Not going to argue the point but you are wrong. Remington's 308W have a long free bore and it is not per SAAMI. Try and load a 168 SMK 0.010" off the lands in a 700 and only the boat tail would be in the case mouth. No, it is not just my rifle. Those of us who reload for this rifle are familiar with this.

Probably NOT wrong....you are not informed.

No argument needed.

I have loaded many thousands of rounds for factory Rem 700s.

it's called tolerence, which all gun manufacturers must adhere to, and most likely in SAAMI spec ...which is quite generous or there would be a recall, if discovered.

Many of these barrels are not chambered with a reamer, but hammer forged chamber and rifled all in one hammer forging operation.

There is a plus .015" tolerance added to the length of the free bore, so the bullets can be seated out or a longer jump to the rifling and still be in SAMMI spec.

Chamber headspace is actually ten thousands total!... min to max.

Add that to the cartridge min in the specs and a min cartridge and a max headspsce chamber.

A new factory 308 cartridge could be .013 from hitting the shoulder in the 308 max chamber and still be in SAAMI specs!

And many of you were concerned about plus .001" to .004" headspace!

When you can actually have a max chamber .010" above min, and a cartridge .003" shorter than min chamber for a total of .013" excess space and still be in SAAMI specs.

Not good for reloaders...one shot only.

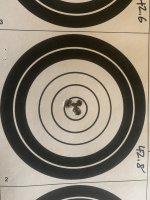

So here's a SAAMI reamer Rem 700 rifle I chambered tight headspace.

168 gr Sierra tipped MK 2.970" hits rifling

169 SMK 2.922"

308 AR 10 16" auto loader barrel purchased from WC very accurate barrel.

169 gr SMK 2.926" hits the rifling.

There are two rifle examples with SAAMI reamers. The boat tail is close to out of the neck....but with the added free bore tolerences it could be out even farther and still be in SAMMI specs.

You can order a shorter freebore reamer of your choice and have your gunsmith chamber a barrel for you... but it won't be a SAAMI spec reamer.