Hey all,

New as a participant but long time forum reader.

I’m blueprinting a howa 1500 short action. I bought a .308 copy in 2014 or so and it’s harvested several animals. Despite being generally happy with the performance, It would have left-right POI shifts in addition to the usual up/down when you change ammunition. I could shoot a 1ish moa group with a 168 grain round, and then switch to 200 grain ammo and I’d have to come over 5-6 inches to the side. This led to wanting to rebarrel it. I decided to go with 300 WSM, and I’m a machinist by trade, so I figured it’d be a fun project to do myself.

I routinely produce parts at work with tolerances ranging from +/- 0.001” to +/- 0.0003”, so I had every confidence taking it on.

I’ve been somewhat shocked at the tolerances on the action and wanted to hear if anyone else had similar experiences to mine.

Starting with the action body itself: I built a spider fixture out of some spare aluminum and made perfect precise bushings for a rod to indicate the action in straight and true on my lathe. After getting the center of the action aligned within 0.0001”, I measured the face of it. I found that the front face of the action was out of square 0.006”, and the counterbore for the barrel out of concentricity 0.016”

I felt that this was excessive, made a note, and blueprinted the body.

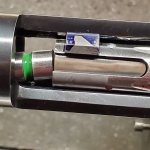

It’s necessary to increase the bolt face to accommodate the new round, so I chucked my bolt between a four jaw chuck and a steady rest. Here’s where I encountered serious error. I’m unable to get the bolt to run true, and have lost confidence in the bolt itself.

Upon measuring, I found that the firing pin hole is 0.007” off the center of the bolt body.

I’m going to proceed with the rebarreling, since it’s nearly impossible for me to end up worse than it was, but I’m curious if this is the standard amount of runout that one should expect. I genuinely believed that it would be less than .002” for my worst dimension.

New as a participant but long time forum reader.

I’m blueprinting a howa 1500 short action. I bought a .308 copy in 2014 or so and it’s harvested several animals. Despite being generally happy with the performance, It would have left-right POI shifts in addition to the usual up/down when you change ammunition. I could shoot a 1ish moa group with a 168 grain round, and then switch to 200 grain ammo and I’d have to come over 5-6 inches to the side. This led to wanting to rebarrel it. I decided to go with 300 WSM, and I’m a machinist by trade, so I figured it’d be a fun project to do myself.

I routinely produce parts at work with tolerances ranging from +/- 0.001” to +/- 0.0003”, so I had every confidence taking it on.

I’ve been somewhat shocked at the tolerances on the action and wanted to hear if anyone else had similar experiences to mine.

Starting with the action body itself: I built a spider fixture out of some spare aluminum and made perfect precise bushings for a rod to indicate the action in straight and true on my lathe. After getting the center of the action aligned within 0.0001”, I measured the face of it. I found that the front face of the action was out of square 0.006”, and the counterbore for the barrel out of concentricity 0.016”

I felt that this was excessive, made a note, and blueprinted the body.

It’s necessary to increase the bolt face to accommodate the new round, so I chucked my bolt between a four jaw chuck and a steady rest. Here’s where I encountered serious error. I’m unable to get the bolt to run true, and have lost confidence in the bolt itself.

Upon measuring, I found that the firing pin hole is 0.007” off the center of the bolt body.

I’m going to proceed with the rebarreling, since it’s nearly impossible for me to end up worse than it was, but I’m curious if this is the standard amount of runout that one should expect. I genuinely believed that it would be less than .002” for my worst dimension.