I shot some SIG Elite Hunter 130 grain tipped ammo in my SP10. This factory ammo has nickel plated cases. It shot real well and feeds well. Is there any downside to running nickel plated cases through an AR?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Will nickel plated cases scratch chamber or feed ramps in AR10?

- Thread starter rmiked

- Start date

A FEED ramp will tend to show wear [scratches] if you shoot the weapon often ...even if they were made of plastic .

The nickel is harder than your chamber. Any slivers shaved off have the potential to leave minor scratches in chambers or reloading dies.

Reloading dies are hardened steel, much harder than your barrel and any tiny pieces of nickle from case processing, such as trimming or a flake of the nickel plating chipped off will scratch the hell out of your FL sizing die, causing you to have to lightly polish it.

I never run nickel cases.

You'll notice them harder to size and more spring back.

Reloading dies are hardened steel, much harder than your barrel and any tiny pieces of nickle from case processing, such as trimming or a flake of the nickel plating chipped off will scratch the hell out of your FL sizing die, causing you to have to lightly polish it.

I never run nickel cases.

You'll notice them harder to size and more spring back.

Yes, it's ruined.I shot some SIG Elite Hunter 130 grain tipped ammo in my SP10. This factory ammo has nickel plated cases. It shot real well and feeds well. Is there any downside to running nickel plated cases through an AR?

So I checked out the scientific scratch rate scale of nickel vs steel, which turns out to be the same...resulting in sharp tiny pieces of nickel able to lightly scratch steel as it wears to dull the sharp nickel edges.

So sharp nickel edges can have an effect on steel.

If you use nickel cases, make sure they are clean, free of nicks, burrs, and sharp edges.

Brass IS softer, and will not scratch unless it has picked up something hard that gets embedded in the brass case, like maybe grit from primer residue.

Clean smooth cases and clean chambers might be the key.

So sharp nickel edges can have an effect on steel.

If you use nickel cases, make sure they are clean, free of nicks, burrs, and sharp edges.

Brass IS softer, and will not scratch unless it has picked up something hard that gets embedded in the brass case, like maybe grit from primer residue.

Clean smooth cases and clean chambers might be the key.

You realize the cases are nickel PLATED brass right? The plating, as thin as it is, can't be much harder than it's substrate. In fact, one could argue based on its lower coefficient of friction that nickel is actually less abrasive than brass.So I checked out the scientific scratch rate scale of nickel vs steel, which turns out to be the same...resulting in sharp tiny pieces of nickel able to lightly scratch steel as it wears to dull the sharp nickel edges.

So sharp nickel edges can have an effect on steel.

If you use nickel cases, make sure they are clean, free of nicks, burrs, and sharp edges.

Brass IS softer, and will not scratch unless it has picked up something hard that gets embedded in the brass case, like maybe grit from primer residue.

Clean smooth cases and clean chambers might be the key.

FFS, I can't even tell if some of these threads are for real or just a joke.

I challenge the OP to shoot 4k rounds of nickel plated in one gun then 4k of brass in another then compare feed ramp condition.

Except it won't matter because the throat will be toast in both of them. People seem to forget barrels are like tires. You use them, they die, you install new ones.

I shot some SIG Elite Hunter 130 grain tipped ammo in my SP10. This factory ammo has nickel plated cases. It shot real well and feeds well. Is there any downside to running nickel plated cases through an AR?

That guys still around spreading fuddlore?Yeah, well Ron Spoomer said...

He's king of the Fudds. Sometimes I'll feel my disgust for humanity beginning to recede, and I'll go look at his latest article, and I'm right back to normal.That guys still around spreading fuddlore?

agree!!!!! I was going to jump in but I've been too 'argumentative' lately lolYou realize the cases are nickel PLATED brass right? The plating, as thin as it is, can't be much harder than it's substrate. In fact, one could argue based on its lower coefficient of friction that nickel is actually less abrasive than brass.

FFS, I can't even tell if some of these threads are for real or just a joke.

I challenge the OP to shoot 4k rounds of nickel plated in one gun then 4k of brass in another then compare feed ramp condition.

Except it won't matter because the throat will be toast in both of them. People seem to forget barrels are like tires. You use them, they die, you install new ones.

couple of things of late; reading is fundamental, common sense is lacking, people post for attention and don't you dare condemn a board favorite company

lol

You make some great points. I realize it’s nickel plating over a brass case. There are some articles where guys claim they have damaged reloading dies so that all subsequent brass gets scratched until they polish out the dies. I am just now getting set up to reload 6.5 Creedmoor. I am collecting spent brass from factory ammo fired thru my newer SP10, mostly Hornady. I only have 149 rounds thru my rifle. I would not pay extra to buy nickel plated brass. But this SIG factory ammo is the best performing factory ammo I have shot. After reading the article about scratching the reloading dies, I just thought I would ask here with all the experience on this site. I appreciate your response.You realize the cases are nickel PLATED brass right? The plating, as thin as it is, can't be much harder than it's substrate. In fact, one could argue based on its lower coefficient of friction that nickel is actually less abrasive than brass.

FFS, I can't even tell if some of these threads are for real or just a joke.

I challenge the OP to shoot 4k rounds of nickel plated in one gun then 4k of brass in another then compare feed ramp condition.

Except it won't matter because the throat will be toast in both of them. People seem to forget barrels are like tires. You use them, they die, you install new ones.

I've loaded hundreds, probably over a thousand, but definitely hundreds of nickel plated cases. They are more likely to stick in a die if not well lubed. Beyond that I've never had a problem. The necks seem to crack after fewer firings than plain brass and eventually the plating wears through/off. I've not encountered any die scratching but I wouldn't argue with someone who had.You make some great points. I realize it’s nickel plating over a brass case. There are some articles where guys claim they have damaged reloading dies so that all subsequent brass gets scratched until they polish out the dies. I am just now getting set up to reload 6.5 Creedmoor. I am collecting spent brass from factory ammo fired thru my newer SP10, mostly Hornady. I only have 149 rounds thru my rifle. I would not pay extra to buy nickel plated brass. But this SIG factory ammo is the best performing factory ammo I have shot. After reading the article about scratching the reloading dies, I just thought I would ask here with all the experience on this site. I appreciate your response.

Do you anneal? Ever try it on nickle brass?I've loaded hundreds, probably over a thousand, but definitely hundreds of nickel plated cases. They are more likely to stick in a die if not well lubed. Beyond that I've never had a problem. The necks seem to crack after fewer firings than plain brass and eventually the plating wears through/off. I've not encountered any die scratching but I wouldn't argue with someone who had.

Just the science, the nickel plating is still all nickel, and has the hardness of nickel.You realize the cases are nickel PLATED brass right? The plating, as thin as it is, can't be much harder than it's substrate. In fact, one could argue based on its lower coefficient of friction that nickel is actually less abrasive than brass.

FFS, I can't even tell if some of these threads are for real or just a joke.

I challenge the OP to shoot 4k rounds of nickel plated in one gun then 4k of brass in another then compare feed ramp condition.

Except it won't matter because the throat will be toast in both of them. People seem to forget barrels are like tires. You use them, they die, you install new ones.

It could be fine nickel dust, any sharp corners would tend to be a problem until they are rounded off, rubbing against equally hard steel surface.

Let's do a test I have the stuff...

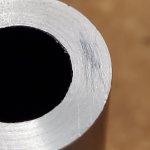

Pictured 45-70 barrel, nickel case rubbed across it's surface, scratches the face of the barrel steel, and it's not particularly sharp...notice it even breaks down the sharp edges of the rifle barrels steel, as the case head goes off the edge of the barrel.

Attachments

Nope. Not that kinda handloader.Do you anneal? Ever try it on nickle brass?

Definitely made me curious. Just tried the same thing. Got a couple nickel plated cases, some barrels, some dies, my bench vise. Went to town trying to scratch things. They all showed what appeared to be scratches but it all wiped right off with my finger. Looked at my finger. It was shiny. Looked at the cases, they are missing plating anywhere I rubbed them hard on my test surfaces. I remain unconvinced that nickel plating poses any danger to barrel steel.Just the science, the nickel plating is still all nickel, and has the hardness of nickel.

It could be fine nickel dust, any sharp corners would tend to be a problem until they are rounded off, rubbing against equally hard steel surface.

Let's do a test I have the stuff...

Pictured 45-70 barrel, nickel case rubbed across it's surface, scratches the face of the barrel steel, and it's not particularly sharp...notice it even breaks down the sharp edges of the rifle barrels steel, as the case head goes off the edge of the barrel.

Your plated cases must be a hell of a lot tougher than any I have here, I can't manage to damage anything with them.

Things can be too smooth to work. Like trying to slide 2 glass panes across each other. Surface tension is tied to surface area, somebody smarter than me alluded to.I've loaded hundreds, probably over a thousand, but definitely hundreds of nickel plated cases. They are more likely to stick in a die if not well lubed. Beyond that I've never had a problem. The necks seem to crack after fewer firings than plain brass and eventually the plating wears through/off. I've not encountered any die scratching but I wouldn't argue with someone who had.

Yeah that was my best guess as to why they stick harder in dies.Things can be too smooth to work. Like trying to slide 2 glass panes across each other. Surface tension is tied to surface area, somebody smarter than me alluded to.

Does he still hate the new flash in the pan chambering, 6.5CM? It'll die out any day now and you'll see he was right. Just wait.He's king of the Fudds. Sometimes I'll feel my disgust for humanity beginning to recede, and I'll go look at his latest article, and I'm right back to normal.

Yes, working on a microscopic level. It's why its nice if bolts are fluted, it's all about reducing friction. Nickel cases are nice, sure, but we did fine without it so far. I wonder if anyone sat around debating if they would have survived, succeeded, or won the match if only their shit was nickel plated?Yeah that was my best guess as to why they stick harder in dies.

Some where, some one has considered it, just because people are that retarded.I wonder if anyone sat around debating if they would have survived, succeeded, or won the match if only their shit was nickel plated?

To be clear, all my experience with nickel cases is because they pick up off the range floor the same as brass does. Not because I care either way about any of the perceived pros/cons of them.

My case wasn't missing any nickel off the rim, plus it dinged the sharp edge of the barrel steel as seen, actually cutting into it, very slightly.Definitely made me curious. Just tried the same thing. Got a couple nickel plated cases, some barrels, some dies, my bench vise. Went to town trying to scratch things. They all showed what appeared to be scratches but it all wiped right off with my finger. Looked at my finger. It was shiny. Looked at the cases, they are missing plating anywhere I rubbed them hard on my test surfaces. I remain unconvinced that nickel plating poses any danger to barrel steel.

Your plated cases must be a hell of a lot tougher than any I have here, I can't manage to damage anything with them.

It does not rub off and I can feel the scratches with my nail.

As one can clearly see the scratches in the barrel steel, made by the rim of a new nickel 222 case.

Pretty much as the science says.

Just the facts,... believe what you like.

Use what you like.

Attachments

I don't see an edge worn down. I can also see stuff that would catch your nail all the way around from where the barrel was cut.

A riffle barrel especially in a AR platform is considered a "consumable / easily replaceable item" If you are shooting enough ammo especially nickel platted ammo to cause damage / wear out your barrel then you can easily afford to replace the barrel when the time comes.

A while back when Russian steel cased ammo was cheap and readily available, I got into a debate with this guy about steel cased ammo wearing out barrel chambers quicker than brass cased ammo. I told him the money you can save shooting steel cased vs brass cased far outweighed the money to replace a AR15 barrel even with the little bit of tools it takes to do it.

A while back when Russian steel cased ammo was cheap and readily available, I got into a debate with this guy about steel cased ammo wearing out barrel chambers quicker than brass cased ammo. I told him the money you can save shooting steel cased vs brass cased far outweighed the money to replace a AR15 barrel even with the little bit of tools it takes to do it.

I kid you not I know a few ar owners that do not shoot theirs because they are afraid of wear BUT they are nut jobs over cleaning them and i mean nut jobs . Kinda like the next door neighbor that has the new corvette or harley that is cleaner than when it left the factory ,has a bunch of lic um stik um add ons but still the same gas in the tank and never leaves the heated/cooled carpeted garage . My AK 's are propped up in the closet against the wall each has a loaded 30 rounder [empty chamber] ,they see the range 2 times a month they get the bore cleaned and a little look over .....when the piston looks like a chia pet it gets a deeper cleaning and 60 year old white auto chassis grease . They could care less what you feed them probably for years and years

In a DI AR the entire upper area, chamber and barrel extension gets covered in carbon. Add a lubricant

and you have abrasive soup. Worrying about Nickel cases is pointless the only issue with them is reloading.

If you are concerned about wear on your AR put it in a display case and never shoot it.

and you have abrasive soup. Worrying about Nickel cases is pointless the only issue with them is reloading.

If you are concerned about wear on your AR put it in a display case and never shoot it.

None so blind as those who will not see!I don't see an edge worn down. I can also see stuff that would catch your nail all the way around from where the barrel was cut.

It's not the circular pattern, (and you know it) , caused by cutting action. .. It's the scratches back and forth, and when the nickle case rim slides over the edge it takes a small chunk of steel with it, as clearly seen, by anyone with even fair eyesight.

And the circular pattern of the cut would act as a tiny file on the barrel steel, but it was scratched buy the nickel plated rim instead, of cutting into the nickel plating on the case rim.

Amazing how many guys on this site deny the obvious. They won't believe what they see, and make phony excuses, on many levels, not just on this.

Logical reasoning, and critical thinking have evaporated.

It's the science of metallurgy, I actually investigated it...then actually did the experiment, in real time.

Kind of a lost cause, but maybe one ot two will appreciate it.

The 2+2 = 5 crowd ...if it makes you "feel" better... then, that's "your" answer!

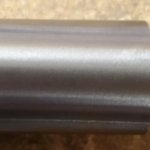

So I went to town on this junker McGowan barrel with a nickle plated case trying to scrath this ss barrel with the rim of the case. You can see the nickle stuck in the machine marks.

Then wiped it with rem oil. You can still see all the ridges on the machine marks.

Then I went again.

Wiped it off.

And

And still didn't even scratch the machine marks.

Then wiped it with rem oil. You can still see all the ridges on the machine marks.

Then I went again.

Wiped it off.

And

And still didn't even scratch the machine marks.

Took some nickle off the case. LoL

The "those who refuse to see" bullshit is funny because I was about to tell you to get you eyes checked since you missed it was the machine marks and not the "scratches" that caught you finger. But I figured I would out "science" you instread of making fun of you.

Then I did it to the side of an SS barrel. After a wipe down you can see the marks, you can't feel them. I woukd have to take the barrel off to put it under my microscope, but as a rule. If I can't feel it. I am not worried about it. I went up and down about 30 times on the barrel.like a kid scribbling on a peice a paper. Not just a couple passes.

The "those who refuse to see" bullshit is funny because I was about to tell you to get you eyes checked since you missed it was the machine marks and not the "scratches" that caught you finger. But I figured I would out "science" you instread of making fun of you.

Then I did it to the side of an SS barrel. After a wipe down you can see the marks, you can't feel them. I woukd have to take the barrel off to put it under my microscope, but as a rule. If I can't feel it. I am not worried about it. I went up and down about 30 times on the barrel.like a kid scribbling on a peice a paper. Not just a couple passes.

Attachments

Last edited:

Pretty much as the science says.

Just the facts,... believe what you like.

Use what you like.

I'm not "denying" or "refusing to see" anything. Instead of just arguing with you, since you seem to feed off of that, I went and did the same test. Then I posted my results. They exactly mirror those of @supercorndogs . Your test gave you very different results that I can't replicate, and I wasn't there to see it, and your pictures aren't exactly of amazing quality, so I'm just going to keep on believing exactly what my "science" showed me and you're free to do you.Amazing how many guys on this site deny the obvious. They won't believe what they see, and make phony excuses, on many levels, not just on this.

Logical reasoning, and critical thinking have evaporated.

It's the science of metallurgy, I actually investigated it...then actually did the experiment, in real time.

Kind of a lost cause, but maybe one ot two will appreciate it.

The 2+2 = 5 crowd ...if it makes you "feel" better... then, that's "your" answer!

This whole thread reminds me of people that buy things to use and enjoy but worry too much about harming or the resale value of said item and don't even get the use out of it for the reason they bought it in the first place.

I dated a girl in college whose father was so anal about putting miles on the vehicles they had it was almost abnormal. They lived in Fayetteville, NC and her grandparents lived in Charleston, SC her dad would make her mom take an Amtrak train to Charleston to visit her parents because he didn't want her mom putting miles on the new Ford Expedition they had at the time. So basically, a 3hr drive vs a 6hr by the time it's said and done train ride......

I dated a girl in college whose father was so anal about putting miles on the vehicles they had it was almost abnormal. They lived in Fayetteville, NC and her grandparents lived in Charleston, SC her dad would make her mom take an Amtrak train to Charleston to visit her parents because he didn't want her mom putting miles on the new Ford Expedition they had at the time. So basically, a 3hr drive vs a 6hr by the time it's said and done train ride......

I'm surprised you didn't cut that barrel in half with that nickle plated brass case and all that rubbing...or start a fire!So I went to town on this junker McGowan barrel with a nickle plated case trying to scrath this ss barrel with the rim of the case. You can see the nickle stuck in the machine marks. View attachment 8390712

Then wiped it with rem oil. You can still see all the ridges on the machine marks.

View attachment 8390711

Then I went again.

View attachment 8390716

Wiped it off.

View attachment 8390718

And

View attachment 8390719

And still didn't even scratch the machine marks.

New York times will melt it for sure.I wanna use newspaper as a case ,will they leave burn marks in my chamber , its an M 177 ?

I’m gonna go hammer some 45 colt brass into a 303 chamber to see how bad it fuggs it up. Be back soon

Last night I annealed some LC nickel 5.56 brass. With the black coating it was hard to see the annealing but it sized just fine and I didn’t measure any spring back. Going to shoot it today and see how it does.Do you anneal? Ever try it on nickle brass?

Last edited:

Damn! It took a 2 pound sledge to jam that case in the chamber. I think it messed something up. In conclusion, nickel plated brass is bad for your gun

I've loaded hundreds, probably over a thousand, but definitely hundreds of nickel plated cases. They are more likely to stick in a die if not well lubed. Beyond that I've never had a problem. The necks seem to crack after fewer firings than plain brass and eventually the plating wears through/off. I've not encountered any die scratching but I wouldn't argue with someone who had.

That's because of the process of electroplating the brass with the nickel, it makes the brass slightly more brittle than if it were not electroplated. not really anything to worry about

The main reason nickel brass is used is factory defensive ammo and factory hunting ammo, where the ammunition may be stored in "less than ideal conditions" for an extended period before use, so it acts as a corrosion/tarnish resistant coating to prevent the rounds from giving top performance when called on.Some where, some one has considered it, just because people are that retarded.

To be clear, all my experience with nickel cases is because they pick up off the range floor the same as brass does. Not because I care either way about any of the perceived pros/cons of them.

my opinion is that you're probably better off using regular brass for reloading because it will have a longer lifespan, and small flakes of nickel plating can cause cases to stick in dies if not properly lubricated. Not because of scratching or other bullshit, just by causing extra friction

Nickel brass cases are probably worth considering if you're making ammo you want to endure the elements until you need it (example: hardcast pig/bear/predator defense loads, etc) but I would also advise using sealant on those and coated projectiles as well!

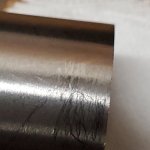

Took a new SS unchambered McGowen barrel, same Rem 222 nickel case rim, over the nicer finish, more like a chamber finish.

Where the muzzle brake thread will be added.

It scratches my McGowen SS barrel, but to a lesser extent the the Marlin steel barrel.

It does not wipe off with solvent sn a wet patch.

Any visible interruptions in the grain structure or grain pattern is a scratch. This would have to be technically remachined on a high tech manufacturing facility as the finish is out of print...

This could be easily polished, but sometimes polishing is not allowed, in manufacturing of certain products.

In conclusion, only my barrel steel, from the same manufacturer, can be scratched, by my nickel cases. ..typical.

Where the muzzle brake thread will be added.

It scratches my McGowen SS barrel, but to a lesser extent the the Marlin steel barrel.

It does not wipe off with solvent sn a wet patch.

Any visible interruptions in the grain structure or grain pattern is a scratch. This would have to be technically remachined on a high tech manufacturing facility as the finish is out of print...

This could be easily polished, but sometimes polishing is not allowed, in manufacturing of certain products.

In conclusion, only my barrel steel, from the same manufacturer, can be scratched, by my nickel cases. ..typical.

Attachments

I loaded and fired then annealed sized and fired several of the same LC nickel plated black 5.56 cases Saturday & Sunday. Never had any issues. It would seem that the nickel cases might need 0.1 more grains of Ramshot TAC to get back in the velocity node for that gun with 77 grain TMKs.I mixed a bunch of 280 plain and nickle plated brass after I was told the nickle plated was harder to size. I couldn't tell the diffrence between them. I seem to remember the two needing diffrent charge weights.

The primer pockets were fine and so were the necks of each case. I didn’t see any unusual residue when I cleaned the chamber & barrel.

I've been intentionally shooting and loading a batch of Lapua cases, and a batch of nickel cases, (.308) Specifically because I had heard this and wanted to find out for myself. I feel like I don't have enough data yet to draw any conclusions.

Also, I do nickel plating myself as well on many different things for people. There are a lot of variables to take into account. You can almost just dip a case slowly in and slowly out and it's going to come out looking just like a nickel plated case. Nickel and brass are about the best bonding metals to each other. Usually you'll brass plate something before you nickel plate over the top. There are 3 different common ways to do it and I could see where doing something like electro less plating could actually degrade case life. Again I don't have enough data to prove that. It's just speculation.

I'm actually playing around with plating just the primer pocket/ case rim area on some of my ADG brass for my 7-300 PRC to see if its a feasible way to restore some life into a bunch of cases that are still in really good shape otherwise. My thought was if I was just missing like a half to a thou of clearance I could probably make up that difference safely and structurally.

Final thought, I've been doing all kinds of gun parts. Magazines, slides, guide rods, firing pins....etc... and had very good results. These parts are heavily contacting each other and sliding under load on each other without any indications of bad wear. To clarify, I'm aware that's not apples to apples as those parts are not being expanded under 50,000psi and then resized. I'm just pointing out that pistols are regularly plated with Nicole for it's superior corrosion resistance and natural lubricating properties.

Aaaaannnndddd ... I'm done.

Also, I do nickel plating myself as well on many different things for people. There are a lot of variables to take into account. You can almost just dip a case slowly in and slowly out and it's going to come out looking just like a nickel plated case. Nickel and brass are about the best bonding metals to each other. Usually you'll brass plate something before you nickel plate over the top. There are 3 different common ways to do it and I could see where doing something like electro less plating could actually degrade case life. Again I don't have enough data to prove that. It's just speculation.

I'm actually playing around with plating just the primer pocket/ case rim area on some of my ADG brass for my 7-300 PRC to see if its a feasible way to restore some life into a bunch of cases that are still in really good shape otherwise. My thought was if I was just missing like a half to a thou of clearance I could probably make up that difference safely and structurally.

Final thought, I've been doing all kinds of gun parts. Magazines, slides, guide rods, firing pins....etc... and had very good results. These parts are heavily contacting each other and sliding under load on each other without any indications of bad wear. To clarify, I'm aware that's not apples to apples as those parts are not being expanded under 50,000psi and then resized. I'm just pointing out that pistols are regularly plated with Nicole for it's superior corrosion resistance and natural lubricating properties.

Aaaaannnndddd ... I'm done.

I don’t shoot nickel plating because it’s white and privileged. I paint all my brass red green yellow and violet to be equitable.

Similar threads

- Replies

- 0

- Views

- 212

- Replies

- 0

- Views

- 111

- Replies

- 33

- Views

- 4K

- Replies

- 5

- Views

- 1K