Re: Bad knob job.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: sobrbiker883</div><div class="ubbcode-body">If you have a CNC mill, the shaving the factory and threading the stub (as 300sniper pictured, and APA and GAP do) is the most cost effective way to do it.</div></div>

Cost effective yes - as long as any visible voids are filled and the install is performed correctly.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: sobrbiker883</div><div class="ubbcode-body">As far as length, it looks like the OP's knob had a long stud on it, longer than Keith's pics of the TacOps.</div></div>

Possibly. Maybe the long, slender handle provided too much leverage and it broke under the pressure. Looks like a poor installation job though.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: sobrbiker883</div><div class="ubbcode-body">Length is a give and take-while it adds leverage and clerance, it also can become a hindrance if folks have meaty trigger fingers.</div></div>

As I understand it, <span style="font-style: italic">Rob01</span> has rather thick fingers, and the Tac Ops BKC worked much better than the Badger knob that had been installed on his bolt handle before. This was despite the fact that the existing bolt handle had been shortened quite a bit when a Badger knob had been installed.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: sobrbiker883</div><div class="ubbcode-body">Mark pegged it with the what works best being user preference.</div></div>

True.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: sobrbiker883</div><div class="ubbcode-body">I just think the OP is a bit off by declaring that doing stud installs is a bad way to do knobs-he just got a bad knob job. </div></div>

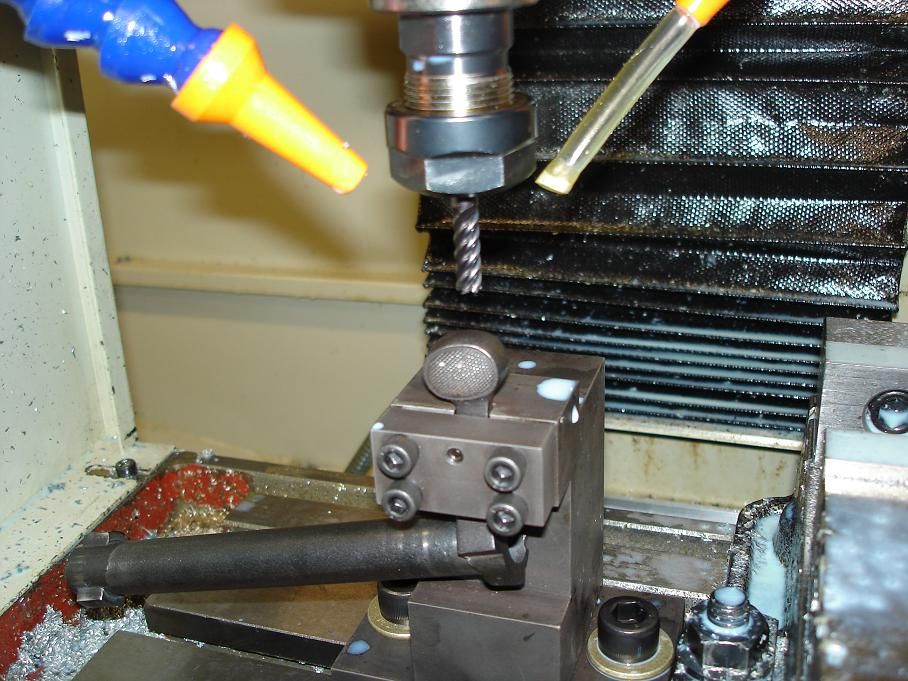

I'd say more than <span style="font-style: italic">"a bit off"</span>, but agree that it looks like a poor installation. Below is a "bolt knob photo montage" of <span style="font-style: italic">TXBRASS</span>'s that I borrowed from a thread of his. The photo montage shows a hack job installation that someone did on a Tac Ops BKC. Goes to show that having the mechanical skills and the right tools for the job can make a world of difference.

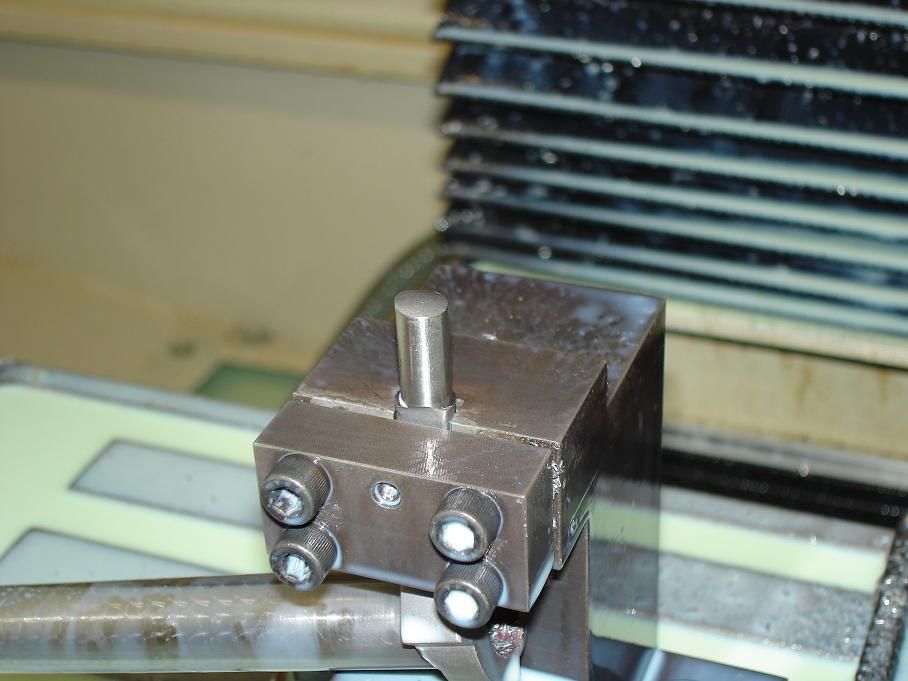

<span style="font-weight: bold"><span style="font-style: italic">The photos below are representative of how a properly installed TO BKC should look like when completed:</span></span>

<span style="font-weight: bold"><span style="font-style: italic">Close up of the bolt knob on the rifle from the side:</span></span>

<span style="font-weight: bold"><span style="font-style: italic">Seamless, perfect transition from the (round) knob to round shank on bolt handle:</span></span>

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: mtscott</div><div class="ubbcode-body">I stand corrected on stud installs. As illustrated in some of the post above there appears to be situations where stud installs are viable options. On this bolt the diameter of the bolt handle and the size of the stud created a problem.

Yes it is an HS Precision bolt.

Thanks for all of the information and posts. </div></div>

You're welcome.

Keith