I finally fixed my M2013/KRG W3 CIP setup. I'll try to keep this simple, here's what I've done over the last couple of years:

1: Reduce the vertical play with the longer mag catch that KRG sells. Just file, try, repeat until the magazine latches easily and sits up against the bottom of the aluminum backbone.

2: I moved the trigger guard/mag catch as far back as the chassis would allow. The forend needed to slide back to restore magazine fit. To get any additional rearward movement, I removed material from the grip panels because they can't move and they're cheap. The magazine now fit snugly and didn't rattle.

3: The feed ramp was still hanging over and hanging up rounds. I put a stripped magazine body in to look through and gauge how much movement was needed (.030"-.040"). The only issue was the mag cutout in the aluminum would not allow anymore rearward movement. Enter the Dremel...

4: I scribed some guide marks every .020" on the aluminum to gauge how much I removed. Using a carbide burr and a router guard on the Dremel, I did my best impression of a cnc mill. After removing half of the material needed, I test fit to make sure I wasn't over doing it and finally crept up on the final dimension.

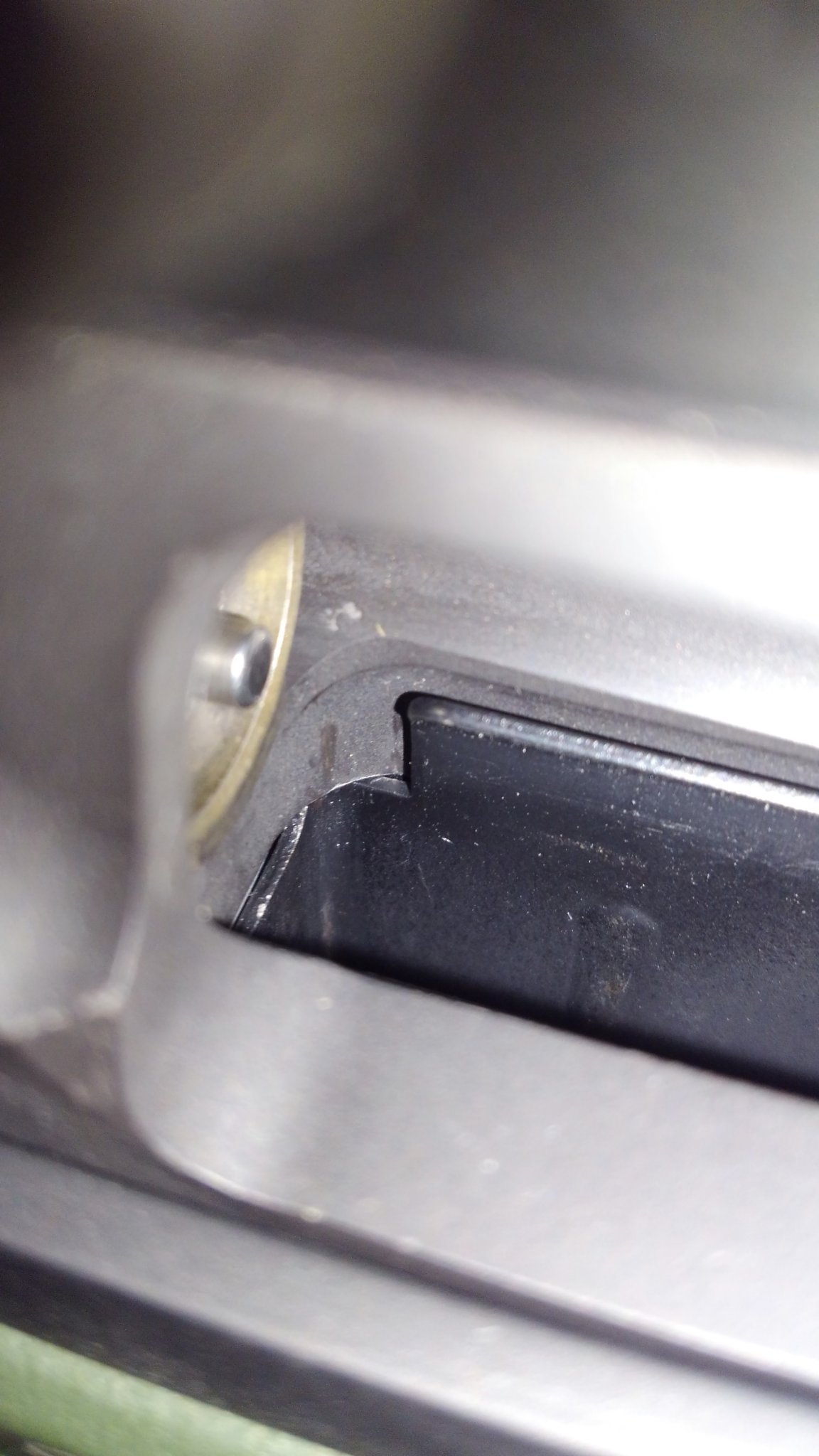

5: With the aluminum clearanced, the magazine could move rearward enough to where the bolt could still pick up a round and the feed ramp could not catch the tips of the rounds. The rear action screw is running out of clearance at this point and I needed to clearance the grip panels a bit more for the rear of the trigger guard. Here's the view from inside a stripped magazine body.

6: With the extra rearward movement of the trigger guard, the magazine fit is loose again. Not wanting to slide the forend back anymore because the plastic was flush at the front of the chassis, I decided to modify the Non-CIP magwell spacer that KRG includes. I figured this would take up the extra space and also get rid of the unsightly open space in front of the magazine. Using a magazine wrapped in sandpaper, I sanded the area where the magazine rides, while not touching the edges that lock into the plastic forend. After getting the fit right, I bolted everything together and Dremeled the spacer to match the bevel on the magwell. The spacer doesn't seem to snag on magazines, but I'm thinking about using a little epoxy on the seam to smooth it out. I've also opened up the action screw hole in the plastic for better access.

Here's a couple other pics:

Some assembly required

1: Reduce the vertical play with the longer mag catch that KRG sells. Just file, try, repeat until the magazine latches easily and sits up against the bottom of the aluminum backbone.

2: I moved the trigger guard/mag catch as far back as the chassis would allow. The forend needed to slide back to restore magazine fit. To get any additional rearward movement, I removed material from the grip panels because they can't move and they're cheap. The magazine now fit snugly and didn't rattle.

3: The feed ramp was still hanging over and hanging up rounds. I put a stripped magazine body in to look through and gauge how much movement was needed (.030"-.040"). The only issue was the mag cutout in the aluminum would not allow anymore rearward movement. Enter the Dremel...

4: I scribed some guide marks every .020" on the aluminum to gauge how much I removed. Using a carbide burr and a router guard on the Dremel, I did my best impression of a cnc mill. After removing half of the material needed, I test fit to make sure I wasn't over doing it and finally crept up on the final dimension.

5: With the aluminum clearanced, the magazine could move rearward enough to where the bolt could still pick up a round and the feed ramp could not catch the tips of the rounds. The rear action screw is running out of clearance at this point and I needed to clearance the grip panels a bit more for the rear of the trigger guard. Here's the view from inside a stripped magazine body.

6: With the extra rearward movement of the trigger guard, the magazine fit is loose again. Not wanting to slide the forend back anymore because the plastic was flush at the front of the chassis, I decided to modify the Non-CIP magwell spacer that KRG includes. I figured this would take up the extra space and also get rid of the unsightly open space in front of the magazine. Using a magazine wrapped in sandpaper, I sanded the area where the magazine rides, while not touching the edges that lock into the plastic forend. After getting the fit right, I bolted everything together and Dremeled the spacer to match the bevel on the magwell. The spacer doesn't seem to snag on magazines, but I'm thinking about using a little epoxy on the seam to smooth it out. I've also opened up the action screw hole in the plastic for better access.

Here's a couple other pics:

Some assembly required

Last edited: