Searched on Google and here to find more info on the Armanov Zero Play but couldn't find any so I'll give my version of a review. I'll continue to update with more use, and hopefully get some info out there for anyone who wants to use these.

I needed more toolheads for my 550, and I felt like the small bump in price for these zero play toolheads over the regular toolheads wasn't much, and since they're cheaper than the Uniquetek clamped Whidden floating toolheads, I figured I'd give them a chance.

Do I think they'll help? I don't think thats a simple or straightforward question that can be answered. After all, we're talking about machines here. I'm sure some 550's produce great ammo, and I'm sure sometimes floating toolheads help some 550's more than others. Its all part of that game we play with 1000's of variables, in a never ending game for perfection. Anywho, I've heard enough good things about floating/clamped toolheads, from real competitors to give them a try...after all, I doubt they'll hurt my reloading.

Enough with the novel....

I bought 2 Armanov Zero Play toolheads, and 3 lock rings. I actually purchased these toolheads from the european site, as the prices were better and the shipping was actually cheaper haha (DHL rocks). Total for 2 toolheads and 3 lock rings (lock rings are sold separately) was around $105 shipped.

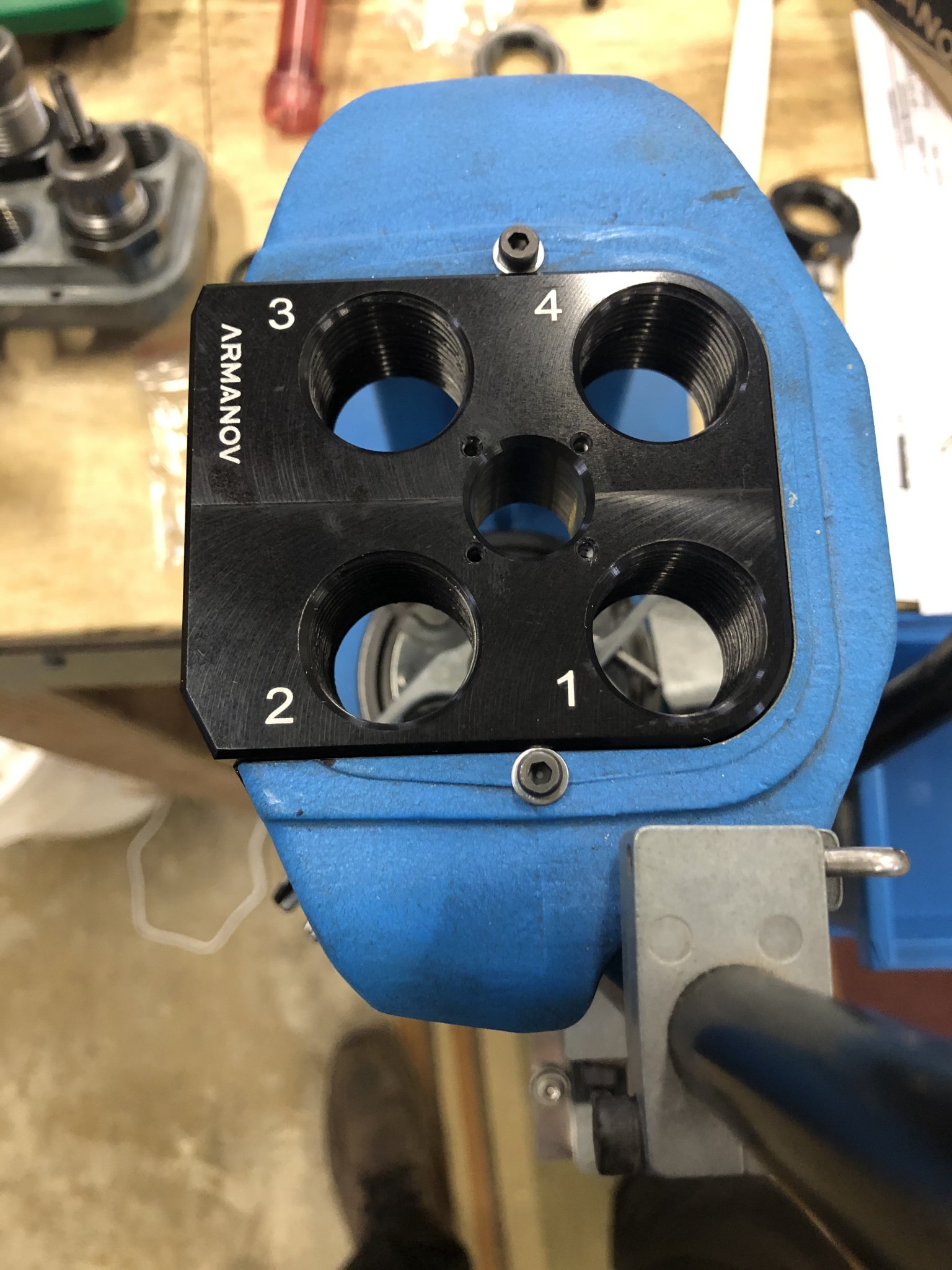

TO BE CLEAR...these are the zero play toolheads, so they not only clamp the toolhead in the upper position, but also float all 4 die spots.

Who Doesn't love free stickers

Who Doesn't love free stickers

The come very well packaged with all things needed to set them up. The toolheads are around $35 or so, and the lock rings are about $12. The lock rings use a threaded bolt, not a roll pin like the whidden toolheads, which I liked. I felt like the bolts were not any easier to get in considering you have to fit them in the hole of the lock ring and get it started. On the first die its not bad, but I would imagine the 4th die would be a little trickier. That being said, I don't need to float 4 dies on mine.

The tool head is well made in my opinion. Edges are clean, threads are sharp, both looked great to me.

The toolheads slide in like normal, then you use the provided M13 bolts and washer to lock the toolhead in the upper position. Like the Uniquetek clamped toolheads, they recommend putting all your dies in, loading in 4 cases and taking the shellplate up to imitate what the exact positions will be while reloading with the shellplate full.

With the ram all the way up, you should the lock the toolhead into place. It locks into place well and you can tighten the bolts easily. Its a solid setup and obviously doesn't move AT ALL. I can definitely see how this could help the process of consistency, once paired with the floating dies.

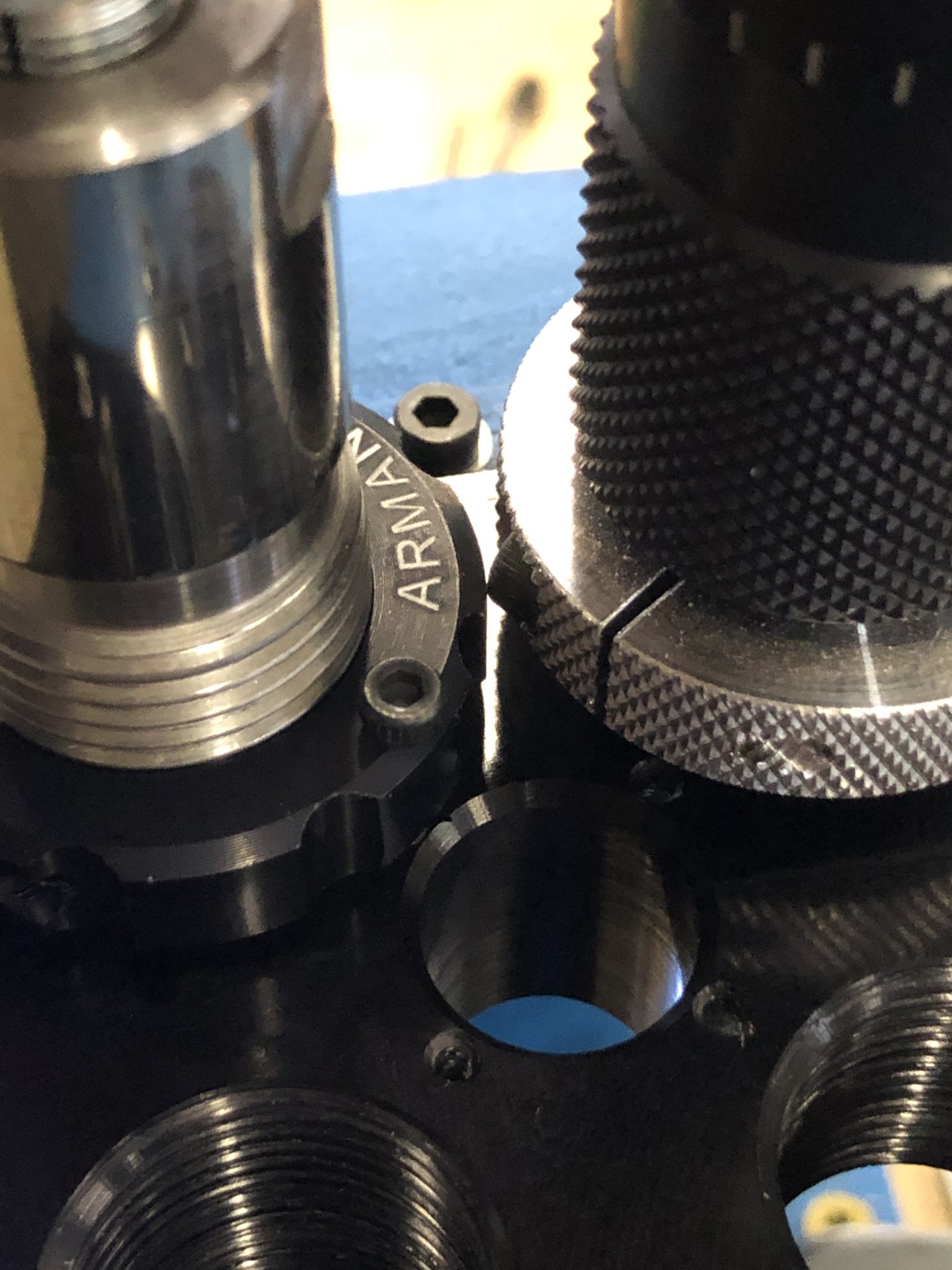

Lock rings fit great on dies, and use an imbedded allen bolt to tighten around the die, NOT screwing an allen bolt into the threads. This is the preferred lock rings that I like. The lock rings are timed so they are exactly one turn back from flush when the bolt fits into the hole on the lock ring. What I did was just screw the die in until it was close to the final position I liked, then screwed the lock ring down all the way until it hits flush, back it out one turn until the holes line up and screw the M13 bolt in the hole. It will tighten with about 2mm to go as you can see in the right photo. Then I set my FINAL position of the die and tighten the lock ring to the die.

If you notice on the first photo, using a different lock ring with allen heads that extend out will not really work. ON the photo on the right you can see the Armanov rings are imbedded into the ring. The allen heads are also time so they will be on the outer edge of the lock ring so that can aid in tightening the lock ring down, so its not stuck in the middle or something. Really like these lock rings, albeit sort of expensive, but worth it....especiaily for these toolheads.

The only other problem I had was with my Forster Micrometer seater for .223. The damn die has to be screwed so far down into the lock ring to follow forsters die set up procedure, that the housing contacted the M13 bolt in the lock ring that free floats it. I had to take a little skin off the bottom on the edge to make it work. I have to screw the die down this far to depress the spring mechanism in the seating die, as Forster recommends. Has anyone not done this and still get good seating?

Anyways, for now I'm very happy with these, especially for the money. I'm a big believer in how they work, although I will admit that I doubt they are necessary to make good ammunition, but they MAY be necessary depending on your machine, techniques, etc. Not all 550's are exactly the same and all sorts of variables could attribute to why these toolheads may give someone more success than others.

Heres my theory as to why it works:

1.) the clamped toolhead puts the whole machine into alignment with the shellplate. Every time the ram goes up WITH cases in it, it moves and rest into a specific position, and you lock the toolhead at that top position. This takes away any movement that the shellplate w/ 4 cases enacts on the toolhead.

2.) Once you have the shellplate with 4 cases and the toolhead aligned and in sync, the floating dies allow ALL 4 DIES to slightly move INDEPENDANTLY to self align/rotate/jiggle to perfectly fit the specific case being brought into the die. Each case, each stroke, each time may do this slightly differently, and its this floating motion paired with the perfectly aligned and clamped toolhead that CAN bring more consistency and less runout, etc.

Just my theory and my experience so far. Thanks for coming to my TED Talk.

.....To Be Continued with more results and my thoughts after some more use. Begin discussion lol

I needed more toolheads for my 550, and I felt like the small bump in price for these zero play toolheads over the regular toolheads wasn't much, and since they're cheaper than the Uniquetek clamped Whidden floating toolheads, I figured I'd give them a chance.

Do I think they'll help? I don't think thats a simple or straightforward question that can be answered. After all, we're talking about machines here. I'm sure some 550's produce great ammo, and I'm sure sometimes floating toolheads help some 550's more than others. Its all part of that game we play with 1000's of variables, in a never ending game for perfection. Anywho, I've heard enough good things about floating/clamped toolheads, from real competitors to give them a try...after all, I doubt they'll hurt my reloading.

Enough with the novel....

I bought 2 Armanov Zero Play toolheads, and 3 lock rings. I actually purchased these toolheads from the european site, as the prices were better and the shipping was actually cheaper haha (DHL rocks). Total for 2 toolheads and 3 lock rings (lock rings are sold separately) was around $105 shipped.

TO BE CLEAR...these are the zero play toolheads, so they not only clamp the toolhead in the upper position, but also float all 4 die spots.

The come very well packaged with all things needed to set them up. The toolheads are around $35 or so, and the lock rings are about $12. The lock rings use a threaded bolt, not a roll pin like the whidden toolheads, which I liked. I felt like the bolts were not any easier to get in considering you have to fit them in the hole of the lock ring and get it started. On the first die its not bad, but I would imagine the 4th die would be a little trickier. That being said, I don't need to float 4 dies on mine.

The tool head is well made in my opinion. Edges are clean, threads are sharp, both looked great to me.

The toolheads slide in like normal, then you use the provided M13 bolts and washer to lock the toolhead in the upper position. Like the Uniquetek clamped toolheads, they recommend putting all your dies in, loading in 4 cases and taking the shellplate up to imitate what the exact positions will be while reloading with the shellplate full.

With the ram all the way up, you should the lock the toolhead into place. It locks into place well and you can tighten the bolts easily. Its a solid setup and obviously doesn't move AT ALL. I can definitely see how this could help the process of consistency, once paired with the floating dies.

Lock rings fit great on dies, and use an imbedded allen bolt to tighten around the die, NOT screwing an allen bolt into the threads. This is the preferred lock rings that I like. The lock rings are timed so they are exactly one turn back from flush when the bolt fits into the hole on the lock ring. What I did was just screw the die in until it was close to the final position I liked, then screwed the lock ring down all the way until it hits flush, back it out one turn until the holes line up and screw the M13 bolt in the hole. It will tighten with about 2mm to go as you can see in the right photo. Then I set my FINAL position of the die and tighten the lock ring to the die.

If you notice on the first photo, using a different lock ring with allen heads that extend out will not really work. ON the photo on the right you can see the Armanov rings are imbedded into the ring. The allen heads are also time so they will be on the outer edge of the lock ring so that can aid in tightening the lock ring down, so its not stuck in the middle or something. Really like these lock rings, albeit sort of expensive, but worth it....especiaily for these toolheads.

The only other problem I had was with my Forster Micrometer seater for .223. The damn die has to be screwed so far down into the lock ring to follow forsters die set up procedure, that the housing contacted the M13 bolt in the lock ring that free floats it. I had to take a little skin off the bottom on the edge to make it work. I have to screw the die down this far to depress the spring mechanism in the seating die, as Forster recommends. Has anyone not done this and still get good seating?

Anyways, for now I'm very happy with these, especially for the money. I'm a big believer in how they work, although I will admit that I doubt they are necessary to make good ammunition, but they MAY be necessary depending on your machine, techniques, etc. Not all 550's are exactly the same and all sorts of variables could attribute to why these toolheads may give someone more success than others.

Heres my theory as to why it works:

1.) the clamped toolhead puts the whole machine into alignment with the shellplate. Every time the ram goes up WITH cases in it, it moves and rest into a specific position, and you lock the toolhead at that top position. This takes away any movement that the shellplate w/ 4 cases enacts on the toolhead.

2.) Once you have the shellplate with 4 cases and the toolhead aligned and in sync, the floating dies allow ALL 4 DIES to slightly move INDEPENDANTLY to self align/rotate/jiggle to perfectly fit the specific case being brought into the die. Each case, each stroke, each time may do this slightly differently, and its this floating motion paired with the perfectly aligned and clamped toolhead that CAN bring more consistency and less runout, etc.

Just my theory and my experience so far. Thanks for coming to my TED Talk.

.....To Be Continued with more results and my thoughts after some more use. Begin discussion lol