I know i could easily build a no gas upper. But does anyone know if any companies that build these and have them readily available?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"Bolt Action" AR15 Upper?

- Thread starter g3ninfinite

- Start date

When I say bolt action Im using the term loosely. It can be side charging or Charging handle operated as well.

Due to the gun laws in England and the greater commonwealth, the AR-15's sold there are all "bolt action". I think they call them straight pulls. Don't know any names of manufacturers though.

As Jmnielsen mentioned, the Bushmaster BA50 is a bolt-action upper. In the deep dark recesses of my brain it seems that someone else was playing with one as well but I can't remember where I read about it. It could have very likely been here quite a while back.

What's your "goal" for the gasless upper?

What's your "goal" for the gasless upper?

Brownells is selling JP uppers which are side charging but also include the typical charging handle.

If you want it to run like a bolt get an untapped barrel and exclude the gas system.

Tubb rifles kind of fit the bill.

If you want it to run like a bolt get an untapped barrel and exclude the gas system.

Tubb rifles kind of fit the bill.

Last edited:

As Jmnielsen mentioned, the Bushmaster BA50 is a bolt-action upper. In the deep dark recesses of my brain it seems that someone else was playing with one as well but I can't remember where I read about it. It could have very likely been here quite a while back.

What's your "goal" for the gasless upper?

Safety harbor makes a bolt 50 upper as well.

I got a left side charging, non reciprocating upper from American spirit arms recently for a build. You could put an adjustable gas block on it and use it as a bolt or semi platform. The machining is perfect but you may have to grind down your mag catch latch.

Sent from my SCH-I545 using Tapatalk

I'm kind of confused why you would do this. Why not just build a proper bolt action rifle?

This. But if you must I'd get a JP rifle with wide charging handle and turn the gas off.

If you want a bolt gun...BUY A BOLT GUN.

While I have seen plenty of "accurate" bolt on uppers for the AR-platform rifles (primarily .50BMG, .338LM, etc.) over the years, its just a half-assed compromise for the real thing. There are plenty of quality "AR-esque" chassis systems on the market that will get you the AR ergos (stocks, grips, etc.) if that's what you are after and will ultimately prove to be more accurate than trying to shoehorn a compromise out of your AR. As to your exact question...the only company I know of that has ventured into the "bolt action" type uppers for an AR-15 like what you are talking about would be Franklin Armory (I think its the .308 SSAR or something like that). Don't know if they are still offering them or whether they are worth a @#$% or not, but its one option anyway (not that you couldn't more or less build the same thing yourself if you were so inclined). I am not aware of anyone else making standard, short action type bolt action uppers (.223, .308, etc.) for the AR-pattern rifles at this time, although several others have proposed the idea which has generally met with little to no meaningful interest for what would be involved in R&D, production costs, etc. (thus...they've not really made it into production).

If you are really just shot in the butt about doing this, then I agree that it can be done in a number of different ways, including an AR minus a gas system, or with an adjustable block that will permit you to completely shut off the gas port (likely the better option because at least then, you can still open it up and run it as God and Eugene Stoner intended it to be run)! I would, without a doubt, opt for a side-charging upper of whatever flavor you prefer (ASA, JP, Fulton Armory, etc.) as the standard CH position isn't really all that great for running an AR single-shot as you propose despite the Brits having been forced into that option for a LONG time now.

I would, without a doubt, opt for a side-charging upper of whatever flavor you prefer (ASA, JP, Fulton Armory, etc.) as the standard CH position isn't really all that great for running an AR single-shot as you propose despite the Brits having been forced into that option for a LONG time now.

While I have seen plenty of "accurate" bolt on uppers for the AR-platform rifles (primarily .50BMG, .338LM, etc.) over the years, its just a half-assed compromise for the real thing. There are plenty of quality "AR-esque" chassis systems on the market that will get you the AR ergos (stocks, grips, etc.) if that's what you are after and will ultimately prove to be more accurate than trying to shoehorn a compromise out of your AR. As to your exact question...the only company I know of that has ventured into the "bolt action" type uppers for an AR-15 like what you are talking about would be Franklin Armory (I think its the .308 SSAR or something like that). Don't know if they are still offering them or whether they are worth a @#$% or not, but its one option anyway (not that you couldn't more or less build the same thing yourself if you were so inclined). I am not aware of anyone else making standard, short action type bolt action uppers (.223, .308, etc.) for the AR-pattern rifles at this time, although several others have proposed the idea which has generally met with little to no meaningful interest for what would be involved in R&D, production costs, etc. (thus...they've not really made it into production).

If you are really just shot in the butt about doing this, then I agree that it can be done in a number of different ways, including an AR minus a gas system, or with an adjustable block that will permit you to completely shut off the gas port (likely the better option because at least then, you can still open it up and run it as God and Eugene Stoner intended it to be run)!

My first AR pistol was assembled using a rifle barrel that had been chopped off behind the gas port, so I simply pull the bcg back with the charging handle and allow the spring and buffer to return it to battery. Thinking of converting it to a side-charger and removing the spring and buffer to the spares box, but I've already got too many projects going at this time, that can wait.

The manual AR makes sense to me. Plenty of parts availability, easy assembly/maintenance/modification, convert to semi-auto by swapping uppers (and reinstall the buffer/spring if you've removed them), great ergonomics at a much lower price than the tubegun chassis systems I've seen, etc, etc.

The manual AR makes sense to me. Plenty of parts availability, easy assembly/maintenance/modification, convert to semi-auto by swapping uppers (and reinstall the buffer/spring if you've removed them), great ergonomics at a much lower price than the tubegun chassis systems I've seen, etc, etc.

Last edited:

When I say bolt action Im using the term loosely. It can be side charging or Charging handle operated as well.

Check out the Mega side-charging upper.

yes

Mostly all the above. Way cheaper than a full build. Have a bunch of 556 77gr BH ammo sitting around. Figure I could build or buy something on the cheap.

My first AR pistol was assembled using a rifle barrel that had been chopped off behind the gas port, so I simply pull the bcg back with the charging handle and allow the spring and buffer to return it to battery. Thinking of converting it to a side-charger and removing the spring and buffer to the spares box, but I've already got too many projects going at this time, that can wait.

The manual AR mkakes sense to me. Plenty of parts availability, easy assembly/maintenance/modification, convert to semi-auto by swapping uppers (and reinstall the buffer/spring if you've removed them), great ergonomics at a much lower price than the tubegun chassis systems I've seen, etc, etc.

Mostly all the above. Way cheaper than a full build. Have a bunch of 556 77gr BH ammo sitting around. Figure I could build or buy something on the cheap.

I built one like this in 6.5 grendel

<iframe width="640" height="360" src="//www.youtube.com/embed/QTHECgM1APQ?feature=player_embedded" frameborder="0" allowfullscreen></iframe>

<iframe width="640" height="360" src="//www.youtube.com/embed/LE4FigimH9g?feature=player_embedded" frameborder="0" allowfullscreen></iframe>

<iframe width="640" height="360" src="//www.youtube.com/embed/QTHECgM1APQ?feature=player_embedded" frameborder="0" allowfullscreen></iframe>

<iframe width="640" height="360" src="//www.youtube.com/embed/LE4FigimH9g?feature=player_embedded" frameborder="0" allowfullscreen></iframe>

Last edited:

I'm kind of confused why you would do this. Why not just build a proper bolt action rifle?

I am really digging these uppers with the side cut out for a side charging handle. I myself have thought about building a manual feed AR10 straight pull back chambered in 260 an NO gas system, or maybe a AR15 chambered in 6.5 Grendel with NO gas system.

Why you ask?

- The Gas System on all Semi-Auto guns do seem to affect the barrel harmonics, if not the first 5-10 rounds, it will eventually. Shoot any semi auto for a 20 shot group, and you will see how fast the group spreads. With no gas system on the barrel, the harmonics of the barrel will be affected much less, and will be on par with the "real" bolt action rifles.

- The AR10 and AR15 platform has massed produced parts. The uppers, mags, bolts, etc are easily obtainable and at a very decent price. Not just the critical parts, but the accessories and choices for forearms, triggers, grips, buttstocks are endless.

- AR style locking lugs -

the best! the locking lugs of the AR on the Bolt enables the bolt to barrel lock up to be the tightest and best! Way better than any the bolt action system out there.

- AR Upper is the stock -

barrel is mated right to the upper, and no special aluminum block or bedding needed in a special stock because the AR upper is both the action and the stock.

- AR barrels bolt right in -

no special magic "headspace" needed when installing the barrel, no timing of barrel or lapping of lugs needed. The headspace is all in the barrel extension, which means when the extension is on the barrel, the rifle is already pre-headspaced.

- Flexibility -

Think about how easy it would be to change barrels if you shoot a lot. Or you could even have multiple uppers for the same lower with different calibers. Use .308 upper for training, and .260 for comps.

It only takes 1 second to manually cycle the action, and if you are shooting "precision", you will taking shots at LEAST 1 second apart (if not 5 or 10 seconds apart), Therefore, no need for an autofeeder.

I guess if you don't mind cycling it by hand then just install a lo pro gas block backward and boom, instant bolt action.

I guess if you don't mind cycling it by hand then just install a lo pro gas block backward and boom, instant bolt action.

Problem with that is there is still a gas block bolted/pinned to the barrel. Want to go Heavy Varmint Style barrel with no gas block at all. I am sure a company like White Oak could get me a barrel with the .260 Barrel Extension with no gas block.

Problem with that is there is still a gas block bolted/pinned to the barrel. Want to go Heavy Varmint Style barrel with no gas block at all. I am sure a company like White Oak could get me a barrel with the .260 Barrel Extension with no gas block.

Drilling the gas port is generally the LAST (or close to it) step in making an AR barrel from a blank. Its a step that could easily be skipped altogether if you don't want to run an adjustable block with a shut-off so you can have it both semi (when you want it) and single (when you don't).

As for a ".260 barrel extension"...there is no such beastie. There are AR-15 extensions and large-frame AR extensions (Armalite and DPMS/etc.) for use on AR-10, LR-308, etc. platform rifles. If you've already got a large-frame AR bolt, provide it to your smith at the time of them setting up the barrel for you and they'll square the headspacing away to your bolt and you are done.

As for "heavy varmint" you are still limited by the confines of the basic AR-10 type barrel nut which will max out your barrel's OD at ~1.1".

Drilling the gas port is generally the LAST (or close to it) step in making an AR barrel from a blank. Its a step that could easily be skipped altogether if you don't want to run an adjustable block with a shut-off so you can have it both semi (when you want it) and single (when you don't).

As for a ".260 barrel extension"...there is no such beastie. There are AR-15 extensions and large-frame AR extensions (Armalite and DPMS/etc.) for use on AR-10, LR-308, etc. platform rifles. If you've already got a large-frame AR bolt, provide it to your smith at the time of them setting up the barrel for you and they'll square the headspacing away to your bolt and you are done.

As for "heavy varmint" you are still limited by the confines of the basic AR-10 type barrel nut which will max out your barrel's OD at ~1.1".

Thanks for the heads up on the barrel nut and barrelextension, that is good info.

1) Those Special AR10's chambered in special calibers do not have barrel extensions?

2) Is 1.1" really the max for the barrel nut? If it is, I guess I can always go with a straight profile for the heaviest.

One of the first places to have erosion affecting accuracy on an AR pattern barrel is the gas port, so eliminating that would have some benefits. The gas system also should be balanced, or tuned and in reality, the pressures that can be safely fired are limited to what the gas system can handle.

A case which really illustrates the issue is the .450BM. Factory ammo is about 40Kpsi and some handloaders, with some techniques, have been able to push to 44Kpsi before they start getting extraction, case damage issues. But the .450 Professional was 60Kpsi and the parent case was 64Kpsi. Today, shooting an 18" barreled AR-15 with a .450BM chamber with NO gas port, I was able to significantly increase the bullet mass and or velocity without case damage or pressure signs. Granted, it is slated to become a .450Corvette, but still, it proves out the issue that increased performance can be derived in some calibers when a properly functioning gas system does not have to be included.

The Mossberg MVP is a very good selling rifle...a bolt action that takes AR pattern mags. An upper that goes on your $400 to $800 lower with a good free-floated barrel and manual operation...guess no-one thinks it will sell.

A case which really illustrates the issue is the .450BM. Factory ammo is about 40Kpsi and some handloaders, with some techniques, have been able to push to 44Kpsi before they start getting extraction, case damage issues. But the .450 Professional was 60Kpsi and the parent case was 64Kpsi. Today, shooting an 18" barreled AR-15 with a .450BM chamber with NO gas port, I was able to significantly increase the bullet mass and or velocity without case damage or pressure signs. Granted, it is slated to become a .450Corvette, but still, it proves out the issue that increased performance can be derived in some calibers when a properly functioning gas system does not have to be included.

The Mossberg MVP is a very good selling rifle...a bolt action that takes AR pattern mags. An upper that goes on your $400 to $800 lower with a good free-floated barrel and manual operation...guess no-one thinks it will sell.

One of the first places to have erosion affecting accuracy on an AR pattern barrel is the gas port, so eliminating that would have some benefits. The gas system also should be balanced, or tuned and in reality, the pressures that can be safely fired are limited to what the gas system can handle.

A case which really illustrates the issue is the .450BM. Factory ammo is about 40Kpsi and some handloaders, with some techniques, have been able to push to 44Kpsi before they start getting extraction, case damage issues. But the .450 Professional was 60Kpsi and the parent case was 64Kpsi. Today, shooting an 18" barreled AR-15 with a .450BM chamber with NO gas port, I was able to significantly increase the bullet mass and or velocity without case damage or pressure signs. Granted, it is slated to become a .450Corvette, but still, it proves out the issue that increased performance can be derived in some calibers when a properly functioning gas system does not have to be included.

The Mossberg MVP is a very good selling rifle...a bolt action that takes AR pattern mags. An upper that goes on your $400 to $800 lower with a good free-floated barrel and manual operation...guess no-one thinks it will sell.

What bullet are you pushing out of your .450BM now? and how fast? I too have a .450 Bushy, never shot reloads with it, only Hornady Factory ammo.

Oh and another thing about the AR system that is a + is the extractor and ejector. No extractor/ejector combo works better. Another benefit of the AR extractor and ejector is that it is easy to replace.

In the 450BMC, 260s to 320s at velocities above what the factory 250/260 fodder runs by several hundred feet per second. Not safe in a stock .450BM.

In my stock .450 BM, I run 230 XTPs at about 2300 and the 250 Hornady at about 2200.

In my stock .450 BM, I run 230 XTPs at about 2300 and the 250 Hornady at about 2200.

In the 450BMC, 260s to 320s at velocities above what the factory 250/260 fodder runs by several hundred feet per second. Not safe in a stock .450BM.

In my stock .450 BM, I run 230 XTPs at about 2300 and the 250 Hornady at about 2200.

320 grains at 2400 fps? Dam!!! that is awesome.

Thanks for the heads up on the barrel nut and barrelextension, that is good info.

1) Those Special AR10's chambered in special calibers do not have barrel extensions?

2) Is 1.1" really the max for the barrel nut? If it is, I guess I can always go with a straight profile for the heaviest.

1) No...they still use a barrel extension just like any other AR-platform rifle/carbine, but on a large-frame AR chambered in .260 Remington to take your example, it is the SAME extension used by any AR-10 (Armalite pattern) or LR-308/etc. (DPMS pattern) barrel regardless of caliber...there is not one specific for one-off extension to any specific caliber. Think of it this way, the .308/.260/7mm-08/6.5CM/6CM/etc. all use the exact same large-frame pattern bolt (whether it be an Armalite-pattern or DPMS-pattern bolt). Thus, there is no need to reinvent the wheel redesigning the lugs or a new barrel extension for every "one-off" caliber out there when the same bolt/lugs/etc. are used across the board. Even on some large-frame ARs that are chambered in calibers larger than your average .308 class cartridge, the bolts are designed to fit/function with the standard barrel extensions without modification to the extension, but rather to the bolt face itself.

2) There are practical limitations to going "bigger" with an AR barrel, but if memory serves, the max ID of an AR-10 barrel nut is ~1.1" or less (don't have any in front of me at present or I'd snap a quick measurement pic for you). In fact, I have NEVER to the best of my knowledge, seen a factory production barrel on any large-frame AR larger than 1" from behind the journal to the barrel extension. Without having to worry with a step-down for the journal or otherwise fitting of the gas system, etc., it would be easy to source a straight taper or like barrel or otherwise have one of roughly that size turned down to a straight 1" or so from the extension to the muzzle if you really wanna go big.

1) No...they still use a barrel extension just like any other AR-platform rifle/carbine, but on a large-frame AR chambered in .260 Remington to take your example, it is the SAME extension used by any AR-10 (Armalite pattern) or LR-308/etc. (DPMS pattern) barrel regardless of caliber...there is not one specific for one-off extension to any specific caliber. Think of it this way, the .308/.260/7mm-08/6.5CM/6CM/etc. all use the exact same large-frame pattern bolt (whether it be an Armalite-pattern or DPMS-pattern bolt). Thus, there is no need to reinvent the wheel redesigning the lugs or a new barrel extension for every "one-off" caliber out there when the same bolt/lugs/etc. are used across the board. Even on some large-frame ARs that are chambered in calibers larger than your average .308 class cartridge, the bolts are designed to fit/function with the standard barrel extensions without modification to the extension, but rather to the bolt face itself.

2) There are practical limitations to going "bigger" with an AR barrel, but if memory serves, the max ID of an AR-10 barrel nut is ~1.1" or less (don't have any in front of me at present or I'd snap a quick measurement pic for you). In fact, I have NEVER to the best of my knowledge, seen a factory production barrel on any large-frame AR larger than 1" from behind the journal to the barrel extension. Without having to worry with a step-down for the journal or otherwise fitting of the gas system, etc., it would be easy to source a straight taper or like barrel or otherwise have one of roughly that size turned down to a straight 1" or so from the extension to the muzzle if you really wanna go big.

That makes sense that all the barrel extension would be the same now that I really think about it. Only difference really would be the bolt face and how the throat of the barrel is reamed. Be awhile before I start my manual feeding straight pull AR10-260, but it's nice to get as much as possible all these little details out of the way first. Thanks for all the info!

I built one like this in 6.5 grendel

<iframe width="640" height="360" src="//www.youtube.com/embed/QTHECgM1APQ?feature=player_embedded" frameborder="0" allowfullscreen></iframe>

<iframe width="640" height="360" src="//www.youtube.com/embed/LE4FigimH9g?feature=player_embedded" frameborder="0" allowfullscreen></iframe>

Did you build the straight pull yourself or did a company do it? I am strangely intrigued by the concept of a "bolt action" AR upper, mainly for precision work.

I made it, pretty simple

hardest part is drill and tap the hardened bolt carrier

I put a helper spring in the bolt and took out the gas rings

My first was using a pre-made barrel with a gas port, I moved the gas block forward to shut it off, when I took it apart the gas block had completely filled up soild with copper.No more gas port! just FYI

increase in accuracy was about .2 as I recall, from gas to bolt

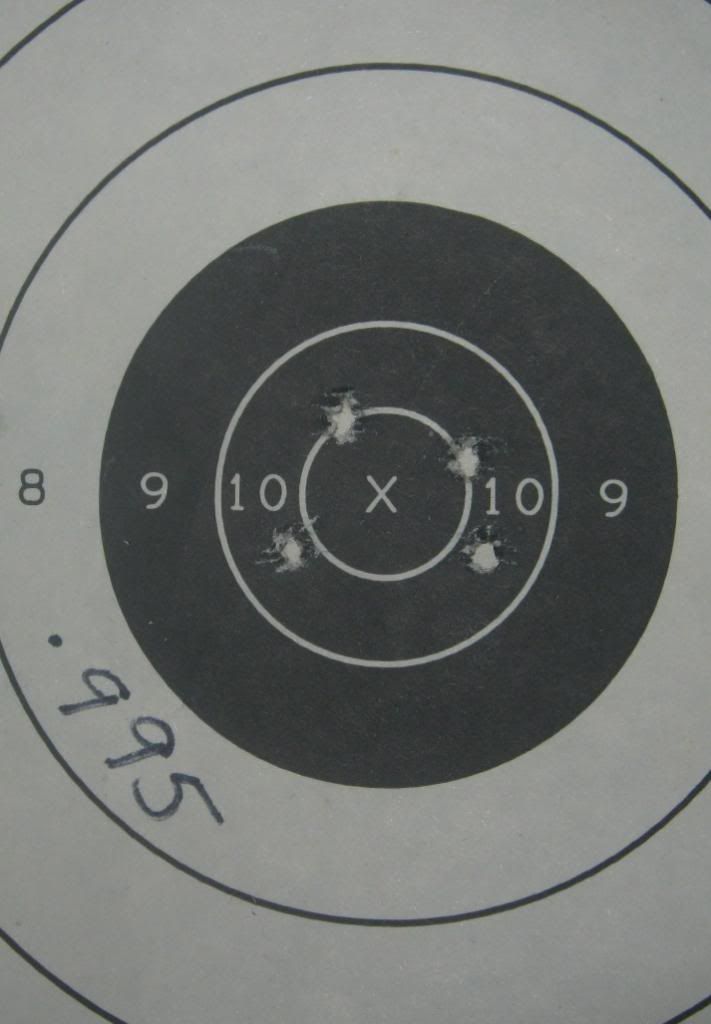

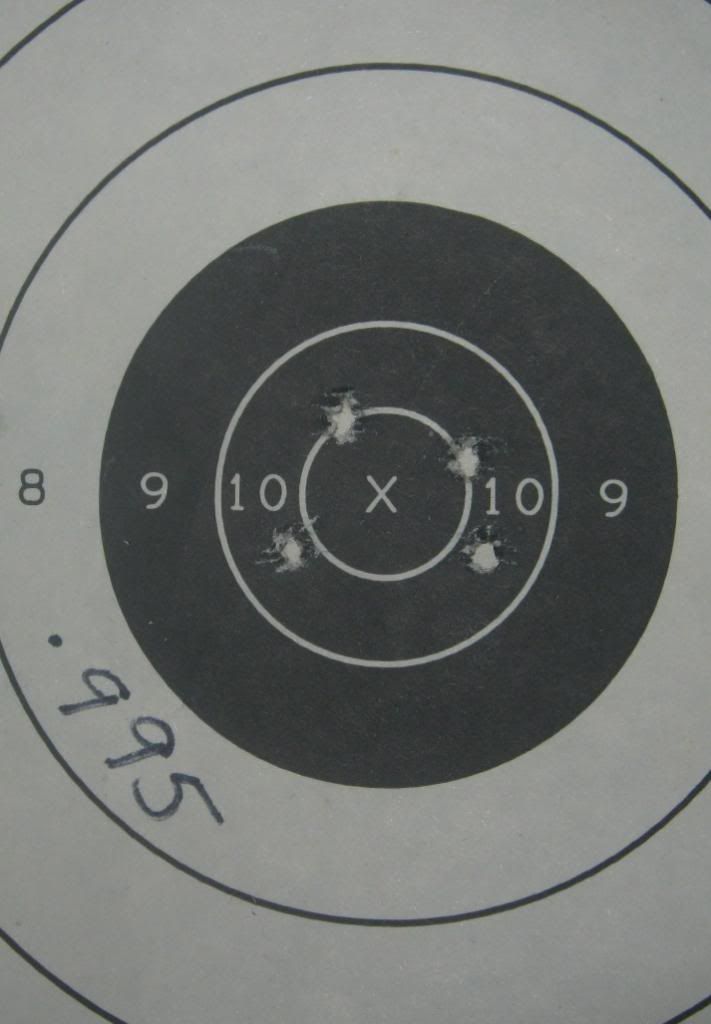

200 yard yard targets

Gas

Bolt

hardest part is drill and tap the hardened bolt carrier

I put a helper spring in the bolt and took out the gas rings

My first was using a pre-made barrel with a gas port, I moved the gas block forward to shut it off, when I took it apart the gas block had completely filled up soild with copper.No more gas port! just FYI

increase in accuracy was about .2 as I recall, from gas to bolt

200 yard yard targets

Gas

Bolt

Last edited:

Resurrection of 7 year old thread.

No-gas might make sense for F-Class where you have to single load anyway.

22 pound, 28" bull barrel, No-Gas.

Pretty easy to go with multiple uppers, some with gas, some without.

No-gas might make sense for F-Class where you have to single load anyway.

22 pound, 28" bull barrel, No-Gas.

Pretty easy to go with multiple uppers, some with gas, some without.

@g3ninfiniteI know i could easily build a no gas upper. But does anyone know if any companies that build these and have them readily available?

To answer your question...Uintah Precision has exactly what you were asking for.

A few months off.Holy Necro thread.

I guess it is the season of resurrection.

Well hell, I totally missed the date of the original post, haha! I hope he's figured it out by now.

BCA 308 upper for 300, side charging, pull off handguard and remove gas tube and block. boom

just in case he's still looking lol

just in case he's still looking lol

might be a necro thread, but the info about being able to puch a .450BM harder with no gas system is very interesting indeed.... just as I am trying to decide how I want to set up a straight wall cartridge shooter for next seasonHoly Necro thread.

I guess it is the season of resurrection.

One of the first places to have erosion affecting accuracy on an AR pattern barrel is the gas port, so eliminating that would have some benefits. The gas system also should be balanced, or tuned and in reality, the pressures that can be safely fired are limited to what the gas system can handle.

A case which really illustrates the issue is the .450BM. Factory ammo is about 40Kpsi and some handloaders, with some techniques, have been able to push to 44Kpsi before they start getting extraction, case damage issues. But the .450 Professional was 60Kpsi and the parent case was 64Kpsi. Today, shooting an 18" barreled AR-15 with a .450BM chamber with NO gas port, I was able to significantly increase the bullet mass and or velocity without case damage or pressure signs. Granted, it is slated to become a .450Corvette, but still, it proves out the issue that increased performance can be derived in some calibers when a properly functioning gas system does not have to be included.

The Mossberg MVP is a very good selling rifle...a bolt action that takes AR pattern mags. An upper that goes on your $400 to $800 lower with a good free-floated barrel and manual operation...guess no-one thinks it wil

Just found this thread. The same search mentioned Lantac. I'm interested as gun laws might change and I would rather turn in a semi-automatic upper or two and keep my lowers with some inexpensive bolt uppers. As Unitah states: you can separate an AR easier than a typical bolt gun and put it into a smaller bag, ruck, etc...I know i could easily build a no gas upper. But does anyone know if any companies that build these and have them readily available?

Currently, the AR lower is the FIREARM.

Capable of holding large capacity mags (clips ),

),

and semi auto operation.

Would a stripped lower (legally a semiauto gun) qualify for one of those gun buy backs?

Cheap lower, get $150 or more

Capable of holding large capacity mags (clips

and semi auto operation.

Would a stripped lower (legally a semiauto gun) qualify for one of those gun buy backs?

Cheap lower, get $150 or more

Similar threads

- Replies

- 12

- Views

- 2K