Yes, I saw significant ES/SD drop when switching from flame to AMP in both my 6.5cm and 6GT loads. Lapua and Alpha brass specifically. I assume its better neck tension control, as nothing else was changed.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Low Cost Annealers

- Thread starter MMH

- Start date

And they would be wrong in that case. Its ok though, no one is perfect.Look, I know you're an AMP fanboy, but dude just wants to know if annealing will help him/her with case neck cracking. If they wanted PhD level knowledge on metallurgy, they'd go take a college course. Don't make it more complicated than needed.

Below, straight up from AMP themselves (the makers of your god tier annealer), if you're looking for a low cost annealer, they recommend a gas flame based option.

https://www.ampannealing.com/articles/52/salt-bath-annealing--does-it-work-/

View attachment 8405248

Got any data to back that up? or you gonna stick with "trust me it works"Yes, I saw significant ES/SD drop when switching from flame to AMP in both my 6.5cm and 6GT loads. Lapua and Alpha brass specifically. I assume its better neck tension control, as nothing else was changed.

I may as well counter and say my limited testing showed no improvement.

SD calcs imply (require) the existence data ...Got any data to back that up? or you gonna stick with "trust me it works"

Got any data to back that up? or you gonna stick with "trust me it works"

I may as well counter and say my limited testing showed no improvement.

Got any data to back that up? or you gonna stick with "trust me it don't work"

Flame annealing lowered my SD/ES and Im seeing consistent groups but not smaller ones. I have no data to back that up.

Exactly. I dont record every shot I take. My loads before the amp were around 6-8 SD/ES. Post AMP I am around 3-4.

This wont show up unless you are shooting small targets far away, but its does add up to points gained over a season. To me, That matters.

This wont show up unless you are shooting small targets far away, but its does add up to points gained over a season. To me, That matters.

EXACTLY MY POINTGot any data to back that up? or you gonna stick with "trust me it don't work"

Flame annealing lowered my SD/ES and Im seeing consistent groups but not smaller ones. I have no data to back that up.

For starters 6-8 SD or ES? it can't be both.Exactly. I dont record every shot I take. My loads before the amp were around 6-8 SD/ES. Post AMP I am around 3-4.

This wont show up unless you are shooting small targets far away, but its does add up to points gained over a season. To me, That matters.

How many rounds is this over?

What is your sample size?

Don't forget I asked for legitimate testing.

I don’t know why this is so hard to figure out. Surely someone has done some unbiased testing on this and translated it to English so that a second grader can understand it?

I am far too dumb to understand all this science; I shoot a nail gun for a living.

I just want to know if flame annealing will make my brass last more firings without the necks cracking.

It seems like the only people saying you have to buy an AMP are

1) the people selling an AMP

2) the people who already bought an AMP

That’s a bit of a red flag to my uneducated little brain….but maybe they are right.

Ok you PHDs and people who took a college class about metal can go back to your internet fight now.

Partner it's NOT difficult to understand at all . Do You run your nail gun dry or do You lube with inline air ?. Do You think running a nail gun would benefit from Lube ?. See it's NOT difficult at all .

Regardless of method used to heat the cartridge case's neck and shoulder ,BENEFITS BRASS LIFE Period .

The faster and more direct one does it at temperature near 1200-1300 Deg. F. or a dull orange glow ,the BETTER .

Just remember REGARDLESS OF METHOD USED , NO one is actually annealing their brass ,the BEST you can achieve is restoring ductility !.

AKA softening or removing brittleness from shoulder ,neck of said cartridge cases .

I would be willing to wager Major Monies on the Conclusive Tests that George Vander Voort performed on Cartridge Brass .

Please be My guest and send in a sample of each of YOUR cases of various manufactures to have them scanned etched and cut and YOU to will know exactly the property of said manufacturers Brass stock .

I don't know about anyone else but when I want a definitive answer to a specific question , I DON'T look to some ass clown on the Boob Tube to answer it . I prefer to consult EXPERTS !. So George just happens to be one of the Worlds Leading Authorities ,so George or Boob you Tube ?.

What is Metallography?

Metallography is the study of the microstructure of all types of metallic alloys. It can be more precisely defined as the scientific discipline of observing and determining the chemical and atomic structure and spatial distribution of the grains, constituents, inclusions or phases in metallic alloys. By extension, these same principles can be applied to the characterization of any material.

Different techniques are used to reveal the microstructural features of metals. Most investigations are carried out with incident light microscopy in brightfield mode, but other less common contrasting techniques, like darkfield or differential interference contrast (DIC), and the use of color (tint) etching are expanding the scope of light microscopy for metallographic applications.

Many important macroscopic properties of metallic materials are highly sensitive to the microstructure. Critical mechanical properties, like tensile strength or elongation, as well as other thermal or electrical properties, are directly related to the microstructure. The understanding of the relationship between the microstructure and macroscopic properties plays a key role in the development and manufacture of materials and is the ultimate aim of metallography.

Metallography, as we know it today, owes much to the contribution of the 19th century scientist Henry Clifton Sorby. His pioneering work with modern manufactured iron and steel in Sheffield (UK) highlighted this intimate bond between the microstructure and macroscopic properties. As he stated towards the end of his life: "In those early days, if a railway accident had occurred and I had suggested that the company should take up a rail and have it examined with the microscope, I would have been looked upon as a fit man to send to an asylum. But that is what is now being done ..."

Annealing makes so many people go full retard...I truly don't understand it.

It was invented buy guys basically using candles...Annealing is understood to have been discovered as a heat treatment in the Middle Ages, around the 12th century. The word likely originated from the Middle English term “anelen”, meaning to set on fire or to bake.

Being a complete idiot, I anneal with flame after every firing, especially with gas gun brass. I see how much easier it is to size cases and have what I sense as more consistent seating of bullets. My very limited testing showed me that my annealing also results in lower SD's. But mine is not enough to really qualify as it is such a small sample size.

I do know that if some internet ASSCLOWN tells me I'm full of shit for thinking my annealing is helping in any way, well, that particular internet ASSCLOWN can run it in his ass... Just sayin'

I do know that if some internet ASSCLOWN tells me I'm full of shit for thinking my annealing is helping in any way, well, that particular internet ASSCLOWN can run it in his ass... Just sayin'

LOL. Do you just go around believing everything, everyone says on forums?This isn't a point.

SD. ES tightened up as well but i dont remember numbers off the top of my head. I think my ES is around 12-15 with the 3.5SD loads. Thats a .04gr spread and the difference between about a kernal or 2 of H4350.For starters 6-8 SD or ES? it can't be both.

How many rounds is this over?

What is your sample size?

Don't forget I asked for legitimate testing.

Over hundreds of shots of each. I dont even start to trust SD/ES until I have already 30 shots to measure. I ran the Andiscan so the whole barrel break in had a chrono attached, as well as whenever I zero and verify dope before a match.

Believe it , don't believe it, I dont really give a shit. My goal was never to placate people on here and spoon feed them all my data. Its just observation over many thousands of rounds.

The point you are trying to make is sloppy.LOL. Do you just go around believing everything, everyone says on forums?

Last edited:

I have not annealed brass before and want to start. What are some decent low cost annealers?

Alternatively, I got all of the parts for a DIY annealer (Elfster's) following this youtube:

Anybody use this DIY annealer?

Take a look at the Annie induction annealer

What is the point of even mentioning that it lowered your ES/SD if you don't want to share the numbers to back it up?SD. ES tightened up as well but i dont remember numbers off the top of my head. I think my ES is around 12-15 with the 3.5SD loads. Thats a .04gr spread and the difference between about a kernal or 2 of H4350.

Over hundreds of shots of each. I dont even start to trust SD/ES until I have already 30 shots to measure. I ran the Andiscan so the whole barrel break in had a chrono attached, as well as whenever I zero and verify dope before a match.

Believe it , don't believe it, I dont really give a shit. My goal was never to placate people on here and spoon feed them all my data. Its just observation over many thousands of rounds.

Sharing those numbers would be much more effective at conveying your point than calling people stupid and spouting off about brass alloy's which I'm sure you are very educated on.

It sounds like you may actually have some numbers of value, if you've got several 30 round strings of each where the SD was 3.5 vs 8 in AMP vs flame annealed that would be compelling to say the AMP does in fact work better. (not sure I believe it but that doesn't matter)

The point you are trying to make is sloppy.

SD calcs imply (require) the existence data ...

You are absolutely essential to this conversation.repeat.

I DGAF if you want to pick a fight bwith DBDM,You are absolutely essential to this conversation.

but don't shit up the thread

with illogical 'witticisms'...

carry on...

Something of interest to those of you who may need to know . Where Your Brass comes from IF YOU'RE buying domestic Brass ,regardless of manufacturer .

http://www.ahgp.org/inter-mt/united-states-smelting-refining-mining-company.html

Now as for say Alpha Brass , CS26000 Cold Rolled plate or HO2 aka 1/2 hard 70/30 cartridge brass .

I know their supplier and who smelts it . Yet that isn't gonna come out of ME ,so Don't ask !. I believe they're on this site and will tell you IF they want anyone to know .

Just as a frame of reference : When I started working before batching for Hercules , I did Drilling & blasting work in nearly every copper strip pit gold marble granite mine in AZ. UT. NV. and CA. as well as . I also batched dynamite which supplied Union Carbide at Pine Creek Mine outside Bishop ,CA. . Being the only other employee at the plant with a class 1 license ,occasionally required my delivering 40K lb. of 2x16 80% Niro industrial gel up too that mine . With an old Pete aka Peterbuilt . So hot one summer I broke down outside Adelanto ,CA. the tires left 4" impressions in the asphalt . CHP came by reported Me down . NO cell phones back in those days or phones out there for that matter and couldn't leave the truck .

It was 126 Deg. F. when I finally pulled out of that hell hole . Try slipping chains on drivers at 6 Deg. F. at 5800 Ft. snowing as never before seen and the mine sets at 11,000 Ft. ! . Failure to chain up at lookout Pt. ,you'll never do it again !!!. Boy the things a guy will do for money

https://www.mtnmouse.com/california/sng11_pine_creek_mine_story_blog.html

http://www.ahgp.org/inter-mt/united-states-smelting-refining-mining-company.html

Now as for say Alpha Brass , CS26000 Cold Rolled plate or HO2 aka 1/2 hard 70/30 cartridge brass .

I know their supplier and who smelts it . Yet that isn't gonna come out of ME ,so Don't ask !. I believe they're on this site and will tell you IF they want anyone to know .

Just as a frame of reference : When I started working before batching for Hercules , I did Drilling & blasting work in nearly every copper strip pit gold marble granite mine in AZ. UT. NV. and CA. as well as . I also batched dynamite which supplied Union Carbide at Pine Creek Mine outside Bishop ,CA. . Being the only other employee at the plant with a class 1 license ,occasionally required my delivering 40K lb. of 2x16 80% Niro industrial gel up too that mine . With an old Pete aka Peterbuilt . So hot one summer I broke down outside Adelanto ,CA. the tires left 4" impressions in the asphalt . CHP came by reported Me down . NO cell phones back in those days or phones out there for that matter and couldn't leave the truck .

It was 126 Deg. F. when I finally pulled out of that hell hole . Try slipping chains on drivers at 6 Deg. F. at 5800 Ft. snowing as never before seen and the mine sets at 11,000 Ft. ! . Failure to chain up at lookout Pt. ,you'll never do it again !!!. Boy the things a guy will do for money

https://www.mtnmouse.com/california/sng11_pine_creek_mine_story_blog.html

I have not annealed brass before and want to start. What are some decent low cost annealers?

Alternatively, I got all of the parts for a DIY annealer (Elfster's) following this youtube:

Anybody use this DIY annealer?

that's awesome... man, it's been that long since i made that video already!?!? time goes by wayyyy to fast!

yeah, there is a reason why we developed the EP 2.0 annealer over the DIY model in the above quoted video I made years ago. #1 it will adjust from 5.7x27 to 50bmgs, rim or no rim, and adjust in less than 30 seconds without having to add or remove any parts. It is purely based in the KISS method and its hard to explain until you use the simplicity of the EP 2.0 annealer.... Also, there is a reason there is no hopper = IMO a hopper is not needed... Why? If we are talking a case feeder, then maybe yes.... but a hopper is not a case feeder. Regardless if you're using a hopper or single feeding a fence like the EP 2.0 annealer, you still need to pick up the brass, orientate the brass in a particular direction, and feed the hopper or single feed fence. A hopper doesn't make the process of annealing faster. If 1 pc of brass takes 6 seconds to be annealed, then hopper or no hopper it still takes 6 seconds. By the time I orientate brass in the right direction, fill up a hopper, and swap out parts, I'm already 1/4 of the way into annealing with the EP 2.0 annealer. All you're doing is filling up a hopper and its not like you can go mow the grass while you have a flame running in your reloading room anyway. On average it might take approx ~6 seconds per anneal x 100pcs of brass = 600 seconds = 10 minutes of your reloading process per 100pcs = not that much time in the reloading process. Now a case feeder would be a whole different story where you are throwing in handful of brass and the machine does all of the work, but this makes it very difficult to do when it comes to the adjustability of the EP 2.0 annealer from 5.7x28 to 50 bmg, rim or no rim, = once again = KISS (keep it simple stupid). $239.99 gets ya everything you need to anneal other than the propane tank... there is a ton more info here too www.epintegrations.com

with that said, i actually talked to the guys with AMP at the last shot show and had a wonderful conversation with them... and not naming names, but 1 of the 2 actually told me if you would like to start with annealing, then "if you want to anneal and dabble with it flame annealing is the right way to go" & "there is no debate that you can or can not anneal with a flame, if you can melt the case with a flame then at some point you can anneal with it"... I'll agree that the AMP is a wonderful product and obviously produces an amazing anneal as mentioned in the video link below, but not everyone has $1675+ to drop on an annealer..... personally i like to use the "glow method" and using "test brass" to set up my flame based annealers = quick and simple and 100% will notice a more consistent headspace bump when testing resizing with bump gauges from pc to pc of brass resized & can be tested for a consistent bump.

anyone that has tried to bump back stubborn lake city brass (especially 7.62x51) with and without annealing will KNOW that annealing defiantly helps with the resizing process 100%... not only does annealing help with cracked necks and just better brass longevity, but IMO the #1 reason why I anneal is for more consistent headspace bumps.

this is how i use ANY flame based annealer & how it get it going and set up in approx a min using test brass... hope this helps

Last edited:

that's awesome... man, it's been that long since i made that video already!?!? time goes by wayyyy to fast!

yeah, there is a reason why we developed the EP 2.0 annealer over the DIY model in the above quoted video I made years ago. #1 it will adjust from 5.7x27 to 50bmgs, rim or no rim, and adjust in less than 30 seconds without having to add or remove any parts. It is purely based in the KISS method and its hard to explain until you use the simplicity of the EP 2.0 annealer.... Also, there is a reason there is no hopper = IMO a hopper is not needed... Why? If we are talking a case feeder, then maybe yes.... but a hopper is not a case feeder. Regardless if you're using a hopper or single feeding a fence like the EP 2.0 annealer, you still need to pick up the brass, orientate the brass in a particular direction, and feed the hopper or single feed fence. A hopper doesn't make the process of annealing faster. If 1 pc of brass takes 6 seconds to be annealed, then hopper or no hopper it still takes 6 seconds. By the time I orientate brass in the right direction, fill up a hopper, and swap out parts, I'm already 1/4 of the way into annealing with the EP 2.0 annealer. All you're doing is filling up a hopper and its not like you can go mow the grass while you have a flame running in your reloading room anyway. On average it might take approx ~6 seconds per anneal x 100pcs of brass = 600 seconds = 10 minutes of your reloading process per 100pcs = not that much time in the reloading process. Now a case feeder would be a whole different story where you are throwing in handful of brass and the machine does all of the work, but this makes it very difficult to do when it comes to the adjustability of the EP 2.0 annealer from 5.7x28 to 50 bmg, rim or no rim, = once again = KISS (keep it simple stupid). $239.99 gets ya everything you need to anneal other than the propane tank... there is a ton more info here too www.epintegrations.com

with that said, i actually talked to the guys with AMP at the last shot show and had a wonderful conversation with them... and not naming names, but 1 of the 2 actually told me if you would like to start with annealing, then "if you want to anneal and dabble with it flame annealing is the right way to go" & "there is no debate that you can or can not anneal with a flame, if you can melt the case with a flame then at some point you can anneal with it"... I'll agree that the AMP is a wonderful product and obviously produces an amazing anneal as mentioned in the video link below, but not everyone has $1675+ to drop on an annealer..... personally i like to use the "glow method" and using "test brass" to set up my flame based annealers = quick and simple and 100% will notice a more consistent headspace bump when testing resizing with bump gauges from pc to pc of brass resized & can be tested for a consistent bump.

anyone that has tried to bump back stubborn lake city brass (especially 7.62x51) with and without annealing will KNOW that annealing defiantly helps with the resizing process 100%... not only does annealing help with cracked necks and just better brass longevity, but IMO the #1 reason why I anneal is for more consistent headspace bumps.

this is how i use ANY flame based annealer & how it get it going and set up in approx a min using test brass... hope this helps

You are wasting your time. That's a whole lot of effort for unpredictable results and zero confirmation of brass end state.

Flame annealing is pissing in the wind without testing on the backend that can be repeated and would require constant checking/confirmation as flame temp, position, gas pressure, case time all vary from batch to batch.

The un educated will still buy into the bullshit, which is is good for sales.

You are wasting your time. That's a whole lot of effort for unpredictable results and zero confirmation of brass end state.

Flame annealing is pissing in the wind without testing on the backend that can be repeated and would require constant checking/confirmation as flame temp, position, gas pressure, case time all vary from batch to batch.

The un educated will still buy into the bullshit, which is is good for sales.

You again blowing smoke

Thank God you finally posted something that wasn't a meth infused manefesto.You again blowing smoke

Excellent repeatable results can be obtained using flame as well as induction . Production case stress relief is done faster with induction ,yet depending upon electric KW $ might not be less expensive .

Either method works EQUALLY WELL . As one is simply restoring ductility to the neck and shoulder and NOT repeat NOT annealing, at best can be referred too as PARTIAL ANNEALING .

I do K's of cases a year in #14 various calibers and have had ZERO issues with MY modified Annealeez . Key is pin point flame placement and direction of flame . Aim at base of neck where shoulder meets torch angle 22-37 Deg. flowing over case neck NOT THE BODY . Takes mere seconds and brass reaches 1200 Deg. at the neck shoulder perhaps 950 Deg. . Yet case base NEVER sees 250 Deg. . I DON'T use water to cool as it's totally unnecessary . However if one wants to stand brass in a tray of water and flame the neck shoulder area for the necessary duration ,you most certainly can as it won't hurt anything .

COST verses QUALITY and QUANTITY ; For home reloaders induction via AMP ,ISN'T cost nor quality effective sorry you pissed away your $$$$'s but it's your monies .

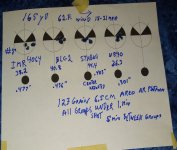

As someone once wrote proof is in the target and mine are producing desirable RESULTS . In case longevity if nothing else PAYS FOR ITSELF IN NO TIME . Match's Lapua's witness marks perfectly .every single time regardless of case ,once I set the correct flame angle . Group 7.62X51mm one case is Lapua all others LC note witness marks ,all those rounds went relatively into one hole aka 1/2 MOA .

For those of you who also doubt the ability of a proper Ultrasonic cleaner and solution ,THINK AGAIN !. I've restored nearly 5K .30 Cal M2 cases which are head stamped 1942 and 43 from worse than photo shows ,to as clean and shiny as Military brass gets . Ultrasonic bath 3.5 minutes then rinse in DI water,shake place onto the dryer wait 1 hr. run em in the annealeez ( Flame partial annealing ) ,resize and trim ,prime load and fire .

So far #38 firings on original 1 once fired 1942 & 43 brass ,without losing a single case and all loads are within 1 grain of Max. charge .

I believe I can obtain #50 reloads on those those 42-43 , .30 Cal M2 cases before they become too thin to safely reload . I'll finish that test by Labor day

Fyi : I shoot off a sand bag without a rear ear bag or happy sack if one prefers ,so imagine what could be done using a BR setup . I don't even own a BR setup any longer .

Fyi : Those Triple deuce loads were from 1994 and I shot the remainder of them in 2022 on a near windless day ,which is like having Two blue moons in a Month around these parts . A light breeze around here is 22 mph , no one bats an eye or speaks of the wind until it reaches 60-80 mph !.

Bottom line DON'T believe everything you see or read on line , there's enough BS too fuel a Country on line !!. ASK PEOPLE WHO KNOW or read Reputable Publishing's !.

Bottom line DON'T believe everything you see or read on line , there's enough BS too fuel a Country on line !!. ASK PEOPLE WHO KNOW or read Reputable Publishing's !.

https://vacaero.com/?s=Brass+annealing

Either method works EQUALLY WELL . As one is simply restoring ductility to the neck and shoulder and NOT repeat NOT annealing, at best can be referred too as PARTIAL ANNEALING .

I do K's of cases a year in #14 various calibers and have had ZERO issues with MY modified Annealeez . Key is pin point flame placement and direction of flame . Aim at base of neck where shoulder meets torch angle 22-37 Deg. flowing over case neck NOT THE BODY . Takes mere seconds and brass reaches 1200 Deg. at the neck shoulder perhaps 950 Deg. . Yet case base NEVER sees 250 Deg. . I DON'T use water to cool as it's totally unnecessary . However if one wants to stand brass in a tray of water and flame the neck shoulder area for the necessary duration ,you most certainly can as it won't hurt anything .

COST verses QUALITY and QUANTITY ; For home reloaders induction via AMP ,ISN'T cost nor quality effective sorry you pissed away your $$$$'s but it's your monies .

As someone once wrote proof is in the target and mine are producing desirable RESULTS . In case longevity if nothing else PAYS FOR ITSELF IN NO TIME . Match's Lapua's witness marks perfectly .every single time regardless of case ,once I set the correct flame angle . Group 7.62X51mm one case is Lapua all others LC note witness marks ,all those rounds went relatively into one hole aka 1/2 MOA .

For those of you who also doubt the ability of a proper Ultrasonic cleaner and solution ,THINK AGAIN !. I've restored nearly 5K .30 Cal M2 cases which are head stamped 1942 and 43 from worse than photo shows ,to as clean and shiny as Military brass gets . Ultrasonic bath 3.5 minutes then rinse in DI water,shake place onto the dryer wait 1 hr. run em in the annealeez ( Flame partial annealing ) ,resize and trim ,prime load and fire .

So far #38 firings on original 1 once fired 1942 & 43 brass ,without losing a single case and all loads are within 1 grain of Max. charge .

I believe I can obtain #50 reloads on those those 42-43 , .30 Cal M2 cases before they become too thin to safely reload . I'll finish that test by Labor day

Fyi : I shoot off a sand bag without a rear ear bag or happy sack if one prefers ,so imagine what could be done using a BR setup . I don't even own a BR setup any longer .

Fyi : Those Triple deuce loads were from 1994 and I shot the remainder of them in 2022 on a near windless day ,which is like having Two blue moons in a Month around these parts . A light breeze around here is 22 mph , no one bats an eye or speaks of the wind until it reaches 60-80 mph !.

https://vacaero.com/?s=Brass+annealing

Attachments

-

Hunting load 129 gr 278 Yd April 2024 2.jpg245.9 KB · Views: 30

Hunting load 129 gr 278 Yd April 2024 2.jpg245.9 KB · Views: 30 -

Aero precision AR 6 5 CM April 2024.jpg309.3 KB · Views: 26

Aero precision AR 6 5 CM April 2024.jpg309.3 KB · Views: 26 -

Annealeez Wheel fix 2.jpg715.1 KB · Views: 28

Annealeez Wheel fix 2.jpg715.1 KB · Views: 28 -

Labor Day Targets Close up 1.jpg380.8 KB · Views: 32

Labor Day Targets Close up 1.jpg380.8 KB · Views: 32 -

Annealed Lapua 223 308.jpg361.9 KB · Views: 33

Annealed Lapua 223 308.jpg361.9 KB · Views: 33 -

Match Lapua cases 308 neck shoulder.jpg223.1 KB · Views: 25

Match Lapua cases 308 neck shoulder.jpg223.1 KB · Views: 25 -

M2 173 grain 4895.jpg559.4 KB · Views: 26

M2 173 grain 4895.jpg559.4 KB · Views: 26 -

before and after .jpg246.9 KB · Views: 25

before and after .jpg246.9 KB · Views: 25