Looking for your methods/ideas for annealing brass. I have read that 7WSM should be annealed after a few firings to keep neck tension consistent. Also, I have a 17 Ackley Hornet that brass needs annealed after fire forming.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

Having trouble using the site?

Contact support

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Re: Annealing Brass

For my 7 WSM's I use a Ken Light BC -1000 case annealing machine....contact Ken --website www.kenlightmfg.com

For my 7 WSM's I use a Ken Light BC -1000 case annealing machine....contact Ken --website www.kenlightmfg.com

Re: Annealing Brass

Kombayotch I love that setup... every time you post that picture it reminds me to go to home depot and get a couple pipe fittings.

Kombayotch I love that setup... every time you post that picture it reminds me to go to home depot and get a couple pipe fittings.

Re: Annealing Brass

I've been meaning to design a dirt simple machine with auto-case feel, but I haven't gotten around to it... Too damn busy lately and when I have time, I spend it either reloading or shooting.

I have a bunch of Hornady brass that needs it again. The runouts have crept up to 7 thou in some cases... I dread doing it manually.

I've been meaning to design a dirt simple machine with auto-case feel, but I haven't gotten around to it... Too damn busy lately and when I have time, I spend it either reloading or shooting.

I have a bunch of Hornady brass that needs it again. The runouts have crept up to 7 thou in some cases... I dread doing it manually.

Re: Annealing Brass

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Cowboy</div><div class="ubbcode-body">Kombayotch, I would love to hear some detail on that setup. Specifically, what size parts, and how loose/tight does the case fit in the holder? </div></div>

I asked that a bit ago in another thread. You take the brass to the hardware store and flip through the shelf til you find something that fits well, holds the brass enough so it doesn't fall out and just assemble the pieces at the store.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Cowboy</div><div class="ubbcode-body">Kombayotch, I would love to hear some detail on that setup. Specifically, what size parts, and how loose/tight does the case fit in the holder? </div></div>

I asked that a bit ago in another thread. You take the brass to the hardware store and flip through the shelf til you find something that fits well, holds the brass enough so it doesn't fall out and just assemble the pieces at the store.

Re: Annealing Brass

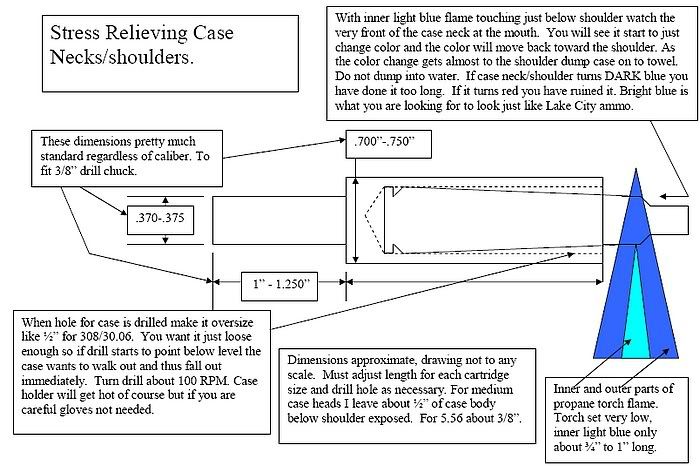

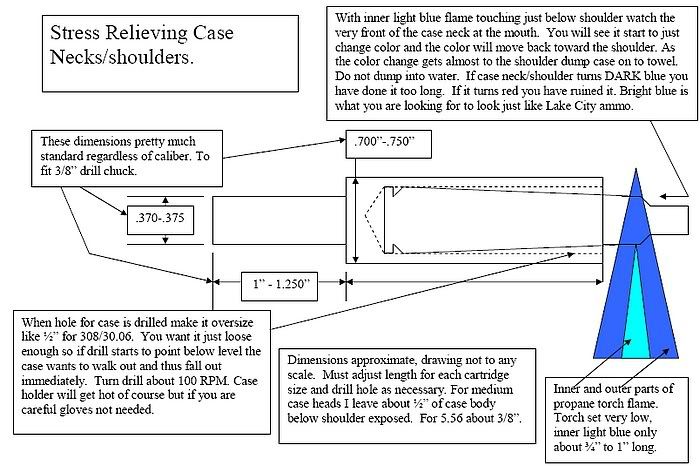

Stainless steel drill rod bored out to allow the brass to slide out when tipped! Drilled just deep enough to allow approx 1/4"(50's) and 1/8" (308, 223, and 22 hornets) below the shoulder to be exposed.

Terry

Stainless steel drill rod bored out to allow the brass to slide out when tipped! Drilled just deep enough to allow approx 1/4"(50's) and 1/8" (308, 223, and 22 hornets) below the shoulder to be exposed.

Terry

Re: Annealing Brass

i have read all there is to read about annealing and tried a few cases. is the general consesus to use tempilaq, watch for color changes, or just count seconds until it is right?

chuck

i have read all there is to read about annealing and tried a few cases. is the general consesus to use tempilaq, watch for color changes, or just count seconds until it is right?

chuck

Re: Annealing Brass

suasponte,

That's exactly what I did on my cheapo lathe.I just grabbed some scrap steel and made some.they look like yours.

Steve

suasponte,

That's exactly what I did on my cheapo lathe.I just grabbed some scrap steel and made some.they look like yours.

Steve

Re: Annealing Brass

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: selfbowhunter</div><div class="ubbcode-body">i have read all there is to read about annealing and tried a few cases. is the general consesus to use tempilaq, watch for color changes, or just count seconds until it is right?

chuck </div></div>

308's I go 6 seconds, 223's 5 seconds, 22 hornets 4 seconds, and the 50's I go 10 seconds. I watch for a light blue color change in the neck area then I drop it on a wet towel (NOT INTO WATER).

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: selfbowhunter</div><div class="ubbcode-body">i have read all there is to read about annealing and tried a few cases. is the general consesus to use tempilaq, watch for color changes, or just count seconds until it is right?

chuck </div></div>

308's I go 6 seconds, 223's 5 seconds, 22 hornets 4 seconds, and the 50's I go 10 seconds. I watch for a light blue color change in the neck area then I drop it on a wet towel (NOT INTO WATER).

Re: Annealing Brass

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: kombayotch</div><div class="ubbcode-body">For $3 worth of plumbing fitting:

</div></div>

</div></div>

I will be heading to Lowes tomorrow. Thanks for the idea.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: kombayotch</div><div class="ubbcode-body">For $3 worth of plumbing fitting:

I will be heading to Lowes tomorrow. Thanks for the idea.

Re: Annealing Brass

Thanks for all the info guys. I think I will start in the middle here and try the Hornady kit.

Why on a wet towel instead of dunking?

Thanks for all the info guys. I think I will start in the middle here and try the Hornady kit.

Why on a wet towel instead of dunking?

Re: Annealing Brass

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: shoot4fun</div><div class="ubbcode-body">

Why on a wet towel instead of dunking? </div></div>

I'd like to know as well.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: shoot4fun</div><div class="ubbcode-body">

Why on a wet towel instead of dunking? </div></div>

I'd like to know as well.

Re: Annealing Brass

I am gonna guess so that it cools slowly. Rapid cooling might actually cause the case to harden again. Correct me if i'm wrong.

I am gonna guess so that it cools slowly. Rapid cooling might actually cause the case to harden again. Correct me if i'm wrong.

Re: Annealing Brass

Brass won't harden like steel and other like metals to where rapid cooling will make it harder Brass has to be worked to make it harder. How fast it cools doesn't effect the hardness of brass.

Brass won't harden like steel and other like metals to where rapid cooling will make it harder Brass has to be worked to make it harder. How fast it cools doesn't effect the hardness of brass.

Re: Annealing Brass

But its still does expand and contract with temperature variation. You're causing the material to cool (and contract) on one side faster than on the other. That may or may not make a difference... I'd like to know if he's measuring runouts afterwards. It would probably straighten out after the first firing if it did warp, but I prefer get low runouts on every loading. Which I do after annealing and dropping onto water.

I also use ultrasonic cleaning to get the oxidization off the inside of the necks after annealing anyway, so getting the cases wet doesn't bother me.

But its still does expand and contract with temperature variation. You're causing the material to cool (and contract) on one side faster than on the other. That may or may not make a difference... I'd like to know if he's measuring runouts afterwards. It would probably straighten out after the first firing if it did warp, but I prefer get low runouts on every loading. Which I do after annealing and dropping onto water.

I also use ultrasonic cleaning to get the oxidization off the inside of the necks after annealing anyway, so getting the cases wet doesn't bother me.

Re: Annealing Brass

A ammo Engineer from Frankford Arsenal told me not to drop into water.

A metallurgist told me not to drop into water.

If you watch the History Channel special with Winchester. They show the brass going down the line thru the flames to anneal and dropping out into a box not water.

A friend of mine that worked at the Small Cal Lab at Aberdeen told me not to drop into water after annealing!

There is a old article I have in regards to annealing that says to drop onto a towel and not into water.

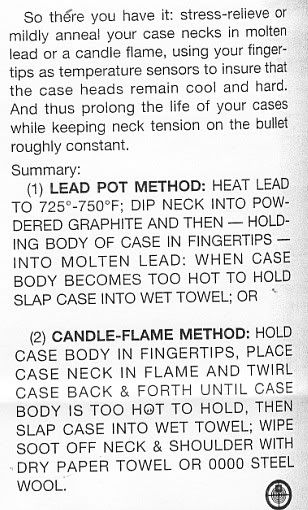

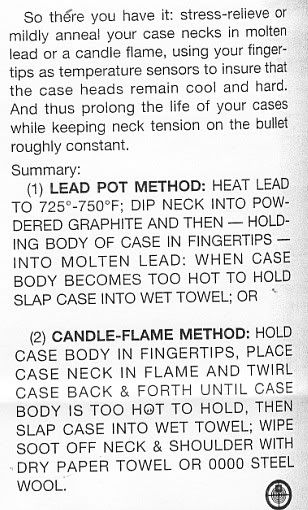

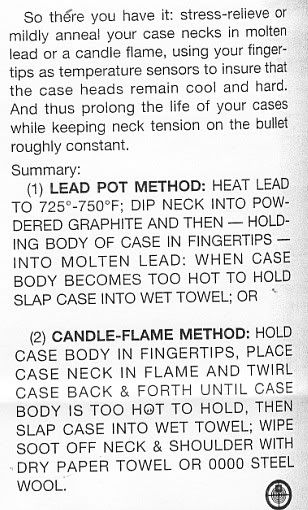

Below is the summary of that article Written by: Fred Barker in the 1996 Precision Shooting magazine!

I have other references that state not to quench in water but allow it to cool in a wet towel.

If you have access to the 1996 Precision Shooting magazine that article goes into it in depth including the metallurgy of the annealing process

it starts on page 90.

Terry

A ammo Engineer from Frankford Arsenal told me not to drop into water.

A metallurgist told me not to drop into water.

If you watch the History Channel special with Winchester. They show the brass going down the line thru the flames to anneal and dropping out into a box not water.

A friend of mine that worked at the Small Cal Lab at Aberdeen told me not to drop into water after annealing!

There is a old article I have in regards to annealing that says to drop onto a towel and not into water.

Below is the summary of that article Written by: Fred Barker in the 1996 Precision Shooting magazine!

I have other references that state not to quench in water but allow it to cool in a wet towel.

If you have access to the 1996 Precision Shooting magazine that article goes into it in depth including the metallurgy of the annealing process

it starts on page 90.

Terry

Re: Annealing Brass

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: suasponte</div><div class="ubbcode-body">A ammo Engineer from Frankford Arsenal told me not to drop into water.

A metallurgist told me not to drop into water.

If you watch the History Channel special with Winchester. They show the brass going down the line thru the flames to anneal and dropping out into a box not water.

A friend of mine that worked at the Small Cal Lab at Aberdeen told me not to drop into water after annealing!

There is a old article I have in regards to annealing that says to drop onto a towel and not into water.

Below is the summary of that article Written by: Fred Barker in the 1996 Precision Shooting magazine!

I have other references that state not to quench in water but allow it to cool in a wet towel.

If you have access to the 1996 Precision Shooting magazine that article goes into it in depth including the metallurgy of the annealing process

it starts on page 90.

Terry </div></div>

I still don't see why not, you have lots of circumstantial "don't do it" but no hard reason. I'm not trying to sass you on it, but without a good reason and my experience with metals processing I don't see why you shouldn't drop it in water except for high cooling rates that might make it crack from quick contraction.

I can see a reason not to roll it in a wet towel, and that is differential cooling that could cause it to runout.

Also, I don't have access to the article, if you have it, can you put up a couple of bulleted reasons why they say this is a bad idea?

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: suasponte</div><div class="ubbcode-body">A ammo Engineer from Frankford Arsenal told me not to drop into water.

A metallurgist told me not to drop into water.

If you watch the History Channel special with Winchester. They show the brass going down the line thru the flames to anneal and dropping out into a box not water.

A friend of mine that worked at the Small Cal Lab at Aberdeen told me not to drop into water after annealing!

There is a old article I have in regards to annealing that says to drop onto a towel and not into water.

Below is the summary of that article Written by: Fred Barker in the 1996 Precision Shooting magazine!

I have other references that state not to quench in water but allow it to cool in a wet towel.

If you have access to the 1996 Precision Shooting magazine that article goes into it in depth including the metallurgy of the annealing process

it starts on page 90.

Terry </div></div>

I still don't see why not, you have lots of circumstantial "don't do it" but no hard reason. I'm not trying to sass you on it, but without a good reason and my experience with metals processing I don't see why you shouldn't drop it in water except for high cooling rates that might make it crack from quick contraction.

I can see a reason not to roll it in a wet towel, and that is differential cooling that could cause it to runout.

Also, I don't have access to the article, if you have it, can you put up a couple of bulleted reasons why they say this is a bad idea?

Re: Annealing Brass

<div class="ubbcode-block"><div class="ubbcode-header">Quote:</div><div class="ubbcode-body">I still don't see why not, you have lots of circumstantial "don't do it" but no hard reason.</div></div>

Had this conversation with a friend who's worked with some radical wildcats. He was in contact with a metalurgist who had the equipment to test brass after annealing. Basically the metalurgist said that because the cross-section of the brass is so small you can allow it to aircool. If the brass were a solid bar quenching would be needed to remove the heat quickly. Quenching brass won't hurt it. The key is that you don't allow excessive heat in the case head area.

<div class="ubbcode-block"><div class="ubbcode-header">Quote:</div><div class="ubbcode-body">I still don't see why not, you have lots of circumstantial "don't do it" but no hard reason.</div></div>

Had this conversation with a friend who's worked with some radical wildcats. He was in contact with a metalurgist who had the equipment to test brass after annealing. Basically the metalurgist said that because the cross-section of the brass is so small you can allow it to aircool. If the brass were a solid bar quenching would be needed to remove the heat quickly. Quenching brass won't hurt it. The key is that you don't allow excessive heat in the case head area.

Re: Annealing Brass

Another form of annealing spin. Mug a crappy socket set in conjunction with a cordless screwdriver...

25WSSM, .243, .223

Another form of annealing spin. Mug a crappy socket set in conjunction with a cordless screwdriver...

25WSSM, .243, .223

Re: Annealing Brass

Thanks for update AJ, and susaponte for the PM explaining it more.

I'll give it a try next time, it will be nice not having to roll the brass out on a towel and lay it in the sun before tumbling to dry it off.

I like the crappy socket set and cordless drill, I even have that at home, I don't have to spend $3 on plumbing parts LOL.

Thanks for update AJ, and susaponte for the PM explaining it more.

I'll give it a try next time, it will be nice not having to roll the brass out on a towel and lay it in the sun before tumbling to dry it off.

I like the crappy socket set and cordless drill, I even have that at home, I don't have to spend $3 on plumbing parts LOL.

Re: Annealing Brass

I like having material up to just below the neck! Like on the rigs I have and like the pipe fitting rigs. This limits the flame exposure to just that area and shields the case body from the direct flame! It just allows you to be a little more sloppy with holding the torch!

I also found that it gives a more uniform annealing at the top of the case! You can see by the case in the picture below that it is a uniform distance to the annealing from the case neck.

Terry

I like having material up to just below the neck! Like on the rigs I have and like the pipe fitting rigs. This limits the flame exposure to just that area and shields the case body from the direct flame! It just allows you to be a little more sloppy with holding the torch!

I also found that it gives a more uniform annealing at the top of the case! You can see by the case in the picture below that it is a uniform distance to the annealing from the case neck.

Terry

Re: Annealing Brass

This topic should be stickied.

Thank you gentlemen for the wealth of information.

This topic should be stickied.

Thank you gentlemen for the wealth of information.

Re: Annealing Brass

Annealing article on 6mmBR.com

Good read! It covers most methods used for annealing!

Terry

Annealing article on 6mmBR.com

Good read! It covers most methods used for annealing!

Terry

Re: Annealing Brass

So what do you do after annealing?

Is it ready to load?

Do you do case prep work annealing (decapping, sizing, trimming)?

I have the stuff to do the annealing. Need to be sure what to do and when to do it.

So what do you do after annealing?

Is it ready to load?

Do you do case prep work annealing (decapping, sizing, trimming)?

I have the stuff to do the annealing. Need to be sure what to do and when to do it.

Re: Annealing Brass

The link suasponte provided is very educational. Thanks. I'm new to reloading and this answered all of my questions, including the ones above.

I'm quickly finding out that what started out as a way to produce cheaper amunition is quickly turning into its own obscession.

While the less expensive methods appeal to me, I'm thinking that, like anything to do with reloading, consistency is king. The automated annealing machines seem to accomplish that better.

Now, how to find the extra $400 to get the Ken Light automated annealing machine. Let's see, how much brass do I have to anneal before it pays for itself...

The link suasponte provided is very educational. Thanks. I'm new to reloading and this answered all of my questions, including the ones above.

I'm quickly finding out that what started out as a way to produce cheaper amunition is quickly turning into its own obscession.

While the less expensive methods appeal to me, I'm thinking that, like anything to do with reloading, consistency is king. The automated annealing machines seem to accomplish that better.

Now, how to find the extra $400 to get the Ken Light automated annealing machine. Let's see, how much brass do I have to anneal before it pays for itself...

Re: Annealing Brass

I agree that it provided good info on annealing. But I want to know the steps before and after.

Do I anneal, wait to cool/dry, then load them up?

I agree that it provided good info on annealing. But I want to know the steps before and after.

Do I anneal, wait to cool/dry, then load them up?

Re: Annealing Brass

1) Clean brass

2) Anneal (I anneal every 3rd load)

3) Case prep

4) prime, powder, bullet.

LC brass that you buy from Goverment Liquidation bulk purchases (Gunbroker, etc) I clean then anneal.

If you are annealing dirty brass it is impossible to see any color change in the neck and shoulder area. Clean brass is the way to go.

Terry

1) Clean brass

2) Anneal (I anneal every 3rd load)

3) Case prep

4) prime, powder, bullet.

LC brass that you buy from Goverment Liquidation bulk purchases (Gunbroker, etc) I clean then anneal.

If you are annealing dirty brass it is impossible to see any color change in the neck and shoulder area. Clean brass is the way to go.

Terry

Re: Annealing Brass

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Savage_Jake</div><div class="ubbcode-body">OK. So FL or neck size after annealing? </div></div>

Yes, that's what I do. Annealing changes the dimensions of the case, so you need to resize afterwards.

I have a Ken Light annealing machine and the hot cases simply fall into a cardboard box at the exit of the case wheel. A wet towel has no purpose in the annealing process, it's just a place to put the hot cases, and the towel won't burn if it's wet.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Savage_Jake</div><div class="ubbcode-body">OK. So FL or neck size after annealing? </div></div>

Yes, that's what I do. Annealing changes the dimensions of the case, so you need to resize afterwards.

I have a Ken Light annealing machine and the hot cases simply fall into a cardboard box at the exit of the case wheel. A wet towel has no purpose in the annealing process, it's just a place to put the hot cases, and the towel won't burn if it's wet.

Re: Annealing Brass

Ok thanks for the info fellas. Sorry for all the questions. I just dont want to hurt myself by doing something wrong. But I am gonna give it a try and see how it goes.

Ok thanks for the info fellas. Sorry for all the questions. I just dont want to hurt myself by doing something wrong. But I am gonna give it a try and see how it goes.

Re: Annealing Brass

I ordered the Hornady annealing kit from Midway (they were the only ones to have it) and only after talking to Lenny at Hornady. He said the three case holders would fit my application for 17 AH but not for 7WSM. He sold me an extra magnum holder that I can open up. I'll come back and let you know how it goes.

Thanks to all for the great info.

I ordered the Hornady annealing kit from Midway (they were the only ones to have it) and only after talking to Lenny at Hornady. He said the three case holders would fit my application for 17 AH but not for 7WSM. He sold me an extra magnum holder that I can open up. I'll come back and let you know how it goes.

Thanks to all for the great info.

Re: Annealing Brass

Has anyone used the Brass-O-Matic?

http://www.zephyrdynamics.com/page3.html

I like that it is a universal machine that you don't have to change out different shell plates. With two torches you don't have t worry about the case spinning in the plate to get an even heat on the neck.

Pricey bugger though, just shy of 500 bucks.

Has anyone used the Brass-O-Matic?

http://www.zephyrdynamics.com/page3.html

I like that it is a universal machine that you don't have to change out different shell plates. With two torches you don't have t worry about the case spinning in the plate to get an even heat on the neck.

Pricey bugger though, just shy of 500 bucks.

Re: Annealing Brass

The Brass-O-Matic or the Ken Light are both on the high side. I would love to hear personal experiences with both.

The Brass-O-Matic or the Ken Light are both on the high side. I would love to hear personal experiences with both.

Re: Annealing Brass

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Creature</div><div class="ubbcode-body">Shit I thought about using the method on the bottom part of that article posted above. I can afford a candle

. Would using your fingers(as a temp gauge) while holding onto the case body be effective? </div></div>

. Would using your fingers(as a temp gauge) while holding onto the case body be effective? </div></div>

Yes, guys have done that for years before Ken Light came along and automated it!

Just make sure to turn the case back and forth to heat all sides as evenly as you can.

Plus you will have to wipe off the black stuff from the candle flame.

Terry

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Creature</div><div class="ubbcode-body">Shit I thought about using the method on the bottom part of that article posted above. I can afford a candle

Yes, guys have done that for years before Ken Light came along and automated it!

Just make sure to turn the case back and forth to heat all sides as evenly as you can.

Plus you will have to wipe off the black stuff from the candle flame.

Terry

Re: Annealing Brass

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: kombayotch</div><div class="ubbcode-body">For $3 worth of plumbing fitting:

</div></div>

</div></div>

Komb, you don't happen to remember/know what size pipe nipples you used do you? Is it a 1/2" to 1/4" reducer? It should be marked on the reducer somewhere.

Thanks!

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: kombayotch</div><div class="ubbcode-body">For $3 worth of plumbing fitting:

Komb, you don't happen to remember/know what size pipe nipples you used do you? Is it a 1/2" to 1/4" reducer? It should be marked on the reducer somewhere.

Thanks!

Re: Annealing Brass

Someone asked for authoritative sources of why no water quench.

Well lets see - Frankford Arsenal made billions of rounds and saw no need to water quench. Lake City makes trillions of rounds and saw/see no need to water quench. Then there was Twin Cities, Denver, Eau Claire, and they saw no need to water quench.

Why didn't they use water to quench? Simple they are made to engineering drawings and process sheets and they have metallurgists to advise on heat treating etc and they saw no need to quench thusly it is not on the process sheets to do so.

Winchester, Federal, Remington makes billions of rounds and see no need to water quench.

All real manufacturers rotate cases to stress relieve them evenly all the way around. None of them use the heat crayons on the necks and they have no problems.

Some jerk sixty years ago couldn't figure out how to do it so he sat them in a pan of water and burned crap out of one side of the cases at a time and knocked them over to cool them down. He wrote a article for a gun rag and that is how urban legends are born.

Obviously the guy with a propane torch and a pan of water is the EXSPURT on the subject and everyone else is a idiot.

Someone is obviously going to ask "Why don't the ammo boys tell us how they do it?" Lets see, they sell ammo........the quicker you screw your cases up............the sooner you buy more ammo......... and they make more MONEY.

Personally I dump them on a dry towel. I know fire when I see it and ain't had the first towel burst into flames. Then again I don't use towels with residue of flammable materials impregnated there in. Also I don't get the cases red hot before dropping them on the towel. I did have some lettering off a T shirt adhere to some case necks so that was stopped. I have also used old sweat shirts. Main reason for the towel? The plastic dish pans don't like the heat. I am too lazy to build a wooden box. Don't have a big metal pan but come to think of it I could drop them in ammo can and just put lid on and store them away after letting them cool down.

Suasponte is absolutely right on having the cases clean so you can see what you are doing.

If you want to determine if you are doing it right, use a unfired LC round as a visual sample. Place your cases up next to them and compare. If yours are darker you will not get a attaboy. If they are the same you get one. If they are lighter add a number to your count. The absolute class act way to do it is get a metronome and set it for one second tics and you just count the tics to five or six. You can set it faster but that gets into higher math and I don't want to overload nothing haha.

Maybe one of the pan and water types will show some pics of their work and compare them to Suasponte photos.

The big question is why to stress relieve in the first place. Simple all the old ammo that was not stress relieved developed stress crack failures in long term storage. Thus enter the metallurgical boys who said to heat them a tad before loading and shazaam -- the problem went away. Anyone ever notice why there is very little 30-40 Krag ammo around? There is also very little FA ammo around from the pre stress relieving days.

I have some 1933 FA fired cases and when I got them I noticed there were a number of split necks. I stress relieved them and for some reason I have not had one split since. I have been using it since the 70s. Yeah I am cheap but I want to see just how long it will run.

I haven't used the pan and water crap since I was a teenager back in 60s. I figured out during the first session "this sucks" and never did it again.

Someone asked for authoritative sources of why no water quench.

Well lets see - Frankford Arsenal made billions of rounds and saw no need to water quench. Lake City makes trillions of rounds and saw/see no need to water quench. Then there was Twin Cities, Denver, Eau Claire, and they saw no need to water quench.

Why didn't they use water to quench? Simple they are made to engineering drawings and process sheets and they have metallurgists to advise on heat treating etc and they saw no need to quench thusly it is not on the process sheets to do so.

Winchester, Federal, Remington makes billions of rounds and see no need to water quench.

All real manufacturers rotate cases to stress relieve them evenly all the way around. None of them use the heat crayons on the necks and they have no problems.

Some jerk sixty years ago couldn't figure out how to do it so he sat them in a pan of water and burned crap out of one side of the cases at a time and knocked them over to cool them down. He wrote a article for a gun rag and that is how urban legends are born.

Obviously the guy with a propane torch and a pan of water is the EXSPURT on the subject and everyone else is a idiot.

Someone is obviously going to ask "Why don't the ammo boys tell us how they do it?" Lets see, they sell ammo........the quicker you screw your cases up............the sooner you buy more ammo......... and they make more MONEY.

Personally I dump them on a dry towel. I know fire when I see it and ain't had the first towel burst into flames. Then again I don't use towels with residue of flammable materials impregnated there in. Also I don't get the cases red hot before dropping them on the towel. I did have some lettering off a T shirt adhere to some case necks so that was stopped. I have also used old sweat shirts. Main reason for the towel? The plastic dish pans don't like the heat. I am too lazy to build a wooden box. Don't have a big metal pan but come to think of it I could drop them in ammo can and just put lid on and store them away after letting them cool down.

Suasponte is absolutely right on having the cases clean so you can see what you are doing.

If you want to determine if you are doing it right, use a unfired LC round as a visual sample. Place your cases up next to them and compare. If yours are darker you will not get a attaboy. If they are the same you get one. If they are lighter add a number to your count. The absolute class act way to do it is get a metronome and set it for one second tics and you just count the tics to five or six. You can set it faster but that gets into higher math and I don't want to overload nothing haha.

Maybe one of the pan and water types will show some pics of their work and compare them to Suasponte photos.

The big question is why to stress relieve in the first place. Simple all the old ammo that was not stress relieved developed stress crack failures in long term storage. Thus enter the metallurgical boys who said to heat them a tad before loading and shazaam -- the problem went away. Anyone ever notice why there is very little 30-40 Krag ammo around? There is also very little FA ammo around from the pre stress relieving days.

I have some 1933 FA fired cases and when I got them I noticed there were a number of split necks. I stress relieved them and for some reason I have not had one split since. I have been using it since the 70s. Yeah I am cheap but I want to see just how long it will run.

I haven't used the pan and water crap since I was a teenager back in 60s. I figured out during the first session "this sucks" and never did it again.

Re: Annealing Brass

Sorry for resurrecting an old thread, but after reading this and several other SH annealing threads, plus the 6BR article.... I set out to anneal some .308 cases this morning. I'm still not sure I'm doing it right because I'm not seeing the blue color that I see in most of the pics.

I bought a little propane torch kit at home depot and followed all the directions here: spun the case in a cordless drill in a socket, held inner tip of the flame to the junction of the neck and shoulder for about 6-7 sec im even using a metronome app on my ipad to get the time right There is a definite change in color just below the shoulder like I would expect, but it seems to just make the brass look more brass colored rather than the traditional "annealed" color (silver/blue). I'm afraid to overdo it, but I wonder if I'm going long enough. one thing I wonder is if the torch head was the wrong shape. Instead of a single pointed inner flame - there are three pointed inner flames which makes me wonder if I'm getting it too hot. I bought a new torch head that's supposes to have the normal pencil flame, so maybe that'll work better.

I'm probably over thinking this, but I just want to be sure before I go blow myself up with over annealed brass. Thanks!

Sorry for resurrecting an old thread, but after reading this and several other SH annealing threads, plus the 6BR article.... I set out to anneal some .308 cases this morning. I'm still not sure I'm doing it right because I'm not seeing the blue color that I see in most of the pics.

I bought a little propane torch kit at home depot and followed all the directions here: spun the case in a cordless drill in a socket, held inner tip of the flame to the junction of the neck and shoulder for about 6-7 sec im even using a metronome app on my ipad to get the time right There is a definite change in color just below the shoulder like I would expect, but it seems to just make the brass look more brass colored rather than the traditional "annealed" color (silver/blue). I'm afraid to overdo it, but I wonder if I'm going long enough. one thing I wonder is if the torch head was the wrong shape. Instead of a single pointed inner flame - there are three pointed inner flames which makes me wonder if I'm getting it too hot. I bought a new torch head that's supposes to have the normal pencil flame, so maybe that'll work better.

I'm probably over thinking this, but I just want to be sure before I go blow myself up with over annealed brass. Thanks!

Re: Annealing Brass

That's a great article from 6MMbr: http://www.6mmbr.com/annealing.html

Looks like, as long as you're not annealing the BASE of the cartridge, you're fairly safe from catastrophic damage/injury.

That's a great article from 6MMbr: http://www.6mmbr.com/annealing.html

Looks like, as long as you're not annealing the BASE of the cartridge, you're fairly safe from catastrophic damage/injury.

Re: Annealing Brass

I solved my annealing issues. The solution was DJ's Brass Restoration.

I just got almost 500 22-250 and 250 7WSM cases ultra sonic cleaned an annealed. The 22250 cases are 11 years old and have been FL sized (two different guns) at least 8 times. They look like new now.

I just don't have the time to do it myself.

I solved my annealing issues. The solution was DJ's Brass Restoration.

I just got almost 500 22-250 and 250 7WSM cases ultra sonic cleaned an annealed. The 22250 cases are 11 years old and have been FL sized (two different guns) at least 8 times. They look like new now.

I just don't have the time to do it myself.

Similar threads

- Replies

- 54

- Views

- 1K

- Replies

- 9

- Views

- 276