Alright got back out to the range today, I now have my own copy of QuickLoad that I'm checking pressure bounds with, fixed my headspace, and worked up some new loads using the Alpha brass.

Happy to report zero signs of pressure issues, but still getting faster than expected velocities with LVR out of this 20" barrel. As a litmus test I also chrono'd some factory Hornady intended for Gas Guns.

Data points to consider:

- Hornady book max LVR load for a gas gun is 29.7gr on a 2.245 COAL with a 108gr eld-m, based on 52000PSI PMAX

- Hornady book max LVR load for a bolt gun is 31.2gr on a 2.245 COAL with a 108gr eld-m, based on 62000PSI PMAX

- Hornady fired 6ARC brass has a h20 volume weight of ~34.5gr

- Alpha fired 6ARC brass also has a h20 volume weight of ~34.5gr

- Hornady 24" barrel reference loads:

https://static.hornady.media/site/hornady/files/load-data/6mm-arc-bolt.pdf

Rifle data:

- Zermatt Origin Action, 20" 1:75 benchmark cut with the following reamer print:

https://terminalcurves.com/6MM_ARC_BMP.pdf

Base info for my loads (pretty much factory spec in terms of seating depth):

COAL: 2.250

CBTO: 1.699

Primer: CCI BR4

Brass: Alpha

Powder: LeverEvolution, loaded at ~77 degrees, shot at ~75degrees

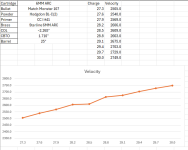

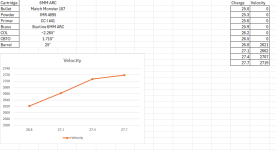

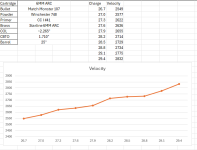

Velocities and SD over 5 shot groups vs closest Hornady book load data:

My 20": 29.2gr LVR Chrono'd 2730fps sd 6 ... 24" Hornady book data: 29.1gr LVR 2650fps

My 20": 29.7gr LVR Chrono'd 2784fps sd 6 ... 24" Hornady book data: 29.6gr LVR 2700fps

My 20": 30.2gr LVR Chrono'd 2803fps sd 6 ... 24" Hornady book data: 30.2gr LVR 2750fps

QuickLoad Predictions based on 34.500gr H20 vs my loads and Hornady book data:

20": 29.2gr LVR 2621fps ... 24": 29.1gr LVR 2711fps

20": 29.7gr LVR 2669fps ... 24": 29.6gr LVR 2759fps

20": 30.2gr LVR 2717fps ... 24": 30.2gr LVR 2816fps

Hornady factory 6ARC 108gr eld-m ammo notes:

- Posted box velocity out of 24" barrel is 2750fps

- Chrono'd velocity out of my 20" barrel over a 10 shot group is 2665fps which at about 20fps per inch slower tracks pretty darn close to what I'd expect to see out of the 20" with factory ammo. If my barrel was mechanically causing some sort of pressure issue I'd expect to see a velocity increase with factory ammo as well.

I don't know which powder Hornady is using for their factory rounds, but I assume something temp stable.

With LVR, assuming their book data is out of a 24" barrel I'm still running considerably faster than their book data, to the tune of 130-160fps when also taking into account the 80fps I _SHOULD_ be giving up on barrel length vs their data. Half of that is likely explained by LVR just being a powder that gets better velocities than most I suppose. But even with that my barrel seems to be running LVR very fast for a 20".

But it MUST be the powder itself, because again, Hornady factory ammo loaded to the same measurements with the same bullet is running exactly what I'd expect to see out of the 20".

So beyond the primer and using LVR, not sure how to explain that large of a velocity increase.

At 29.7gr LVR QuickLoad has me in an acceptable PSI range but thinks I should be around 2669fps out of the 20" and 2621fps at 29.2gr of LVR. I am consistently 110fps faster than what QuickLoad predicts.

What's interesting, when setting a 24" barrel length QuickLoad fairly closely tracks to the Hornady book 24" barrel data but is consistently 60fps high (which you can chalk up to minor burn rate and temperature diffs probably).

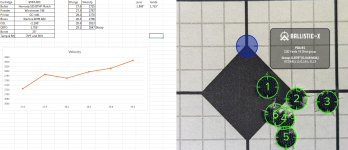

For me 29.7gr hits the 2750fps mark I was aiming for as a baseline and I don't see any pressure signs like ejector marks anymore with the correct headspacing. Primers also look fine, so I _THINK_ I'm going to call that good and chalk up the difference to LVR gremlins!? I mean clearly my velocities are still high to the point where you'd think _something_ is causing a pressure difference but I'm scratching my head on what it might be if not just my lot of LVR and the CCI primer.

EDIT: to be on the safe side rooted on real world chrono data, since ~2800-2850fps indicates max pressure of around 62000psi in a 24" barrel based on both QuickLoad and Hornady data, in a 20" that should be around ~2700-2750fps so any charges that keep me comfortably at or below that velocity line _SHOULD_ be fine in my 20" and I reckon that should account for whatever burn rate variance is going on with my lot of LVR.

Groups are still 0.3-0.5MOA on average with each load. SD was surprisingly consistent amongst all of the loads (~6 for all on 5 round groups).