Does a gunsmith need the receiver to replace/install a bolt handle on Remington bolt in order to get timing right?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing Bolt handle/timing

- Thread starter tspearsrph

- Start date

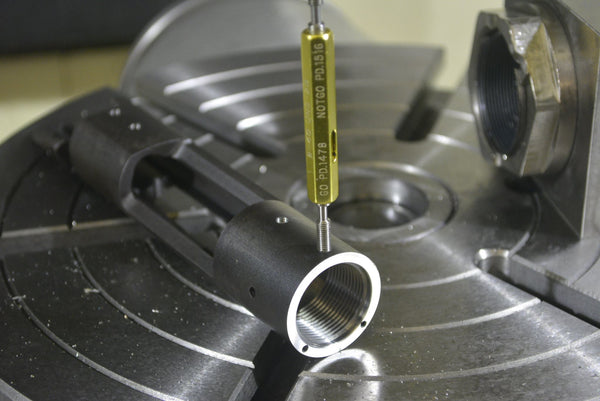

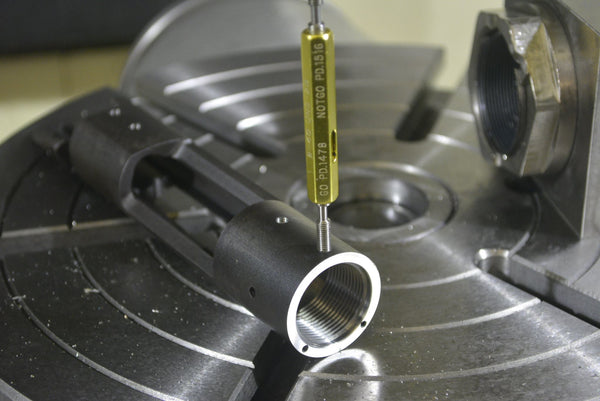

Dan at accu-tig.com just asked for a measurement with feeler gauges between the bolt handle and receiver.

He built up and reshaped the primary extraction ramp and moved everything forward and it works perfect.

Not Defiance or Impact perfect of course, but definitely better extracting and feeling than any late Rem 700 I’ve shot.

He built up and reshaped the primary extraction ramp and moved everything forward and it works perfect.

Not Defiance or Impact perfect of course, but definitely better extracting and feeling than any late Rem 700 I’ve shot.

This is just from my experience and Im sure others will chime in. A lot of the remingtons I see I would say take advantage of 60-70% of the caming/extraction surfaces. Yes they shoot fine and extract fine. Where you'll really run into issues is when you true the action and stock bolt up you'll loose even more. I fit a macbros bolt the other day and measured the amount of movement from when it hit the extraction cam and when it stopped, .074 a PTG was right at .080. I see a lot of guys pay to have an oversized bolt knob installed when you can buy a threaded PTG handle and have the bolt timed for a little more.

If on the other hand...you are talking about for accuracy....do you already shoot good enough to notice the difference between neck turned and un-neck turned brass...did you already true your primer pockets and flash holes and do extensive testing on which brand of primers give you the best SD's for the powder/bullet combination you are using?

Then you graduate to bolt timing for that issue

Then you graduate to bolt timing for that issue

By using another Remington action. Best practice is to time and fix it to the action it's going to be paired with, however it is possible to do it on a donor action.How can they time it to something they don’t have?

If they eject fine...then you are timed right...or close enough. If you have problems slinging that brass out...then you may have timing issues.

Symptoms: Primary extraction problems

Not picking on you but this is incorrect. Timing has nothing to do with throwing brass but the angled pieces are meant to use the leverage of bolt rotation to dislodge the brass from the chamber. If you've ever rotated your bolt all the way and could not pull the brass out because of a hot load or dirty conditions your timing may be part of the problem. The ejector and extractor tooth are what give you the brass toss.

For the best job yes the action and bolt should be together. You can, as mentioned get a good job done by measuring with a feeler guage and moving the handle forward but to have both in hand will give you the best result. Sophisticated shops like LRI may have a way to do things differently.

I havent felt a recent QR code RR action but the newer the action is the worse they have been with timing in my experience...some had none at all. I've had to touch less 6/7/C/E actions but it seems G and newer could all benefit from timing. This isnt 100% guaranteed but the older ones were put together better.

As mentioned...if you cut the abutments or lugs its likely it would benefit from being timed.

No worries...I worded it to where my thoughts didn't translate to what I was trying to convey.

I havent felt a recent QR code RR action but the newer the action is the worse they have been with timing in my experience...some had none at all. I've had to touch less 6/7/C/E actions but it seems G and newer could all benefit from timing. This isnt 100% guaranteed but the older ones were put together better.

As mentioned...if you cut the abutments or lugs its likely it would benefit from being timed.

top to bottom;

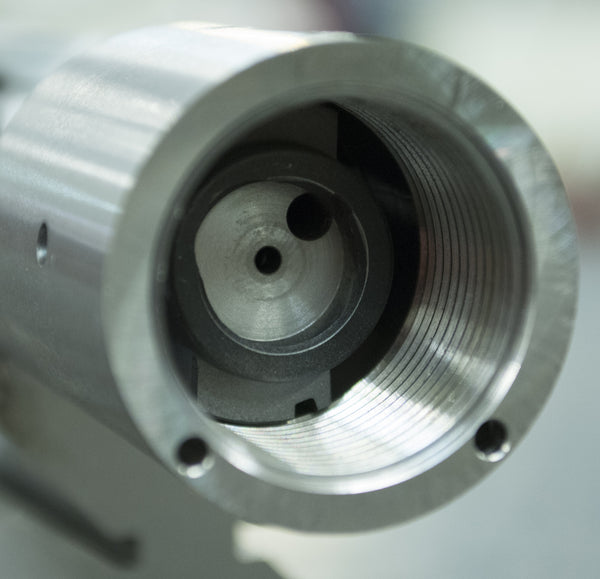

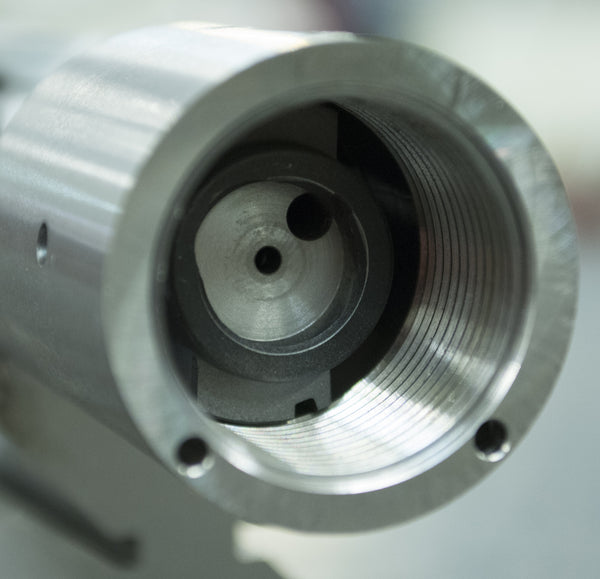

RR serial original bolt

RR serial with the primary extraction ramp built up and bolt handle moved forward by accu-tig.com

C serial original bolt

You can see how the original RR bolt has very little camming, when you add extra fore-aft play, you get a lot of difficult extraction that gets blamed on ammo

I agree with what you are describing but no pics. Were there supposed to be pics?top to bottom;

RR serial original bolt

RR serial with the primary extraction ramp built up and bolt handle moved forward by accu-tig.com

C serial original bolt

You can see how the original RR bolt has very little camming, when you add extra fore-aft play, you get a lot of difficult extraction that gets blamed on ammo

odd. it works on my desktop but heres the link

Not that tolerances couldnt have changed but you can almost tell from the gap between striker housing to back of bolt handle how far off the action the caming surfaces will be. C is close to your accu-tig bolt...RR is way off.

Typically the measure is between bolt handle and receiver when bolt is closed. Thats the measurement gap youd measure to get a closer fitting bolt...among a few other checks.

I do a metric shit ton of these. Whenever possible I do prefer to have the receiver in hand. X10 if the action has been blueprinted by someone other than us.

Metric shit ton equates to around 1000+ per year. Welded, soldered, and the cam surface advanced or the handle replaced altogether. I have a 5-gallon bucket full of NOS 40x handles that we use as replacements when guys want tac knobs as well on the legacy bolts with the narrow transition at the OEM knob.

In addition, LRI offers what is likely the most comprehensive upgrade packages for the Remington M7, M700, and 40x receivers. Our 5 axis blueprinting service is the only one of its kind in the entire industry. Our bolt work is also state of the art and we manufacture most of our own peripheral parts now just to ensure continuity and quality assurance.

Back this with sterling CS and the quickest turnaround and its an easy solution.

Happy to help.

Metric shit ton equates to around 1000+ per year. Welded, soldered, and the cam surface advanced or the handle replaced altogether. I have a 5-gallon bucket full of NOS 40x handles that we use as replacements when guys want tac knobs as well on the legacy bolts with the narrow transition at the OEM knob.

GUNSMITHING SERVICES: Time/TIG and Time advance/Tig Handle attachement for M700

Our Bolt handle fitting process for the M700 restores the Primary Extraction feature after the action has been blueprinted. Careful TIG (Tungsten Inert Gas) welding aids in joint reliability by creating a stronger union at the shear point between the bolt handle and bolt body. The process we...

www.longriflesinc.com

In addition, LRI offers what is likely the most comprehensive upgrade packages for the Remington M7, M700, and 40x receivers. Our 5 axis blueprinting service is the only one of its kind in the entire industry. Our bolt work is also state of the art and we manufacture most of our own peripheral parts now just to ensure continuity and quality assurance.

Back this with sterling CS and the quickest turnaround and its an easy solution.

Happy to help.

GUNSMITHING SERVICES: BOLT FLUTING

In 2010 LRI launched a Group Buy that ushered in a new chapter in how this work gets performed. In one month we fluted over 600 bolts! Since that time we've fluted literally thousands of bolts covering a broad range of manufacturers. Our service is performed using a state of the art 4 axis cnc...

www.longriflesinc.com

GUNSMITHING SERVICES: Remington M700, Howa 1500, and Winchester M70 Tactical Bolt Knob Installation

Having a customized bolt knob installed on a bolt action ranks as probably the single most popular way to personalize a rifle. This upgrade is performed every day by hundreds of smiths all over the country. The Remington Model 700: Not all installations are created equal. The traditional...

www.longriflesinc.com

GUNSMITHING SERVICES: Bolt Handle Skeletonizing for the M700

Drilling a series of holes is one way to skeletonize a bolt handle. At LRI, we pocket machine the center portion so that it follows the handle's natural contour. The weight savings is minimal. An 18+lb "gamer gun" really isn't going to benefit enough to even consider this as relevant. In this...

www.longriflesinc.com

GUNSMITHING SERVICES: AR-15/M-16 Extractor installation

The AR-15 /M-16 extractor upgrade for an M700 bolt is a very popular and almost required service for several applications. When working with magnum bolt face cartridges, the AR-15/M-16 extractor is almost a must-have as the riveted factory piece is prone to be problematic. The AR-15/M-16...

www.longriflesinc.com

GUNSMITHING SERVICES: STRIKER PIN BUSHING: M7, M700, M70(PF AND CRF), ACCURACY INTERNATIONAL, BERGARA, HOWA 1500, & RUGER RPR

A relatively frequent complaint with M700 and Accuracy International actions (and others) are cratered primers with factory made ammunition. The root cause of this is from excessive clearance between the striker and the hole through the bolt face. When fired, the primer cup flows into the void...

www.longriflesinc.com

GUNSMITHING SERVICES: Receiver Blueprinting

Blueprinting, or "truing" is a machining process intended to improve the accuracy potential of a factory bolt action by forensically machining existing features to ensure they are square, parallel, and concentric. LRI pioneered the use of CNC Vertical Machining Centers to blueprint bolt action...

www.longriflesinc.com

GUNSMITHING SERVICES: Dual ejectors for M700's with AR15/M16 Extractors

Problem Statement: Ejection with a factory bolt M700 fitted with an AR15/M16 extractor has always been plagued with potential problems. The issue is the ejection angle of the case body as it leaves the port. The factory ejector's clock position combined with the altered position of the claw...

www.longriflesinc.com

GUNSMITHING SERVICES: Clip Slotting M700 for M40 Style Optic Base

"Clip Slotting" is the popular term for modifying the M700 receiver to accept an M40 Sniper Rifle type scope base. This service is limited to the Lugged base used on the DARPA XM-3 rifle (and other variants). The purpose of this is to attach the scope base to the receiver in a manner that...

www.longriflesinc.com

GUNSMITHING SERVICES: 8-40 Optic Base Threads for Remington M700 and Winchester M70

A nagging side effect of production grade receivers is the tendency for certain features to be machined slightly out of position. The 8-40 optic base hole upgrade is intended to resolve this issue. By aligning the receiver bore to an axis on the milling center, we are able to correct position...

www.longriflesinc.com

Last edited:

Is this only an issue on the R700 and clones?

The latest "RR" prefix receivers are the ones with the biggest issue. Older M700's weren't so bad. Remington made a foundry change and that is where the problem surfaced. The mold tools failed to migrate to the new vendor.

Just can't figure out why people buy into a platform that requires an entire cottage industry to fix before it will even function at a basic level.

Just can't figure out why people buy into a platform that requires an entire cottage industry to fix before it will even function at a basic level.

Because there's 5.5+ million of them in circulation and the entire aftermarket supports them. For what they cost and what you need to do, it's still far more affordable than the boutique aftermarkets.

It's really no more different than dragging a stock 6.0 LS block out of junkyard or going and spending money on an LSX block from GM. By the time you're done with both, your pocket feels it about the same. That may not be the best comparison as the LSX block will have some more girth and features, but there are a whole lotta drag racers killing it with OEM parts.

Just like guys do with a pawn shop grade M700

Last edited:

Its easier to hide the cost from the wife a couple hundred at a time !

Its easier to hide the cost from the wife a couple hundred at a time !

Gotta hand it to you, I never looked at it that way before!