight stock. Rifle is not noticeably rear heavy although balance not important since I do not do PRS/NRL22 shooting. The support will be a bench with a bipod and rear squeeze bag to do rapid shooting at 200yd at steel targets with diameters of 10", 5" and 3". Goal is 4 impacts on the 10" and 3 impacts on the other two within a minute. Something like KYL with a time constraint.

I agree with you about Hawkins M5 DBM bottom metal with extended latch. It can eliminate lock and feeding issues for both 22LR and 223 Rem mags in a variety of stocks.[/USER]

I'll try out your type of bench match. Sounds interesting.

I enjoy my rifles balanced so I'm not fighting them on barricades, but they do end up heavy which sucks in field type matches.

@BadjujuuNice, sounds interesting. I got the centurion from another member here so it's not the light weight option. Had I ordered from foundation directly I'd definitely go with that.

I'll try out your type of bench match. Sounds interesting.

I enjoy my rifles balanced so I'm not fighting them on barricades, but they do end up heavy which sucks in field type matches.

If my back allowed it, I would shoot in prone position. How many snipers shoot from a bench? But, in addition to being extremely uncomfortable, if I shot prone would have to visit a chiropractor on way home from the range.

My true love is standing, offhand shooting for which weight, balance and all other ergonomic factors plus smooth feeding, extraction and ejection are most important. Bench rest and all other supported shooting is a divertissement for me.

Last edited:

So to follow up on my issue with Eley brass getting stuck in the chamber - that is not even extracting - I have to take a knife to pop the stuck brass out of the chamber - I cleaned everything thoroughly as per VGW instructions - issue is still there.

It shoots Lapua flawlessly - shoots Norma (produced by RWS) flawlessly - but just doesn't want to extract the Eley.

What a bummer.

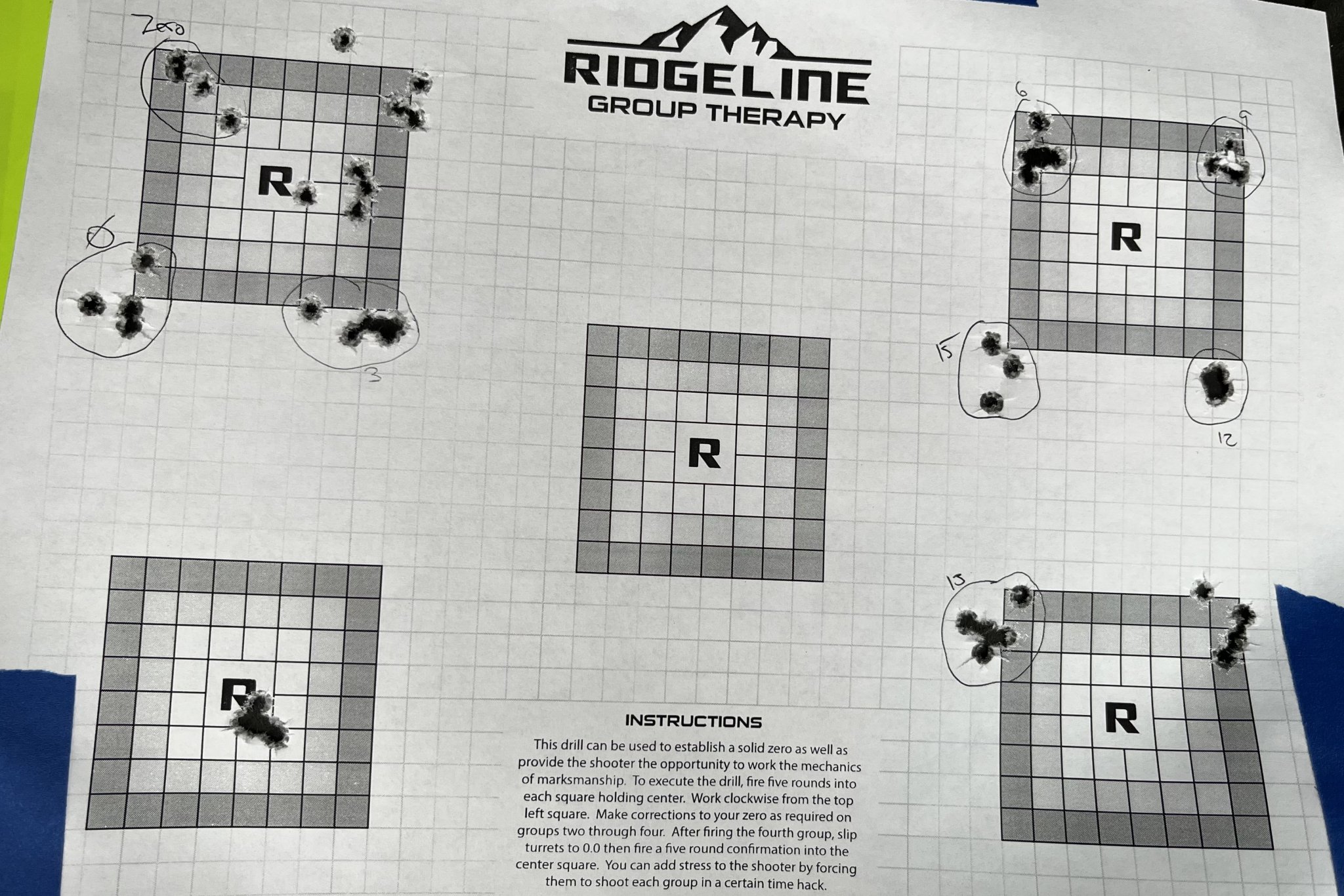

Using the EC tuner on a 22" MTU barrel and SK STD+ at 50 yards. I think it likes setting #12.

Using the EC tuner on a 22" MTU barrel and SK STD+ at 50 yards. I think it likes setting #12.

Definitely! Did you try additional groups with that setting?

Not really, the wind was really picking up. The bottom left target was the confirmation group after tightening the set screws. Then I proceeded to verify my dope for an upcoming match.Definitely! Did you try additional groups with that setting?

I would like to see how it does at 100 and 150. Been thinking about getting one.Not really, the wind was really picking up. The bottom left target was the confirmation group after tightening the set screws. Then I proceeded to verify my dope for an upcoming match.

NiceUsing the EC tuner on a 22" MTU barrel and SK STD+ at 50 yards. I think it likes setting #12.

Mostly buttoned up! Can't get enough height out of the Grayboe cheek piece so WeiBad to the rescue! Other than that I am pleased, tickled, and in awe of the Vudoo! Can't wait to send some rounds down range this weekend! Crappy photo on the kitchen counter...Awesome sauce!! Post pics!

Mostly buttoned up! Can't get enough height out of the Grayboe cheek piece so WeiBad to the rescue! Other than that I am pleased, tickled, and in awe of the Vudoo! Can't wait to send some rounds down range this weekend! Crappy photo on the kitchen counter...

View attachment 7813823

I have the same problem with cheek risers. It must be our Blue Steel cheek bones.

So serious question from an overly paranoid Vudoo owner...

Would y'all move that back ring further back or let it eat? The front one has to say where it is for eye relief reasons but would the gurus of the rimfire realm move it or no? Thank you for the input and let the flaming begin!

Would y'all move that back ring further back or let it eat? The front one has to say where it is for eye relief reasons but would the gurus of the rimfire realm move it or no? Thank you for the input and let the flaming begin!

I would move the rear ring back as far as possible.So serious question from an overly paranoid Vudoo owner...

Would y'all move that back ring further back or let it eat? The front one has to say where it is for eye relief reasons but would the gurus of the rimfire realm move it or no? Thank you for the input and let the flaming begin!

So serious question from an overly paranoid Vudoo owner...

Would y'all move that back ring further back or let it eat? The front one has to say where it is for eye relief reasons but would the gurus of the rimfire realm move it or no? Thank you for the input and let the flaming begin!

Curious, how tall are you? From the way it's setup with the scope as far forward as it is, seems like you're tall / have a very long neck.

Similar threads

- Replies

- 2

- Views

- 1K

- Replies

- 205

- Views

- 54K

- Replies

- 39

- Views

- 14K