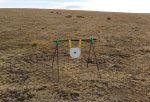

Is there anything that you guys can recommend for a relatively small/light/portable swinging target stand.

I know there are some old threads of target stands, but it seems most are commercial options or welded one piece options. I carry everything in my car, not a truck, so one piece options are a no-go. Also preferably something that doesn't need to be hammered into the ground.

Currently I use 2 stakes with a piece of rebar in between them. They are connected with PVC piping elbows. The advantages is that it work OK and when broken up Its as easy as carrying a bunch of metal rods and a bag of connectors. But the disadvantages are that its hard to hammer spike into hard ground(sometimes close to impossible) and that the entire fixture starts to come apart after X amount of shots. I can provide some pictures, but its really not the best setup.

I'm sure someone out there has thought of something more clever and useful

I know there are some old threads of target stands, but it seems most are commercial options or welded one piece options. I carry everything in my car, not a truck, so one piece options are a no-go. Also preferably something that doesn't need to be hammered into the ground.

Currently I use 2 stakes with a piece of rebar in between them. They are connected with PVC piping elbows. The advantages is that it work OK and when broken up Its as easy as carrying a bunch of metal rods and a bag of connectors. But the disadvantages are that its hard to hammer spike into hard ground(sometimes close to impossible) and that the entire fixture starts to come apart after X amount of shots. I can provide some pictures, but its really not the best setup.

I'm sure someone out there has thought of something more clever and useful

Last edited: