Background/Abstract: I was gifted a Lee Auto Breech Lock Pro and wanted to share my results seeking cheap, accurate, hastily reloaded ammo from a progressive. This is a very cheap setup and you'll see that theme should you choose to read my thread. I have some high end stuff that I use for PRS, but wanted to put this press to work for some fun AR ammo to take buckets full out to the long range steel without the guilt of shooting up ammo that took several full evenings to reload. The goal was cheap and fast ammo with acceptable accuracy. (note: I posted this in ARF as well since it's gas-gun focused, but look forward to some more educated critiques here.) The details of my adventure follow...

I used the following equipment:

-Lee Auto Breech Lock Pro

-Redding BR-30 powder measure, mounted to the bench

-RCBS Standard .223 dies

-Lee .223 shellholder

-Lee case collater

-Lee safety prime system

-Wilson case gauge

and the following components:

-Silver State Armory once-fired brass from a deal they ran on loaded 77gr ammo from Shooter's Pro Shop

-Hornady 75gr BTHP (18 cents apiece from midway)

-23.1gr IMR 8208XBR

-CCI 400 primers

-Hornady OneShot case lube

Process:

Brass: The SSA brass was perfect for this project. The primers weren't crimped on the factory ammo, it didn't need trimmed, and it seemed pretty soft yet consistent. I simply tumbled overnight in almond shell media. Prior to throwing it in the case hopper, I threw a handful at a time into a large plastic coffee can and gave it a good dose of Hornady OneShot, shook it around a bit, gave it another dose, let it dry for a minute, then dumped it in the hopper. Initially I was only doing one dose because I'm not crazy about the idea of not tumbling off lube after resizing/prior to loading but I ended up sticking a case (RIP expanding ball) hence the second dose. Everything went buttery smooth with the added lube. I don't think I'd have as good of luck with LC brass or other hard stuff. During set up, I dropped several sized cases in a Wilson case gauge and chambered several more pieces of loaded ammo. I wanted to make sure I didn't pump out 200+ rounds of ammo that wasn't going to feed. Finally, with my loaded ammo, I rolled a handful at a time around in an old tshirt sprayed with brake cleaner so I wasn't running case lube through my rifle.

Powder: As you see in the video, I chose to use my Redding powder measure off-press. Johnny's Reloading Bench inspired my use of the powder measure in this fashion. I ran a test using a quality scale and found that it was within a tenth of a grain using this powder and Johnny's method of tapping the handle on the upstroke for each charge to help settle the powder in. I used this time to dial in my 23.1gr which I had settled on from a previous ladder test. Unfortunately the powder-through die doesn't mate up with the Redding measure. It was even more worthless when I tried just using the die in combination with the funnel but couldn't get the damn thing to line up with the cases and ended up dumping powder off its mark several times despite trying the die in every imaginable configuration. Hence, the funnel sitting there and having to use a pan. This is by far the most laborious step of the process but I think it's necessary to get the results I did. I'm going to try one of the Lee automated powder measures with the discs but I'm not getting my hopes up. One perk of this set up is that you get to double check for powder before sitting the bullet on there. Each time I sit a bullet, I look down into the case to verify the powder is in there and the level doesn't look weird.

Bullet Seating: I'm simply seating with whatever neck tension the standard RCBS dies are giving me with the expanding ball it comes with. Seated to max mag length in my 20rd magpul mags. I don't like to crimp stuff. It's only given me trouble. I may have to revisit this approach and see what it does to my SDs.

Here's a short video of the action.

The human actions that take place with each stroke: primer, powder, bullet.

Special thanks to my special lady for the camera work!

Results:

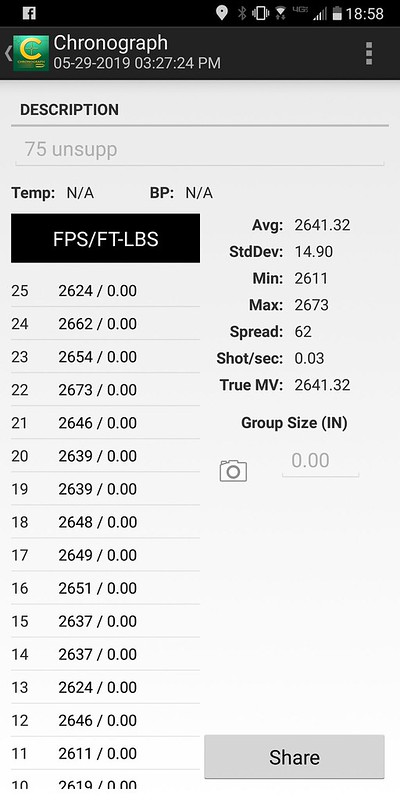

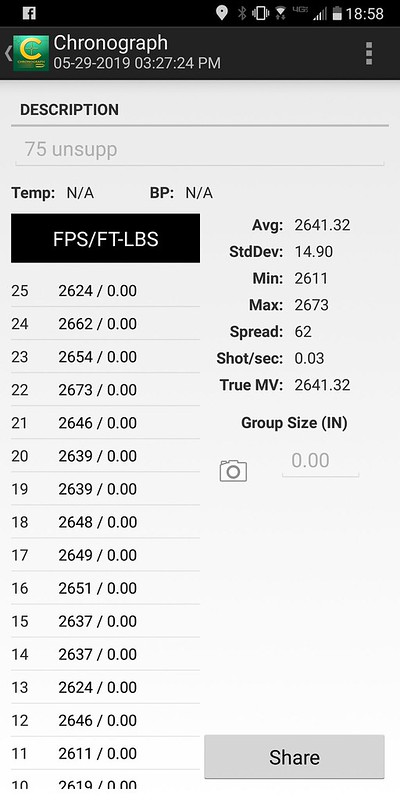

Chronograph Data (25rds Unsuppressed):

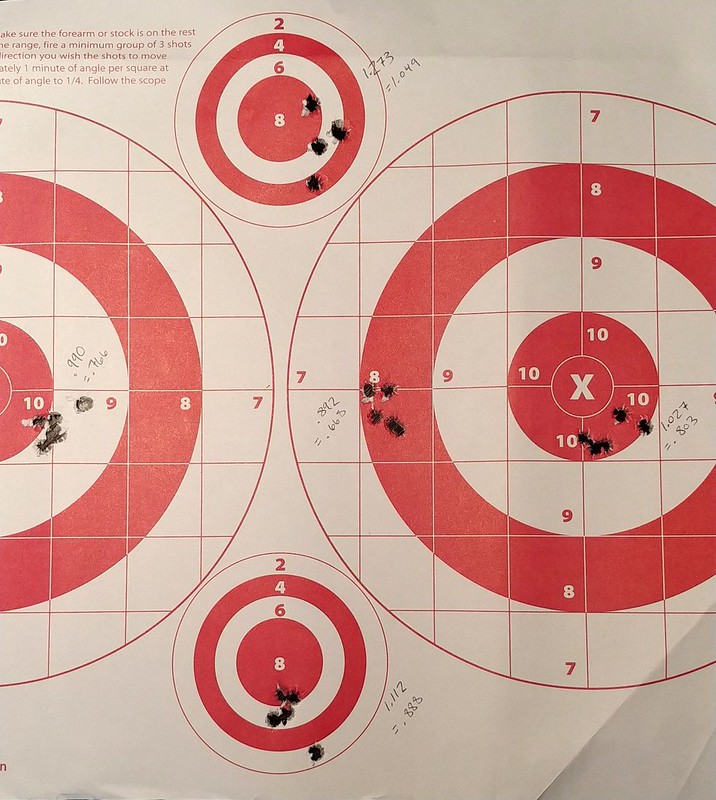

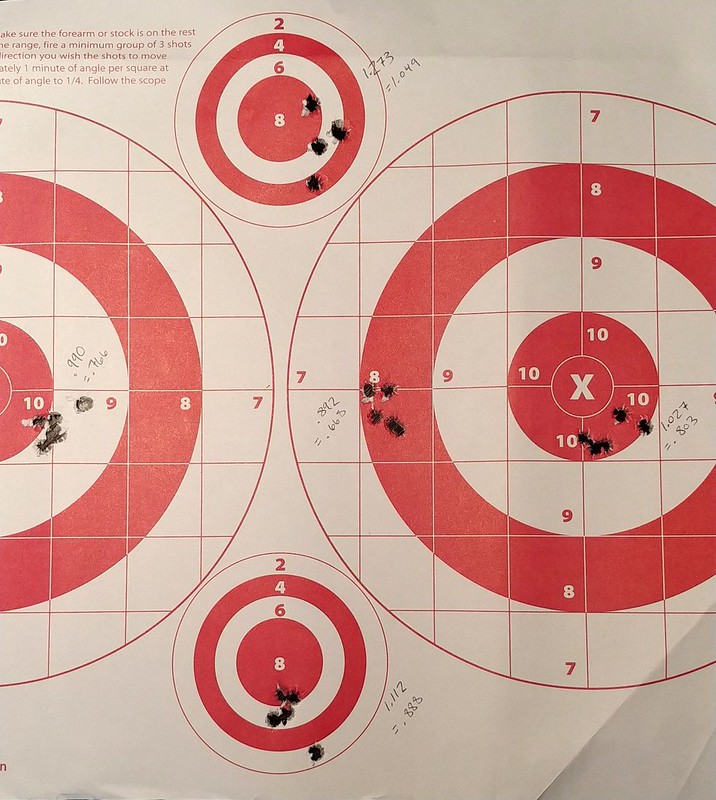

Target:

Five, 5-shot groups @100yds = Avg .835"

Test Gun:

18" DPMS MK12 Barrel with thousands of rounds (unknown round count)

Young MFG BCG

PSA Receivers. Upper receiver squared using the brownells tool.

Matrix 15" Handguard (Joebobs)

B5 SOPMOD stock and Sierra grip

Geissele NM trigger

SWFA SS 5-25 in ADM

Harris bipod and Midway small cylinder rear bag*

*This bag was not ideal, especially having to hold it on-end, and the groups definitely would've been tighter had I used my gamechanger. I used this bag because I wanted to try my hand at the MOA all day challenge.

I also shot a promising group using the Silencerco Specwar. It measured close to half inch with the exception of one fliers (surely on me). Unfortunately, I was trying the can on another rifle and got the muzzle brake stuck inside of it so that one group was the end of the testing with the can. Hopefully more to follow with suppressed use.

Final Thoughts:

The SDs look pretty great at 14.9fps but note that this is over 25rds and the ES was 62fps. Plugging in the numbers to my ballistics calculator, this would equate to a .5mil POI difference at 800yrds if you shot the min velocity (2611fps), then the max velocity (2673fps). Since I'm currently already dumping the powder into a pan, I think the next time around I might as well throw it on a scale just to eliminate any outliers. This will slow down the process; however, I feel it worth my time to correct those outliers. Another variable is the case lube. I'm a firm believer in tumbling off case lube after resizing for precision rounds and I know that some of these cases ended up with more lube inside the necks than others. I do believe this negatively affects SDs/ES.

The process isn't as quick and easy as I'd hoped, but it's bearable and certainly faster than the single stage. The case feeder doesn't really work that well and occasionally spits a whole tube of cases onto the floor. Charging the powder this way gets old when you're doing it 200 times in a row. The safety primer system doesn't work 100% of the time. It's a $99 press (before the add-ons) so it's not a super smooth stroke. But at the end of the day, I feel this is a solid, repeatable process and look forward to this becoming my go-to AR load. The cost of the fun is 32 cents per round (bullet, powder, primer) and 30 seconds per. Or $60 and 1hr40m of press time for 200rds. I'm pretty happy with these results.

One last consideration is to take a look at my test equipment - weak points were an old school Caldwell chronograph, a possibly shot-out DPMS barrel, and a less-than-ideal rear bag. I hope to update this thread as I refine my process and upgrade my equipment. I'm open to feedback. What do you think?

I used the following equipment:

-Lee Auto Breech Lock Pro

-Redding BR-30 powder measure, mounted to the bench

-RCBS Standard .223 dies

-Lee .223 shellholder

-Lee case collater

-Lee safety prime system

-Wilson case gauge

and the following components:

-Silver State Armory once-fired brass from a deal they ran on loaded 77gr ammo from Shooter's Pro Shop

-Hornady 75gr BTHP (18 cents apiece from midway)

-23.1gr IMR 8208XBR

-CCI 400 primers

-Hornady OneShot case lube

Process:

Brass: The SSA brass was perfect for this project. The primers weren't crimped on the factory ammo, it didn't need trimmed, and it seemed pretty soft yet consistent. I simply tumbled overnight in almond shell media. Prior to throwing it in the case hopper, I threw a handful at a time into a large plastic coffee can and gave it a good dose of Hornady OneShot, shook it around a bit, gave it another dose, let it dry for a minute, then dumped it in the hopper. Initially I was only doing one dose because I'm not crazy about the idea of not tumbling off lube after resizing/prior to loading but I ended up sticking a case (RIP expanding ball) hence the second dose. Everything went buttery smooth with the added lube. I don't think I'd have as good of luck with LC brass or other hard stuff. During set up, I dropped several sized cases in a Wilson case gauge and chambered several more pieces of loaded ammo. I wanted to make sure I didn't pump out 200+ rounds of ammo that wasn't going to feed. Finally, with my loaded ammo, I rolled a handful at a time around in an old tshirt sprayed with brake cleaner so I wasn't running case lube through my rifle.

Powder: As you see in the video, I chose to use my Redding powder measure off-press. Johnny's Reloading Bench inspired my use of the powder measure in this fashion. I ran a test using a quality scale and found that it was within a tenth of a grain using this powder and Johnny's method of tapping the handle on the upstroke for each charge to help settle the powder in. I used this time to dial in my 23.1gr which I had settled on from a previous ladder test. Unfortunately the powder-through die doesn't mate up with the Redding measure. It was even more worthless when I tried just using the die in combination with the funnel but couldn't get the damn thing to line up with the cases and ended up dumping powder off its mark several times despite trying the die in every imaginable configuration. Hence, the funnel sitting there and having to use a pan. This is by far the most laborious step of the process but I think it's necessary to get the results I did. I'm going to try one of the Lee automated powder measures with the discs but I'm not getting my hopes up. One perk of this set up is that you get to double check for powder before sitting the bullet on there. Each time I sit a bullet, I look down into the case to verify the powder is in there and the level doesn't look weird.

Bullet Seating: I'm simply seating with whatever neck tension the standard RCBS dies are giving me with the expanding ball it comes with. Seated to max mag length in my 20rd magpul mags. I don't like to crimp stuff. It's only given me trouble. I may have to revisit this approach and see what it does to my SDs.

Here's a short video of the action.

The human actions that take place with each stroke: primer, powder, bullet.

Special thanks to my special lady for the camera work!

Results:

Chronograph Data (25rds Unsuppressed):

Target:

Five, 5-shot groups @100yds = Avg .835"

Test Gun:

18" DPMS MK12 Barrel with thousands of rounds (unknown round count)

Young MFG BCG

PSA Receivers. Upper receiver squared using the brownells tool.

Matrix 15" Handguard (Joebobs)

B5 SOPMOD stock and Sierra grip

Geissele NM trigger

SWFA SS 5-25 in ADM

Harris bipod and Midway small cylinder rear bag*

*This bag was not ideal, especially having to hold it on-end, and the groups definitely would've been tighter had I used my gamechanger. I used this bag because I wanted to try my hand at the MOA all day challenge.

I also shot a promising group using the Silencerco Specwar. It measured close to half inch with the exception of one fliers (surely on me). Unfortunately, I was trying the can on another rifle and got the muzzle brake stuck inside of it so that one group was the end of the testing with the can. Hopefully more to follow with suppressed use.

Final Thoughts:

The SDs look pretty great at 14.9fps but note that this is over 25rds and the ES was 62fps. Plugging in the numbers to my ballistics calculator, this would equate to a .5mil POI difference at 800yrds if you shot the min velocity (2611fps), then the max velocity (2673fps). Since I'm currently already dumping the powder into a pan, I think the next time around I might as well throw it on a scale just to eliminate any outliers. This will slow down the process; however, I feel it worth my time to correct those outliers. Another variable is the case lube. I'm a firm believer in tumbling off case lube after resizing for precision rounds and I know that some of these cases ended up with more lube inside the necks than others. I do believe this negatively affects SDs/ES.

The process isn't as quick and easy as I'd hoped, but it's bearable and certainly faster than the single stage. The case feeder doesn't really work that well and occasionally spits a whole tube of cases onto the floor. Charging the powder this way gets old when you're doing it 200 times in a row. The safety primer system doesn't work 100% of the time. It's a $99 press (before the add-ons) so it's not a super smooth stroke. But at the end of the day, I feel this is a solid, repeatable process and look forward to this becoming my go-to AR load. The cost of the fun is 32 cents per round (bullet, powder, primer) and 30 seconds per. Or $60 and 1hr40m of press time for 200rds. I'm pretty happy with these results.

One last consideration is to take a look at my test equipment - weak points were an old school Caldwell chronograph, a possibly shot-out DPMS barrel, and a less-than-ideal rear bag. I hope to update this thread as I refine my process and upgrade my equipment. I'm open to feedback. What do you think?