New here, thanks for all the advice and knowledge given. I started reloading recently on a Ruger precision rifle 6.5cm. Ran into a few issues as I went. Brass had a hell of a time being run thru a Hornady FL dies. Ended using wax inserted of spray and made it easier to cycle but still a lot of force needed to cycle. I asked a friend of mine to check over my reloading and he brought to my attention the size of my spent cases. Apparently he said I should be looking at just a few thousands of case expansion as the brass fills the chamber. Mine is expanding 60/thousands. No wonder I have such a hard time resizing. I never ran hot loads and only reloaded 3 times. 143 ELDX with 41.3 Staball 6.5. Prior to that was all factory ammo. What do I do from here on? I bought the rifle 3 years ago and it only has around 300 rounds thru it. Any advice is appreciated. Will Ruger do anything about this or am I on my own?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

Having trouble using the site?

Post any issues in the thread below or reach out directly to support!

View thread Contact support

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oversized Chamber

- Thread starter Thepopo

- Start date

If your brass is expanding 60 thousands then you should go to the next largest caliber case, the 6.5PRC

You should contact ruger and see if they will indeed do anything about it. "IF" the chamber is "oversized" (outside of SAAMI specs), then they should, purely out of potential liability concerns.New here, thanks for all the advice and knowledge given. I started reloading recently on a Ruger precision rifle 6.5cm. Ran into a few issues as I went. Brass had a hell of a time being run thru a Hornady FL dies. Ended using wax inserted of spray and made it easier to cycle but still a lot of force needed to cycle. I asked a friend of mine to check over my reloading and he brought to my attention the size of my spent cases. Apparently he said I should be looking at just a few thousands of case expansion as the brass fills the chamber. Mine is expanding 60/thousands. No wonder I have such a hard time resizing. I never ran hot loads and only reloaded 3 times. 143 ELDX with 41.3 Staball 6.5. Prior to that was all factory ammo. What do I do from here on? I bought the rifle 3 years ago and it only has around 300 rounds thru it. Any advice is appreciated. Will Ruger do anything about this or am I on my own?

If they are not willing to do anything about it (at no cost to you), I wouldn't send it back to Ruger. I would find a competent Gunsmith to either "set back" the existing barrel/chamber, or chamber a brand new barrel blank.

How did you determine they expanded that much? I have a hard time believeing they stayed in one piece.

Another incompetent tale of disaster.

Sound like firing a 6.5 CM in a 6.5 PRC chamber .060" is the basic difference.

If the measurement is correct,... which I doubt.

In a oversized 6.5 CM chamber the brass will not expand .060" at the solid case head.

The brass case will be surrounded by steel chamber, the steel will burst if it expands .060".

Forget primer pockets...

If the brass solid head expands just .002" with high pressure, it's close to bursting pressure.

So go find a competent friend or gunsmith at this point, who can properly measure everything that needs checked.

Or fix yourself...

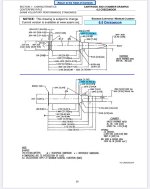

So get a "go" and "no go" 6.5 CM chamber gauges, barrel vise, and action wrench specifically made for the task.

If the no go goes into the chamber easily with no resistance.

Take your RPR and reset the headspace with the go gauge. Easy to do with the proper tools...instructions are most likely on line.

Sound like firing a 6.5 CM in a 6.5 PRC chamber .060" is the basic difference.

If the measurement is correct,... which I doubt.

In a oversized 6.5 CM chamber the brass will not expand .060" at the solid case head.

The brass case will be surrounded by steel chamber, the steel will burst if it expands .060".

Forget primer pockets...

If the brass solid head expands just .002" with high pressure, it's close to bursting pressure.

So go find a competent friend or gunsmith at this point, who can properly measure everything that needs checked.

Or fix yourself...

So get a "go" and "no go" 6.5 CM chamber gauges, barrel vise, and action wrench specifically made for the task.

If the no go goes into the chamber easily with no resistance.

Take your RPR and reset the headspace with the go gauge. Easy to do with the proper tools...instructions are most likely on line.

I ran into the opposite on my last range trip. Guy was shooting a new RPR in 6.5cm. He was having a hard time getting small groups. He had hunting rounds, so I suggested ELDMs. He said he got a few but they were too long for the mag. My suspicions were confirmed when I looked at the stamp on the base... 6.5 PRC rounds. At least he never would have gotten them to chamber

You're right, 60 thousandths is right at the difference between the 6.5 PRC and 6.5 CM as measured at the shoulder-body junction.Another incompetent tale of disaster.

Sound like firing a 6.5 CM in a 6.5 PRC chamber .060" is the basic difference.

If the measurement is correct,... which I doubt.

In a oversized 6.5 CM chamber the brass will not expand .060" at the solid case head.

The brass case will be surrounded by steel chamber, the steel will burst if it expands .060".

Forget primer pockets...

If the brass solid head expands just .002" with high pressure, it's close to bursting pressure.

So go find a competent friend or gunsmith at this point, who can properly measure everything that needs checked.

Or fix yourself...

So get a "go" and "no go" 6.5 CM chamber gauges, barrel vise, and action wrench specifically made for the task.

If the no go goes into the chamber easily with no resistance.

Take your RPR and reset the headspace with the go gauge. Easy to do with the proper tools...instructions are most likely on line.

With that much expansion, I'm surprised the cases didn't just blowup, and doesn't sound like they're even reusable.

Last edited:

@Thepopo not trying to be a dick just addressing a possibility. Are you sure you have a 6.5CM and not a 6.5PRC?

You're right, 60 thousandths is right at the difference between the 6.5 PRC and 6.5 CM as measured at the shoulder-body junction.

With that much expansion, I'm surprised the cases didn't just blowup, and doesn't sound like they're even reusable.

+1

Pics or it didn't happen.

I am in the process of contacting them and se what they can do for me. Thank you.You should contact ruger and see if they will indeed do anything about it. "IF" the chamber is "oversized" (outside of SAAMI specs), then they should, purely out of potential liability concerns.

If they are not willing to do anything about it (at no cost to you), I wouldn't send it back to Ruger. I would find a competent Gunsmith to either "set back" the existing barrel/chamber, or chamber a brand new barrel blank.

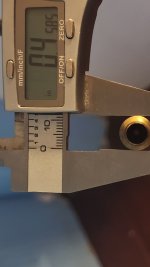

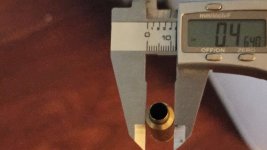

Measured the cases with a caliper gauge. It's width expansion not length. Yeah thats the part that got me worried. I'm thinking of chucking the brass amd getting some Lapua brass. The brass is on its 3rd firing.How did you determine they expanded that much? I have a hard time believeing they stayed in one piece.

I am getting the gagues to measure the headspace and internal dimensions. Some adjustments to headpsace I beleive will be required.Another incompetent tale of disaster.

Sound like firing a 6.5 CM in a 6.5 PRC chamber .060" is the basic difference.

If the measurement is correct,... which I doubt.

In a oversized 6.5 CM chamber the brass will not expand .060" at the solid case head.

The brass case will be surrounded by steel chamber, the steel will burst if it expands .060".

Forget primer pockets...

If the brass solid head expands just .002" with high pressure, it's close to bursting pressure.

So go find a competent friend or gunsmith at this point, who can properly measure everything that needs checked.

Or fix yourself...

So get a "go" and "no go" 6.5 CM chamber gauges, barrel vise, and action wrench specifically made for the task.

If the no go goes into the chamber easily with no resistance.

Take your RPR and reset the headspace with the go gauge. Easy to do with the proper tools...instructions are most likely on line.

They are usable and according to the guys at the range that reload much longer than I say the cases are not showing pressure wave or damage.You're right, 60 thousandths is right at the difference between the 6.5 PRC and 6.5 CM as measured at the shoulder-body junction.

With that much expansion, I'm surprised the cases didn't just blowup, and doesn't sound like they're even reusable.

Nope, new rifle, never pulled the barrel.Or it's a used rifle someone messed with. Maybe he took it apart to clean and thought pulling the barrel out was a good idea and didn't use a headspace gauge to reassemble????

Never know what someone might do if they don't know what they should and should not do..

If you are actually seeing .060" of expansion in the case do not shoot it until the issue is rectified.Measured the cases with a caliper gauge. It's width expansion not length. Yeah thats the part that got me worried. I'm thinking of chucking the brass amd getting some Lapua brass. The brass is on its 3rd firing.

I am really having a hard time believing what you are saying is happening.

Post a couple of pictures of the barrel clambering stamp, brass in question and caliper measurement on brass above the case head.

He’s not seeing 60 thou. He’s confusing thousandths with ten thousandths. His cases are expanding .006”, prolly from .468” to .474”

I should clarify the areas of the brass I am measuring. I am measuring the width below the shoulder as well as lower down middle of the case body. I think i confused a few as to where my case expasiin is happening. Its width expansion not length. Sorry for any confusion I may have caused.

I should clarify the areas of the brass I am measuring. I am measuring the width below the shoulder as well as lower down middle of the case body. I think i confused a few as to where my case expasiin is happening. Its width expansion not length. Sorry for any confusion I may have caused.

Where you are measuring. If you are ~.054 - .062" larger than what the 6.5 Creedmoor SAAMI specs are (or your resized brass)...You are getting 100% 6.5 PRC case diameter (width) measurements there.

Still waiting on those pics.

Checked the barrel. Yall got me really paranoid there for a bit. Its a 6.5 CMWhere you are measuring. If you are ~.054 - .062" larger than what the 6.5 Creedmoor SAAMI specs are (or your resized brass)...You are getting 100% 6.5 PRC case diameter (width) measurements there.

Still waiting on those pics.

Attachments

Please also show a picture with your calipers on fired brass were you are saying you have .060" of expansion.Checked the barrel. Yall got me really paranoid there for a bit. Its a 6.5 CM

Not trying to be an ass but I think there is something in this that isn't being accurately translated due to knowledge/experience level.

Main thing here is your safety first and formost.

The brass is on its 3rd firing.

If your brass expanded 60 thou you would not be able to resize it. It would not be on its 3rd firing.

Hmmmm??? I have a feeling he's measuring in millimeters rather than inches. . . ???Please also show a picture with your calipers on fired brass were you are saying you have .060" of expansion.

Not trying to be an ass but I think there is something in this that isn't being accurately translated due to knowledge/experience level.

Main thing here is your safety first and formost.

.060 millimeters = .0024", which in inches would be about right and change the whole conversation.

Last edited:

Well nobody is perfect and I'm not going to the guy that punches him in nuts for not using the gods measurement.Hmmmm??? I have a feeling he's measuring in millimeters rather than inches. . . ???

Hmmmm??? I have a feeling he's measuring in millimeters rather than inches. . . ???

.060 millimeters = .0024", which in inches would be about right and change the whole conversation.

.060 millimeters? You mean 1/1,500,000 football fields. We don't use those euro-numbers here.

What? You mean you use cubits?.060 millimeters? You mean 1/1,500,000 football fields. We don't use those euro-numbers here.

Hmmmm??? I have a feeling he's measuring in millimeters rather than inches. . . ???

.060 millimeters = .0024", which in inches would be about right and change the whole conversation.

I wouldn't doubt that you could be correct here. I don't know if you could actually get a 6.5 PRC case down a Creedmoor die (regardless of length) unless one was of both simian intellect and strength.

I have however had decades of having Marines work for me...so I know that just about anything is possible. Some people are capable of breaking an anvil in a toilet paper factory.

Did we not doubt his measurements?

Inches or mm?

Press the little button on the caliper or micrometer to change inch/mm.

The .0023" or .060 mm plus expansion at the case head, would not likely hold a primer for the next firing.

The FL die will not size that area down, as the shell holder takes some of that area of the case head.

The case head is solid brass for about .2" on most cases, and expansion takes place ahead of that. Leaving a slight bulge to be resized. But under enough pressure to expand the solid portion you have a problem, with pressure, leaving loose primer pockets to blown primers.

Chamber gauges measures length...not diameter. That will be incorporated in the chamber reamer specifications.

Which if running true, clean, sharp, properly ground, and well lubed will never cut .0023" oversize....

One could have a small base die and a slightly larger diameter chamber to make sizing more difficult, and chamber still be in print.

it could even be reamed an improved chamber with standard dies ...that will not work.

A chamber cast would be in order.

... but who knows without exacting information, garbage in garbage out.

A competent person or gunsmith would be recommended.

Inches or mm?

Press the little button on the caliper or micrometer to change inch/mm.

The .0023" or .060 mm plus expansion at the case head, would not likely hold a primer for the next firing.

The FL die will not size that area down, as the shell holder takes some of that area of the case head.

The case head is solid brass for about .2" on most cases, and expansion takes place ahead of that. Leaving a slight bulge to be resized. But under enough pressure to expand the solid portion you have a problem, with pressure, leaving loose primer pockets to blown primers.

Chamber gauges measures length...not diameter. That will be incorporated in the chamber reamer specifications.

Which if running true, clean, sharp, properly ground, and well lubed will never cut .0023" oversize....

One could have a small base die and a slightly larger diameter chamber to make sizing more difficult, and chamber still be in print.

it could even be reamed an improved chamber with standard dies ...that will not work.

A chamber cast would be in order.

... but who knows without exacting information, garbage in garbage out.

A competent person or gunsmith would be recommended.

I want to see this brass if it's blowing the webbing out .060. Are you calling .006 60/ thousands?

I had already resized the brass when I first posted so I'm not able to take a photo of it. I trimmed all the cases down to 1.9 and that seems to have reduced the expansion on this last reload. I'm ordering some go/no go gauges as well. Reloaded them again tonight and the ammount of force needed to fully resize them has gone down drastically. So keeping the case short seems to be helping. I also did the threadlocker method for getting the measurement to the lands. It came out at 2.772.

Attachments

OK, so initially, you simply misstated 60 thousandths for 60 ten thousandths.I had already resized the brass when I first posted so I'm not able to take a photo of it. I trimmed all the cases down to 1.9 and that seems to have reduced the expansion on this last reload. I'm ordering some go/no go gauges as well. Reloaded them again tonight and the ammount of force needed to fully resize them has gone down drastically. So keeping the case short seems to be helping. I also did the threadlocker method for getting the measurement to the lands. It came out at 2.772.

I'd say something is very wrong with a chamber that's producing an expansion of .0055 - .006 on that part of the case. I've not seen that from my RPR factory barrels or the replacement barrels I've put on. You should REALLY call Ruger and explain your issue to them and get them to replace the barrel.

Your brass isn't going to last very long with that kind of movement. Or, you could get a custom die that doesn't size it down by .001 or so.

They'll want you to send your whole gun to them in a box they provide that they can directly inspect the barrel themselves. I had an issue with one of my new RPR's throat and had to do that. They sent me a whole new gun rather than just replacing the barrel.

How much of an expansion should I be seeing?OK, so initially, you simply misstated 60 thousandths for 60 ten thousandths.

I'd say something is very wrong with a chamber that's producing an expansion of .0055 - .006 on that part of the case. I've not seen that from my RPR factory barrels or the replacement barrels I've put on. You should REALLY call Ruger and explain your issue to them and get them to replace the barrel.

Your brass isn't going to last very long with that kind of movement. Or, you could get a custom die that doesn't size it down by .001 or so.But I don't really think that's a good solution.

They'll want you to send your whole gun to them in a box they provide that they can directly inspect the barrel themselves. I had an issue with one of my new RPR's throat and had to do that. They sent me a whole new gun rather than just replacing the barrel.

I’d slow down a bit.

That measurement from SAAMI max cartridge is supposed to be .462, and minimum chamber is .463. Your fired brass isn’t that far off. That measurement should also be taken with a micrometer (vice calipers) if we want to start rejecting parts.

WRT sizing feel, that could be anything from your press, to your lube, to how far you’re pushing the shoulder back (what’s your comparator measurement from fired to resized?)

As another esteemed poster here would say, we really need to see all of your fired and resized case dimensions.

That measurement from SAAMI max cartridge is supposed to be .462, and minimum chamber is .463. Your fired brass isn’t that far off. That measurement should also be taken with a micrometer (vice calipers) if we want to start rejecting parts.

WRT sizing feel, that could be anything from your press, to your lube, to how far you’re pushing the shoulder back (what’s your comparator measurement from fired to resized?)

As another esteemed poster here would say, we really need to see all of your fired and resized case dimensions.

Attachments

How much of an expansion should I be seeing?

With my 6.5 Creed I get .4625 diameter at the top of the shoulder with fired brass, and sized brass measures .4605 using a Whidden die.

My guess is that you're dealing with stacked tolerances here... your chamber is on the large end of the spectrum and your Hornady sizing die is on the small end of the spectrum. Might look into a different sizing die to get the dimensions closer to each other.

About .002. . .maybe .003 max. In the different barrels I've had over the last few years, I get ~.0015 expansion at that junction and about .001 at .200 above the case base , which is what I like to see.How much of an expansion should I be seeing?

Last edited:

What kind of die do you recommend?With my 6.5 Creed I get .4625 diameter at the top of the shoulder with fired brass, and sized brass measures .4605 using a Whidden die.

My guess is that you're dealing with stacked tolerances here... your chamber is on the large end of the spectrum and your Hornady sizing die is on the small end of the spectrum. Might look into a different sizing die to get the dimensions closer to each other.

What kind of die do you recommend?

Not sure, there are a lot of good dies out there and it would depend on which one had larger dimensions closer to your chamber. Looks like my Whidden die is larger than your Hornady die but not sure what others measure out at.

If this is the way you want to go, check this out, they do great work:I read there are some that make custom dies based on your fireformed brass. Who can I use for this?

Custom Reloading Dies - Whidden Gunworks

Custom Dies Whether you're a hunter or a competition shooter Whidden Gunworks can manufacture Custom dies to your exact specifications and if needed can

PS: Keep in mind that if you ever change to a new barrel, the custom die may not work for it unless you have a custom reamer for the new barrel. You might be better off just getting a new barrel from a barrel manufacturer or having Ruger get you a new one???

Yes at this point I am considering a new barrel and start with custom dies from there.If this is the way you want to go, check this out, they do great work:

Custom Reloading Dies - Whidden Gunworks

Custom Dies Whether you're a hunter or a competition shooter Whidden Gunworks can manufacture Custom dies to your exact specifications and if needed canwww.whiddengunworks.com

PS: Keep in mind that if you ever change to a new barrel, the custom die may not work for it unless you have a custom reamer for the new barrel. You might be better off just getting a new barrel from a barrel manufacturer or having Ruger get you a new one???

I recently put a new barrel on, a 6.5 CM .put a few round through it . then when resizing the brass it took a great deal of force to resize .I'm thinking the chamber is oversized . going to retest . what to do if the chamber is bad ?

Why not just take various measurements of your fired and sized brass and see how it compares to others?I recently put a new barrel on, a 6.5 CM .put a few round through it . then when resizing the brass it took a great deal of force to resize .I'm thinking the chamber is oversized . going to retest . what to do if the chamber is bad ?

If its large its large, just have to work around it. I found that by using a mandrel and keeping neck tensions in the .002 range I saw less brass expansion and less effort to FL resize since the brass has less resistance in getting the projectile moving. If the barrel is new might want to contact the manufacturer and send them sized and once fired brass for them to verify your chamber.I recently put a new barrel on, a 6.5 CM .put a few round through it . then when resizing the brass it took a great deal of force to resize .I'm thinking the chamber is oversized . going to retest . what to do if the chamber is bad ?

Measuring is the name of the game.Why not just take various measurements of your fired and sized brass and see how it compares to others?

Accurate measurements is critical.

But that won't happen...

Try different FL dies they are not all the same. Get a cheap Lee FL die and polish it out, accurately.

But you don't have a lathe...

I have a Hornady die in 308 that is difficult to size brass...it's not the only Hornady die, that's that way.

I like their seater dies but not their FL dies, some work okay others do not.

Here's what will work, for the average shooter.

If it's a bolt gun use a neck die and every third firing use a Redding 308 body die, to bump the shoulder back .002"

If an auto or bolt, one can use the Redding body die first then your FL sizing die every firing.

I had an oversized Rem factory chamber the "No-go" gauge would go, but it was very accurate for a factory rifle. I used the Redding body die to move the shoulder back and a neck bushing die to size the neck. Got up to 40 firings on the Lapua LR brass and 48 gr of Varget with 155s, in this oversized 308 chamber.

Use the white Lee Resizing Lube on tough sizing, better than the others ...I use it on oversized 50BMG brass fired in Machineguns, to fit my bolt gun.

But that won't happen...

Try different FL dies they are not all the same. Get a cheap Lee FL die and polish it out, accurately.

But you don't have a lathe...

I have a Hornady die in 308 that is difficult to size brass...it's not the only Hornady die, that's that way.

I like their seater dies but not their FL dies, some work okay others do not.

Here's what will work, for the average shooter.

If it's a bolt gun use a neck die and every third firing use a Redding 308 body die, to bump the shoulder back .002"

If an auto or bolt, one can use the Redding body die first then your FL sizing die every firing.

I had an oversized Rem factory chamber the "No-go" gauge would go, but it was very accurate for a factory rifle. I used the Redding body die to move the shoulder back and a neck bushing die to size the neck. Got up to 40 firings on the Lapua LR brass and 48 gr of Varget with 155s, in this oversized 308 chamber.

Use the white Lee Resizing Lube on tough sizing, better than the others ...I use it on oversized 50BMG brass fired in Machineguns, to fit my bolt gun.

actually i do have a lathe , sooo haha. my dies are RCBS FL SB . the thought of getting an additional set of dies (not SB )does intrigue me . Lee dies are available from a large sporting goods store 7 miles away, yea would rather borrow a set for a test ,....saylavee. after checking fired brass against resized brass i can only find .003 differentsAccurate measurements is critical.

But that won't happen...

Try different FL dies they are not all the same. Get a cheap Lee FL die and polish it out, accurately.

But you don't have a lathe...

I have a Hornady die in 308 that is difficult to size brass...it's not the only Hornady die, that's that way.

I like their seater dies but not their FL dies, some work okay others do not.

Here's what will work, for the average shooter.

If it's a bolt gun use a neck die and every third firing use a Redding 308 body die, to bump the shoulder back .002"

If an auto or bolt, one can use the Redding body die first then your FL sizing die every firing.

I had an oversized Rem factory chamber the "No-go" gauge would go, but it was very accurate for a factory rifle. I used the Redding body die to move the shoulder back and a neck bushing die to size the neck. Got up to 40 firings on the Lapua LR brass and 48 gr of Varget with 155s, in this oversized 308 chamber.

Use the white Lee Resizing Lube on tough sizing, better than the others ...I use it on oversized 50BMG brass fired in Machineguns, to fit my bolt gun.

I have many 308 dies, 3 Lee, 2 Wilson, 2 Redding, RCBS, Hornady, and a Redding body die I just got done using.actually i do have a lathe , sooo haha. my dies are RCBS FL SB . the thought of getting an additional set of dies (not SB )does intrigue me . Lee dies are available from a large sporting goods store 7 miles away, yea would rather borrow a set for a test ,....saylavee. after checking fired brass against resized brass i can only find .003 differents

Lee dies are cheap, I buy many of their dies and modify them with carbide cutting tools or polishing.

You have a lathe...great...most do not.

You can make your own dies our of steel, no need to harden them, they will last a long time.

Or buy the Lee FL die, try it out ...if it oversizes your "oversized" fired brass polish it out in your lathe a little at a time ...polish and check, do not polish the 20° 308 shoulder. Easy to do.

You just have a slightly custom chamber, make the brass fit, by slightly altering the FL die.

Example home built die in action to convert 308 Win brass to 8.6 Blackout brass, in one pass no dented shoulders.

Making 510 whisper brass, out of 338 Lapua. There are no cartridge gauges so ya make your own, with your finish chamber reamer, and use that to chamber your barrel. The Aluminum gauge is .338 RCM AR 10 build with reamer next to it... the Wilson cartridge gauges are off a bit as shown by the go gauge inserted in them, used to chamber the barrel.

You have a lathe use it,...not everything is readily available to the shooter.

Attachments

Last edited:

Similar threads

- Replies

- 7

- Views

- 276

- Replies

- 39

- Views

- 428