Guys need a longer knob for my cz455 as factory one sucks and barely clears the scope.

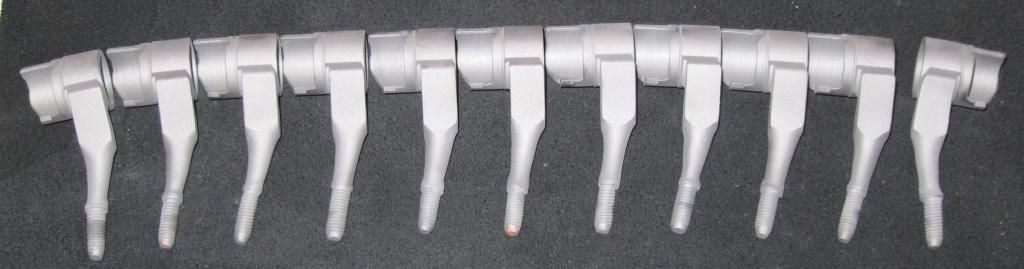

Lots of smiths do bolt knobs, problem is that half of the knobs are kind of hack-jobs. GAP/TacOps/Karl/RD do a great job on remmy knobs buuuuut what about CZ????

Here is an example of beautiful work; CZ452 Bolt Knob Conversion - Varmint Rifles & Heavy Plinkers - UK Varminting

someone out there must be doing CZ's ??

Lots of smiths do bolt knobs, problem is that half of the knobs are kind of hack-jobs. GAP/TacOps/Karl/RD do a great job on remmy knobs buuuuut what about CZ????

Here is an example of beautiful work; CZ452 Bolt Knob Conversion - Varmint Rifles & Heavy Plinkers - UK Varminting

someone out there must be doing CZ's ??