So here is my issue... I built an AR10 (DPMS style) in .308 with a Criterion 18" rifle length gas system, standard weight rifle buffer and spring, and a Toolcraft BCG; this setup runs flawlessly with pretty much all my loadings and with the factory ammunition that I've (sparingly) used.

I decided that I wanted to build another upper in 6.5 Creedmoor. I am using a Ballistic Advantage 22" Premium barrel (rifle length gas) Superflous Arms adjustable gas block, and a Toolcraft HP BCG. Since assembling this upper, and during load development I have had continued issues with cycling. The problem appears to be short cycling.

When I developed a load for this upper I began using SMK 142gr bullets with H4350 powder at 39 grains and worked my way up to 42 grains; I had short stroke issues with the lighter loadings (39.0 and 39.5), but things seemed to be reliable at higher loadings. This was all done with the gas block in the most "open" position. However, I was only testing 5 rounds of each charge weight.

Today I took the upper out to sight it in and initially it seemed to work fine with the load I chose (42 grains of H4350 / SMK 142's); ejection was initially at 3:00. After twenty rounds or so it started to short stroke and the ejection pattern moved to about 4:00. The gas block remained in the most "open" position throughout, I have also verified that the gas port is in alignment with the block.

So, here is what I am wondering about. With the .308 upper the rifle has been super reliable. With the 6.5 upper it has always appeared to be undergassed. Could my issue be the standard .308 rifle buffer and buffer spring? I am temped to change out the buffer spring to a lighter one, but I really don't want to change the parts of the lower; I thought it would be cool to have a large frame gas gun with two uppers in different calibers that could just be push pinned on and things would work...

I could go hotter on my loads, but I am already seeing signs of minor pressure, so I don't think that is the best option. I haven't done a lot of testing with any factory ammo. due to me not having any currently, but I have never had issues with developing functional ammunition across multiple calibers in the past.

Any ideas?

I'm gonna say theres not a thing wrong with it other than, just like me you probably don't understand the term run it wet. That means let that thing drown in it i broke the bolt down, soaked in oil overnite then let it drain off, cleaned it, then oil the shit out of it and in my case with a magnifying glass there was some roughness on the bolt rails so i used a little emory cloth on it. so that and soaking it to death i pumped 200 rounds through it and now its fine. by the way 4pm is not short stroking, its perfect from 3-430. oil it first , once you start messing with the buffers and springs for a band aide you'll wind up chasing more issues. Have you tried any factory ammo? M80s or 168s? and have you done the one round mag test? My post was almost identical to yours and after all the bs it was simple breakin and a shit ton of lube.

Read this before messing with buffers.

AR-10/AR 308 BUFFER WEIGHTS

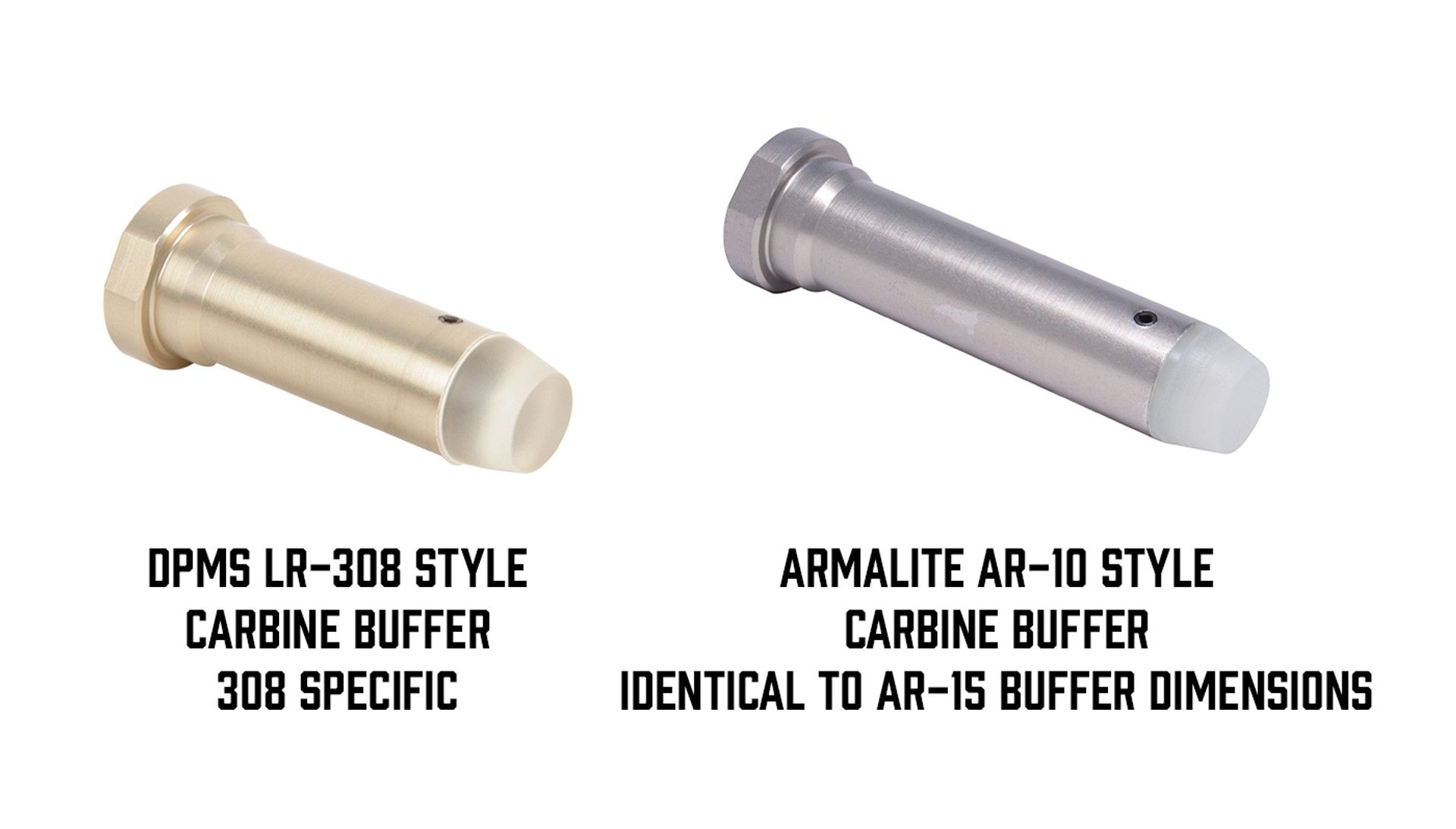

There’s a good amount of information out there online already when it comes to what buffer weights and springs you should use for AR-15s but not a whole lot of clarity when it comes to AR 10 buffer weights. Today, we aim to remedy that. We’ve gotten great feedback on customers utilizing our

AR-15 buffer weights blogs and now want to do AR10 buffer weights and springs the same justice.

To figure out which AR-10 buffer weight and spring combination will work best in your AR10 or LR308 rifle, you’ll have to first understand some key

differences between the AR-10 and LR 308 platforms. Essentially, here are the main takeaways that you should know:

- AR10 is a term often incorrectly and interchangeably used with LR308.

- Most people actually mean LR308 when they say “AR-10”.

- Armalite 10 rifle parts are largely not interchangeable with the AR-15.

- Several LR-308 parts are universally interchangeable with the AR15.

- The shape of the two different upper receivers are different but have no functional difference.

- AR-10 refers to Armalite’s design.

- LR308 refers to the DPMS design. Sometimes also called ‘AR-308’.

- DPMS stands for Defense Procurement Manufacturing Services (company’s full name is DPMS Panther Arms).

Going forward we’ll continue to use the term ‘AR-10’ (in your head you can replace this term with ‘AR-308’ specifically because that’s what we sell) just think of “AR-10” as an overarching, caliber specific designation and not a reference to the original Armalite rifle.

ARE AR 15 AND AR 10 BUFFER SPRINGS THE SAME?

Technically, yes. All AR10 buffer springs and buffer weights are going to be able to fit in any AR-15 or LR-308 rifle. Whether they will make your rifle cycle consistently and perform reliably is a different story. That’s why there are specific buffer spring designs and various buffer weights which will work better or worse for certain length rifles. But yes, AR-15 and AR308 buffer springs specifically are the same length which makes them directly interchangeable.

You can actually run your AR10 rifle without any “AR10 buffer” and just use the spring. Only the first couple or few shots will work but the experience will not be pleasant. The violent action of the BCG going back and forth will be more intense and cause more wear and tear on your gun. There’s also no guarantee that the gun will cycle consistently.

The main difference in the AR buffer springs lies in the length. Going back to the actual AR-10 (Armalite design), the interchangeability is not reliant on whether you’re using an AR10 or AR308, it’s actually a buffer tube issue. AR15 style stocks are compatible with both AR15’s and AR10’s, hence the compatibility, because they use the same length buffer tubes. But if you use an A1/A2 style stock it will require a longer spring.

AR10 BUFFERS (LR 308) EXPLAINED

There are three types of buffers – rifle buffers, carbine buffers and adjustable buffers. So when do you use a carbine buffer vs a rifle buffer? Carbine buffers or buffers with weights that fall under the H2 or H3 category are most commonly what AR-10 owners should be using along with carbine length butt stocks. Rifle buffers are really only used with the A1/A2 style buttstocks due to the rifle buffer tube being longer. Basically every buffer used today is going to be some sort of carbine length buffer.

Why are buffer weights important? If you were to shoot with just a buffer spring and no buffer weight in a full auto/select fire AR-10 — you’d likely experience light strikes and because the timing of the bolt going back and forth would be off and not completely in sync with the hammer.

Having a buffer slows that cyclical action down to help you avoid light strikes, promote reliable cycling of rounds being fired, ejected and properly fed into the chamber. Once dialed in, you might surprise yourself with a softer and flatter shooting AR10 style rifle than you initially expected. You also don’t want too heavy of a buffer either otherwise you risk slowing down that bolt way too much which would cause malfunctions or failures.

CHOOSING AN AR10 BUFFER WEIGHT

Generally speaking, don’t get hung on the rifle length buffers. AR10 carbine buffer weights will range anywhere between 3.8 to 5.4 oz for any AR10 style rifle. But that weight range can also depend on where you’re getting the AR 10 buffer from as well. The chart above is specifically for

Odin Works’ adjustable buffers which allow users to tune their buffer weight to get your AR308 rifle cycling just the way you want.

There’s no “one size fits all” answer when it comes to the topic of AR10 buffer weights and springs because there are just so many factors involved. Namely, the rifle length, ammunition load, buffer weight, buffer spring type, whether you’re shooting suppressed, etc. Some experimentation or trial and error is going to be inevitable but with this information you can make a better and more educated guess. Unlike the AR-15 buffer weights, we don’t have a chart for you based on length of rifle for AR-10s because there is less of a barrel length difference in AR10 style rifles. Most barrels are going to be around 18” to 20”.

But understanding the symptoms, like if you’re experiencing short stroking or a failure to feed or eject — will also help you know what you’re dealing with and advise your next move. Below, you’ll see a figure for how to diagnose the “health” of your rifle’s ejection angle based on which direction empty casings are flying after extraction. This concept applies to the AR-15 just the same as the AR-10 or AR-308.

DON’T FORGET ABOUT THE GAS BLOCK

A lot of people seem to forget how big of an impact the gas block can have on the shooting experience of any AR platform rifle. Most factory built guns are going to come with an overgassed gas block which will promote higher reliability between different parts and a wider variety of ammunition loads.

But when you’re building your own rifle from the ground up that tends to get in the way of properly tuning your rifle. That’s why it’s highly advantageous to have an adjustable gas block as it could mean the difference of your rifle cycling or not. Still, it’s best to think about the adjustable gas block as a fine tuning process whereas the majority of your guesswork is going to be within the buffer system.