I posted my troubleshooting quest in another forum:

and have gotten to thinking I have a tolerance issue with ammo, so this forum is more appropriate.

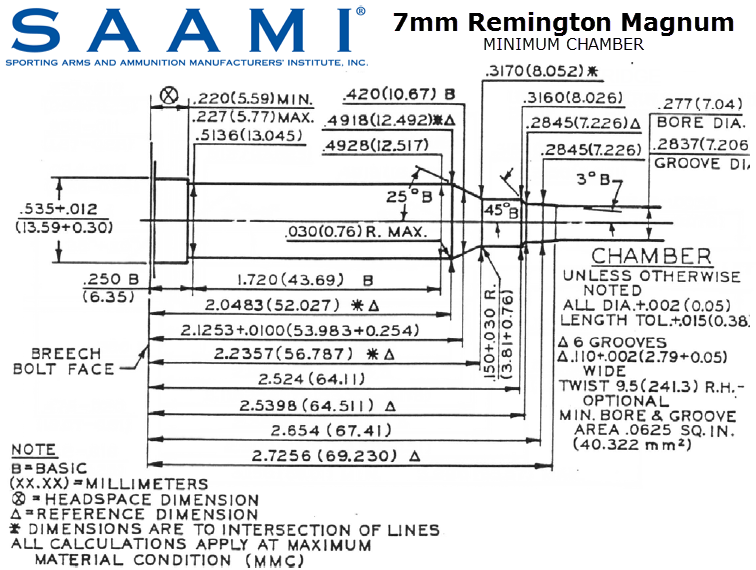

I have a basic setup for handloading my 7mm Rem Mag but have been buying cheap factory ammo. Lately my bolt won't close on a few Federal and almost all Winchester. Headspace for 7RM is 0.2200". My bolt closes smoothly on cases up to 0.2220".

Even if I start handloading again, I will need to buy brass. Is it reasonable to expect it to be 0.2200 plus or minus two thousandths?

Thanks!

and have gotten to thinking I have a tolerance issue with ammo, so this forum is more appropriate.

I have a basic setup for handloading my 7mm Rem Mag but have been buying cheap factory ammo. Lately my bolt won't close on a few Federal and almost all Winchester. Headspace for 7RM is 0.2200". My bolt closes smoothly on cases up to 0.2220".

Even if I start handloading again, I will need to buy brass. Is it reasonable to expect it to be 0.2200 plus or minus two thousandths?

Thanks!