Since we are all hunkered down for Covid 19 I figured I would put together a little DIY for making your own heavy butt-pad spacer from an old break rotor.

Tools:

Angle grinder

c-clamps

hammer

bench grinder

drill press and bits

thick work gloves

safety goggles

Materials:

Buttpad and or spacer template

Old break rotor

emery cloth/ wet sand paper

white vinegar

cleaning supplies

sharpie

I used a spacer from my stock (KRG Bravo) to find a rotor in my pile that was wide enough for a spacer;

I’m working with a rear rotor from a Subaru Impreza.

I mounted it to a work surface and used an angle grinder to cut the rotor disc into sections. Then using a large hammer, I could just break the sections off with a whack or two.

using my spacer as a template i trimmed up the hunks with the angle grinder.

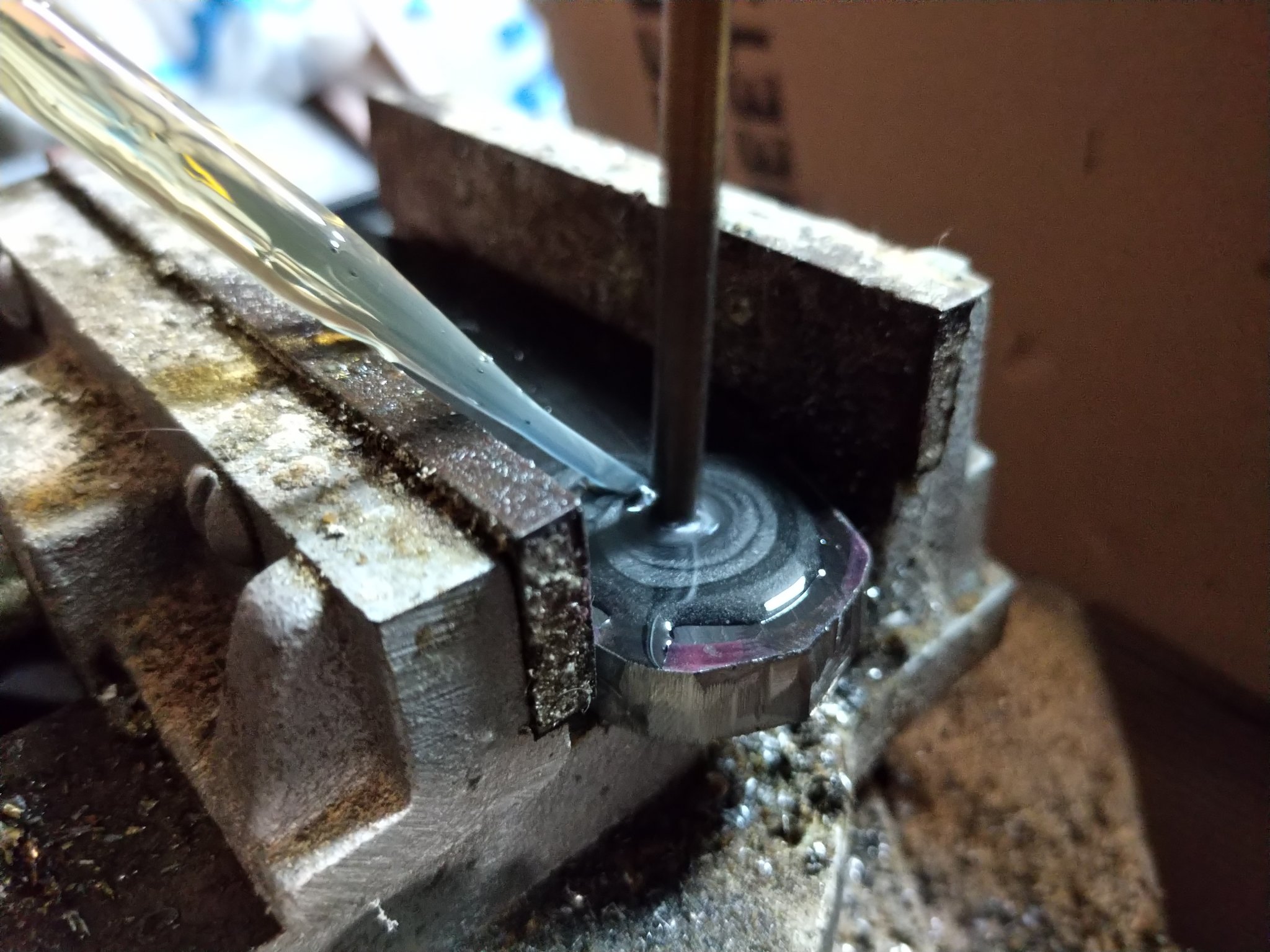

I then drilled out the mounting holes on my drill press.

with the spacer drilled out I can mark the final areas to remove on the bench grinder.

Take your time and check your piece often its easy to go too far. Also the piece will get very hot.

Once you're happy with the fit you'll want to clean up the edges.

my bench grinder has a wet stone which worked great for me.

Tools:

Angle grinder

c-clamps

hammer

bench grinder

drill press and bits

thick work gloves

safety goggles

Materials:

Buttpad and or spacer template

Old break rotor

emery cloth/ wet sand paper

white vinegar

cleaning supplies

sharpie

I used a spacer from my stock (KRG Bravo) to find a rotor in my pile that was wide enough for a spacer;

I’m working with a rear rotor from a Subaru Impreza.

I mounted it to a work surface and used an angle grinder to cut the rotor disc into sections. Then using a large hammer, I could just break the sections off with a whack or two.

using my spacer as a template i trimmed up the hunks with the angle grinder.

I then drilled out the mounting holes on my drill press.

with the spacer drilled out I can mark the final areas to remove on the bench grinder.

Take your time and check your piece often its easy to go too far. Also the piece will get very hot.

Once you're happy with the fit you'll want to clean up the edges.

my bench grinder has a wet stone which worked great for me.

Last edited: