I love shooting steel (like who doesn't?) and enjoy building things so I decided to make my own steel target for desert shoots.

My mission was to create a hard steel target that was self-standing, could break down to easily fit in my car/truck and take a beating from either pistol/carbine/rifle.

First, I bought a A500 hardened plate cut to 2/3 IPSC dimensions from Artnzen Steel

Then picked up some scrap square steel tubing from the local steel supply place. I didn't have plans, simply eyeballed the lengths and made it up as I went along. I have seen a bunch of designs but the hard part was I had to find materials that didn't need a lot of cutting/machining since I don't have a metal shop. (yet)

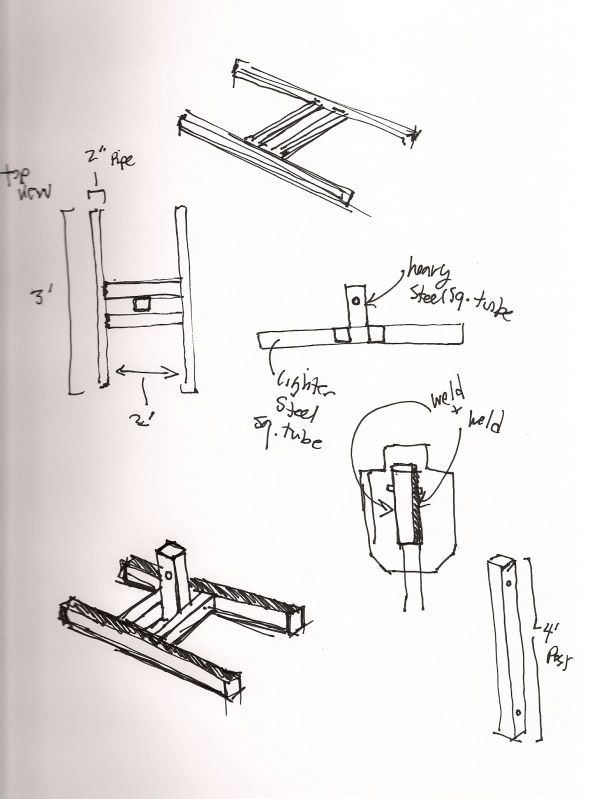

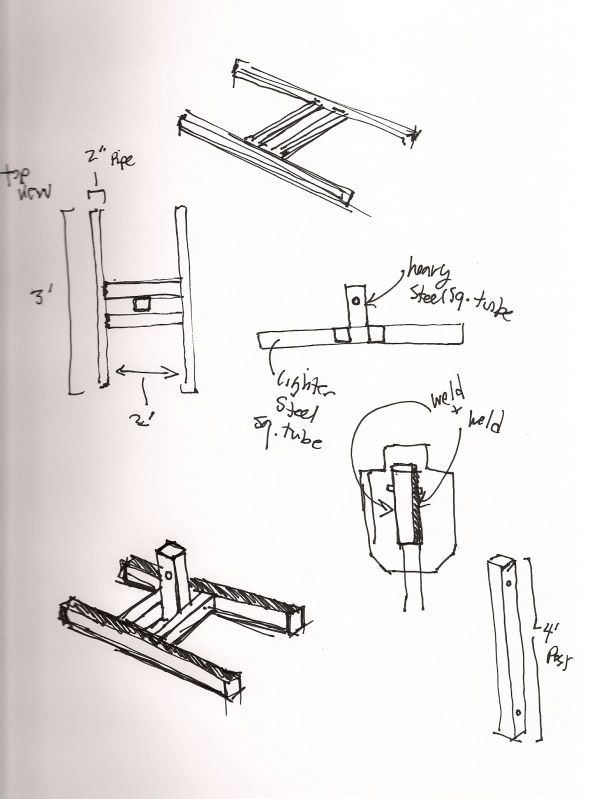

Simpler was better, so I drew up some plans for the material I had:

The two longest rails on the outside are 3 feet long and the two rails in the middle are 2 feet each with a thicker and heavier steel square tube in the center to support the main target shaft.

With my rough plans and steel in hand and very little knowledge about mig welding, I rented a Miller 135 Mig welder from a local supplier.

Laid out the basic shape of my tube:

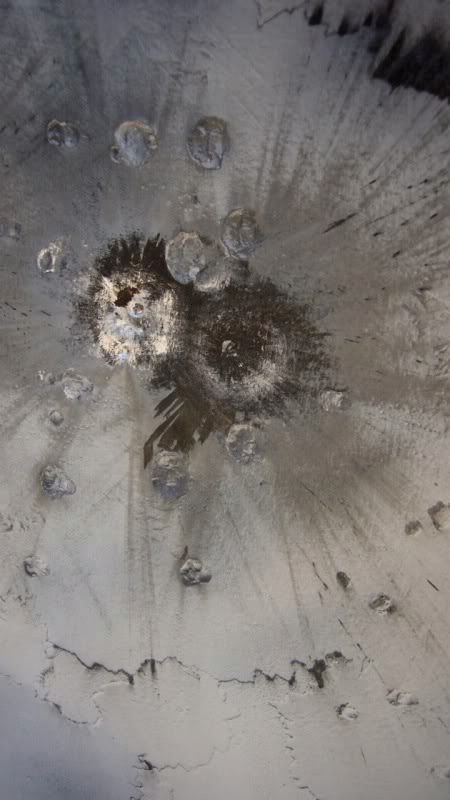

Got the wire and gas set up and ran a few test beads... boring! So jumped right into my project. Man I have to give props to all the welders out there--- it takes some serious skill!! I blew so many holes in the tubes, they looked like a flute.

Yeah I know the welds are ugly, I'm pretty sure our local welder's job is safe from me making a career change. After some of the triple beaded mountains I created, a little grinding was in order:

And whammo, my stand was together!

My mission was to create a hard steel target that was self-standing, could break down to easily fit in my car/truck and take a beating from either pistol/carbine/rifle.

First, I bought a A500 hardened plate cut to 2/3 IPSC dimensions from Artnzen Steel

Then picked up some scrap square steel tubing from the local steel supply place. I didn't have plans, simply eyeballed the lengths and made it up as I went along. I have seen a bunch of designs but the hard part was I had to find materials that didn't need a lot of cutting/machining since I don't have a metal shop. (yet)

Simpler was better, so I drew up some plans for the material I had:

The two longest rails on the outside are 3 feet long and the two rails in the middle are 2 feet each with a thicker and heavier steel square tube in the center to support the main target shaft.

With my rough plans and steel in hand and very little knowledge about mig welding, I rented a Miller 135 Mig welder from a local supplier.

Laid out the basic shape of my tube:

Got the wire and gas set up and ran a few test beads... boring! So jumped right into my project. Man I have to give props to all the welders out there--- it takes some serious skill!! I blew so many holes in the tubes, they looked like a flute.

Yeah I know the welds are ugly, I'm pretty sure our local welder's job is safe from me making a career change. After some of the triple beaded mountains I created, a little grinding was in order:

And whammo, my stand was together!