Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

.375 Snipetac load data.

- Thread starter Sotahirvi

- Start date

Re: .375 Snipetac load data.

I used some N170 with my .375 cheytac and its very close to Retumbo, maybe just alittle slower. I was loading 131gr. of N170 with a 370gr. bullet.

I used some N170 with my .375 cheytac and its very close to Retumbo, maybe just alittle slower. I was loading 131gr. of N170 with a 370gr. bullet.

Re: .375 Snipetac load data.

What velocity do you get with 131 grn of N170? What bullet are you using?

I plan to Use N570, but will try N170 also.

Cheers,

Master Diver

What velocity do you get with 131 grn of N170? What bullet are you using?

I plan to Use N570, but will try N170 also.

Cheers,

Master Diver

Re: .375 Snipetac load data.

Master Driver - I shoot Rocky Mountain Bullets, I don't have my loading notes with me but it was around 2950 fps I think.

Master Driver - I shoot Rocky Mountain Bullets, I don't have my loading notes with me but it was around 2950 fps I think.

Re: .375 Snipetac load data.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: bulletsmith</div><div class="ubbcode-body">Master Driver - I shoot Rocky Mountain Bullets, I don't have my loading notes with me but it was around 2950 fps I think. </div></div>

Thanks, it seems like a good starting point for me. What brand of brass are you using?

Cheers,

Master Diver

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: bulletsmith</div><div class="ubbcode-body">Master Driver - I shoot Rocky Mountain Bullets, I don't have my loading notes with me but it was around 2950 fps I think. </div></div>

Thanks, it seems like a good starting point for me. What brand of brass are you using?

Cheers,

Master Diver

Re: .375 Snipetac load data.

How is the N170 for temp sensitivity? I hate Retumbo for it and want to try something else. I know the slower the more sensitive but......

Jason

How is the N170 for temp sensitivity? I hate Retumbo for it and want to try something else. I know the slower the more sensitive but......

Jason

Re: .375 Snipetac load data.

Can't say for sure, my .338 snipe-tac came about that time and I put the .375 on the back burner. I'll get back to the .375 this winter and try the n-170 some more.

Can't say for sure, my .338 snipe-tac came about that time and I put the .375 on the back burner. I'll get back to the .375 this winter and try the n-170 some more.

Re: .375 Snipetac load data.

Gentlemen,

I tested N170 ans N570 powder today.

Bullet was 355 grn SP GSC.

131 grn of N170 = 924 m/s (3034 fps) average V0 and a slightly stiff bolt accuracy was about 1 moa at 200m

132 grn of N170 = 937 m/s (3075 fps) average V0 and a stiff bolt accuracy was 1.2" at 200m 3 shots only.

I have also been testing N570 powder and it is faster with No presure sighns up to 135 grn.

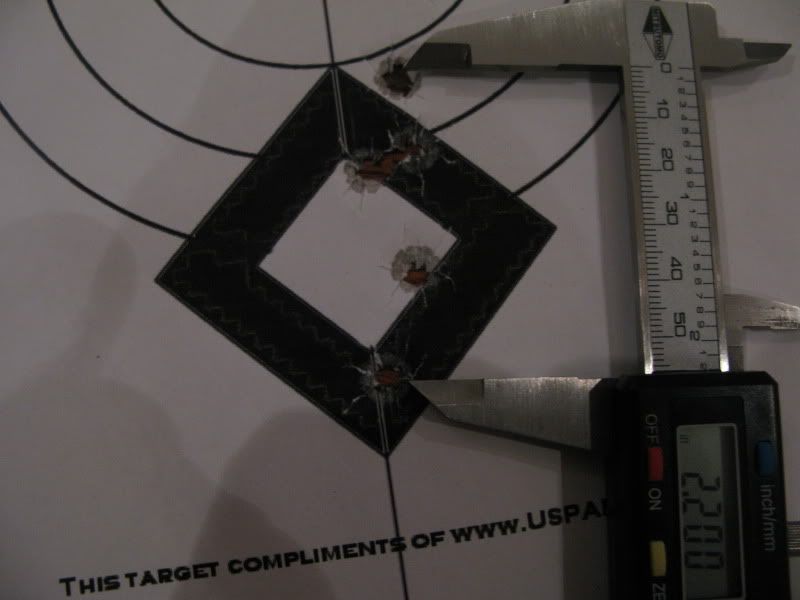

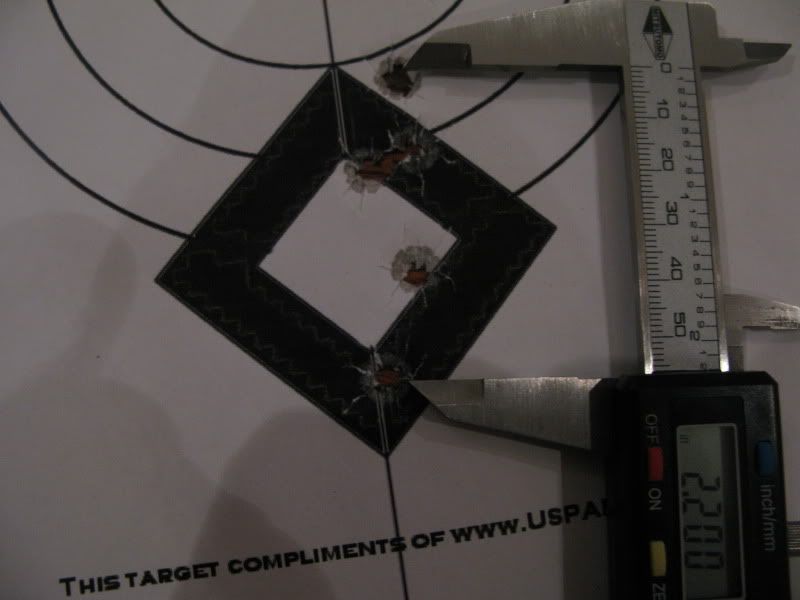

My best test results so fare is 136 grn of N570 = 970 m/s (3182 fps) average V0 and 2.2" groups at 200m. There is however a slightly stiff bolt and it seems that getting more velocity with this combo is not possible.

The barrel has shot less then 50 rounds and accuracy might improve along with my shooting

Cheers,

Master Diver

132 grn of N170

136 grn of N570

Gentlemen,

I tested N170 ans N570 powder today.

Bullet was 355 grn SP GSC.

131 grn of N170 = 924 m/s (3034 fps) average V0 and a slightly stiff bolt accuracy was about 1 moa at 200m

132 grn of N170 = 937 m/s (3075 fps) average V0 and a stiff bolt accuracy was 1.2" at 200m 3 shots only.

I have also been testing N570 powder and it is faster with No presure sighns up to 135 grn.

My best test results so fare is 136 grn of N570 = 970 m/s (3182 fps) average V0 and 2.2" groups at 200m. There is however a slightly stiff bolt and it seems that getting more velocity with this combo is not possible.

The barrel has shot less then 50 rounds and accuracy might improve along with my shooting

Cheers,

Master Diver

132 grn of N170

136 grn of N570

Re: .375 Snipetac load data.

Gents,

I did some more testing today.

355 grn SP Moly coated

Powder N570 136 grn

CL 76.57mm

COAL 108.20mm (2/10mm of the lands)

Primer Fed 215 GM

The distance was 200m.

After a good cleaning of the barrel with Robla solomil the barrel got a lot smother and the GS bullets shor better groups

temp was about 0c (10F) perfect day for CBS.

The group left of my hand was the first 5 shot group I did and V0 was 3182.

The group on the right side of my hand is only 3 shots V0 is also 3182.

10 min cool down between each shot.

The GSC work great with the N570 my barrel only has only shot 70 rounds, it is still in the breaking in phase.

Nuff said

Cheers,

Master Diver

Gents,

I did some more testing today.

355 grn SP Moly coated

Powder N570 136 grn

CL 76.57mm

COAL 108.20mm (2/10mm of the lands)

Primer Fed 215 GM

The distance was 200m.

After a good cleaning of the barrel with Robla solomil the barrel got a lot smother and the GS bullets shor better groups

temp was about 0c (10F) perfect day for CBS.

The group left of my hand was the first 5 shot group I did and V0 was 3182.

The group on the right side of my hand is only 3 shots V0 is also 3182.

10 min cool down between each shot.

The GSC work great with the N570 my barrel only has only shot 70 rounds, it is still in the breaking in phase.

Nuff said

Cheers,

Master Diver

Re: .375 Snipetac load data.

i've been using N170 for about 10 years now on all my big magnums,and its probably the best and cleanest burning powder outhere . also seems to be very temp friendly in terms of sensitivity.300/338L/408C <div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: strictlyRUM</div><div class="ubbcode-body">How is the N170 for temp sensitivity? I hate Retumbo for it and want to try something else. I know the slower the more sensitive but......

Jason</div></div>

i've been using N170 for about 10 years now on all my big magnums,and its probably the best and cleanest burning powder outhere . also seems to be very temp friendly in terms of sensitivity.300/338L/408C <div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: strictlyRUM</div><div class="ubbcode-body">How is the N170 for temp sensitivity? I hate Retumbo for it and want to try something else. I know the slower the more sensitive but......

Jason</div></div>

Re: .375 Snipetac load data.

Sweet! Whats the BC on those?

I wish those GS 355's were available over here in the US for immediate sale.I'd like to try some.

Sweet! Whats the BC on those?

I wish those GS 355's were available over here in the US for immediate sale.I'd like to try some.

Re: .375 Snipetac load data.

Augustus,

You got it right

It seems the barrel got faster as I am breaking it in. (shooting and cleaning) The weather got colder also, and all shots where close to CBS.

Regarding BC on the 355 grn SP GSC, it is listed to .921 at 3000 fps.

http://www.gsgroup.co.za/375355SP173.html

I did this trajectory calculation on JBMballistic. Seems to be supersonic out past 2300m and I have elevation out to 2700m with my rifle sighted in at 200m.

Cheers,

Master Diver

Trajectory

Input Data

Ballistic Coefficient: 0.921 G1 Caliber: 0.375 in

Bullet Weight: 355.0 gr Bullet Length: 55.000 mm

Muzzle Velocity: 1040.0 m/sec Distance to Chronograph: 1.0 m

Sight Height: 1.50 in Sight Offset: 0.00 in

Zero Height: 0.00 in Zero Offset: 0.00 in

Windage: 0.000 mil Elevation: 0.000 mil

Line Of Sight Angle: 0.0 deg Cant Angle: 0.0 deg

Barrel Twist: 10.5 in Twist Direction: Right

Wind Speed: 5.0 m/sec Wind Angle: 90.0 deg

Target Speed: 0.0 m/sec Target Angle: 90.0 deg

Target Height: 50.0 cm

Temperature: 0.0 °C Pressure: 1010.00 mb

Humidity: 90.0 % Altitude: 0.0 ft

Vital Zone Radius: 5.0 in

Std. Atmosphere at Altitude: No Pressure is Corrected: Yes

Zero at Max. Point Blank Range: No Target Relative Drops: Yes

Mark Sound Barrier Crossing: No Include Extra Rows: No

Column 1 Units: 1.00 mil Column 2 Units: 1.00 cm

Round Output to Whole Numbers: No

Output Data

Elevation: 1.147 mil Windage: 0.000 mil

Atmospheric Density: 0.08025 lb/ft³ Speed of Sound: 331.3 m/sec

Maximum PBR: 395 m Maximum PBR Zero: 334 m

Range of Maximum Height: 182 m Energy at Maximum PBR: 9052.8 J

Sectional Density: 0.361 lb/in² Stability at Muzzle: 1.320

Calculated Table

Range Drop Drop Windage Windage Velocity Mach Energy Time Lead Lead

(m) (mil) (cm) (mil) (cm) (m/sec) (none) (J) (s) (mil) (cm)

0 *** -3.8 *** 0.0 1040.4 3.140 12450.3 0.000 *** 0.0

100 0.3 3.0 0.1 1.1 999.8 3.018 11496.5 0.098 0.0 0.0

200 -0.0 -0.0 0.2 4.4 960.4 2.899 10609.8 0.200 0.0 0.0

300 -0.5 -13.6 0.3 9.9 922.3 2.784 9784.6 0.306 0.0 0.0

400 -1.0 -38.8 0.4 17.9 885.4 2.672 9015.7 0.417 0.0 0.0

500 -1.5 -76.5 0.6 28.4 849.4 2.564 8298.7 0.532 0.0 0.0

600 -2.1 -127.8 0.7 41.6 814.5 2.458 7629.9 0.653 0.0 0.0

700 -2.8 -193.9 0.8 57.7 780.4 2.356 7005.7 0.778 0.0 0.0

800 -3.5 -276.1 1.0 76.7 747.3 2.255 6422.8 0.909 0.0 0.0

900 -4.2 -375.9 1.1 99.1 714.9 2.158 5878.8 1.046 0.0 0.0

1000 -4.9 -494.9 1.2 124.8 683.4 2.063 5371.4 1.189 0.0 0.0

1100 -5.8 -634.9 1.4 154.3 652.6 1.970 4898.6 1.339 0.0 0.0

1200 -6.6 -797.9 1.6 187.8 622.6 1.879 4458.7 1.496 0.0 0.0

1300 -7.6 -986.3 1.7 225.5 593.4 1.791 4050.7 1.660 0.0 0.0

1400 -8.6 -1202.6 1.9 267.8 565.1 1.706 3673.1 1.833 0.0 0.0

1500 -9.7 -1449.6 2.1 315.1 537.7 1.623 3325.0 2.014 0.0 0.0

1600 -10.8 -1730.6 2.3 367.6 511.2 1.543 3005.4 2.205 0.0 0.0

1700 -12.1 -2049.2 2.5 425.9 485.7 1.466 2713.4 2.406 0.0 0.0

1800 -13.4 -2409.5 2.7 490.2 461.4 1.392 2448.2 2.617 0.0 0.0

1900 -14.8 -2815.9 3.0 560.9 438.2 1.323 2208.9 2.840 0.0 0.0

2000 -16.4 -3273.6 3.2 638.5 416.4 1.257 1994.5 3.074 0.0 0.0

2100 -18.0 -3788.0 3.4 723.2 396.1 1.195 1804.4 3.321 0.0 0.0

2200 -19.8 -4365.1 3.7 815.3 377.3 1.139 1637.7 3.580 0.0 0.0

2300 -21.8 -5011.3 4.0 915.0 360.3 1.088 1493.4 3.852 0.0 0.0

2400 -23.9 -5733.5 4.3 1022.3 345.2 1.042 1370.5 4.136 0.0 0.0

2500 -26.2 -6538.5 4.5 1137.0 332.0 1.002 1267.5 4.433 0.0 0.0

2600 -28.6 -7433.1 4.8 1258.9 320.5 0.967 1181.8 4.741 0.0 0.0

2700 -31.2 -8423.9 5.1 1387.6 310.7 0.938 1110.2 5.059 0.0 0.0

2800 -34.0 -9517.5 5.4 1522.7 302.1 0.912 1049.5 5.388 0.0 0.0

2900 -37.0 -10719.9 5.7 1664.1 294.5 0.889 997.3 5.726 0.0 0.0

3000 -40.1 -12037.3 6.0 1811.5 287.6 0.868 951.6 6.072 0.0 0.0

Augustus,

You got it right

It seems the barrel got faster as I am breaking it in. (shooting and cleaning) The weather got colder also, and all shots where close to CBS.

Regarding BC on the 355 grn SP GSC, it is listed to .921 at 3000 fps.

http://www.gsgroup.co.za/375355SP173.html

I did this trajectory calculation on JBMballistic. Seems to be supersonic out past 2300m and I have elevation out to 2700m with my rifle sighted in at 200m.

Cheers,

Master Diver

Trajectory

Input Data

Ballistic Coefficient: 0.921 G1 Caliber: 0.375 in

Bullet Weight: 355.0 gr Bullet Length: 55.000 mm

Muzzle Velocity: 1040.0 m/sec Distance to Chronograph: 1.0 m

Sight Height: 1.50 in Sight Offset: 0.00 in

Zero Height: 0.00 in Zero Offset: 0.00 in

Windage: 0.000 mil Elevation: 0.000 mil

Line Of Sight Angle: 0.0 deg Cant Angle: 0.0 deg

Barrel Twist: 10.5 in Twist Direction: Right

Wind Speed: 5.0 m/sec Wind Angle: 90.0 deg

Target Speed: 0.0 m/sec Target Angle: 90.0 deg

Target Height: 50.0 cm

Temperature: 0.0 °C Pressure: 1010.00 mb

Humidity: 90.0 % Altitude: 0.0 ft

Vital Zone Radius: 5.0 in

Std. Atmosphere at Altitude: No Pressure is Corrected: Yes

Zero at Max. Point Blank Range: No Target Relative Drops: Yes

Mark Sound Barrier Crossing: No Include Extra Rows: No

Column 1 Units: 1.00 mil Column 2 Units: 1.00 cm

Round Output to Whole Numbers: No

Output Data

Elevation: 1.147 mil Windage: 0.000 mil

Atmospheric Density: 0.08025 lb/ft³ Speed of Sound: 331.3 m/sec

Maximum PBR: 395 m Maximum PBR Zero: 334 m

Range of Maximum Height: 182 m Energy at Maximum PBR: 9052.8 J

Sectional Density: 0.361 lb/in² Stability at Muzzle: 1.320

Calculated Table

Range Drop Drop Windage Windage Velocity Mach Energy Time Lead Lead

(m) (mil) (cm) (mil) (cm) (m/sec) (none) (J) (s) (mil) (cm)

0 *** -3.8 *** 0.0 1040.4 3.140 12450.3 0.000 *** 0.0

100 0.3 3.0 0.1 1.1 999.8 3.018 11496.5 0.098 0.0 0.0

200 -0.0 -0.0 0.2 4.4 960.4 2.899 10609.8 0.200 0.0 0.0

300 -0.5 -13.6 0.3 9.9 922.3 2.784 9784.6 0.306 0.0 0.0

400 -1.0 -38.8 0.4 17.9 885.4 2.672 9015.7 0.417 0.0 0.0

500 -1.5 -76.5 0.6 28.4 849.4 2.564 8298.7 0.532 0.0 0.0

600 -2.1 -127.8 0.7 41.6 814.5 2.458 7629.9 0.653 0.0 0.0

700 -2.8 -193.9 0.8 57.7 780.4 2.356 7005.7 0.778 0.0 0.0

800 -3.5 -276.1 1.0 76.7 747.3 2.255 6422.8 0.909 0.0 0.0

900 -4.2 -375.9 1.1 99.1 714.9 2.158 5878.8 1.046 0.0 0.0

1000 -4.9 -494.9 1.2 124.8 683.4 2.063 5371.4 1.189 0.0 0.0

1100 -5.8 -634.9 1.4 154.3 652.6 1.970 4898.6 1.339 0.0 0.0

1200 -6.6 -797.9 1.6 187.8 622.6 1.879 4458.7 1.496 0.0 0.0

1300 -7.6 -986.3 1.7 225.5 593.4 1.791 4050.7 1.660 0.0 0.0

1400 -8.6 -1202.6 1.9 267.8 565.1 1.706 3673.1 1.833 0.0 0.0

1500 -9.7 -1449.6 2.1 315.1 537.7 1.623 3325.0 2.014 0.0 0.0

1600 -10.8 -1730.6 2.3 367.6 511.2 1.543 3005.4 2.205 0.0 0.0

1700 -12.1 -2049.2 2.5 425.9 485.7 1.466 2713.4 2.406 0.0 0.0

1800 -13.4 -2409.5 2.7 490.2 461.4 1.392 2448.2 2.617 0.0 0.0

1900 -14.8 -2815.9 3.0 560.9 438.2 1.323 2208.9 2.840 0.0 0.0

2000 -16.4 -3273.6 3.2 638.5 416.4 1.257 1994.5 3.074 0.0 0.0

2100 -18.0 -3788.0 3.4 723.2 396.1 1.195 1804.4 3.321 0.0 0.0

2200 -19.8 -4365.1 3.7 815.3 377.3 1.139 1637.7 3.580 0.0 0.0

2300 -21.8 -5011.3 4.0 915.0 360.3 1.088 1493.4 3.852 0.0 0.0

2400 -23.9 -5733.5 4.3 1022.3 345.2 1.042 1370.5 4.136 0.0 0.0

2500 -26.2 -6538.5 4.5 1137.0 332.0 1.002 1267.5 4.433 0.0 0.0

2600 -28.6 -7433.1 4.8 1258.9 320.5 0.967 1181.8 4.741 0.0 0.0

2700 -31.2 -8423.9 5.1 1387.6 310.7 0.938 1110.2 5.059 0.0 0.0

2800 -34.0 -9517.5 5.4 1522.7 302.1 0.912 1049.5 5.388 0.0 0.0

2900 -37.0 -10719.9 5.7 1664.1 294.5 0.889 997.3 5.726 0.0 0.0

3000 -40.1 -12037.3 6.0 1811.5 287.6 0.868 951.6 6.072 0.0 0.0

Re: .375 Snipetac load data.

Master Diver, I took a look at the ballistics of the 355, and it looks like it will make it past 2,700m supersonic. This is because of the slower degredation of B.C. vs the more conventional bullets. Jamison/LRBT bullets share this benefit, and a test was conducted last year to see the actual results. The shooter was using a pure CT 375CT, and impact was measured at 2000m, as that is all the range we could get. Here is what we found.

The 350 Jamison was the baseline, and required X amount of comp to hit center target. The Predator bullet was shot second, and required apx 3 Mil's more adjustment to bring it to center mass; wind drift was slightly greater as well (just noted in report). Our 355 was up next, and required apx 2 Mil's less adjustment then the Jamison (X baseline), and less wind drift was noted.

If this be from higher velocity or heavier weight, then I cannot conclude, but we did find that the 355 bullet losses B.C. slower then the Jamison or Predator (has a higher B.C. at 1200fps as measured), and higher speeds are normal with GS bullets.

Now one issue has come up...it's going to fast! I know, one should never use those words when speaking about rifles, but this is something that we will have to address. The bullet was designed for a max of about 3300, and some slight changes will have to be made. Not that the bullet isn't overdue for some upgrading, and they will certainly work at lower, more conventional speeds, but it will need to be done. Gerard said he is going to take a look at it this week, so I'll report back after he's done. Hope that helps MD!

Master Diver, I took a look at the ballistics of the 355, and it looks like it will make it past 2,700m supersonic. This is because of the slower degredation of B.C. vs the more conventional bullets. Jamison/LRBT bullets share this benefit, and a test was conducted last year to see the actual results. The shooter was using a pure CT 375CT, and impact was measured at 2000m, as that is all the range we could get. Here is what we found.

The 350 Jamison was the baseline, and required X amount of comp to hit center target. The Predator bullet was shot second, and required apx 3 Mil's more adjustment to bring it to center mass; wind drift was slightly greater as well (just noted in report). Our 355 was up next, and required apx 2 Mil's less adjustment then the Jamison (X baseline), and less wind drift was noted.

If this be from higher velocity or heavier weight, then I cannot conclude, but we did find that the 355 bullet losses B.C. slower then the Jamison or Predator (has a higher B.C. at 1200fps as measured), and higher speeds are normal with GS bullets.

Now one issue has come up...it's going to fast! I know, one should never use those words when speaking about rifles, but this is something that we will have to address. The bullet was designed for a max of about 3300, and some slight changes will have to be made. Not that the bullet isn't overdue for some upgrading, and they will certainly work at lower, more conventional speeds, but it will need to be done. Gerard said he is going to take a look at it this week, so I'll report back after he's done. Hope that helps MD!

Re: .375 Snipetac load data.

I've made some shoots past 1 mile with .375 CT.

Powder : 127 grs of VV N 170.

Bullets : 350 SMK and 355 GSC ( same powder charge ).

Primers : Fed 215 M

Cases : Jamison

Barrel : 8" twist Border, 34" lenght

T° : -2 °C

V° : approximatively 920 m/s

It seems that the powder charge was to light, as we had some hangfires. Velocity was also inconsistent, as we had some bad vertical dispersion.

Surprisingly, we had the same drop with the 2 bullets tested ( SMK & GSC ).

Can't wait more to test the 414 GSC in the 8" twist, as I think it will be a real improvment.

Bruno.

I've made some shoots past 1 mile with .375 CT.

Powder : 127 grs of VV N 170.

Bullets : 350 SMK and 355 GSC ( same powder charge ).

Primers : Fed 215 M

Cases : Jamison

Barrel : 8" twist Border, 34" lenght

T° : -2 °C

V° : approximatively 920 m/s

It seems that the powder charge was to light, as we had some hangfires. Velocity was also inconsistent, as we had some bad vertical dispersion.

Surprisingly, we had the same drop with the 2 bullets tested ( SMK & GSC ).

Can't wait more to test the 414 GSC in the 8" twist, as I think it will be a real improvment.

Bruno.

Re: .375 Snipetac load data.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Extremist458</div><div class="ubbcode-body">Now one issue has come up...it's going to fast! I know, one should never use those words when speaking about rifles, but this is something that we will have to address. The bullet was designed for a max of about 3300, and some slight changes will have to be made. Not that the bullet isn't overdue for some upgrading, and they will certainly work at lower, more conventional speeds, but it will need to be done. Gerard said he is going to take a look at it this week, so I'll report back after he's done. Hope that helps MD! </div></div>

Extremist458

Please elaborate on this!

I have 300 of these "fast" bullets batch "3/1/176/10" "3/2/176/10 and plan to order more, but they need to be teh same specs. Was it my barrel beeing run more in that made them fly faster? The moly? Or a upgraded design?

Cheers,

Master Diver

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Extremist458</div><div class="ubbcode-body">Now one issue has come up...it's going to fast! I know, one should never use those words when speaking about rifles, but this is something that we will have to address. The bullet was designed for a max of about 3300, and some slight changes will have to be made. Not that the bullet isn't overdue for some upgrading, and they will certainly work at lower, more conventional speeds, but it will need to be done. Gerard said he is going to take a look at it this week, so I'll report back after he's done. Hope that helps MD! </div></div>

Extremist458

Please elaborate on this!

I have 300 of these "fast" bullets batch "3/1/176/10" "3/2/176/10 and plan to order more, but they need to be teh same specs. Was it my barrel beeing run more in that made them fly faster? The moly? Or a upgraded design?

Cheers,

Master Diver

A

Augustus

Guest

Re: .375 Snipetac load data.

Master Diver, if your scope is 1/4 min clicks or in mils it is highly unlikely that 341 fps gain in velocity would cause four min of verticle poi shift at 200m. If you did not make an error when you reportd that the chrono was only one meter in front of the muzzle during your test, I would move that back a ways and shoot a few more. Also I have never seen or heard of a

barrel gaining that much velocity during a breakin.

Someone more cultured than myself may want to weigh in here but I played with the numbers and it appears that if one zeros a rifle in at 200 meters and the projo has a BC of .92 and is traveling at 3180 then fires the same bullet at the same range traveling at 3520 or so the poi should only be 1/2 min above the first. I think you should go back and tighten things up and move the chrono out a bit more. Shoot a few more and let us know what happened.

Master Diver, if your scope is 1/4 min clicks or in mils it is highly unlikely that 341 fps gain in velocity would cause four min of verticle poi shift at 200m. If you did not make an error when you reportd that the chrono was only one meter in front of the muzzle during your test, I would move that back a ways and shoot a few more. Also I have never seen or heard of a

barrel gaining that much velocity during a breakin.

Someone more cultured than myself may want to weigh in here but I played with the numbers and it appears that if one zeros a rifle in at 200 meters and the projo has a BC of .92 and is traveling at 3180 then fires the same bullet at the same range traveling at 3520 or so the poi should only be 1/2 min above the first. I think you should go back and tighten things up and move the chrono out a bit more. Shoot a few more and let us know what happened.

Re: .375 Snipetac load data.

Augustus,

The bullets was not the same, first test (top of thread) was with NON cpoated bullets and they might have been an early version.

Everything was the samepowder case etc. Cases was just trimmed a bit.

My scope is MIL/MIL and IO had to come 1.4 MIL down to get to center with the new batch I did. Maybe I did play a bit with the tover to reset it to zero.

I will test more next Wednesday if the wind and weather plays along.

I like the precission of this load and batch and LOVE the speed.

I will move the Chrono out a bit more. It was about 1 m away from the muzzle.

Cheers,

Master Diver

Augustus,

The bullets was not the same, first test (top of thread) was with NON cpoated bullets and they might have been an early version.

Everything was the samepowder case etc. Cases was just trimmed a bit.

My scope is MIL/MIL and IO had to come 1.4 MIL down to get to center with the new batch I did. Maybe I did play a bit with the tover to reset it to zero.

I will test more next Wednesday if the wind and weather plays along.

I like the precission of this load and batch and LOVE the speed.

I will move the Chrono out a bit more. It was about 1 m away from the muzzle.

Cheers,

Master Diver

A

Augustus

Guest

Re: .375 Snipetac load data.

There is something else at play here that caused the POI shift. You are talking about a 10 inch shift (approx). I had one doing something similar. It would shoot nice right after the screws were torqued. If the rifle was allowed to sit overnite and fired the next morning there would be a poi shift of 1.5 to 2.0 min. As it turned out the rings were stretching in the stationary hook. They finally broke at this point and the problem was revealed. These were custom rings from a highly respected vendor. Also if your rings and base is not a perfect fit the .375 and its cousins will find the hole and exploit it. A lot of people are pinning the base and are using two sets of rings on these beasts.

There is something else at play here that caused the POI shift. You are talking about a 10 inch shift (approx). I had one doing something similar. It would shoot nice right after the screws were torqued. If the rifle was allowed to sit overnite and fired the next morning there would be a poi shift of 1.5 to 2.0 min. As it turned out the rings were stretching in the stationary hook. They finally broke at this point and the problem was revealed. These were custom rings from a highly respected vendor. Also if your rings and base is not a perfect fit the .375 and its cousins will find the hole and exploit it. A lot of people are pinning the base and are using two sets of rings on these beasts.

Re: .375 Snipetac load data.

I will re-check my system.

I am using badger MAX-50 34mm allu rings on a Lawton .40 moa rail.

Cheers,

Master Diver

I will re-check my system.

I am using badger MAX-50 34mm allu rings on a Lawton .40 moa rail.

Cheers,

Master Diver

A

Augustus

Guest

Re: .375 Snipetac load data.

I just had to replace a Lawton base that was under sized. Look closely at your clamps. If they are leaning in at the bottom you may have one of them that is undersized. Also look at the crack between the clamp and the ring body. There should be a visible space that is uniform top to bottom. I had Badger rings on the base I had to replace.

I just had to replace a Lawton base that was under sized. Look closely at your clamps. If they are leaning in at the bottom you may have one of them that is undersized. Also look at the crack between the clamp and the ring body. There should be a visible space that is uniform top to bottom. I had Badger rings on the base I had to replace.

A

Augustus

Guest

Re: .375 Snipetac load data.

Also dont assume the Badger rings will keep your scope from sliding. Those rings are strong as a truck; however, as with any ring their clamping power is dependent on how much surface area actually contacts the scope tube when everything is torqued. I have a set-up identical to yours. When the rings were tightened onto the base lapping revealed only about 1/8 of an inch of each ring was actually contacting the scope tube. So, I said all that to say this. If you havent lapped your rings you probably should do so and I would then bed the scope into the rings with devcon or something similar.

I really dont want to come off as a smart ass or know it all but ammo and barrels for these things are not cheap and if I can help someone avoid the mistakes I have already made I am happy to do so.

Also dont assume the Badger rings will keep your scope from sliding. Those rings are strong as a truck; however, as with any ring their clamping power is dependent on how much surface area actually contacts the scope tube when everything is torqued. I have a set-up identical to yours. When the rings were tightened onto the base lapping revealed only about 1/8 of an inch of each ring was actually contacting the scope tube. So, I said all that to say this. If you havent lapped your rings you probably should do so and I would then bed the scope into the rings with devcon or something similar.

I really dont want to come off as a smart ass or know it all but ammo and barrels for these things are not cheap and if I can help someone avoid the mistakes I have already made I am happy to do so.

Re: .375 Snipetac load data.

Good advise Augustus! You know your stuff! BTW My ELR friends like those viking paper weights you sent me,LOL.They make a great gift!

I'd add to make sure your all the screws in the whole scope mounting system are loctited.Bedding the base isn't a bad idea either.

My Lawton base came loose very shortly after I got the rifle.

Good advise Augustus! You know your stuff! BTW My ELR friends like those viking paper weights you sent me,LOL.They make a great gift!

I'd add to make sure your all the screws in the whole scope mounting system are loctited.Bedding the base isn't a bad idea either.

My Lawton base came loose very shortly after I got the rifle.

Re: .375 Snipetac load data.

Augustus,

Thank you very much for the MOST EXCELENT advice.

I might have a problem

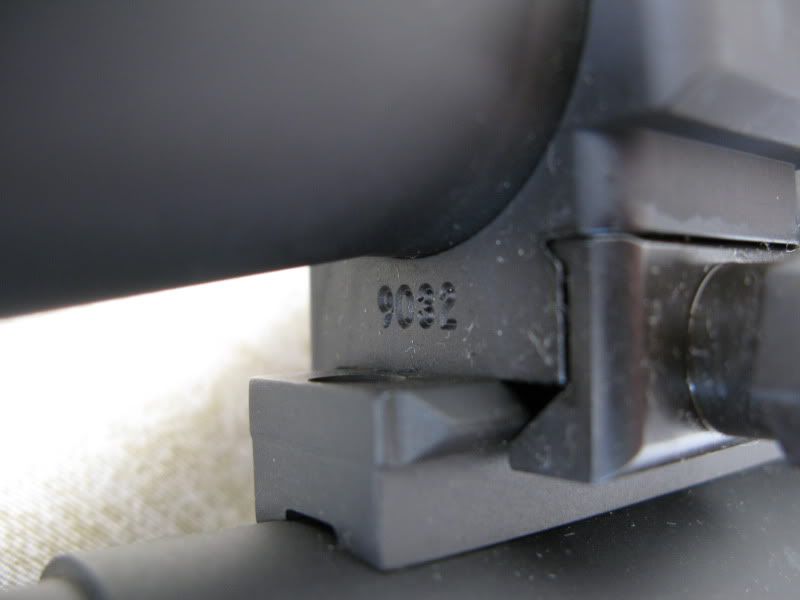

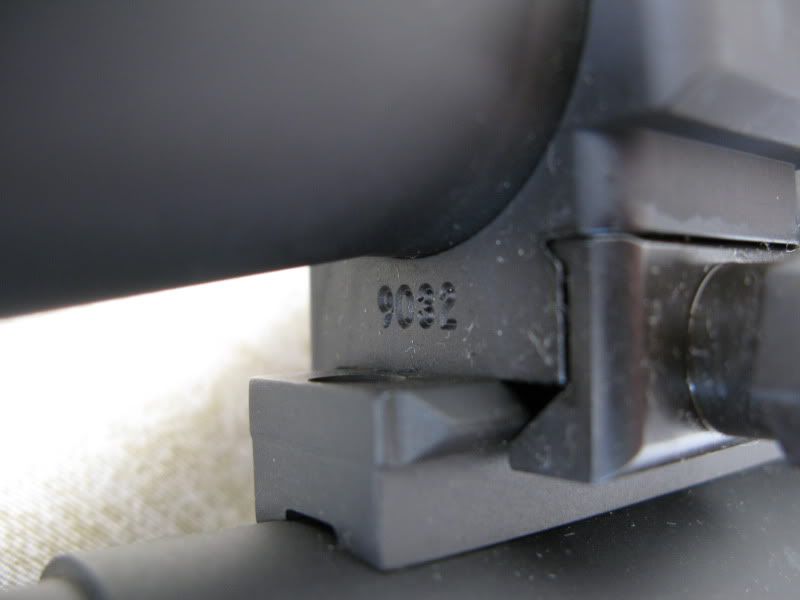

The rings are touching the rail base on the ejector side of the rifle!

But not on the left side

And there is no visible light under the rings

Hope this will help others in the feature

NOW WHAT??????

Cheers,

Master Diver

Augustus,

Thank you very much for the MOST EXCELENT advice.

I might have a problem

The rings are touching the rail base on the ejector side of the rifle!

But not on the left side

And there is no visible light under the rings

Hope this will help others in the feature

NOW WHAT??????

Cheers,

Master Diver

A

Augustus

Guest

Re: .375 Snipetac load data.

I dont really understand what you mean about the rings not touching the base on the left side. The fit of the clamps look good from what I could see. I see the base is not bedded, if that is not causing a problem now, it probably will sometime down the road.

I dont really understand what you mean about the rings not touching the base on the left side. The fit of the clamps look good from what I could see. I see the base is not bedded, if that is not causing a problem now, it probably will sometime down the road.

Re: .375 Snipetac load data.

So the fact that they are leaning in on the body of the rail is not a problem?

What product would you bed the rail to the rifle with?

Cheers,

Master Diver

So the fact that they are leaning in on the body of the rail is not a problem?

What product would you bed the rail to the rifle with?

Cheers,

Master Diver

A

Augustus

Guest

Re: .375 Snipetac load data.

It is really hard to tell by the photo exactly what if anything is wrong. The space between the clamps and and the ring body looks good. If your rings are sliding down the angles of the base to the point the toe of the clamps or the toe of the stationary hook is contacting the body of the base below the angles there is definitely a problem. Get a feeler guage or in lieu of that a credit card will work. See if there is clearance between the toes and base body. If it is a no go you can fix this by relieving the material off the toes. I may not be using the correct terminology in describing the various parts of the ring/base combination, hopefully you can follow what I am trying to desribe.

With all that being said I think I would send a few more down range to see if you are still getting POI shifts. Dont try to fix something that aint broke.

I really believe you should start the mounting process with the base bedded to the action with Devcon. Some are using JB Weld. I have never used this product. Brownells Steel bedding compound works well. Check your base screws and verify they fit the holes in the base. The Lawton bases use oval head screws, other types will screw you over. Dont assume the screws that came with the base are correct. If you have a good smithy close by I would have the base pinned. Next lap the rings to 100 percent contact and bed the scope in the rings with about .025-.030 of Devcon. Apply Loc-tite to all screws during assembly and inspect the ring to base fit. Again confirm you have a POI shift problem for certian before tearing your rig apart. One thing is for certian, if your set-up aint right, the beast you are dealing with will tell you something is wrong post haste.

It is really hard to tell by the photo exactly what if anything is wrong. The space between the clamps and and the ring body looks good. If your rings are sliding down the angles of the base to the point the toe of the clamps or the toe of the stationary hook is contacting the body of the base below the angles there is definitely a problem. Get a feeler guage or in lieu of that a credit card will work. See if there is clearance between the toes and base body. If it is a no go you can fix this by relieving the material off the toes. I may not be using the correct terminology in describing the various parts of the ring/base combination, hopefully you can follow what I am trying to desribe.

With all that being said I think I would send a few more down range to see if you are still getting POI shifts. Dont try to fix something that aint broke.

I really believe you should start the mounting process with the base bedded to the action with Devcon. Some are using JB Weld. I have never used this product. Brownells Steel bedding compound works well. Check your base screws and verify they fit the holes in the base. The Lawton bases use oval head screws, other types will screw you over. Dont assume the screws that came with the base are correct. If you have a good smithy close by I would have the base pinned. Next lap the rings to 100 percent contact and bed the scope in the rings with about .025-.030 of Devcon. Apply Loc-tite to all screws during assembly and inspect the ring to base fit. Again confirm you have a POI shift problem for certian before tearing your rig apart. One thing is for certian, if your set-up aint right, the beast you are dealing with will tell you something is wrong post haste.

Re: .375 Snipetac load data.

Augustus,

My toe on the stationarty hook is touching the body of the base below the angles, look at the first picture. There is NO clearance.

Filing very little off is a excelent advice. I think it need very little work on the edge. The rings does however apear to have a tight contact with the rail, look at the secund picture. and I was able to shoot very tight groups with all my shots on my last outing.

I will test further before dooing the big overhaul on rail, scope and rings.

Thanks for all the input.

Cheers,

Master Diver

Augustus,

My toe on the stationarty hook is touching the body of the base below the angles, look at the first picture. There is NO clearance.

Filing very little off is a excelent advice. I think it need very little work on the edge. The rings does however apear to have a tight contact with the rail, look at the secund picture. and I was able to shoot very tight groups with all my shots on my last outing.

I will test further before dooing the big overhaul on rail, scope and rings.

Thanks for all the input.

Cheers,

Master Diver

Re: .375 Snipetac load data.

Gentlemen,

After consulting with my builder Dave Viers it seems that it is the rings from badger Ordnance thatb is the problem. The Rail from Lawton is up to specs http://www.biggerhammer.net/picatinny/

and it is the Toe on the solid part of the MAX-50 34mm rings that are to long. The movable part of the rings are just fine.

I would like all to know that my builder Dave Viers have been a pleasure to "work" with in the contruction of this ELR system. I have changed spacs many times and he has always been very undestanding with the last minute changes.

I will carfully file off some of the solid part off and sight in the rifle again.

Cheers,

Master Diver

Gentlemen,

After consulting with my builder Dave Viers it seems that it is the rings from badger Ordnance thatb is the problem. The Rail from Lawton is up to specs http://www.biggerhammer.net/picatinny/

and it is the Toe on the solid part of the MAX-50 34mm rings that are to long. The movable part of the rings are just fine.

I would like all to know that my builder Dave Viers have been a pleasure to "work" with in the contruction of this ELR system. I have changed spacs many times and he has always been very undestanding with the last minute changes.

I will carfully file off some of the solid part off and sight in the rifle again.

Cheers,

Master Diver

Re: .375 Snipetac load data.

Gentlemen,

Problem solved.

The fixed part of the Badger MAX-50 34mm ring was 10mm and the movable part 9mm. I filed off 1mm and the fit is now the same on both sides. Before doing this I measured the Lawton .40 moa Cheytac base and it was 100% to specs.

This is what I did. Tape scope up so that it would not be scratched. placed a thin metal ruler under the rings for a guide line, carefully filed 1mm off the toe of the rings.

They now look the same and there is a clearance between the rings toes and the base of the rail.

I know that many would just ship the rings back to where they bought them, but it only took 30 minutes and that is alot faster then shipping them back to Badger. tomorrow it is off to the range again for final ajustments.

Cheers,

Master Diver

Gentlemen,

Problem solved.

The fixed part of the Badger MAX-50 34mm ring was 10mm and the movable part 9mm. I filed off 1mm and the fit is now the same on both sides. Before doing this I measured the Lawton .40 moa Cheytac base and it was 100% to specs.

This is what I did. Tape scope up so that it would not be scratched. placed a thin metal ruler under the rings for a guide line, carefully filed 1mm off the toe of the rings.

They now look the same and there is a clearance between the rings toes and the base of the rail.

I know that many would just ship the rings back to where they bought them, but it only took 30 minutes and that is alot faster then shipping them back to Badger. tomorrow it is off to the range again for final ajustments.

Cheers,

Master Diver

A

Augustus

Guest

Re: .375 Snipetac load data.

Yep, its things like this that makes me yearn for a set-up with the rings milled into the action. I have contemplated welding the base to the action and the rings to the base. I have checked around and some folks seem to think its doable. Others think it will create stress in the system thereby causing a whole new set of problems.

Yep, its things like this that makes me yearn for a set-up with the rings milled into the action. I have contemplated welding the base to the action and the rings to the base. I have checked around and some folks seem to think its doable. Others think it will create stress in the system thereby causing a whole new set of problems.

Re: .375 Snipetac load data.

YEAH

YEAH

Just TIG weld the whole dam thing

I guess that an action could be CNC machines with a .40 moa rail build into the design. And a scope like The Hensoldt SSG-P scope would give fewer parts.

Cheers,

Master Diver

Just TIG weld the whole dam thing

I guess that an action could be CNC machines with a .40 moa rail build into the design. And a scope like The Hensoldt SSG-P scope would give fewer parts.

Cheers,

Master Diver

Re: .375 Snipetac load data.

Hey guys...A Surgeon XXL would do the trick,aye.Of the custom actions I own I like the S-XL best by far!

Hey guys...A Surgeon XXL would do the trick,aye.Of the custom actions I own I like the S-XL best by far!

Re: .375 Snipetac load data.

Back from the range POI was the same after the file work

But the confidence to the system has now improved after clearing the rings from the base of the rail.

But the confidence to the system has now improved after clearing the rings from the base of the rail.

Steve123

Could you post a picture or a link to that XXL Surgeon 408 cartridge size action. I can only find the XL Surgeon on the site

Cheers,

Master Diver

Back from the range POI was the same after the file work

Steve123

Could you post a picture or a link to that XXL Surgeon 408 cartridge size action. I can only find the XL Surgeon on the site

Cheers,

Master Diver

A

Augustus

Guest

Re: .375 Snipetac load data.

The base being an integral part of the action would certianly be an improvement but you still have moveable parts attaching the rings to the base. Machining the rings into the action would stop all of these problems. Then we could concentrate on the new problems this system would create, ie, lack of flexibility of scope ht. and eye relief adjustment.

Anyway I reakon we hi-jacked the thread from the fellow wanting to know how much Vit. powder to use---SORRY ABOUT THAT.

The base being an integral part of the action would certianly be an improvement but you still have moveable parts attaching the rings to the base. Machining the rings into the action would stop all of these problems. Then we could concentrate on the new problems this system would create, ie, lack of flexibility of scope ht. and eye relief adjustment.

Anyway I reakon we hi-jacked the thread from the fellow wanting to know how much Vit. powder to use---SORRY ABOUT THAT.

A

Augustus

Guest

Re: .375 Snipetac load data.

The base being an integral part of the action would certianly be an improvement but you still have moveable parts attaching the rings to the base. Machining the rings into the action would stop all of these problems. Then we could concentrate on the new problems this system would create, ie, lack of flexibility of scope ht. and eye relief adjustment.

Anyway I reakon we hi-jacked the thread from the fellow wanting to know how much Vit. powder to use---SORRY ABOUT THAT.

The base being an integral part of the action would certianly be an improvement but you still have moveable parts attaching the rings to the base. Machining the rings into the action would stop all of these problems. Then we could concentrate on the new problems this system would create, ie, lack of flexibility of scope ht. and eye relief adjustment.

Anyway I reakon we hi-jacked the thread from the fellow wanting to know how much Vit. powder to use---SORRY ABOUT THAT.

Re: .375 Snipetac load data.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Master Diver</div><div class="ubbcode-body">Back from the range POI was the same after the file work

But the confidence to the system has now improved after clearing the rings from the base of the rail.

But the confidence to the system has now improved after clearing the rings from the base of the rail.

Steve123

Could you post a picture or a link to that XXL Surgeon 408 cartridge size action. I can only find the XL Surgeon on the site

Cheers,

Master Diver </div></div>

They don't make a XXL...yet anyways

I just meant it's a well thought out action.

I just meant it's a well thought out action.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Master Diver</div><div class="ubbcode-body">Back from the range POI was the same after the file work

Steve123

Could you post a picture or a link to that XXL Surgeon 408 cartridge size action. I can only find the XL Surgeon on the site

Cheers,

Master Diver </div></div>

They don't make a XXL...yet anyways

Re: .375 Snipetac load data.

Hmmmm I wonder how much it would cost to mill the whole thing, action, base, and rings bottom 1/2 from a single block of stainless.... just thinking out loud...

back to your regularlly scheduled discussion

JeffVN

Hmmmm I wonder how much it would cost to mill the whole thing, action, base, and rings bottom 1/2 from a single block of stainless.... just thinking out loud...

back to your regularlly scheduled discussion

JeffVN

Re: .375 Snipetac load data.

Agustus.

I suspect we'll need to buy more than one each to get a manufacturer to build us one.... hmmmmm time to call Preston and have a chat.

Do we want it with a 408 or 338 boltface?

JeffVN

Agustus.

I suspect we'll need to buy more than one each to get a manufacturer to build us one.... hmmmmm time to call Preston and have a chat.

Do we want it with a 408 or 338 boltface?

JeffVN

A

Augustus

Guest

Re: .375 Snipetac load data.

I imagine if we can talk someone into doing this it aint gonna be cheap, sooo, I want it to go bang REAL LOUD. The 408 Chey boltface would be my pick. Ive been shooting a standard 338/408 and its a really neat cartridge. 300 gr SMK out of a 32 in. barrel at 3300 fps. I think it may be possible to shorten the case a little and do a few other changes and get 3150 or so out of a 26 in barrel. This rifle could easily be built and keep the wt. to around 10 to 11 lbs. I have one that weighs 12 lbs with a 30 in barrel. The recoil is not a problem at all.

Ok, now, anybody want to build this thing?????????

I imagine if we can talk someone into doing this it aint gonna be cheap, sooo, I want it to go bang REAL LOUD. The 408 Chey boltface would be my pick. Ive been shooting a standard 338/408 and its a really neat cartridge. 300 gr SMK out of a 32 in. barrel at 3300 fps. I think it may be possible to shorten the case a little and do a few other changes and get 3150 or so out of a 26 in barrel. This rifle could easily be built and keep the wt. to around 10 to 11 lbs. I have one that weighs 12 lbs with a 30 in barrel. The recoil is not a problem at all.

Ok, now, anybody want to build this thing?????????

Re: .375 Snipetac load data.

Sorry guys but i havent been lurking around lately to see what has been happening.

Some time next year i should have something available with an

intragal base machined to the acton. They will be all wire EDM cut. I have been working with a tool and die maker, he has all the neat machines, to design several actions. One will be a 700 long action clone, and a large action for the 338 lapua or 408 based cases. After some initial testing i might add a lighter version of the 408 action. A 3rd option is also in the design phase, the one with the intregal pic rail built in. My plan is to have a single stack internal magazine for a repeater. It takes a massive amount of cad time and set up time just to make the prototypes. I hope to get things rolling sometime in January. From there a decision will be made on what recievers we are going to go with. I will have a new thread when more details are ready.

Dave

Sorry guys but i havent been lurking around lately to see what has been happening.

Some time next year i should have something available with an

intragal base machined to the acton. They will be all wire EDM cut. I have been working with a tool and die maker, he has all the neat machines, to design several actions. One will be a 700 long action clone, and a large action for the 338 lapua or 408 based cases. After some initial testing i might add a lighter version of the 408 action. A 3rd option is also in the design phase, the one with the intregal pic rail built in. My plan is to have a single stack internal magazine for a repeater. It takes a massive amount of cad time and set up time just to make the prototypes. I hope to get things rolling sometime in January. From there a decision will be made on what recievers we are going to go with. I will have a new thread when more details are ready.

Dave

A

Augustus

Guest

Re: .375 Snipetac load data.

What do you think about a reciever with integral rings. I know it could have issues mounting different scopes on the system;however, I have been playing around with several different scopes and it looks like the rings could be positioned to accommodate most of the most popular brands.

What do you think about a reciever with integral rings. I know it could have issues mounting different scopes on the system;however, I have been playing around with several different scopes and it looks like the rings could be positioned to accommodate most of the most popular brands.

Re: .375 Snipetac load data.

Augustus,

Only problem is what size scope body - 30mm(NXS) 34mm (S&B PR) or 35mm (USO)

Dave,

Sounds great with an action with a integrated rail. but why the internal magazine?

Cheers,

Master Diver

Augustus,

Only problem is what size scope body - 30mm(NXS) 34mm (S&B PR) or 35mm (USO)

Dave,

Sounds great with an action with a integrated rail. but why the internal magazine?

Cheers,

Master Diver