I've found H1000 to be a bit too fast for my liking with anything over 220s, Retumbo was a much better choice for me and my rifle! With H1000 I was having pressure signs around 2800 fps!Ya I saw that.

The Sierras should be different. But I guess I can start 76

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

Having trouble using the site?

Post any issues in the thread below or reach out directly to support!

View thread Contact support

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

300 PRC

- Thread starter category_theory

- Start date

I'm currently using 230 gr ATips over 77.1 gr of H-1000. 30" barrel gives me 2900 FPS with no pressure signs at all. Just one data point tho.I've found H1000 to be a bit too fast for my liking with anything over 220s, Retumbo was a much better choice for me and my rifle! With H1000 I was having pressure signs around 2800 fps!

These are my first 30 shots through my build w/ 22" Proof. Only had BR2s on hand, no magnum primers. I'm going to retest some of the loads with magnum primers to see if there's any difference.

Staball HD 215 Berger

82gr - 2807.7

82.4 - 2776.1?

82.6 - 2794.7

Staball HD 200 ELD X

81.5gr - 2829.8

82 - 2884.6

82.5 - 2887.2

83 - 2864.1 ?

83.5 - 2917.9

Staball HD 180 Barnes TTSX

83gr - 2920.4

83.5 - 2895.8

84 - 3016.0

84.5 - 2992.5

H1000 180 Barnes TTSX

83.5gr - 3037.6

84 - 3102.3

H1000 Ladder 215 Berger

78gr - 2688.1

79 - 2716.4

79.5 - 2760.5

80 - 2791.0

80.2 - 2808.0

80.4 - 2780.1 ?

80.6 - 2805.0

Retumbo Ladder 215 Berger

79gr - 2716.2

79.3 - 2746.7

79.5 - 2759.7

80 - update prompt missed shot

80.3 - 2808.3

Staball HD 215 Berger

82gr - 2807.7

82.4 - 2776.1?

82.6 - 2794.7

Staball HD 200 ELD X

81.5gr - 2829.8

82 - 2884.6

82.5 - 2887.2

83 - 2864.1 ?

83.5 - 2917.9

Staball HD 180 Barnes TTSX

83gr - 2920.4

83.5 - 2895.8

84 - 3016.0

84.5 - 2992.5

H1000 180 Barnes TTSX

83.5gr - 3037.6

84 - 3102.3

H1000 Ladder 215 Berger

78gr - 2688.1

79 - 2716.4

79.5 - 2760.5

80 - 2791.0

80.2 - 2808.0

80.4 - 2780.1 ?

80.6 - 2805.0

Retumbo Ladder 215 Berger

79gr - 2716.2

79.3 - 2746.7

79.5 - 2759.7

80 - update prompt missed shot

80.3 - 2808.3

Im running a 28” 1-8 SAC barrel. I’d like to be in the 2950 range. H1000 may not get me there. RE26 probably will, but it doesn’t exist lol I may have to try some VihtavuoriI'm currently using 230 gr ATips over 77.1 gr of H-1000. 30" barrel gives me 2900 FPS with no pressure signs at all. Just one data point tho.

I was a little surprised at the speed I ended up getting after barrel break in. I was hoping for 2850 so 2900 was nice to see. Not sure how long the barrel will last, but will replace it with a MOD BB Bartlein when it's done.Im running a 28” 1-8 SAC barrel. I’d like to be in the 2950 range. H1000 may not get me there. RE26 probably will, but it doesn’t exist lol I may have to try some Vihtavuori

I fell into a bunch of 250gr Atips and scooped them up before thinking I'm running a 1/9 in my 27" 300PRC vs the recommended 1/8.5. I'm on the east coast pretty much at sea level and was wondering if the 250s would still work, but just give up some BC?

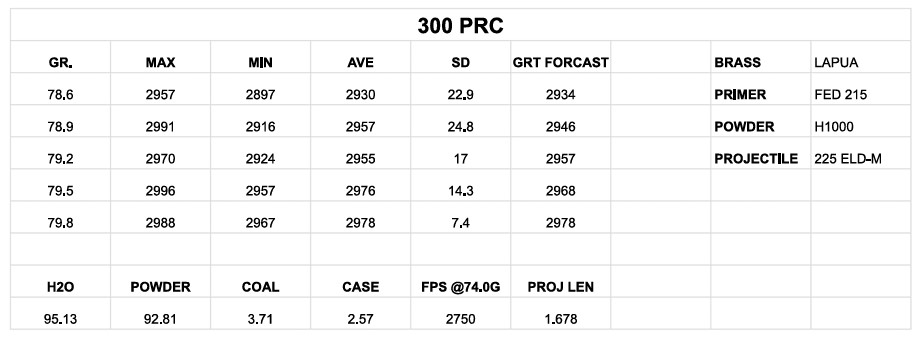

Here is my work up from Monday. I'm kicking myself for not loading 80.1gr. Would have been right at the pressure limit per GRT but might have been good SD too. This barrel only had 40 rounds on it when I started, so definitely some break in fluctuation to be expected along with large swings.

This was 6 rounds of each load. I attribute the abnormalities to new barrel. we will see as I surpass the 150-round mark.

This was 6 rounds of each load. I attribute the abnormalities to new barrel. we will see as I surpass the 150-round mark.

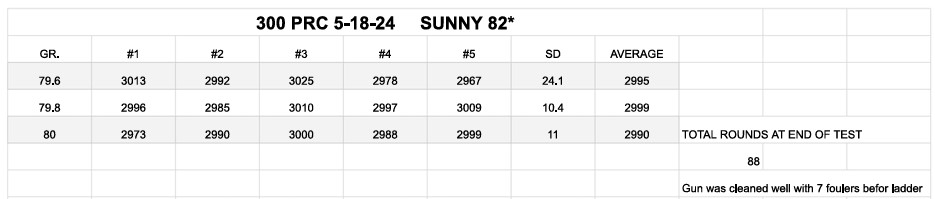

Re tested each side of the 79.8 and that might be the go to point for right now as the barrel breaks in. Moving pretty fast and I like it. 1 round in the 80.0 group has a little extra lift required, but nothing else looked or felt off.

Anyone have seating depth suggestions for the 225's? I'm currently at .020

Anyone have seating depth suggestions for the 225's? I'm currently at .020

I've found H1000 to be a bit too fast for my liking with anything over 220s, Retumbo was a much better choice for me and my rifle! With H1000 I was having pressure signs around 2800 fps!

I was using RL26 with 230s and getting great results at 2865 fps - RL26 is about the same burn rate as H1000. I also was using H1000 in my 37XC with Lehigh 353gr solids.

I started off way down at 76 Grains for about 20 rounds or so to break in the barrel and determine velocity at a known powder weight. I then did all my work up with GRT and came up with the first ladder which brought me up to pressure limit per GRT. I noticed that final load was close to what I was looking for and decided to load each side of that to verify. I will be planning on shooting 79.8 for now and then probably reevaluate after 200 rounds.Thanks J. Im starting a load build when I return from vacation.

I’m a 28” barrel with Sierra 230’s

Using your load data as a jumping off point.

Hoping for 2930-2950

The goal was this gun from the beginning was 225s at 3000 FPS. It is a 29 inch barrel.

I’m going to shoot 60-80 factory Hornady 225 ammo for a solid break in.

And was planning on starting at 75g. Maybe I’ll start at 76 now and jump in .3 increments

Thanks

And was planning on starting at 75g. Maybe I’ll start at 76 now and jump in .3 increments

Thanks

Anyone think a 1:8 twist is too fast for 208’s to 250’s?

What’s the downside of a fast twist in 300 PRC for ELR applications?

My current barrel is a 1:9 - 1:8 gain twist. It's working quite well.

Either you or rocketman run the Berger 208 or the Hornady 208 in your 8 twists?My current is 1-8 and it loves 230’s

AI AXMC with 28" Bartlein, 400MODBB, 5R, 1/9 in their #9 profile. Load testing with 1x Hornady, Federal 215Ms, RL-26 and 220gr Bergers. This barrel has sped up by 75FPS since its first rounds. For this test, the 73.6gr shot really well and I'll be using it for my 1,000yd stuff. I want to find a load in the 2925fps for longer range and will be working up a faster load, as well as one for 230 A-Tips as soon as possible. From my spreadsheet:

Last edited:

I'm fortunate to have 26lbs. /flexoffHope you have lots of R26.

We ain’t gettin anymore of it stateside for awhile, if ever.

I'm using a bartlein 1-9 twist and it stabilizes everything up to 250 atips.Anyone think a 1:8 twist is too fast for 208’s to 250’s?

What’s the downside of a fast twist in 300 PRC for ELR applications?

I'm about to reload for 300 PRC. I can't find Federal 215M anywhere. But I have found CCI 200 and Federal 210M.

Curious if anyone has gotten AMAZING SD's for either one of them?

Is 215M only beneficial vs others when shot in really cold temperature? (I'm in Southern California).

Curious if anyone has gotten AMAZING SD's for either one of them?

Is 215M only beneficial vs others when shot in really cold temperature? (I'm in Southern California).

You are at max pressure and even possibly starting to go over.I'm currently using 230 gr ATips over 77.1 gr of H-1000. 30" barrel gives me 2900 FPS with no pressure signs at all. Just one data point tho.

When my loads went from 76to78gr of powder I was 5000psi or more over max pressure. No tell tale signs of heavy bolt lift, flat primers etc…

Later, Frank

Bartlein Barrels

Cci200s gave me better SDs then 210M or mag primers.I'm about to reload for 300 PRC. I can't find Federal 215M anywhere. But I have found CCI 200 and Federal 210M.

Curious if anyone has gotten AMAZING SD's for either one of them?

Is 215M only beneficial vs others when shot in really cold temperature? (I'm in Southern California).

Most my SDs are in the 6 to 10 range.

Also single SDs as cool as they are doesn’t necessarily mean smaller groups.

Shouldn't have any problems up to 225s.I have a new Proof with 1-10 twist is that going to be to slow for the 300PRC?

What's your powder of choice frank?Cci200s gave me better SDs then 210M or mag primers.

Most my SDs are in the 6 to 10 range.

Also single SDs as cool as they are doesn’t necessarily mean smaller groups.

Hey guys, need some pro advice. I just got a new barrel for the SRS A1. Breaking it in and cleaning every round as usual.

Little hiccup. It’s blowing primers out of factory Hornady ammo. And I mean BLOWING them out. Massive cratering and piercing. Some primers were stuck in the bolt, some would fly out when spent shell was ejected. I shot 1 suppressed and it seemed fine. Started the cleaning process and didn’t want to fiddle with the suppressor every round, so I shot 5 unsupressed.

Those are the 5 that were blowing like crazy and had massive bolt lift etc.

Any ideas on this? Any insight you may have is much appreciated.

Ive never had a barrel do this before with factory ammo. Barrel was cut with a Manson reamer. I contacted the barrel maker and asked for more detailed specs. Waiting on a response. Here are 2 fired brass.

Little hiccup. It’s blowing primers out of factory Hornady ammo. And I mean BLOWING them out. Massive cratering and piercing. Some primers were stuck in the bolt, some would fly out when spent shell was ejected. I shot 1 suppressed and it seemed fine. Started the cleaning process and didn’t want to fiddle with the suppressor every round, so I shot 5 unsupressed.

Those are the 5 that were blowing like crazy and had massive bolt lift etc.

Any ideas on this? Any insight you may have is much appreciated.

Ive never had a barrel do this before with factory ammo. Barrel was cut with a Manson reamer. I contacted the barrel maker and asked for more detailed specs. Waiting on a response. Here are 2 fired brass.

Attachments

Got a response from the barrel maker.

“It is a K&P cut rifled barrel. The chamber is also a SAAMI speck chamber.

There is no reason for the blown primers other than ammo. Shooting with a suppressor will actually cause slightly more pressure. So it should be worse with that.”

How could factory ammo be THAT high pressure? Should I contact Hornady and ask about this batch? I bought 400 rounds

“It is a K&P cut rifled barrel. The chamber is also a SAAMI speck chamber.

There is no reason for the blown primers other than ammo. Shooting with a suppressor will actually cause slightly more pressure. So it should be worse with that.”

How could factory ammo be THAT high pressure? Should I contact Hornady and ask about this batch? I bought 400 rounds

Hold the phone for a second.... It could have nothing to do with the ammo.Got a response from the barrel maker.

“It is a K&P cut rifled barrel. The chamber is also a SAAMI speck chamber.

There is no reason for the blown primers other than ammo. Shooting with a suppressor will actually cause slightly more pressure. So it should be worse with that.”

How could factory ammo be THAT high pressure? Should I contact Hornady and ask about this batch? I bought 400 rounds

You need to know to the 4th decimal place what the barrels bore and groove sizes are made to! If it's a tight bore/tight groove at all that can easily drive up pressures and blow primers.

The OP might want to consider calling K&P and sending the barrel back to have the bore and groove size rechecked.

Also you don't know how many barrels that chamber reamer has done. If the throat is cutting undersize that will cause issues also.

You could have both of those things going on and compounding the problem.

A barrel with a bore and groove size just a .0005" undersize will drive up pressures about 10k psi.

Having a throat area of the chamber even just .0001" to .0002" undersize and bullets at max tolerance.... that drives up pressures about another 6k psi.

If both of those things are going on.... you take a 65K psi round and add another 16k to it... now your in the 80k psi range.

We pretty much make all of the ammunition test barrels for Hornady. When we ship a test barrel to any ammo or bullet or powder maker we also include an inspection report that gives them the bore and groove size so they know exactly what the spec it was made to.

We also chamber all of the pressure barrels for Hornady (OK probably like 98% some of the R&D stuff we might do and might not). If there was a pressure issue with any barrel and it blowing primers etc.... I would get a phone call yesterday from Joe or Jayden and I would've known about it... and if it was happening.... Hornady wouldn't be running that lot of ammo etc...

Later, Frank

Bartlein Barrels

First glance says seated too long and bullet pulled a bit upon ejection. Fortunately didn’t pull out completely.What’s your first thought on this factory ammo chambered and then ejected?

Factory Hornady 225 ammo.First glance says seated too long and bullet pulled a bit upon ejection. Fortunately didn’t pull out completely.

What is the BTO measurement on one of the factory Hornady rounds, that has not been chambered?...Factory Hornady 225 ammo.

What's the BTO measurement of the Hornady round that was chambered?

What are you guys normally seeing for BTO measurements for a SAAMI chambered in 300 PRC...while reloading for the 225 ELD?

Last edited:

I only weigh and measure factory ammo, but I’ve stopped measuring Hdy 225 as every single one I’ve measured has been 3.65 on the button. Weight, that’s a different story lolWhat is the BTO measurement on one of the factory Hornady rounds, that has not been chambered?...

What's the BTO measurement of the Hornady round that was chambered?

What are you guys normally seeing for BTO measurements for a SAAMI chambered in 300 PRC...while reloading for the 225 ELD?

The chambered round still measures 3.65, so it didn’t pull the bullet. That’s how tight barreling in the barrel is that it caused that much damage to the bullet.

The minor measurement was less than .2995!!! Probably .2993, we just didn’t have a pilot that size. Imagine the pressure this added for all 28” being 7/thousandths too small!!!!

BOOOOOM!!!

???I only weigh and measure factory ammo, but I’ve stopped measuring Hdy 225 as every single one I’ve measured has been 3.65 on the button. Weight, that’s a different story lol

The chambered round still measures 3.65, so it didn’t pull the bullet. That’s how tight barreling in the barrel is. The minor measurement was less than .2995!!! Probably .2993, we just didn’t have a pilot that size. Imagine the pressure this added for all 28” being 7/thousandths too small!!!!

BOOOOOM!!!

I think the measurement you are giving is the COAL ...Overall Length... not the BTO

Do you reload? Do you have a .308 bullet comparator?

What is the (BTO) Base To Ogive measurement? That will tell you if the factory ammo is seated to far out, or if your chambered bullet did indeed get pulled out a little...

bullets engraving the rifling.What’s your first thought on this factory ammo chambered and then ejected?

Check the chamber reamer and as well as what size is the bore of the barrel.

Again ammo could be just fine and have nothing to do with the ammo.

Last edited:

If this is accurate than your actually .0007" undersize on the bore. If the grooves are tight also....The minor measurement was less than .2995!!! Probably .2993, we just didn’t have a pilot that size. Imagine the pressure this added for all 28” being 7/thousandths too small!!!!

BOOOOOM!!!

Go back to my post #81... a .0005" under on both will drive up pressures about 10k psi.

Retumbo for me was too fast of a powder for the 245s, At 78 grains I was at 2800 fps and showing signs of a lot of pressure. N568 has been awesome for the 245s, With my 28" Bartlein 81.5 grains of N568 are giving me 2830 fps and just barely starting to feel and see pressure signs. I'm using CCI 250s, Lapua brass, COAL 3.830 .015 jump.What kind of velocities could I expect from 245 Hybrids out of a 30" barrel?

I've got H1000, Retumbo and RL26 on hand, and I'm open to trying N568/N570.

Bryan Litz posted an opinion of over-stabilizing a bullet and said it is better to over-stabilize than to under-stabilize especially when going through the transonic zone.I do not. Built this to run heavies.

Berger twist calc says at sea level and 3k fps you’d be 2.36

I’m not sure when overstabilization begins

What kind of velocities could I expect from 245 Hybrids out of a 30" barrel?

I've got H1000, Retumbo and RL26 on hand, and I'm open to trying N568/N570.

That's what I've always said... better safe than sorry on the twist rates. You run the twist on the ragged edge of stabilizing the bullet and it can lead to accuracy issues... temp changes, velocity changes, altitude etc... can have an effect.Retumbo for me was too fast of a powder for the 245s, At 78 grains I was at 2800 fps and showing signs of a lot of pressure. N568 has been awesome for the 245s, With my 28" Bartlein 81.5 grains of N568 are giving me 2830 fps and just barely starting to feel and see pressure signs. I'm using CCI 250s, Lapua brass, COAL 3.830 .015 jump.

Bryan Litz posted an opinion of over-stabilizing a bullet and said it is better to over-stabilize than to under-stabilize especially when going through the transonic zone.

As long as you shoot good quality bullets a faster twist doesn't hurt you like some would think it would. It's when you run crappy ammo/crappy bullets or ammo that has a lot of runout in it... then a faster twist can work against you.

The only other thing to watch is really fast twist rates and style of rifling in conjunction with velocity causing bullet failures.

Later, Frank

Bartlein Barrels

Is anyone shooting factory Hornady 190s for hunting? If so, is a 1-8 barrel the right choice? Much appreciated.

1-9 twist is plenty.Is anyone shooting factory Hornady 190s for hunting? If so, is a 1-8 barrel the right choice? Much appreciated.

Many ammo and powder manufactures are using 1-8 for testing. And many of the factory rifles seem to be 1-8

I ran a 1-8 till it died and it ate 250’s all the way to 180’s. Just don’t use cheap bullets

I ran a 1-8 till it died and it ate 250’s all the way to 180’s. Just don’t use cheap bullets

This may help, the Berger Twist Stability Calculator. IIRC, many people went 1/8 for the heavier bullets, but the stability calculator indicates a 245 Berger is a 1.97 at 1/9 and 1.57 with a 1/8, both are acceptable (but lower speeds reduce the calculation). Not certain how a 4R vs 5R affects the stability, but I would think the issue with the 5R, heavy bullet and increased speed wouldn't be stability.Is it the latest consensus that a 1-9 is the best all-around for 300 PRC??

Similar threads

- Replies

- 3

- Views

- 190