I just got a 6 dasher that I put together. Zermatt origin with proof pre fit 26" barrel. Brand new alpha brass srp. At 31.7 with varget I got a blown primer didn't come out but it had carbon ring around it and a hole. I started with shooters world precision and had it do the same thing at 31.5 with heavy bolt lift so I stopped cause I was just looking for pressure with the powder and just switched to varget. I did 5 rounds at 31.7 and didn't have a problem with the other 4 rounds but the 1 round had the problem. Shot 5 at 32.2 and they didn't have any problem or heavy bolt lift. I'm using winchester #41 cause it's what I have and I didn't think it would be a problem but is that the problem? Do I need to switch primers i do have some cci450. I also noticed my bolt now has 2 little dimples on the face is it trashed now to?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Primer blowout

- Thread starter Bowtechassassin

- Start date

Looking at the pictures and before I read your post I was guessing it was probably Winchester primers.I just got a 6 dasher that I put together. Zermatt origin with proof pre fit 26" barrel. Brand new alpha brass srp. At 31.7 with varget I got a blown primer didn't come out but it had carbon ring around it and a hole. I started with shooters world precision and had it do the same thing at 31.5 with heavy bolt lift so I stopped cause I was just looking for pressure with the powder and just switched to varget. I did 5 rounds at 31.7 and didn't have a problem with the other 4 rounds but the 1 round had the problem. Shot 5 at 32.2 and they didn't have any problem or heavy bolt lift. I'm using winchester #41 cause it's what I have and I didn't think it would be a problem but is that the problem? Do I need to switch primers i do have some cci450. I also noticed my bolt now has 2 little dimples on the face is it trashed now to?

With Alpha brass there's an issue with their a little larger than the usual SRP flash holes, as that tends to produce this result when using thin skinned SRP's. . . like CCI400's. I got the same result with my Alpha brass using CCI400's; switched to CCI 450's and had no further issue. Also, did real well using Remington 7.5's.

There have been many reports of some bad Win 41’s out there the last year or so. Betting you have some.

I've got 2 bricks i was gonna use specifically for this gun but it sounds like i need to get rid of them entirely. What's the opinions about the bolt head?

Bolt face is fine.

Quit loading too hot on top of crap primers. The choice to then increase powder after blowing primers was a poor one. The bolt face should be fine.

Quit loading too hot on top of crap primers. The choice to then increase powder after blowing primers was a poor one. The bolt face should be fine.

The bolt face is not fine... it could be refaced in the lathe, and reset headspace.

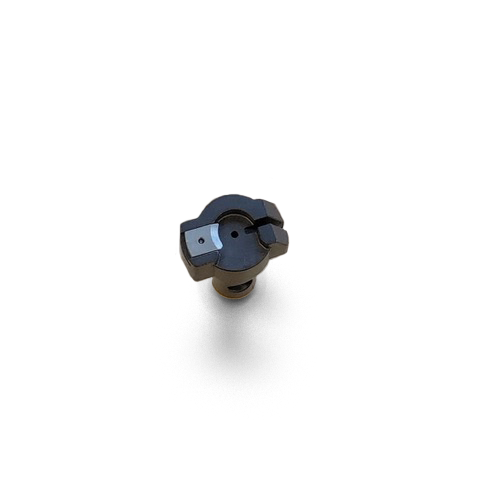

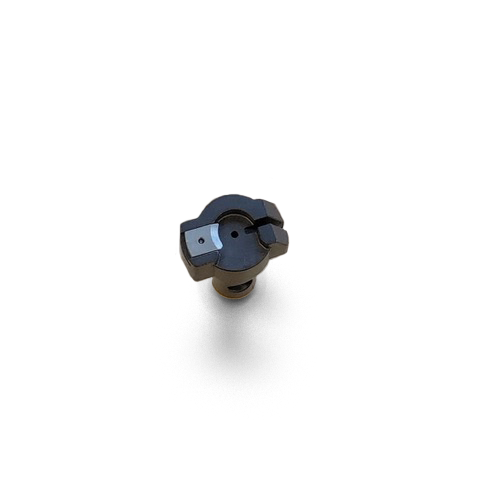

The firing pin hole looks out of round.

So bush the firing pin hole, at the same time.

Primers are struck off center. So barrel, bolt, or reciver are not on the same centerline. Common in old production rifles.

I use Remington 7 1/2 primers in 6 Dasher Alpha brass exclusively, as primer pockets are tight with 450s.

The firing pin hole looks out of round.

So bush the firing pin hole, at the same time.

Primers are struck off center. So barrel, bolt, or reciver are not on the same centerline. Common in old production rifles.

I use Remington 7 1/2 primers in 6 Dasher Alpha brass exclusively, as primer pockets are tight with 450s.

The bolt face is not fine... it could be refaced in the lathe, and reset headspace.

The firing pin hole looks out of round.

So bush the firing pin hole, at the same time.

Primers are struck off center. So barrel, bolt, or reciver are not on the same centerline. Common in old production rifles.

I use Remington 7 1/2 primers in 6 Dasher Alpha brass exclusively, as primer pockets are tight with 450s.

It's an Origin action.

The cost to do all that machining would exceed the price of two new bolt heads.

I wouldn't get rid of the primers personally, I just wouldn't use them for that cartridge at that level. I never have purchased any #41's as I use 450's, 7 1/2's, or my final 5k of Wolf SRM's for "high pressure" loads.

I didn't notice if it was mentioned, but I would check the firing pin tip while I was at it to check and see if it took some of that extra velocity goodness.

I wouldn't worry too much about the bolt face, but you can always just change out the bolthead if it bothers you. Your extractor either is got some small chips taken out of it or has some brass on it from my perspective.

I didn't notice if it was mentioned, but I would check the firing pin tip while I was at it to check and see if it took some of that extra velocity goodness.

I wouldn't worry too much about the bolt face, but you can always just change out the bolthead if it bothers you. Your extractor either is got some small chips taken out of it or has some brass on it from my perspective.

Not if you have access to a lathe, its free and a simple 10 minute task to face the bolt face. Probably take .003" or 004" and it will affect headspace, so reset headspace, if barrel nut is used...or set the barrel back .003" & check clearance.It's an Origin action.

The cost to do all that machining would exceed the price of two new bolt heads.

Not if you have access to a lathe, its free and a simple 10 minute task to face the bolt face. Probably take .003" or 004" and it will affect headspace, so reset headspace, if barrel nut is used...or set the barrel back .003" & check clearance.

I'm gonna go out on a limb here and say the OP doesn't have a lathe.

A friend with lathe or local gunsmith could handle this job...hence "access" to a lathe.I'm gonna go out on a limb here and say the OP doesn't have a lathe.

That looks like the patented Winchester primer shoulder pinhole defect, how old are these primers? Probably 15 years ago they had a bunch of WLRs with this defect, I had some and at least one non-swappable bolt head that got etched. I think they wound up replacing bolts for some folks, would have figured that surely they had fixed this issue in the subsequent decade and a half but.....

A friend with a lathe might work.

Depends on the friends skill of course. I wouldn't trust my own skill to do the job, cause I suck at math and getting the correct tools would cost more than the new bolt head.

A gunsmith would charge more than the cost of a new bolt head just to bush it.

The bolt head is a little over $100.

If he had to reset headspace on a shouldered barrel, then the gunsmith cost goes way up. The OPs friend would also need a reamer.

A nut barrel would be different as long as the modified bolt head doesn't make contact with the breech end of the barrel with the new headspace. (It shouldn't)

I wouldn't have any worries about continued use of the bolt head. I would inspect the firing pin tip for damage though.

However...

My recommendation is for the OP to back way up on his powder charges and start over. If he doesn't trust the 41s, then move on. If he's using the 41s because they handle pressure better, then there's your problem. CCI 400s are perfectly fine and safe with sane loads. If someone insists on shooting in the 70,000psi+ window, then these problems and more will crop up.

Depends on the friends skill of course. I wouldn't trust my own skill to do the job, cause I suck at math and getting the correct tools would cost more than the new bolt head.

A gunsmith would charge more than the cost of a new bolt head just to bush it.

The bolt head is a little over $100.

If he had to reset headspace on a shouldered barrel, then the gunsmith cost goes way up. The OPs friend would also need a reamer.

A nut barrel would be different as long as the modified bolt head doesn't make contact with the breech end of the barrel with the new headspace. (It shouldn't)

I wouldn't have any worries about continued use of the bolt head. I would inspect the firing pin tip for damage though.

However...

My recommendation is for the OP to back way up on his powder charges and start over. If he doesn't trust the 41s, then move on. If he's using the 41s because they handle pressure better, then there's your problem. CCI 400s are perfectly fine and safe with sane loads. If someone insists on shooting in the 70,000psi+ window, then these problems and more will crop up.

That looks like the patented Winchester primer shoulder pinhole defect, how old are these primers? Probably 15 years ago they had a bunch of WLRs with this defect, I had some and at least one non-swappable bolt head that got etched. I think they wound up replacing bolts for some folks, would have figured that surely they had fixed this issue in the subsequent decade and a half but.....

It wasn't just the Winchester primers.

I had a batch of Remington 7-1/2 that fucked up the bolt face on my Cooper 17 Mach IV.

In fact, I've had less problems with the copper colored Winchesters than with the 7-1/2s.

The white box, nickle plated Winchester were fantastic. Good luck finding any of those still on the shelves.

I'm hoarding the few I have left.

It wasn't just the Winchester primers.

I had a batch of Remington 7-1/2 that fucked up the bolt face on my Cooper 17 Mach IV.

In fact, I've had less problems with the copper colored Winchesters than with the 7-1/2s.

The white box, nickle plated Winchester were fantastic. Good luck finding any of those still on the shelves.

I'm hoarding the few I have left.

I'm sure all manufacturers can have issues, but the brass colored Winchester primers are known for having had many lots with this defect in the past, specifically in the '08-'13 timeframe. The ones I had were WLRs, and it seems like those are the most cited online, but there are reports of the same issue in other sizes. I assume these are newer than that, but primers last a while.

I've had great luck with Rem 7.5s and 450s, no problems whatsoever.

Here are a few older links with reported batch numbers in case the primers in the OP are from that timeframe.

Winchester Primer Recall | Single-Actions

Probably should have put this in the reloading section but I figured it will get seen more here. Anyone heard anything about a Winchester primer recall ? Is this something old,new,true, or inte

Bad lot of winchester primers

I bought a box of winchester primers and shot a few loads the other day to discover holes in the sides of my brass/primers and black all around the primers. My bolt face has little burn marks in it. I've read that winchester will send your money back or replace them with new primers. Does anyone...

Switch to CCI450, CCI #41, or 205M/205AR. If the bolt face erosion causes excess primer flow, buy a new bolt head. There's no need to over complicate this by skimming the bolt face, changing HS, and rechambering. This is a $125 dollar fix at most.

www.zermattarms.com

www.zermattarms.com

Bolt Heads - Zermätt Arms Website

Replacement or additional bolt heads are available for purchase. Both models have floating bolt heads that offer Controlled Round Feed and mechanical ejection. IF YOU NEED A LEGACY PRODUCT FOR TL2 OR SR2, PLEASE CALL FOR ASSISTANCE. All returned items will be charged a 20% restocking fee.

I have about 4,000 CCI 400’s

And I’m down to my last 2,000 BR-4’s

I tried using the 400’s in my 6.5 Creedmoor low node load that is 2650fps and my 6BR with Hornady 75gr V-Max at 3,200 and both popped primers where where the BR-4’s never did.

I never popped a primer with CCI 400’s in 5.56

And I’m down to my last 2,000 BR-4’s

I tried using the 400’s in my 6.5 Creedmoor low node load that is 2650fps and my 6BR with Hornady 75gr V-Max at 3,200 and both popped primers where where the BR-4’s never did.

I never popped a primer with CCI 400’s in 5.56

I googled Winchester #41 primer failure and came up with this thread on ARFCOM; not a fan of that forum, but this thread has a lot of info. Skip to the 4th page and scroll down for a list of lot numbers and what Winchester did about it.

www.ar15.com

www.ar15.com

WARNING! Defective Winchester #41 primers on the shelves. - Page 4 - AR15.COM

Firearm Discussion and Resources from AR-15, AK-47, Handguns and more! Buy, Sell, and Trade your Firearms and Gear.

I was shooting WLRMs at that time, and noted that it was "just" the WLRs that had a problem/got recalled, etc. I figured I was safe but it happened to me with the WLRMs, too.That looks like the patented Winchester primer shoulder pinhole defect, how old are these primers? Probably 15 years ago they had a bunch of WLRs with this defect, I had some and at least one non-swappable bolt head that got etched. I think they wound up replacing bolts for some folks, would have figured that surely they had fixed this issue in the subsequent decade and a half but.....

They were bought a year ago. I don't remember where from but I wrote on the box with the date so it's newer primers.

I have 2 metal lathes, and a Bridgeport mill, a fair amount of guys have lathes in my neighborhood. Living in a metals industrial area, with lots of machinists, logging, and large farms have metal lathes.Yeah probably not to many people just have a lathe hanging out in their garage or at their disposal.

My son and neighbor even have one that would do this job, and the neighbor belongs to the local rifle club...ask around.

I myself worked at a machine for many years building downhole tools for baker Hughes and a few other companies, I agree it would be a very simple job to face the bolt. My closest neighbor is a long ways away I live in a pretty rural area not sure about the op, but if I were to need any work done my father in law still works at a machine shop and he could take care of it if it were me.