https://www.pnas.org/content/pnas/117/2/1009.full.pdf#page=6

https://www.pnas.org/content/pnas/117/2/1009.full.pdf#page=6

High-yield monolayer graphene grids for near-atomic

resolution cryoelectron microscopyYimo Hana,1, Xiao Fana, Haozhe Wangb, Fang Zhaoc, Christopher G. Tullyc, Jing Kongb, Nan Yaod, and Nieng Yana,1

aDepartment of Molecular Biology, Princeton University, Princeton, NJ 08544; bDepartment of Electrical Engineering and Computer Science, Massachusetts

Institute of Technology, Cambridge, MA 02139; cDepartment of Physics, Princeton University, Princeton, NJ 08544; and dPRISM Imaging and Analysis Center,

Princeton University, Princeton, NJ 08544

Contributed by Nieng Yan, November 22, 2019 (sent for review November 1, 2019; reviewed by Jun Lou and Qing-Tao Shen)

Cryogenic electron microscopy (cryo-EM) has become one of the

most powerful techniques to reveal the atomic structures and

working mechanisms of biological macromolecules. New designs

of the cryo-EM grids—aimed at preserving thin, uniform vitrified

ice and improving protein adsorption—have been considered a

promising approach to achieving higher resolution with the min-

imal amount of materials and data. Here, we describe a method

for preparing graphene cryo-EM grids with up to 99% monolayer

graphene coverage that allows for more than 70% grid squares for

effective data acquisition with improved image quality and pro-

tein density. Using our graphene grids, we have achieved 2.6-Å

resolution for streptavidin, with a molecular weight of 52 kDa,

from 11,000 particles. Our graphene grids increase the density of

examined soluble, membrane, and lipoproteins by at least 5-fold,

affording the opportunity for structural investigation of challeng-

ing proteins which cannot be produced in large quantity. In addi-

tion, our method employs only simple tools that most structural

biology laboratories can access. Moreover, this approach supports

customized grid designs targeting specific proteins, owing to its

broad compatibility with a variety of nanomaterials.

structure determination |cryo-EM |graphene grid |UV/ozone |high resolution

Cryogenic electron microscopy (cryo-EM) provides an effec-

tive way to investigate the structures of biological macro-

molecules (1–4). Technological breakthroughs in direct electron

detection (5, 6) and advanced algorithms (6–8) have enabled

cryo-EM to map the precise structural details of biological

macromolecules at near-atomic resolutions (9), which is essential

for the understanding of their functions. As the cryo-EM com-

munity expands, a shared view of many researchers is that the

bottleneck for cryo-EM resides in sample preparation. Cryo-EM

requires protein particles to be suspended in a thin layer of vit-

rified ice to avoid denaturation (10, 11). To achieve this, con-

tinuous amorphous carbon films and holey carbon grids

(Quantifoil) have been widely used. Following glow-discharge

plasma treatment, these grids become hydrophilic and allow

the formation of a thin layer of aqueous solution upon blotting

by a filter paper (12).

Among these grids, the continuous carbon film (usually 20 nm

thick) inevitably introduces electron scattering that adds noise

and reduced image resolution. Therefore, holey carbon grids,

where the layer of solution can form in the hole area, have been

considered the preferred cryo-EM grids for high-resolution

single-particle analysis. However, due to the distinct protein

properties, for which we coined a term “proteinality,”Quantifoil

grids do not work for all proteins. While some proteins prefer to

attach to the carbon film and fail to enter the holes, others stay

on the air–water interface with compromised folding (13). In

addition, the nonuniformity of ice thickness makes it difficult

to search across the entire grids for thin ice areas, where the

image contrast is optimal for high-resolution image processing.

Since thin ice and high protein density are key to high-resolution

reconstruction of the protein structure, a better design of the

cryo-EM grid that can solve these problems will benefit the cryo-

EM community.

Graphene materials (such as graphene oxide [GO]) (14) have

been used as supporting films in cryo-EM to improve the protein

density in the hole areas of Quantifoil grids (15–18) (schemati-

cally shown in Fig. 1 A and D). Compared to films made by other

materials, graphene derivatives have the advantages of being

intrinsically thin and made of only light elements (carbon, oxy-

gen, hydrogen, etc). These advantages make functional graphene

transparent to 300-kV electrons. Among the graphene materials,

GO films have been tested using 20S proteasome (700 kDa) at a

low concentration (tens of micrograms per milliliter) to re-

construct a structure at ∼2.5-Å resolution with reasonable ad-

sorption (19). Despite the improvements of protein adsorption,

these grids have yet to be widely used in the community mainly

for 3 reasons: 1) low coverage of graphene limits the effective

areas to acquire cryo-EM data; 2) nonuniform surface contam-

ination results in either protein aggregation or no adsorption;

and 3) an intricate fabrication process or requirement of ex-

pensive instruments that most structural biology laboratories

have little access to.

Here, we demonstrate a more convenient and less costly ap-

proach to fabricating high-quality graphene cryo-EM grids with

nearly full graphene coverage (Fig. 1B) and clean graphene

surfaces (Fig. 1C), which provide a uniform and thin ice layer

Significance

Single-particle cryogenic electron microscopy (cryo-EM) repre-

sents the cutting-edge technology for structural determination

of biomacromolecules. However, technical challenges associ-

ated with cryosample preparation limit cryo-EM from achieving

higher resolution for broader range of targets. Here, we

demonstrated a high-yield, monolayer graphene-supporting

film improved the cryosample quality. Using this approach, we

have achieved, so far, the highest resolution structure of the

smallest protein by cryo-EM with the minimal number of

datasets. Our technique paves the way for more general cry-

osample preparation for near-atomic resolution cryo-EM.

Author contributions: Y.H. and N. Yan designed research; Y.H. and X.F. performed re-

search; Y.H., H.W., and J.K. contributed new reagents/analytic tools; Y.H., X.F., F.Z., C.G.T.,

and N. Yao analyzed data; and Y.H. and X.F. wrote the paper.

Reviewers: J.L., Rice University; and Q.S., ShanghaiTech University.

Competing interest statement: The authors N. Yan and Y.H. are inventors on the patent

application entitled “Fabrication of nanomaterial cryogenic electron microscopy (cryo-

EM) grids.”

Published under the PNAS license.

Data deposition: The data reported in this paper have been deposited in the Electron

Microscopy Data Bank (EMDB) (accession no. EMD-20907) and Electron Microscopy Public

Image Archive (EMPIAR) (accession no. EMPIAR-10335).

1To whom correspondence may be addressed. Email:

[email protected] or nyan@

princeton.edu.

This article contains supporting information online at

https://www.pnas.org/lookup/suppl/

doi:10.1073/pnas.1919114117/-/DCSupplemental.

First published December 26, 2019.

www.pnas.org/cgi/doi/10.1073/pnas.1919114117 PNAS | January 14, 2020 | vol. 117 | no. 2 | 1009–1014

BIOPHYSICS AND

COMPUTATIONAL BIOLOGY

Downloaded by guest on August 12, 2021

(Fig. 1E) and improve the protein density (Fig. 1F) for single-

particle cryo-EM analysis.

Results

Fabrication of Graphene Grids. We fabricated graphene cryo-EM

grids by transferring continuous monolayer graphene from its

original substrate, a copper foil, to a Quantifoil holey carbon grid

using an organic molecule-assisted transfer method, as sche-

matically described in Fig. 2A (more details in SI Appendix, Fig.

S2). With a thin layer of methyl methacrylate (MMA) to support

graphene during the transfer process, our method results in a

very high percentage coverage of hole areas by suspended gra-

phene. Fig. 1B shows a scanning electron microscopy (SEM)

image of a graphene grid where all holes in the holey carbon film

are covered without any broken ones. Statistics from different

areas indicate that the average yield of suspended monolayer

graphene is ∼99% ( Fig. 1 B, Inset), higher than any previously

reported functional graphene cryo-EM grids. The high yield of

graphene using this method is consistent from batch to batch

(SI Appendix, Fig. S1 ). In addition, our cleaning process is suf-

ficient to remove most organic molecule residues and achieve a

clean graphene surface (Fig. 1C). The entire fabrication process

takes about a few hours, and the production of up to hundreds

of grids can be done en masse without the special requirement of

equipment or large quantity of reagent (an overview of the method

appears in SI Appendix, Fig. S2 and a video demonstration in

Movie S1).

Since graphene is hydrophobic, its natural surfaces show lim-

ited adsorption of proteins (SI Appendix, Fig. S3). Conventional

glow-discharge plasma cleaning (Ar or O2 plasma) that has been

widely used to generate hydrophilic carbon films will damage

graphene within seconds, owing to the atomic thinness of gra-

phene. Instead, we employed UV/ozone, which uses ultraviolet

(UV) irradiation to generate a small amount of ozone gas to

gently oxidize sample surfaces (Fig. 2B). UV/ozone has been

widely used to clean the surface of semiconductors and polymers

(20, 21). The ozonation of monolayer graphene forms oxygen-

ated functional groups, which can effectively render the surface

of graphene hydrophilic (22–24).

UV/ozone has the advantage of adding functional groups to

graphitic surfaces at a slow, and thus, controllable rate, there-

fore, fine tuning the surface properties of graphene. The contact-

angle measurements (Fig. 2C) demonstrate that graphene

gradually becomes hydrophilic as the UV exposure time in-

creases. Within 10 min, UV/ozone effectively converts graphene

into a hydrophilic graphene derivative, as shown in the orange

box in Fig. 2C. Raman spectroscopy (Fig. 2D) indicates that the

hydrophilic graphene derivative after 10 min of UV irradiation is

composed of oxygenated graphene (orange curve in Fig. 2D),

while 5 more minutes of UV irradiation turns graphene into

complete GO (blue curve in Fig. 2D). X-ray photoelectron

spectroscopy (XPS) analysis (SI Appendix, Fig. S4A) indicates an

increment of carboxylic groups and C–O bonds from the oxy-

genated functional groups. In the XPS plots, a noticeable drop of

C–O peak appears in the sample in UV irradiation after 10 min,

indicating that a cleaning process removes the surface contami-

nants on graphene due to air exposure. In addition, we found

that under UV irradiation, graphene films can survive up to an

hour, where nanopores start to emerge and expand (SI Appendix,

Fig. S4B). As the 10-min treatment is relatively gentle and pre-

sents clean and uniform surfaces with good hydrophilicity, we

used this parameter to treat our graphene for the following cryo-

EM experiments.

A 2.2-Å Resolution Reconstruction of Apoferritin with Graphene Grids.

To demonstrate that our high-quality graphene grids are suitable

and practical for cryo-EM at near-atomic resolution, we pre-

pared standard apoferritin on our graphene grids for cryo-EM

data collection and single-particle analysis (Fig. 1F). In addition

to the improved protein density, we have reached a high-

resolution reconstruction of apoferritin at 2.2 Å (Fig. 3A and

SI Appendix, Fig. S5A). The resolution was determined by gold

standard Fourier shell correlation (FSC) (SI Appendix, Fig. S5B),

where the information limit has already reached the Nyquist

frequency of the input micrographs, indicating our graphene

grids are suitable for resolution beyond 2.2 Å. In the recon-

structed local density maps, we were able to clearly dock indi-

vidual residues in the side chain from the published Protein Data

Bank (PDB) model (Fig. 3B). In addition, the central holes of

the benzene rings were clearly resolved in the density map (Fig.

3B, Phe51 and Tyr137), confirming we have achieved a veritable

high resolution using the graphene grids. Our reconstruction of

apoferritin at 2.2-Å resolution is the highest among those in the

EM Data Bank (EMDB) using GO or other thin film-supported

grids. These results indicate the bountiful potential of our gra-

phene grids in cryo-EM investigations of protein structures at a

near-atomic resolution.

A 2.6-Å Resolution Reconstruction of 52 kDa Streptavidin with Graphene

Grids. The advantages of using graphene cryo-EM grids can be

divided into 2 categories. For small proteins (<200 kDa), graphene-

supporting film can effectively reduce the ice thickness without

A

BC

D

EF

Fig. 1. High-yield graphene grids for cryo-EM. (A) Side-view schematic of

graphene grids. (B) Large-scale SEM image of graphene film on holey carbon

Quantifoil grids. All of the holes in this area are covered by suspended

graphene. The Inset displays the statistics of graphene yield. On average,

99% of graphene has been successfully suspended over holes. The statistics

were conducted by counting the yield of suspended graphene in 50 squares.

More statistics from different batches are shown in SI Appendix, Fig. S1. ( C )

Zoomed-in TEM image of suspended graphene, showing its uniformity and

cleanness. (D) Side-view schematic of cryo-EM sample on graphene grids. (E )

Low-magnification image of a cryo-EM sample using graphene grids. The

uniformity and cleanness of graphene contributes to a uniform and thin ice

layer with embedded proteins. (F ) Cryo-EM micrograph of apoferritin on

graphene grids, compared to the same sample on holey carbon grids (Inset).

The apoferritin concentration in solution is 1.2 mg/mL.

1010 |

www.pnas.org/cgi/doi/10.1073/pnas.1919114117 Han et al.

Downloaded by guest on August 12, 2021

introducing background noise to the images, allowing for higher

resolution structural determination of the proteins. For mem-

brane proteins embedded in detergent micelles or liposomes,

which are usually hard to acquire in large quantities, graphene

grids can improve the protein adsorption, thus overcoming the

issues of low protein concentration. Therefore, we evaluated the

practical behavior of our graphene grids using a 52-kDa small

soluble protein and a membrane protein in detergent micelles

and liposomes.

We deposited 52 kDa streptavidin (the smallest soluble pro-

tein that has been solved hitherto in EMDB) onto freshly UV/

ozone-treated graphene grids to prepare frozen-hydrated streptavidin

samples in Vitrobot with a general plunge freezing method. The

overall grid montage collected in cryo-EM displays more than

70% of the grid squares containing thin ice layers that are suit-

able for data collection (SI Appendix, Fig. S6 A and B). Each grid

square possesses a uniform thin ice layer with proteins embedded

in it (SI Appendix, Fig. S6 C and D), where it is not necessary to

screen for good areas in high magnification to save time and

effort. After data acquisition, the 52 kDa streptavidin particles

could be identified clearly from the motion-corrected micro-

graphs (Fig. 4A). The good image contrast under such a small

defocus value of −0.85 μm further confirms that the ice is much

thinner than that in cryosamples using conventional grids. Fur-

thermore, the first-order reciprocal lattice of graphene could be

identified precisely in the Fourier transform of the micrograph

(Fig. 4B). The sharp peaks (circled in orange in Fig. 4B) indicate

that the raw information contained in the micrograph could

reach to at least 2.14 Å in frequency.

After single-particle analysis using Relion (25) (details in SI Ap-

pendix, Fig. S7 ), we obtained the structure of apostate streptavidin

at 2.6-Å resolution (Fig. 4C), where the density map has dem-

onstrated convincing structural information of the residues in the

beta strands (Fig. 4D). The structure resolution was estimated

from gold standard FSC criteria (Fig. 4E) and the quality of the

reconstruction was further validated by local resolution and di-

rectional 3-dimensional (3D)-FSC analysis (SI Appendix, Fig. S8

A–D). In addition, the final reconstruction of the 2.6-Å structure

was obtained from only ∼11,000 streptavidin particles with an

estimated Rosenthal–Henderson B factor of 72.8 Å2 (SI Ap-

pendix, Fig. S8 E). This is much smaller than previously pub-

lished reconstruction results of streptavidin (26), indicating that

O3

O3

O2

O2 O2

O-

O-

C O3

MMA

Graphene

TEM grid

Graphene grid

enehpargdetanozOenehparG UV/ozone

2D

G

D

00030021 1800 2400

Intensity (a.u.)

Raman shift (cm-1)

6 min

10 min

15 min

Pristine

0 min

10 min

30 min

D’

OC

A

B

C D

Fig. 2. Fabrication of graphene cryo-EM grids. (A) Schematic summary of graphene grid fabrication process. More details are provided in SI Appendix, Fig. S2 . ( B)

Schematic of surface treatment by UV irradiation. The ozonation of graphene adds oxygenated functional groups to the graphene surface, which makes the

graphene derivative hydrophilic. (C) Contact angle measurements showing that UV/ozone treatment increases the hydrophilicity (original graphene: 89.4°; 10 min:

71.6°; 30 min: 45.5°). (D) Raman spectroscopy shows that 10-min UV/ozone treatment can convert graphene (indicated by the G peak) to oxygenated graphene by

creating disorders (indicated by the D and D’peaks in the orange curve). Fifteen minutes of UV/ozone can effectively convert graphene into GO (blue curve).

AB

Fig. 3. Graphene grids for standard apoferritin. (A) Single-particle re-

construction of apoferritin at 2.2-Å resolution. (B) Representative density

maps of selected residues (fitted with PDB model 1FHA, ref. 37) demonstrate

convincing side chain structures.

Han et al. PNAS | January 14, 2020 | vol. 117 | no. 2 | 1011

BIOPHYSICS AND

COMPUTATIONAL BIOLOGY

Downloaded by guest on August 12, 2021

the high-resolution information is better preserved using our

graphene grids.

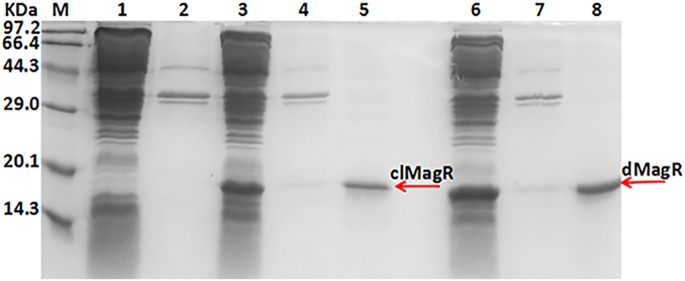

High Density of Membrane and Lipoproteins on Graphene Grids.

Unlike most soluble proteins, membrane proteins are usually

more difficult to obtain in large quantity or high protein con-

centration. Testing with a bacteria sodium channel (NaChBac)

purified in detergent micelles, we observed a 5-fold improvement

of the protein density using our graphene grids (Fig. 5A vs. Fig.

5B). Despite the adsorption of the membrane proteins on

graphene-supporting film, we observed a reasonable distribution

of different views, which is essential for further single-particle

data processing. In addition, we reconstitute NaChBac into li-

posomes for structural investigation, which can provide more

orientations of the protein for single-particle analysis, as well as

reproducing more of the proteins’native physiological environ-

ments. The long-time historical challenge to investigate the

structure of lipoproteins is the low density of liposomes on a

cryo-EM holey carbon grids (27, 28) (Fig. 5C). However, our

graphene grids remarkably improve the liposome density by

providing a hydrophilic surface to attract liposomes (Fig. 5D).

These results imply that our graphene grids can assist single-

particle cryo-EM on membrane proteins in detergent micelles

(or potentially lipid nanodiscs), as well as liposomes by improv-

ing the protein density. Our grids will reduce the requirements of

cryo-EM sample preparation, allowing for structural investiga-

tion of membrane proteins that cannot be produced in large

quantity or concentrated to high concentration.

Conclusions and Discussions

In summary, we developed a robust approach to produce high-

quality graphene grids for cryo-EM with about 99% suspended

graphene coverage. Our graphene grids provide thinner ice

layers and an increased protein density. We have achieved a 2.6-

Å resolution structure of 52 kDa streptavidin and a 2.2-Å reso-

lution structure of standard apoferritin. For membrane proteins

and lipoproteins that are usually hard to prepare in large

quantities, we have achieved more than 5-fold improvement of

protein density, which will aid the studies of membrane proteins

in their more native environments. In addition, the method we

described to make graphene grids can be easily accessed by most

structural biology research groups with reasonable expense. Our

method can also be applied to other nanomaterials such as 1-

dimensional nanowires and nanotubes, which can allow for more

sophisticated grid design targeting specific proteins. We expect

our method to benefit the cryo-EM community by improving the

sample preparation process.

Materials and Methods

Continuous Monolayer Graphene Synthesis. In this research, commercial cop-

per foils with 99.8% purity (Alfa Aesar no. 13382) were used as the substrate

to grow single-layer graphene by chemical vapor deposition (CVD) method.

Before growth, we used nickel etchant (Nickel Etchant TFB by Transene

Company, Inc.) to clean the surface of the copper foil. The foil was then

placed in a CVD system with a base pressure of 35 mTorr. The foil was

annealed in the CVD chamber for 30 min at 1,030 °C with a 10 standard cubic

centimeter per minute (sccm) H2 flow. Subsequently, single-layer graphene

was grown at the same temperature (1,030 °C) with 60 sccm H2 and 3.5 sccm

CH4 for 30 min to form a continuous monolayer. The graphene growth

protocol is similar to the one used in ref. 29. Alternatively, continuous

monolayer graphene on copper foil can be purchased from Graphene

Supermarket.

Graphene Grid Fabrication. The graphene grown by CVD or alternatively

purchased from Graphene Supermarket came with graphene on a copper foil

on both sides. We first coated the graphene on copper foil with MMA EL 6

using a home-made spin coater at the speed of ∼2,500 rpm for 1 min (Movie

S1). The MMA/graphene/Cu/backside graphene can be kept at room

AB

CED

Fig. 4. Graphene grids for small soluble proteins. (A) Cryo-EM micrograph of 52 kDa streptavidin particles. Despite a small defocus value (−0.85 μm),

streptavidin proteins present nice contrasts in the micrograph. (B) Fourier transform of A with graphene reciprocal lattice circled in orange. (C ) Single-particle

reconstruction of 52 kDa streptavidin at 2.6-Å resolution. (D) Representative density maps of 2 beta strands (fitted with PDB model 6J6K, ref. 38). (E ) Gold

standard FSC (criteria 0.143) curve of the masked map with a reported resolution of 2.6 Å.

1012 |

www.pnas.org/cgi/doi/10.1073/pnas.1919114117 Han et al.

Downloaded by guest on August 12, 2021

temperature in air for a few months without severer copper oxidation. After

coating the sample with a thin layer of MMA, the sample was placed in a

glow-discharge system backside up to remove the graphene grown on the

backside of the copper foil (we used a typical glow-discharge condition: 30 s

O2 or Ar plasma).

Afterward, we used 1 M ammonium persulfate (APS) to etch the copper

substrate by floating the MMA/graphene/Cu on APS with the MMA side

facing up. Since it is hard to tell the backside from the topside, keeping track

of the sides from the very beginning is highly encouraged. After the copper

foils were entirely gone, we transferred the film (graphene with MMA) to

deionized (DI) water twice, each for a 10-min interval (or you can transfer to

DI water once and wait for more than 20 min). After that, we used the

Quantifoil (Au 1.2/1.3 300 mesh) to scoop out the MMA/graphene film and air

dry. We noted that the Quantifoil Au 1.2/1.3 300 mesh grids have a large

variation of hole sizes (from ∼500 nm to 1.3 μm). Our method works for most

within this range. A slightly lower yield was observed for Quantifoil grids

with 2-μm hole size. Alternatively, the polymer state of MMA, poly methyl

methacrylate (PMMA), can also be used to make graphene cryo-EM grids.

PMMA has been commonly used in materials science for transferring nano

structures (30, 31), but the high molecular weight of PMMA results in more

polymer residues after the transfer process.

Afterward, we placed the grid on a hot plate and baked at ∼130 °C for

∼20 min, which assists the graphene in stitching to the Quantifoil carbon. Oth-

erwise, the graphene film will detach from the grid in the cleaning process.

Then we picked up the grid and waited for it to cool down, followed by

soaking the grids into acetone vertically. We placed the grids in warm ace-

tone for 30 min to dissolve the MMA. Then we transferred the grids to

another fresh acetone to further clean the MMA. Afterward, we transferred

all grids to isopropyl alcohol (IPA) to clean off the acetone residue. The

process to transfer grids from one organic solvent to another should be very

fast to avoid the acetone drying in any case. We took the grid out of IPA

vertically and used a filter paper to draw remaining IPA away from the grids.

Then, we left the grids on a filter paper to air dry them. Afterward, we

placed the grids on a hot plate for another ∼20 min to bake off organic

residues. This baking process is for removing the IPA residues. The graphene

grids were then checked in a transmission electron microscope (TEM) or an

SEM to confirm the yield and cleanness. The process described above can

result in a high yield of suspended, clean graphene films on Quantifoil holey

carbon grids. Repeating the acetone-IPA baking process can further clean

graphene surfaces. More details can be found in Movie S1. This method was

adapted from previous work (32, 33). The materials used in the transfer

process are as follows: Graphene on Cu was purchased from Graphene Su-

permarket; MMA EL 6 (item no. M310006 0500L1GL) and PMMA 495 A4

(item no. M130004 0500L1GL) were purchased from MicroChem (now

Kayaku); the spin coater was made from a computer fan (Movie S1); APS was

purchased from Sigma-Aldrich; and Quantifoil TEM grids were purchased

from EMS.

UV/Ozone. We used an UV/ozone cleaner (UVOCS T10 ×10 system) to treat

graphene surfaces and make graphene grids hydrophilic. This tool is com-

monly used for cleaning of wafers contaminated with organic substrates.

The UV/ozone used a low pressure, quartz, mercury vapor lamp to generate

185 nm and 254 nm of UV light. The process took place at room temperature

for 10 min. A temperature rise was observed upon prolonged cleaning. The

surface-treated graphene grids were used for cryosample preparation on

the same day. An exposure of the surface-treated graphene grids to the air

for more than a day may introduce surface contamination or broken gra-

phene that reduces the yield.

Characterization of Graphene Grids. The samples for contact angle measure-

ments are prepared following exactly the same process as for graphene grids

but using optical cover slits as the substrate materials instead of Quantifoil

grids. We employed a contact-angle goniometer (Rame–Hart goniometry) to

measure the contact angle of a 2-mL drop of DI water on the graphene

surface. Immediately after applying the droplet, the contact angle was

measured by taking the average of a series of 5 small time intervals on each

side (left and right).

The graphene sheets on glass slides after different UV/ozone treatments

were characterized by Raman spectroscopy on a Horibo Jobin-Yvon LabRAM

aramis Raman system using a 100×objective lens with a numerical aperture

(NA) of 0.95. The excitation source for Raman spectroscopy is a 532 nm laser

(2.33 eV) with a laser power 0.6 mW to avoid laser-induced heating. The

acquisition time is 10 s with 5 accumulations.

High-resolution (HR) XPS analysis of graphene samples was conducted

using a Thermo Fisher K-Alpha X-ray Photoelectron Spectrometer. The sys-

tem is equipped with a monochromatic X-ray source and a focusing lens

allowing for analysis area from 30 to 400 μm in 5- μm steps. In this study, we

selected a 400-μm X-ray spot for all XPS measurements. Survey spectra were

taken at 200 eV pass energy and the HR spectra for carbon ground state

electron configuration 1s subshell (C1s) region was recorded at 20 eV pass

energy. The XPS system has been calibrated by recording a clean Au sample

with the Au 4f7/2 binding energy at 84.0 eV. Chemical compositions were

determined using CasaXPS (Casa Software Ltd.)-fitting software.

Streptavidin Cryo-EM Sample Preparation. Streptavidin stock solution (1 mg/mL,

New England Biolabs, N7021s) was diluted to 0.5 mg/mL using DI water. UV/

ozone freshly treated graphene grids (Quantifoil 300 mesh Au R1.2/1.3)

were used to prepare cryosamples. In Vitrobot Mark IV (Thermo Fisher), 4 μL

of 0.5 mg/mL sample was applied to the grid for 30 s before blotting. The

blot time was 4 s with a blot force of 0 in the Vitrobot. After blotting, the

grid was rapidly plunged into liquid ethane for the vitrification.

Data Collection. A total number of 1,086 raw movie stacks were automatically

collected in 12 h by SerialEM 3.7 on a 300 kV Cs-corrected Titan Krios using a

K2 Summit detector (with GIF Bio-Quantum Energy Filters, Gatan). We col-

lected the raw movies in K2 counted mode at a magnification of 215,000 (in

energy-filtered TEM [EFTEM] mode, spot size 6, C2 aperture 70 μm) with a

pixel size of 0.536 Å. The total exposure time was set to 2.4 s with a 0.075-s

frame time to generate 32-frame gain normalized stacks in MRC format. The

total dose for a stack is 49 e−/Å2.

Data Processing. Movie stacks were motion corrected using Relion’s in-

terpretation with a 5 ×5 patch and a 2-fold binning. Full-frame contrast

transfer function (CTF) values were estimated from nondose weighted im-

ages by CTFFind4.1 (34) in Relion with exhaustive searching. Particles were

automatically picked with the Laplacian-of-Gaussian method in Relion

autopicking. After the particle extraction, the particle stacks were given a

120-Å high pass filter (using relion_image_handler–highpass 120) for the

following processes: Multiple rounds of 2D classification, 3D classification,

3D autorefine. CTF refinement and Bayesian polishing were performed in

Relion 3.0 with standard procedure (7), where the CTF corrections were

AB

CD

Fig. 5. Graphene grids for membrane protein and liposomes. (A) Cryo-EM

micrograph of a bacterial sodium channel (NaChBac) on holey carbon grids.

(B) Cryo-EM micrograph of NaChBac on graphene grids, which increase the

protein density by 5-fold. (The protein concentration in solution is 6 mg/mL.)

(C ) Cryo-EM micrograph of liposomes on holey carbon grids, where the li-

posomes prefer to adsorb to the amorphous carbon-supporting film. (D)

Cryo-EM micrograph of liposomes on graphene grids. The liposomes adsorbed

to the graphene surface uniformly, allowing for cryo-EM data acquisition in

the thin ice on graphene over the hole areas.

Han et al. PNAS | January 14, 2020 | vol. 117 | no. 2 | 1013

BIOPHYSICS AND

COMPUTATIONAL BIOLOGY

Downloaded by guest on August 12, 2021