If I correctly understand what you are describing, another way I’ve heard of doing this is to counterbore the muzzle, make interior threads, and then thread in an adapter.

The bore length decreases about 1/2”, but there is not a section without the full thickness of the barrel around the bore.

Tornado Technologies is known for this type of work but I just read some reviews and they seem to be having issues as they had to move shop. I wouldn’t use them until that’s resolved.

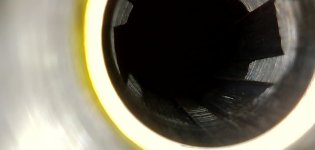

Here is an example (not entirely sure if this is an actual example as it almost looks like this particular adapter is threading

onto barrel threads vs threading

into the barrel, but hopefully you understand. Got it from TT’s Facebook page)

View attachment 8150233

From what I understand they use this approach on barrels that, say, have a sight post right on the end, or if the barrel terminates right at the end of the stock (Mannlicher) or slide (pistol).

And note that this is what I

understand how they approach this problem, as I have never used them. I could be off base.