Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing What action wrench for a Tikka T3 barrel swap?

- Thread starter david walter

- Start date

External, and it has to grab it TIGHT. I used a generic piece originally intended for Savage actions that I got from Northland, and it worked well... but eat your Wheaties and expect to spend some time cussing at it, 'cause the factory barrels are, uh, snug.

External, and it has to grab it TIGHT. I used a generic piece originally intended for Savage actions that I got from Northland, and it worked well... but eat your Wheaties and expect to spend some time cussing at it, 'cause the factory barrels are, uh, snug.

Yes snug

Go ahead and get a few beers down before you start and send anyone away you don't want to hear every curse word in the book.

You'll probably come up with a few new ones before its over.

I use a Wheeler #1 external with a breaker bar to remove Tikka factory barrels the first time because they are so tight.

After that all you will need is an internal wrench to torque another shouldered prefit barrel on or off.

Be sure to use anti-seize on the threads and shoulder and check your headspace with a go-no go.

After that all you will need is an internal wrench to torque another shouldered prefit barrel on or off.

Be sure to use anti-seize on the threads and shoulder and check your headspace with a go-no go.

I use a Wheeler #1 external with a breaker bar to remove Tikka factory barrels the first time because they are so tight.

After that all you will need is an internal wrench to torque another shouldered prefit barrel on or off.

Be sure to use anti-seize on the threads and shoulder and check your headspace with a go-no go.

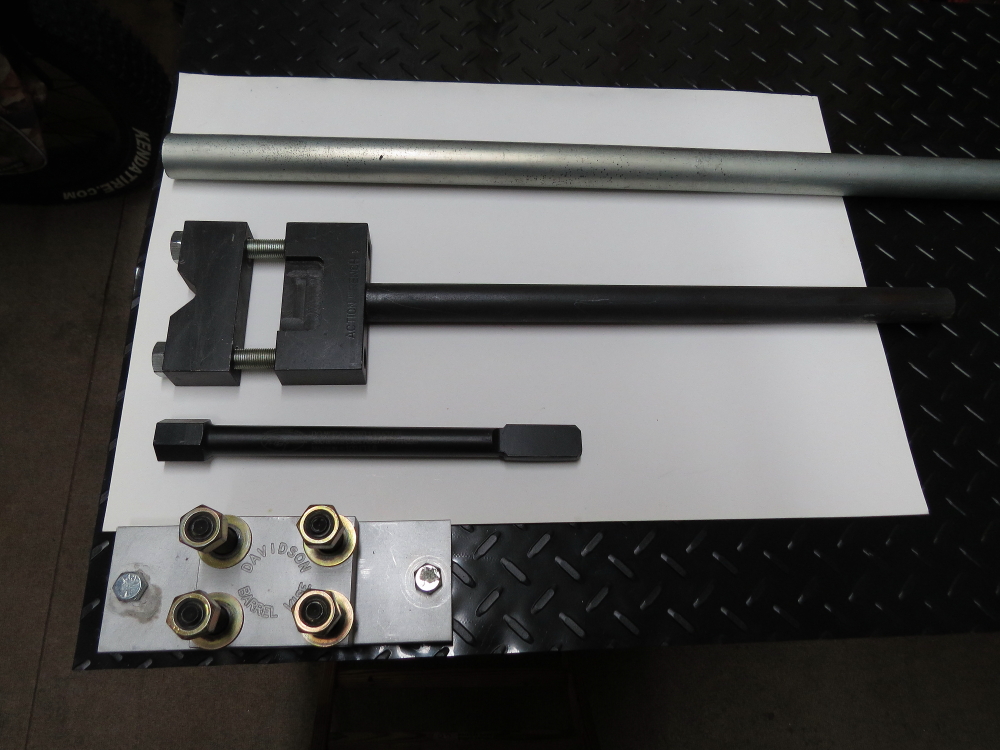

View attachment 7162965

I use the same external wrench. Clamp the barrel in some v-blocks and a phone book in the hydraulic press, give the wrench handle a good smack with a mall and they pop right off. It’s the shock that knocks them loose, not the static torque. Remember to clamp the wrench right up by the action/shoulder.

Interested in how the phone book plays into the scenario.

Two steel v blocks and a barrel. The phone book keeps the v blocks from marring up the barrel. Cheap easy and effective. Good use for that phone book no one uses any more, a Dennis Kirk or midway magazine works too lol. Once you get the Sako Finland tight barrel off you can resume using wood blocks, that first one is often toight.

Phone... book? Like, the user manual that came with my iPhone?

Yes, I'm joking.

Yes, I'm joking.

Stupid question but do you clamp the wrench on the top and bottom or the two sides of the action?I use the same external wrench. Clamp the barrel in some v-blocks and a phone book in the hydraulic press, give the wrench handle a good smack with a mall and they pop right off. It’s the shock that knocks them loose, not the static torque. Remember to clamp the wrench right up by the action/shoulder.

Stupid question but do you clamp the wrench on the top and bottom or the two sides of the action?

There’s a big flat on the bottom, match that to the flat on the wrench and let the v block do the rest of the work. Take the rail off if you have one on it.

You can flip the top plate on the wrench like in my pic and use top,bottom or sides.Stupid question but do you clamp the wrench on the top and bottom or the two sides of the action?

You can clamp the sides if you do not want to remove the rail.

I have a T3 that I want to pull the barrel off of. What’s the best action wrench?

Put it barrel down in a vise and shoot some Kroil into the action where the barrel threads in. Add Kroil every day for a week. Mine came loose and had Kroil halfway down the threads.

I use a Brownells steel barrel vise, 1.150" aluminum vice barrel collet, and lead sheet to make a perfect fit. A touch of powdered sugar to grip the barrel. Then I use a Brownells Universal action (outside the action) wrench. I've popped off 3 Tikkas and a Sako TRG this way. No problems, no damage to the barrels. I have put a thin piece of steel bar stock between the action wrench and the top of the Picatinny rail to prevent marring of the rail.

Well, I surprised myself and successfully removed my tikka barrel, now the wait for a new bugnut barrel.

Was it as bad as everyone makes it out to be? What did you end up using for a wrench, vise, etc.Well, I surprised myself and successfully removed my tikka barrel, now the wait for a new bugnut barrel.

Here's my story. I bought the viper barrel vice, the same outside action wrench (from Midway) as JGR1953 has shown in the above picture. And I bought an inside action wrech from southern precision rifle (bughole.com). I didn't mount the viper vice when i removed the barrel as I wasn't saving the barrel, so...

Step #1 I sprayed kroil inside of the action on the threads and let it soak for a week. Barrel down so the kroil would flow down the threads.

#2 I torqued the outside action wrench too the action (side to side not top and bottom) and I clamped the barrel into a small regular bench vice I had at home (don't flame me, I wasn't saving the barrel ) and tried giving the action wrench handle a couple of whacks but the vice wasn't strong enough to secure the barrel and it spun in the vice and didn't seem like it budge the action any. At this time I stopped and took the action/barrel to work were we have a large bench vice the next day, all the while the action wrench was still bolted too the action. I clamped the barrel in our work bench vice and on the first attempt of grabbing the action wrench handle the action just started to unscrew. So I stopped and removed the action wrench and just unscrewed the action by hand. Not sure if the previous whacks helped? But it didn't take too much effort to get it moving. If I intended on saving the barrel I might have tried with the viper vice. Now I have the proper tools to install the new barrel, viper vice, inside action wrench.

and didn't seem like it budge the action any. At this time I stopped and took the action/barrel to work were we have a large bench vice the next day, all the while the action wrench was still bolted too the action. I clamped the barrel in our work bench vice and on the first attempt of grabbing the action wrench handle the action just started to unscrew. So I stopped and removed the action wrench and just unscrewed the action by hand. Not sure if the previous whacks helped? But it didn't take too much effort to get it moving. If I intended on saving the barrel I might have tried with the viper vice. Now I have the proper tools to install the new barrel, viper vice, inside action wrench.

Step #1 I sprayed kroil inside of the action on the threads and let it soak for a week. Barrel down so the kroil would flow down the threads.

#2 I torqued the outside action wrench too the action (side to side not top and bottom) and I clamped the barrel into a small regular bench vice I had at home (don't flame me, I wasn't saving the barrel ) and tried giving the action wrench handle a couple of whacks but the vice wasn't strong enough to secure the barrel and it spun in the vice

31mm cheapo Tecktonik? box wrench with a cheater off Amazon did mine fine for $20. The nice PVA action wrench I bought first sheared long before the barrel broke even with heat, Kroil, freeze, etc. using a Brownells barrel vice.

Midway Magazine?...'Cause by the time you get them, the sale is already off? I do like their online sales in my email.Two steel v blocks and a barrel. The phone book keeps the v blocks from marring up the barrel. Cheap easy and effective. Good use for that phone book no one uses any more, a Dennis Kirk or midway magazine works too lol. Once you get the Sako Finland tight barrel off you can resume using wood blocks, that first one is often toight.

4”

4” Kurt. 6’ 4x4 . Tikka’s spin right off.

4” Kurt. 6’ 4x4 . Tikka’s spin right off.

Don't forget the Jorgensen F-clamp.4”View attachment 71725504” Kurt. 6’ 4x4 . Tikka’s spin right off.

My advise is, use an external action wrench to remove barrels (especially factory) and an internal action wrench to install them. Reason being, you'll likely need far more torque to remove a barrel than install one. An external action wrench will most effectively transfer the torque to the barrel tenon threads than a 8"-10" long internal action wrench. Flip side, when installing you will want to use a torque wrench - for that you'll need an internal action wrench.I got a Wheeler #1 action wrench, Mechforce barrel vise, and a Tikka inside wrench coming. I will be pulling a few barrels this weekend it looks like. I have a big C-type vice and a press so I could have made some V-blocks but I went ahead and grabbed the barrel vise anyhow.

I got a Wheeler #1 action wrench, Mechforce barrel vise, and a Tikka inside wrench coming. I will be pulling a few barrels this weekend it looks like. I have a big C-type vice and a press so I could have made some V-blocks but I went ahead and grabbed the barrel vise anyhow.

Which Tikka inside wrench? Mined twisted in half long before the barrel popped and that was after a week of Kroil and a MAP torch.

External action wrench to remove factory barrel - internal to install. That said, I'd recommend Bugholes action wrench (http://www.bugholes.com/product-p/t-bug-aw.htm). Greg is great to deal with, he recently built an Accuracy International/Badger M2008/2013 action wrench for me which I'll post on shortly. No better action wrench or customer service out there. @BugholesWhich Tikka inside wrench? Mined twisted in half long before the barrel popped and that was after a week of Kroil and a MAP torch.

That’s what the wheeler #1 is for.Which Tikka inside wrench? Mined twisted in half long before the barrel popped and that was after a week of Kroil and a MAP torch.

Last Tikka I pulled the barrel from, I just cut a relief groove. It came right off. Obviously not an option without a lathe.Tried most methods, failed on all and afraid I would distort the action. Took it to a gunsmith and picked it up the next day

Is it me or the camera angle that makes what's left of the barrel look angled? Especially from the thread side.Last Tikka I pulled the barrel from, I just cut a relief groove. It came right off. Obviously not an option without a lathe.

View attachment 7174230

View attachment 7174231

It's partially the camera angle, partly the way I cut it. I start the plunge slightly wider to allow the curl to not get caught up in the tight confines of the cut. In the first photo you can see the area of a slightly wider cut.

Hopefully this is the right place to ask. Now that I know what tools to use on a prefit barrel with a nut, how would you install say a proof research prefit carbon fiber barrel? I they call the barrels without a nut a shouldered barrel?

This is the way I do my carbon barrel but I'm sure others have their own way of doing it....Hopefully this is the right place to ask. Now that I know what tools to use on a prefit barrel with a nut, how would you install say a proof research prefit carbon fiber barrel? I they call the barrels without a nut a shouldered barrel?

You want to stay off the carbon wrap and just grip the steel shank.

My Davidsons vise is made like your Viper so I just cut and sandwich two pieces of leather on top and bottom and use just the two front bolts on the vise then I coat with powdered rosin.

Lock the barrel in and screw your action on and insert the internal wrench and use whatever ft/lbs of torque you want.

I use 65 to 70 ft/lbs on my Carbon6 per their recommendation and then check my headspace with my go/no go gauges.

Attachments

Ok guys. I pulled a factory barrel on a t3x ctr and a t3x lite. I was prepared for a battle considering all I read about Tikkas. I grabbed the barrel near the action with my mechforce barrel vice with the wheeler #1 action wrench on the action. I hit the handle with my hand and the wrench turned. I thought the barrel spun in the vice. Nope. The action broke loose and i unscrewed it by hand. I put the ctr in the vise next and hit the wrench with my palm again and it broke loose and the action spun off by hand.

I could have saved the $53 on the wheeler wrench and just used the Tikka inside wrench I have. Taking the factory scope base off the ctr proved just as easy. Screwdriver in the screw and turn. No heat required.

I could have saved the $53 on the wheeler wrench and just used the Tikka inside wrench I have. Taking the factory scope base off the ctr proved just as easy. Screwdriver in the screw and turn. No heat required.

Now that I thought about it for a minute, I wonder if the people having a hard time removing the barrels are the T3 models? As the barrel that wasn't too hard for me to remove was a T3X model? And I have no experience with a T3, Just thinking out loud.

Maybe so. Hopefully some other guys chime in. Both of mine were just a quick pop with my bare hand. No heat. No cheater. An inside wrench would have easily done the job.Now that I thought about it for a minute, I wonder if the people having a hard time removing the barrels are the T3 models? As the barrel that wasn't too hard for me to remove was a T3X model? And I have no experience with a T3, Just thinking out loud.

I read on another site somewhere where guys were making a big deal over the Tikkas and someone chimed in and said Tikkas where the easiest factory action to rebarrel. I figured he was talking tough until I unscrewed mine.

The guys at LRI told me the problem is that the T3 barrels are all over the place for torque, from 80 ft-lbs to 140. It’s like it depends on the person who was screening barrels on at the Tikka factory on whatever day.

LRI installs barrels at a consistent 100 Ft-Lbs.

LRI installs barrels at a consistent 100 Ft-Lbs.

I pulled the barrel off the carbon tikka t3x ctr. Same thing. A couple hits with my palm and the action broke loose.

Mechforce vise is$90 shipped. I recommend it. Throw the leather away as soon as you get it though. Wrap the barrel with a piece of paper. No marks even on the blued barrel.

Mechforce vise is$90 shipped. I recommend it. Throw the leather away as soon as you get it though. Wrap the barrel with a piece of paper. No marks even on the blued barrel.

I probably had a double wrap. I doubt it matters. Just put a couple wraps and bite down on it in the vice. No marks and did not slip.Wade2big-just a single wrap of note book paper? Just curious of the different methods.

i didnt have headspace gauges so I used the tape method and the headspace seemed to check out. I put the rifle in a led sled and tied down the front end. I used a long piece of para cord looped around the trigger and shot all of them from about 8’ back. Lol. All is good. ? I knew the led sled would be good for something.

ok, the "external" action wrench, that's the black thing with the two bolts (item #2 from top to bottom), right? you bolt that around your action (left and right sides)? almost doesn't look like it would go wide enough.I use a Wheeler #1 external with a breaker bar to remove Tikka factory barrels the first time because they are so tight.

After that all you will need is an internal wrench to torque another shouldered prefit barrel on or off.

Be sure to use anti-seize on the threads and shoulder and check your headspace with a go-no go.

View attachment 7162965

if not keeping the barrel, how about vising up the action and trying to spin the barrel with a pipe wrench?

a pic of that external action wrench with an action in it would be very helpful. thanks!

Similar threads

- Replies

- 1

- Views

- 77

- Replies

- 8

- Views

- 1K