So was testing some loads again last night with my 6.5CM. I shot these same loads this past Saturday but wanted to re-verify before i loaded up a bunch of them.

The only variable that changed was i used 1x fired FL re-sized brass with a .288 neck bushing trimmed to 1.910".

The loads are as such.

130gr Berger VLD Hunting

New factory brass

My go to load is 42.4gr of H4350 (these are colored red/blue in the pictures)

I've tried 42.8 but they didn't shoot near as well so I've been looking for the next node.

New loads are:

New factory brass

43.2gr of H4350

43.6gr of H4350

These showed a lot of promise on Saturday with zero pressure signs at about 50*F.

It was 32*F last night.

When I loaded the new test rounds used the same bullets from the same lot. Checked the first couple for COAL and they measured out at 2.800. Stuck the bullet comparator on, and they measured at 2.158 at the ogive.

Now, my gunsmith measured the bergers for me and jammed all the way in the rifling gets me a COAL 2.870 so with a COAL of 2.80 they shoudl be jumping about .070".

Rechecked the new loads last night and they measured between 2.810 and 2.817 this was across 9 rounds.

Rechecked the ogive and still measured at 2.158, checked my go to load of 42.4gr and they measure at 2.150/2.151

So obviously the new loads are seated about .007-.009" longer than my normal load. This shouldn't put them into the rifling, but is it possible that it did?

When I loaded these up, i made another charge up and put it in a small sealed plastic container as a control for checking future loads if they shot well. Put it on my digital scale and they weighed in at 43.9/44.0gr. So I'm thinking my 505 scale might have been off when i charged these loads. But even at that, if it was in fact .3/.4gr high, the lower load of 43.2 should have been 43.5/43.6 which shot fine on Saturday with zero pressure signs.

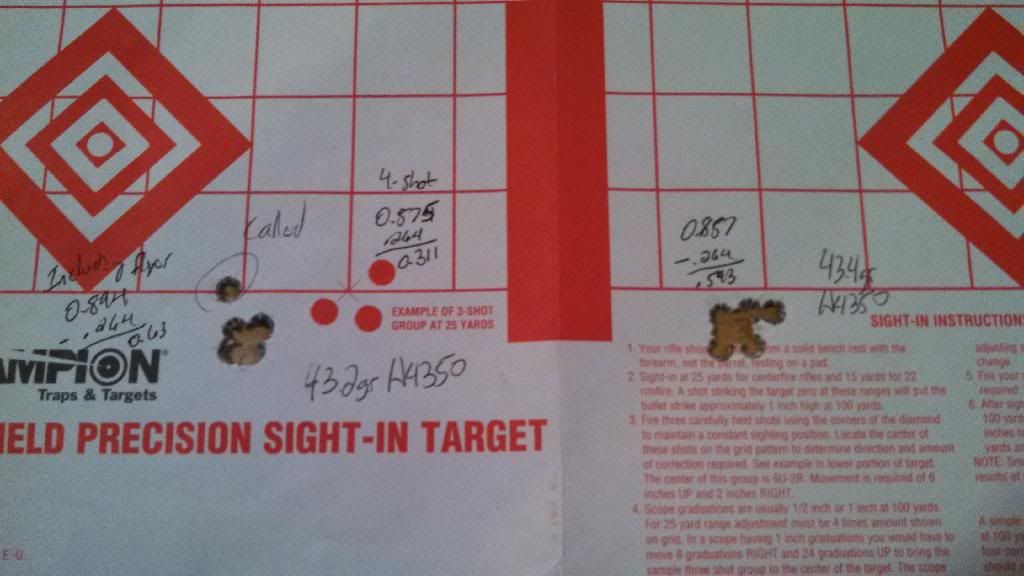

Pictures:

This is my normal 42.4gr load

This is 43.2gr

All the brass, the one in the middle is 43.6gr

The brass grew about .025" after firing.

Also note the circle around the case.

Same thing with 43.6gr

So my questions are as follows:

Could having the bullet seated .007-.009" out be putting the bullets into the rifling even though the measured COAL was 2.870 jammed and these longer rounds measured at 2.817 at the longest?

Would the FL re-sized brass with a .288 neck bushing increase neck tension enough to increase pressure to the point to cause the pressure signs?

Also measured the brass from my 42.4gr load after firing and they come out to 1.919", so what would cause the brass with the new loads to grow .025"?

If my scale was off, that's one thing that can be corrected, but is there anything i might have been doing to cause a severe increase in pressure?

Note, No sticky bolt on 43.2gr load, just extremely flat primers and that ring around the brass. 43.6gr did get me sticky bolt and the same flat primer and ring around the brass.

I'd already tumbled the brass from Saturday, so i can't take pictures of them. They might have had some very faint primer flattening but no other pressure signs.

Also, measured the loaded rounds and the diameter of the neck was .295 which is to spec on via the hornady manual.

Thanks in advance for the help.

The only variable that changed was i used 1x fired FL re-sized brass with a .288 neck bushing trimmed to 1.910".

The loads are as such.

130gr Berger VLD Hunting

New factory brass

My go to load is 42.4gr of H4350 (these are colored red/blue in the pictures)

I've tried 42.8 but they didn't shoot near as well so I've been looking for the next node.

New loads are:

New factory brass

43.2gr of H4350

43.6gr of H4350

These showed a lot of promise on Saturday with zero pressure signs at about 50*F.

It was 32*F last night.

When I loaded the new test rounds used the same bullets from the same lot. Checked the first couple for COAL and they measured out at 2.800. Stuck the bullet comparator on, and they measured at 2.158 at the ogive.

Now, my gunsmith measured the bergers for me and jammed all the way in the rifling gets me a COAL 2.870 so with a COAL of 2.80 they shoudl be jumping about .070".

Rechecked the new loads last night and they measured between 2.810 and 2.817 this was across 9 rounds.

Rechecked the ogive and still measured at 2.158, checked my go to load of 42.4gr and they measure at 2.150/2.151

So obviously the new loads are seated about .007-.009" longer than my normal load. This shouldn't put them into the rifling, but is it possible that it did?

When I loaded these up, i made another charge up and put it in a small sealed plastic container as a control for checking future loads if they shot well. Put it on my digital scale and they weighed in at 43.9/44.0gr. So I'm thinking my 505 scale might have been off when i charged these loads. But even at that, if it was in fact .3/.4gr high, the lower load of 43.2 should have been 43.5/43.6 which shot fine on Saturday with zero pressure signs.

Pictures:

This is my normal 42.4gr load

This is 43.2gr

All the brass, the one in the middle is 43.6gr

The brass grew about .025" after firing.

Also note the circle around the case.

Same thing with 43.6gr

So my questions are as follows:

Could having the bullet seated .007-.009" out be putting the bullets into the rifling even though the measured COAL was 2.870 jammed and these longer rounds measured at 2.817 at the longest?

Would the FL re-sized brass with a .288 neck bushing increase neck tension enough to increase pressure to the point to cause the pressure signs?

Also measured the brass from my 42.4gr load after firing and they come out to 1.919", so what would cause the brass with the new loads to grow .025"?

If my scale was off, that's one thing that can be corrected, but is there anything i might have been doing to cause a severe increase in pressure?

Note, No sticky bolt on 43.2gr load, just extremely flat primers and that ring around the brass. 43.6gr did get me sticky bolt and the same flat primer and ring around the brass.

I'd already tumbled the brass from Saturday, so i can't take pictures of them. They might have had some very faint primer flattening but no other pressure signs.

Also, measured the loaded rounds and the diameter of the neck was .295 which is to spec on via the hornady manual.

Thanks in advance for the help.