Ok,

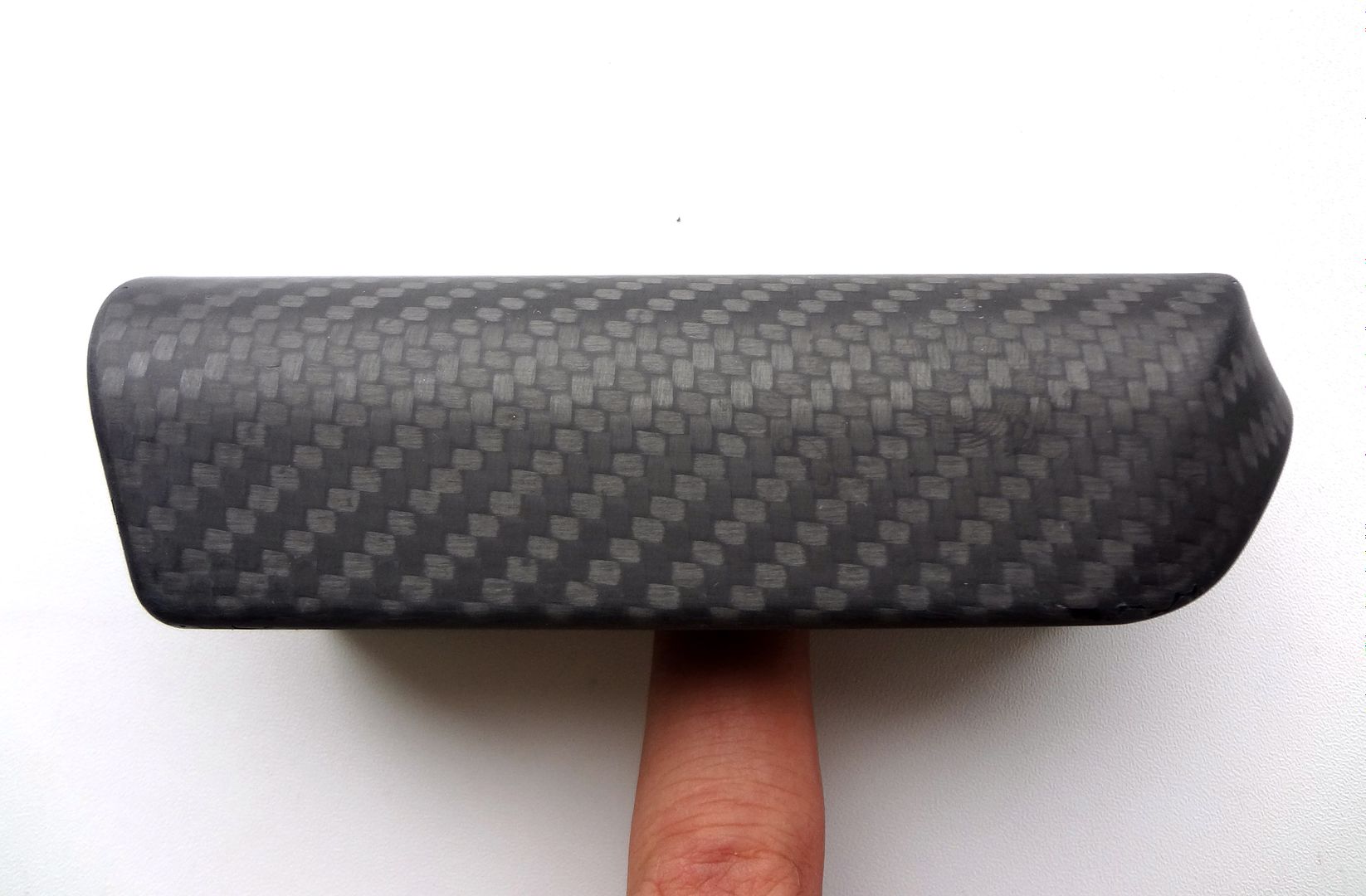

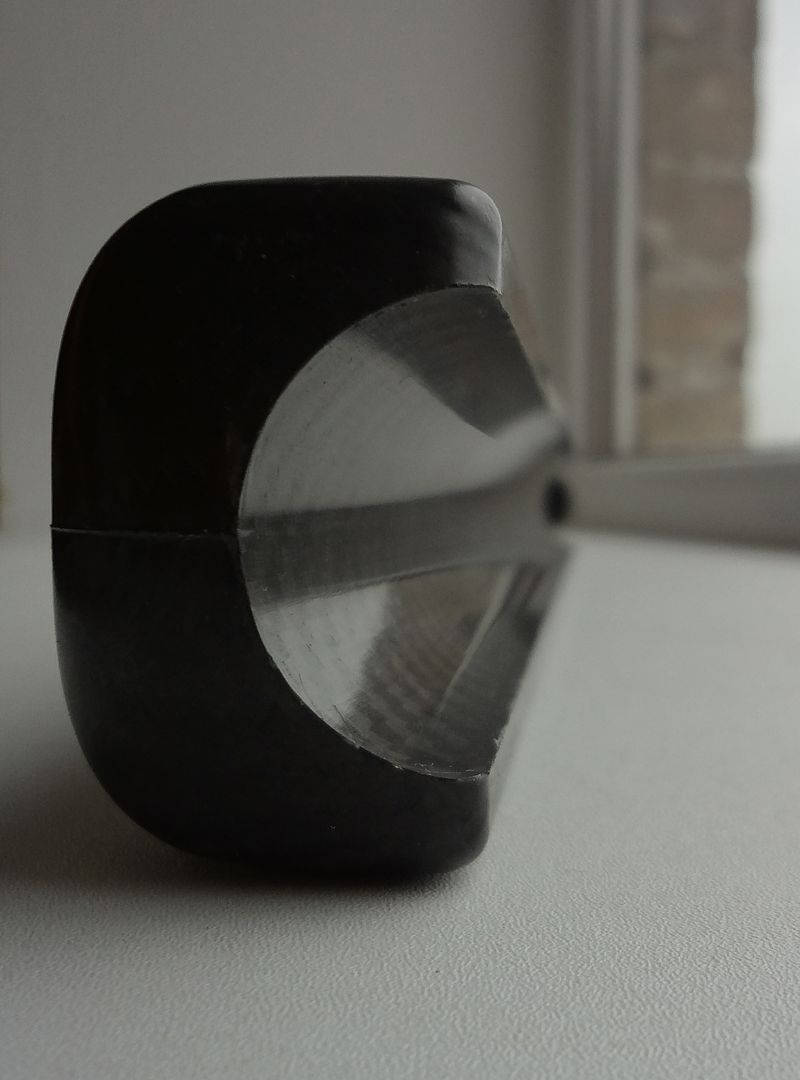

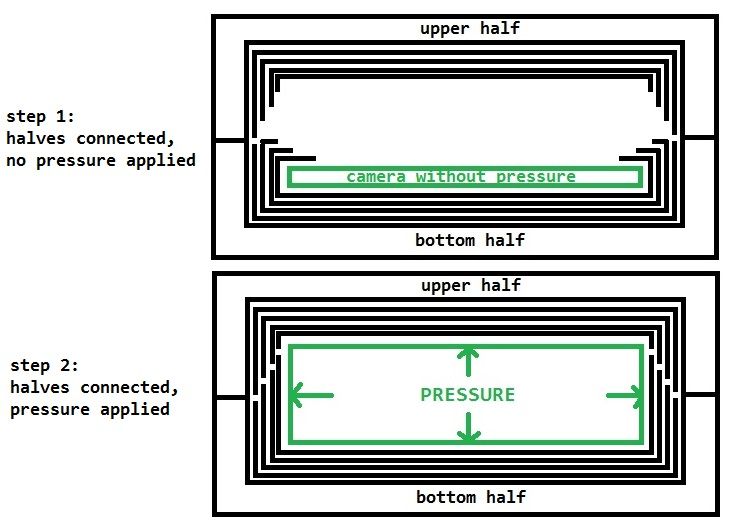

A quick trip to the range...quick sighters and then three groups

- Stock mid-80s Rem 700 w/heavy barrel that I had the barrel cut and threaded at 18"...got lucky, she shoots pretty well

- Intent is to be a lighter weight carry gun, so Bushnell Elite 3200 10x scope

- TBAC 30-BA titanium can

- Entire rig with can and empty mag weighs in at 10.1lbs. I have a 16" fluted lighter barrel that drops about 1/2-3/4 lb that I did not have time to spin on

- Slight mag feed issue with the bolt not picking up the next round...need to trouble shoot it a bit more

- Still sorting out the 168 AMAX load for this rifle, 168 SMK GTG.

BL: shoots just about as good in this stock off two bags as it does in my XLR chassis and A LOT lighter. The stock does exactly what it is supposed to do.

A quick trip to the range...quick sighters and then three groups

- Stock mid-80s Rem 700 w/heavy barrel that I had the barrel cut and threaded at 18"...got lucky, she shoots pretty well

- Intent is to be a lighter weight carry gun, so Bushnell Elite 3200 10x scope

- TBAC 30-BA titanium can

- Entire rig with can and empty mag weighs in at 10.1lbs. I have a 16" fluted lighter barrel that drops about 1/2-3/4 lb that I did not have time to spin on

- Slight mag feed issue with the bolt not picking up the next round...need to trouble shoot it a bit more

- Still sorting out the 168 AMAX load for this rifle, 168 SMK GTG.

BL: shoots just about as good in this stock off two bags as it does in my XLR chassis and A LOT lighter. The stock does exactly what it is supposed to do.