A couple months back I did an impulse buy on a Bergara HMR-14 in 308. I already have more rifles than I can shoot, so it was the voices in me head.

Anyway, straight out of the box it was shooting two groups a couple inches apart from each other right and left. So I removed pant and texture overspray from the stock pillars and it helped some.

Then I discovered that the newly paint-free pillars had a slightly different radius contour than the bottom of the action. So I had to bed the action. This helped with some of my hand-loads.

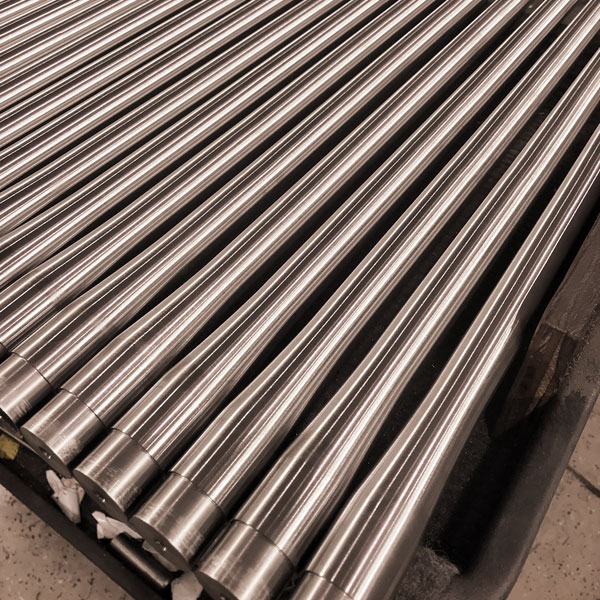

Then I had to lap the bore since it was rather rough and collected copper like a penny-bank.

Now I can obtain less than half MOA groups IF I let the barrel cool for a LONG, Long time.

The first two shots will go in the same hole or touch, but unless I wait forever, I end up with diagonal strings. Even with two or three minutes between shots.

The barrel is fully free floating. But the smallest change in temp makes it go nuts. Almost like it has some sort of stress.

These were some load experiments and not the best for this rifle, they are larger groups but they show what the rifle does when it is only slightly warm.

I have shot it with the factory radial brake ( which does nothing) and just the thread protector.

I am wondering if the cryo-freeze idea would work on this barrel.

I have tried:

150gr SMKs (Hates these)

168gr SMKs

175gr RDF Nosler ( likes these)

175gr Nosler Comp

175gr Hornady ELDX ( Really hates these)

180gr Accubonds ( likes these)

190gr SMKs, ( Likes these sometimes. )

For powders so far:

4064

RL-15

Benchmark

BLC2

3031

8280

H-4895

I ran out of Varget before I could progress much.

Anyway, straight out of the box it was shooting two groups a couple inches apart from each other right and left. So I removed pant and texture overspray from the stock pillars and it helped some.

Then I discovered that the newly paint-free pillars had a slightly different radius contour than the bottom of the action. So I had to bed the action. This helped with some of my hand-loads.

Then I had to lap the bore since it was rather rough and collected copper like a penny-bank.

Now I can obtain less than half MOA groups IF I let the barrel cool for a LONG, Long time.

The first two shots will go in the same hole or touch, but unless I wait forever, I end up with diagonal strings. Even with two or three minutes between shots.

The barrel is fully free floating. But the smallest change in temp makes it go nuts. Almost like it has some sort of stress.

These were some load experiments and not the best for this rifle, they are larger groups but they show what the rifle does when it is only slightly warm.

I have shot it with the factory radial brake ( which does nothing) and just the thread protector.

I am wondering if the cryo-freeze idea would work on this barrel.

I have tried:

150gr SMKs (Hates these)

168gr SMKs

175gr RDF Nosler ( likes these)

175gr Nosler Comp

175gr Hornady ELDX ( Really hates these)

180gr Accubonds ( likes these)

190gr SMKs, ( Likes these sometimes. )

For powders so far:

4064

RL-15

Benchmark

BLC2

3031

8280

H-4895

I ran out of Varget before I could progress much.